In the world of metal fabrication, precision is paramount. Every cut, every millimeter matters. That’s why you need the right tools for the job.

When it comes to laser cutting and milling, both are widely used techniques that offer their own unique advantages. But which one is more precise?

Laser cutting, with its focused beam of intense light, offers exceptional accuracy, allowing for intricate designs and fine details.

On the other hand, milling, with its rotating cutting tool, provides excellent precision and can create complex shapes with ease.

In this article, we will explore the processes of laser cutting and milling in metal fabrication, delve into the factors to consider when choosing between the two, and compare their precision levels.

We will also examine the cost and efficiency considerations, as well as provide case studies and examples to illustrate the real-world applications of each technique.

So, whether you’re a seasoned metal fabricator or just starting out, read on to discover which method is the best fit for your precision needs.

Key Takeaways

- Laser cutting offers exceptional accuracy and is more suitable for intricate designs with fine details.

- Laser cutting is generally considered more accurate than milling in metal fabrication.

- Milling provides excellent precision and can create complex shapes with ease.

- Factors to consider when choosing between laser cutting and milling include complexity of design, material type, and thickness.

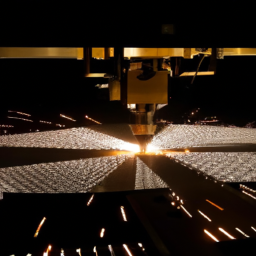

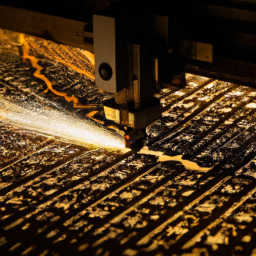

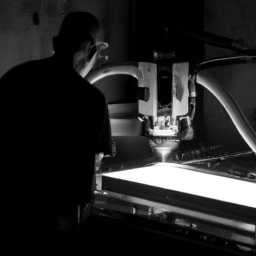

The Process of Laser Cutting in Metal Fabrication

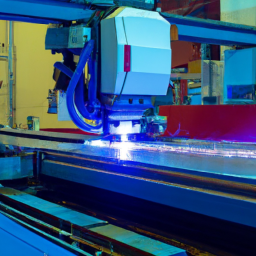

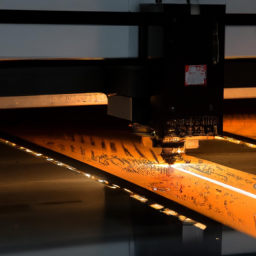

Laser cutting is like having a high-tech metal-slicing superhero, zapping through sheets of metal with precision and speed. It is a popular method in metal fabrication due to its numerous advantages.

First and foremost, laser cutting offers unmatched precision, allowing for intricate and detailed designs. The laser beam is focused to a small point, resulting in clean and precise cuts with minimal material wastage.

Additionally, laser cutting is extremely versatile and can be used on a wide range of materials, including stainless steel, aluminum, and copper. This makes it suitable for various applications, such as creating complex metal parts, signage, and decorative items.

Laser cutting also provides a faster production time compared to traditional methods, reducing overall project timelines.

As we delve into the process of milling in metal fabrication, we’ll explore another precise method that complements laser cutting.

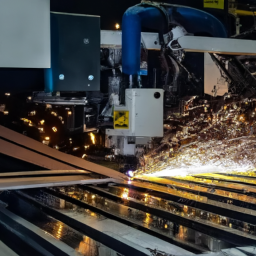

The Process of Milling in Metal Fabrication

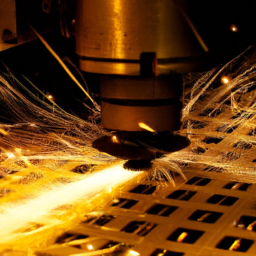

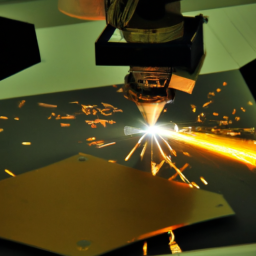

When it comes to the process of milling in metal fabrication, understanding how it works is crucial. Milling involves using a rotating cutting tool to remove material from a workpiece, resulting in the desired shape and size.

The benefits of milling include the ability to produce complex shapes, high precision, and the ability to work with a wide range of materials. However, there are also limitations to milling, such as the need for specialized equipment and the potential for slower production times compared to other methods.

How Milling Works

Milling works by spinning a cutting tool against a metal surface, carving out precise shapes and creating a mesmerizing dance of sparks.

There are various advantages of milling in metal fabrication. One advantage is the ability to create complex designs with high precision. Milling techniques such as face milling, peripheral milling, and end milling allow for the creation of intricate details and smooth finishes.

Additionally, milling can be used with a wide range of metals, including steel, aluminum, and titanium. This versatility makes it a popular choice in various industries, from aerospace to automotive.

However, it’s important to note that milling also has its limitations. It can be time-consuming, especially for larger projects, and it requires skilled operators to ensure accurate results.

Despite these limitations, milling remains a valuable technique in metal fabrication, offering unparalleled precision and design possibilities.

Benefits and Limitations of Milling

With milling, you can achieve intricate designs and smooth finishes, but it does require skilled operators to ensure accurate results. Milling applications have significantly advanced over the years, allowing for a wide range of possibilities in metal fabrication. The process involves the use of a rotating cutting tool to remove material from a workpiece, resulting in precise shapes and dimensions. This technique is commonly used for creating complex parts, such as gears, molds, and prototypes. However, milling does have its limitations. It can be time-consuming and expensive, especially for large-scale production. Additionally, the process may generate heat and cause tool wear, affecting the overall precision. When considering whether to choose milling or laser cutting, factors such as material type, project complexity, and production volume should be taken into account.

Factors to Consider When Choosing Between Laser Cutting and Milling

When choosing between laser cutting and milling in metal fabrication, there are several factors to consider.

Firstly, the complexity of the design plays a crucial role in determining which method to use. Laser cutting is more suitable for intricate designs with fine details, while milling is better for simpler, less intricate designs.

Secondly, the type and thickness of the material should be taken into account. Laser cutting is ideal for cutting thin materials, such as sheet metal, while milling is better for thicker materials, such as blocks or plates.

Lastly, the material type itself can also influence the choice between laser cutting and milling, as certain materials may have specific requirements or limitations for each method.

Complexity of Design

Despite the intricacies involved, laser cutting offers a level of precision that surpasses conventional metal fabrication methods. When it comes to design complexity and intricate patterns, laser cutting excels in delivering highly precise results. The laser beam can easily maneuver through intricate designs, cutting with precision and accuracy. This allows for the creation of complex shapes and fine details that may be challenging or impossible to achieve with milling methods. To illustrate this point, consider the following table:

| Factor | Laser Cutting | Milling |

|---|---|---|

| Precision | High | Moderate |

| Intricate Design | Excellent | Limited |

| Speed | Fast | Slow |

As shown in the table, laser cutting outperforms milling in terms of precision and intricate design capabilities. Moving forward, it is essential to consider the material type and thickness in metal fabrication.

Material Type and Thickness

In considering the material type and thickness, one must take into account various factors in metal fabrication.

Material compatibility is a crucial factor to consider when choosing between laser cutting and milling. Laser cutting is generally more suitable for materials like stainless steel, aluminum, and mild steel, while milling is better for harder materials like titanium and hardened steel.

Additionally, the thickness of the material plays a role in determining the appropriate method. Laser cutting is preferred for thinner materials, as it provides higher precision and faster cutting speeds. On the other hand, milling is better suited for thicker materials, as it allows for more control and accuracy.

When it comes to speed and productivity, laser cutting generally offers faster cutting speeds, making it more efficient for high-volume production.

Transitioning into the subsequent section, the precision comparison between laser cutting and milling reveals further insights into these two methods.

Precision Comparison: Laser Cutting vs. Milling

When comparing laser cutting and milling in terms of precision, there are key points to consider. Tolerance levels, accuracy, and repeatability are important factors. Tolerance levels refer to the allowable variation in dimensions. Laser cutting typically offers higher tolerance levels compared to milling.

Accuracy is another factor to consider. It refers to the ability to cut or mill a part to its intended dimensions. Both methods can achieve high accuracy.

Repeatability is also important. It refers to the ability to consistently produce identical parts. Laser cutting generally offers better repeatability due to its automated nature.

Tolerance Levels

Laser cutting and milling in metal fabrication have different tolerance levels, but the proof is in the pudding when it comes to achieving precision. When it comes to tolerance levels, laser cutting tends to have a tighter range compared to milling.

Laser cutting can achieve tolerances as low as ±0.005 inches, while milling typically achieves tolerances around ±0.010 inches. This means that laser cutting is capable of producing more precise cuts with less deviation from the desired measurements.

Additionally, laser cutting generally provides a smoother surface finish compared to milling, reducing the need for additional post-processing. However, it’s important to note that accuracy and repeatability are also crucial factors in determining the overall precision of a fabrication method.

Accuracy and Repeatability

Now let’s delve into the current subtopic, which is the accuracy and repeatability of laser cutting and milling in metal fabrication.

When it comes to precision, laser cutting is generally considered more accurate than milling. Laser cutting uses a focused beam of light to cut through the metal, resulting in minimal material loss and precise cuts. On the other hand, milling relies on rotating cutting tools that remove material, which can lead to slightly less precision.

However, it’s important to note that both methods can achieve high levels of accuracy and repeatability, and the choice between the two depends on the specific requirements of the project. Precision is often traded off with speed in metal fabrication, and engineers must carefully consider the balance between the two.

Now let’s move on to the subsequent section, where we will discuss the cost and efficiency considerations in laser cutting and milling.

Cost and Efficiency Considerations

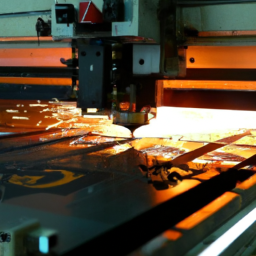

Choosing between laser cutting and milling in metal fabrication involves considering the cost and efficiency. This makes it crucial to assess the overall economic impact of each method. When it comes to cost-effectiveness, laser cutting proves to be more efficient due to its faster production speed. The laser beam can cut through metal with high precision and speed, reducing production time and labor costs.

Additionally, laser cutting minimizes material waste by optimizing the cutting path, resulting in cost savings. Furthermore, laser cutting machines require less maintenance compared to milling machines, reducing downtime and increasing overall productivity. By considering these factors, it becomes evident that laser cutting provides a more cost-effective and efficient solution for metal fabrication.

Moving forward, let’s explore case studies and examples to further illustrate the benefits of laser cutting in metal fabrication.

Case Studies and Examples

When it comes to metal fabrication, time is money, and laser cutting has proven to be the hare that wins the race. Laser cutting offers a high level of precision and efficiency that is unmatched by milling.

Case studies and real-life examples further emphasize this point. For instance, in a case study conducted by a leading metal fabrication company, laser cutting was found to be significantly faster than milling when it came to producing intricate metal parts.

Another example is a real-life project where a manufacturer used laser cutting to create complex designs on stainless steel sheets. The precision and speed of laser cutting allowed them to complete the project in a fraction of the time it would have taken with milling.

These case studies and examples demonstrate how laser cutting is the superior choice when it comes to precision and efficiency in metal fabrication.

Frequently Asked Questions

What types of metals can be used with laser cutting and milling processes?

In laser cutting and milling processes, a wide range of metals can be used. Common types include steel, aluminum, brass, copper, and titanium.

Laser cutting offers the advantage of precise and intricate cuts, making it suitable for thin materials.

Milling, on the other hand, is versatile and can handle various metal types, including harder materials.

Both methods have their benefits in metal fabrication, allowing for precise shaping and intricate designs.

Are there any limitations in terms of the size or thickness of the metal that can be cut or milled?

There are indeed limitations when it comes to the size and thickness of the metal that can be cut or milled.

In terms of metal thickness, laser cutting typically works best with materials that are up to 25mm thick, while milling can handle thicker materials, usually up to 100mm.

As for the maximum size of metal pieces, laser cutting machines generally have a maximum cutting area of around 1500mm x 3000mm, while milling machines can accommodate larger sizes, often up to 4000mm x 2000mm.

How does the choice between laser cutting and milling affect the overall turnaround time for a metal fabrication project?

When it comes to the choice between laser cutting and milling in metal fabrication, the decision can have a significant impact on the overall turnaround time of your project.

Laser cutting, with its high precision and speed, can greatly improve production efficiency. On the other hand, milling may take longer due to its slower cutting speed and the need for multiple passes.

Ultimately, the choice depends on the required precision levels and the specific requirements of your metal fabrication project.

What safety precautions should be taken when using laser cutting or milling equipment?

To ensure safety when using laser cutting or milling equipment, several precautions must be taken. First, operators should wear appropriate personal protective equipment, such as safety glasses and gloves.

It is crucial to follow equipment manufacturer guidelines for operation and maintenance, including regular inspections and cleaning. Additionally, operators should be trained in proper handling and emergency procedures.

Regular equipment maintenance and calibration are necessary to prevent accidents and maintain accuracy.

Can laser cutting or milling processes be used on materials other than metal, such as wood or plastic?

While laser cutting and milling are commonly used in metal fabrication, they can also be applied to wood and plastic materials. Laser cutting offers advantages such as high precision and intricate designs, but it may cause discoloration or charring on wood surfaces. On the other hand, milling provides precise cuts and smooth finishes, but it may produce more waste. When comparing precision and quality, laser cutting is generally considered more precise for non-metal materials due to its ability to create intricate designs with minimal material waste.

Conclusion

In conclusion, when it comes to precision in metal fabrication, laser cutting reigns supreme. Its ability to create intricate and detailed designs with utmost accuracy is unmatched.

Milling, on the other hand, may not offer the same level of precision, but it does excel in versatility and cost-effectiveness.

However, for those seeking the pinnacle of precision, laser cutting is the way to go. So, if you’re looking for impeccable precision in your metal fabrication projects, laser cutting is your ticket to tantalizingly accurate results.