Hey there, woodworking enthusiast! So, you’ve found yourself in a bit of a quandary, huh? You’re torn between the precision of laser cutting and the tried-and-true milling technique.

Well, fear not, because I’m here to shed some light on this age-old debate. In the world of woodworking, precision is everything. And when it comes to achieving that precision, laser cutting and milling are two heavyweights vying for the top spot.

Each technique has its own unique set of qualities and benefits, making the decision a tough one. But fear not, my friend, for I am about to break it all down for you.

In this article, we’ll dive deep into the world of laser cutting and milling, comparing their precision, exploring their techniques, and giving you all the factors you need to consider when making your choice.

So grab your tools, buckle up, and let’s get started on this precision-packed woodworking journey!

Key Takeaways

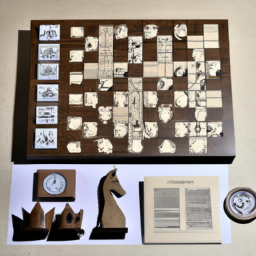

- Laser cutting offers high precision and clean cuts, while milling allows for more depth and texture in the final product.

- Laser cutting is ideal for intricate patterns, engraving, and cutting complex shapes, while milling is better suited for projects that require more depth and texture.

- Laser cutting is cost-efficient and time-saving, with less material wastage and quicker turnaround times.

- Laser cutting works best with materials like acrylic and plywood, while milling can handle a wider range of materials, including hardwoods and metals.

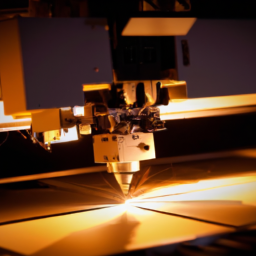

Understanding Laser Cutting in Woodworking

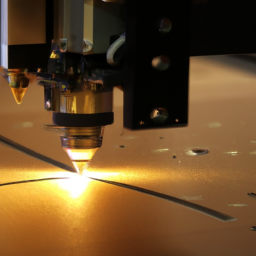

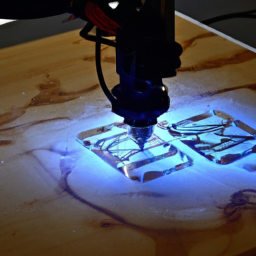

Laser cutting in woodworking creates intricate designs with precise and clean edges. The advantages of laser cutting are numerous. First, the laser beam is incredibly accurate, allowing for intricate details and complex shapes to be cut with ease. Additionally, the laser beam is powerful and can cut through a variety of materials, including wood, with precision and speed.

Laser cutting techniques include vector cutting, which involves cutting along the outline of a design, and raster engraving, which creates detailed patterns by burning the surface of the wood. Laser cutting is a versatile and efficient method that produces high-quality results.

Moving on to exploring milling techniques in woodworking, you’ll discover another method that offers its own unique advantages.

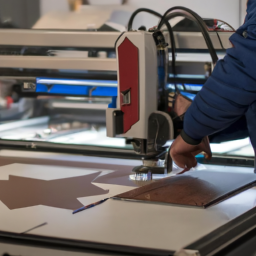

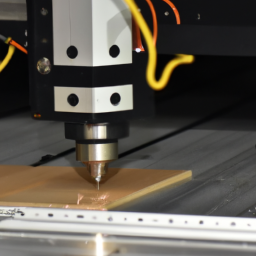

Exploring Milling Techniques in Woodworking

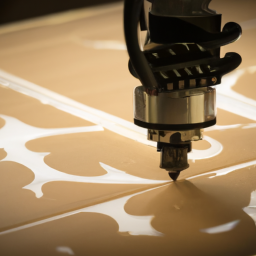

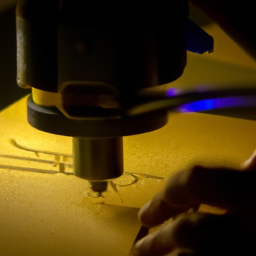

To achieve greater precision in woodworking, you can explore various milling techniques such as using a CNC router to create intricate designs on wood surfaces. For example, imagine you want to create a custom wooden sign with intricate detailing, a CNC router can precisely carve out the design with accuracy and efficiency.

When it comes to milling wood, there are both traditional and advanced CNC milling methods available. Traditional milling techniques involve using manual tools like chisels and saws to shape and carve wood. While these methods require skill and craftsmanship, they may not always deliver the level of precision desired.

On the other hand, advanced CNC milling methods utilize computer-controlled machines that can execute complex designs with unmatched precision. These machines follow digital instructions to precisely cut, shape, and carve wood, resulting in highly accurate and intricate woodworking projects.

Using the table below, you can see the key differences between traditional milling techniques and advanced CNC milling methods in woodworking:

| Traditional Milling Techniques | Advanced CNC Milling Methods |

|---|---|

| Requires manual labor and skill | Utilizes computer-controlled machines |

| Limited precision and accuracy | Offers unmatched precision and accuracy |

| Time-consuming process | Efficient and time-saving |

| Limited design possibilities | Can execute complex designs |

| May result in human errors | Minimizes human errors |

Exploring these milling techniques provides a solid foundation for understanding the precision and intricacy that can be achieved in woodworking. Moving forward, let’s delve into a comparison between laser cutting and milling in woodworking.

Comparing Laser Cutting and Milling in Woodworking

When comparing laser cutting and milling in woodworking, there are several key points to consider.

Firstly, differences in precision and accuracy play a significant role. Laser cutting is known for its high precision and clean cuts, making it ideal for intricate designs and detailed work. On the other hand, milling offers a different level of precision, allowing for more depth and texture in the final product.

Secondly, the applications and project suitability of laser cutting and milling differ. Laser cutting is often used for creating intricate patterns, engraving, and cutting complex shapes. It’s particularly well-suited for projects that require high precision and delicate detailing. Milling, on the other hand, is better suited for projects that require more depth and texture, such as creating three-dimensional sculptures or roughing out larger pieces of wood.

Lastly, cost and time considerations are important factors to take into account. Laser cutting can be more expensive initially, as it requires specialized equipment and materials. However, it offers faster production times and minimal post-processing. Milling, on the other hand, may require more time for setup and post-processing, but it can be a more cost-effective option in the long run, especially for larger-scale projects.

Overall, when deciding between laser cutting and milling in woodworking, it’s important to consider the precision and accuracy required, the specific project and its suitability for each technique, as well as the cost and time considerations.

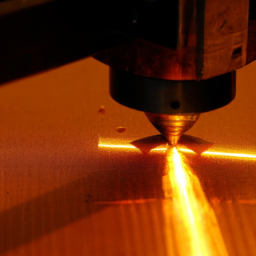

Differences in Precision and Accuracy

Imagine standing in a woodworking shop, where you can achieve a level of precision and accuracy that is unparalleled with laser cutting or milling. When it comes to precision, laser cutting takes the lead. The laser beam is incredibly thin, allowing for intricate cuts with minimal material wastage. It can achieve accuracy down to a fraction of a millimeter, ensuring precise and clean edges.

On the other hand, milling techniques excel in accuracy. With milling, you have full control over the depth and width of the cut, resulting in accurate dimensions and shapes. The precision of laser cutting combined with the accuracy of milling techniques can produce remarkable woodworking projects.

Now, let’s dive into the applications and project suitability of these methods.

Applications and Project Suitability

In the world of woodworking, the choice between laser cutting and milling techniques ultimately depends on the specific project and its desired outcome.

Laser cutting is ideal for projects that involve intricate designs and complex shapes, as the precision and accuracy of the laser beam allow for precise cuts. It is particularly well-suited for projects that require delicate detailing or fine engraving.

On the other hand, milling is better suited for projects that involve larger, bulkier pieces of wood or require more substantial material removal. It is perfect for creating furniture or large-scale sculptures.

When choosing between laser cutting and milling, it is important to consider the complexity of the project and the compatibility of the material with each technique.

Moving on to cost and time considerations, it is important to evaluate the financial and time investment required for each method.

Cost and Time Considerations

Now that you have an understanding of the various applications and project suitability of laser cutting and milling in woodworking, let’s dive into the cost and time considerations.

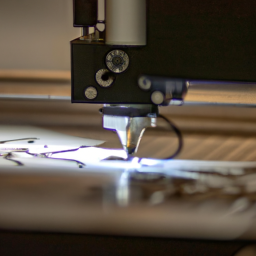

When it comes to cost efficiency, laser cutting has an advantage over milling. Laser cutting requires less material wastage, as the laser beam is precise and minimizes errors. Additionally, laser cutting is a faster process compared to milling, allowing for quicker turnaround times on projects. Time-saving techniques such as automated loading and unloading systems further enhance the efficiency of laser cutting. These factors not only save money but also increase productivity.

Considering the cost and time savings, laser cutting can be a more practical choice for certain woodworking projects.

Now, let’s explore the key factors to consider when choosing between laser cutting and milling in woodworking.

Factors to Consider When Choosing Between Laser Cutting and Milling

Picture yourself standing in a woodworking studio, weighing the factors that come into play when deciding between laser cutting and milling, as you strive for absolute precision in your craft. When choosing between these two methods, it’s important to consider the trade-off between speed and quality.

Laser cutting is faster, making it ideal for projects with tight deadlines. However, milling offers superior precision, ensuring clean and accurate cuts.

Another factor to consider is material compatibility. Laser cutting works best with materials like acrylic and plywood, while milling is more versatile and can handle a wider range of materials, including hardwoods and metals.

These factors should guide your decision-making process, as you aim for the perfect balance between speed, quality, and material compatibility.

Now, let’s move on to the best practices for achieving precision in woodworking.

Best Practices for Achieving Precision in Woodworking

Imagine achieving the highest level of precision in your woodworking projects by following these best practices. When it comes to woodworking, precision is key. By using the right woodworking techniques and precision tools, you can ensure that every cut and measurement is accurate. Here are some best practices to help you achieve precision in your woodworking projects:

-

Use a sharp blade: A dull blade can lead to inaccurate cuts and splintered wood. Make sure to regularly sharpen your blade or replace it when necessary.

-

Measure twice, cut once: Taking the time to double-check your measurements before making a cut can save you from costly mistakes.

-

Use jigs and fixtures: Jigs and fixtures can help guide your cuts and ensure consistent results. They can be especially useful when working with complex shapes or angles.

By following these best practices, you can achieve the highest level of precision in your woodworking projects.

Frequently Asked Questions

Can laser cutting be used on materials other than wood?

Laser cutting is not limited to wood; it has various applications on different materials. Laser cutting can be used on materials like metal, acrylic, fabric, and even stone. Compared to other cutting methods, laser cutting offers unparalleled precision and accuracy. It allows intricate designs and complex shapes to be cut with ease.

With its versatility and ability to work on various materials, laser cutting has become a preferred choice in many industries.

How much does a laser cutting machine typically cost?

Laser cutting machines can vary in price depending on factors such as power, size, and additional features. The cost typically ranges from a few thousand dollars to several hundred thousand dollars.

For small woodworking businesses, the price may seem high initially, but considering the precision and efficiency it offers, laser cutting can be a worthwhile investment. It allows for intricate designs, reduces material waste, and increases productivity, making it a valuable tool for businesses in the long run.

Are there any safety concerns associated with laser cutting in woodworking?

When it comes to laser cutting in woodworking, safety is of utmost importance. Safety precautions must be taken to ensure the well-being of both the operator and the environment.

One important consideration is ventilation requirements. Proper ventilation helps to remove smoke and fumes generated during the cutting process, preventing health hazards.

Additionally, it’s crucial to wear appropriate personal protective equipment, such as safety glasses and gloves, to minimize the risk of injuries.

Remember, in woodworking, safety always comes first.

What types of woodworking projects are better suited for milling techniques?

Types of woodworking projects that require intricate designs are better suited for milling techniques. Milling allows for greater precision and control when working on complex and detailed designs.

Additionally, milling techniques are highly beneficial for large scale woodworking projects. They offer the advantage of being able to work with larger materials and create more substantial pieces.

Overall, milling techniques are ideal for projects that demand intricate details and require a larger scale of work.

Can laser cutting and milling be used together in the same woodworking project?

Combining laser cutting and milling techniques in woodworking projects can yield exceptional results. By utilizing both methods, you can achieve a superior level of precision and intricacy in your designs.

Laser cutting allows for intricate detailing and precise cuts, while milling techniques offer versatility and the ability to shape and carve wood with precision. The benefits of combining these techniques include enhanced design possibilities, increased efficiency, and the ability to create complex, visually stunning woodworking projects.

Conclusion

In conclusion, when it comes to precision in woodworking, laser cutting takes the lead. Its ability to create intricate designs with utmost accuracy is simply extraordinary.

With the power of a laser beam, it effortlessly glides through wood, leaving behind immaculate cuts.

While milling techniques have their own merits, laser cutting surpasses them in terms of precision.

So, if you’re aiming for perfection in your woodworking projects, embrace the laser’s magical touch. Prepare to witness a symphony of craftsmanship that will make your creations shine like a thousand suns.