Are you looking to cut through acrylic with precision and accuracy? Well, you’re in luck because there are two methods at your disposal: laser cutting and plasma cutting. While both techniques have their merits, it’s important to understand the key differences between them to make an informed decision.

In this article, we will explore the battle of laser cutting vs. plasma cutting for acrylic designs and help you determine which method is best suited for your needs.

Now, you might think that cutting through a material as delicate as acrylic would require a delicate technique. However, irony is at play here, as both laser cutting and plasma cutting offer a level of precision and accuracy that may surprise you. But precision is just the tip of the iceberg. We will also delve into the speed, efficiency, versatility, and flexibility of these methods, as well as the cost-effectiveness and the consideration of material thickness. Furthermore, we will compare the maintenance and safety aspects of laser cutting and plasma cutting.

So, whether you’re a DIY enthusiast or a professional designer, join us on this technical journey as we explore the world of laser cutting and plasma cutting for acrylic designs. It’s time to discover which method will reign supreme in your workshop.

Key Takeaways

- Laser cutting offers precision, accuracy, and the ability to create intricate designs, making it ideal for acrylic projects that require intricate details.

- Plasma cutting is faster and better suited for larger acrylic designs that don’t require as much detail, but it may result in rougher edges.

- Laser cutting is cost-effective and requires minimal maintenance, while plasma cutting requires regular inspection and replacement of consumables.

- Safety precautions, such as proper ventilation and the use of personal protective equipment, are necessary for both laser cutting and plasma cutting due to potential hazards and harmful fumes.

Precision and Accuracy

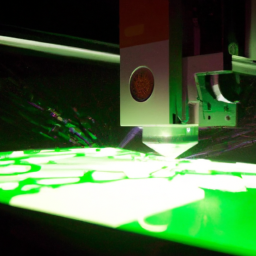

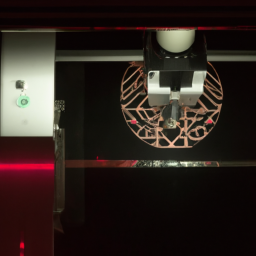

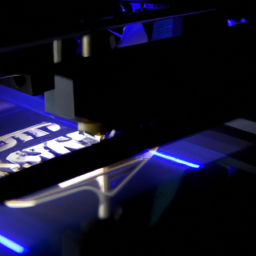

When it comes to precision and accuracy for your acrylic designs, you can’t go wrong with laser cutting—it’ll blow your mind with its meticulousness and attention to detail!

Laser cutting offers unparalleled precision, allowing for intricate and complex designs that plasma cutting simply can’t match. While plasma cutting may be faster, laser cutting prioritizes precision over speed.

Laser beams are incredibly precise, making clean and precise cuts with minimal material wastage. In contrast, plasma cutting can sometimes result in rougher edges and imprecise cuts.

Laser cutting also ensures accuracy, as it follows the programmed design with utmost precision. Efficiency is important, but when it comes to acrylic designs, the precision and accuracy offered by laser cutting make it the superior choice.

Speed and Efficiency

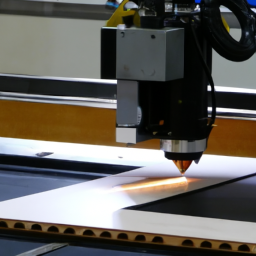

If you’re looking for a way to get the job done quickly and efficiently, it’s like finding the express lane for your acrylic designs. Laser cutting and plasma cutting both offer speed and efficiency, but they have different impacts on the quality and complexity of your designs.

Here are four reasons why speed and efficiency matter when choosing between laser cutting and plasma cutting for acrylic designs:

-

Laser cutting offers high-speed cutting, allowing you to complete your projects in less time.

-

Plasma cutting is also fast, but it may result in a slightly lower quality finish compared to laser cutting.

-

Laser cutting is more precise and accurate, which is important for intricate and complex designs.

-

Plasma cutting is better suited for simpler designs that require less precision.

Considering the speed vs quality and the impact on design complexity, the choice between laser cutting and plasma cutting depends on your specific needs.

Moving on to the next section about versatility and flexibility…

Versatility and Flexibility

Looking for a way to bring your acrylic designs to life with endless possibilities and creative freedom? Let’s explore the versatility and flexibility of laser cutting and plasma cutting.

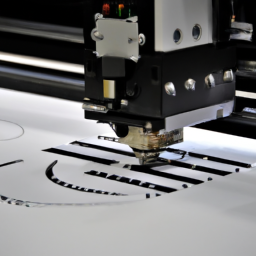

When it comes to customization options, laser cutting offers precise and intricate designs that are perfect for detailed projects. With its high level of accuracy, laser cutting allows you to create intricate patterns and shapes, giving your acrylic designs a professional and polished look.

On the other hand, plasma cutting may not provide the same level of intricacy, but it offers a wide range of design options. It allows for faster cutting speeds and is better suited for larger projects that require less detail.

Transitioning into the next section, let’s now discuss the cost-effectiveness of these cutting methods.

Cost-effectiveness

To get the most bang for your buck, consider the cost-effectiveness of these cutting techniques and how they can stretch your budget while still delivering impressive results. Conducting a cost benefit analysis between laser cutting and plasma cutting is crucial when making a long term investment in acrylic designs. While both methods have their advantages, laser cutting tends to be more cost-effective in the long run. Although the initial setup cost for laser cutting may be higher, the precision and efficiency of the process can save you money on material wastage and labor costs. Additionally, laser cutting requires minimal maintenance compared to plasma cutting, reducing potential expenses over time. By choosing laser cutting for your acrylic designs, you can optimize your budget without compromising on quality. Considering the material thickness is the next important step in determining the ideal cutting method for your project.

Consideration of Material Thickness

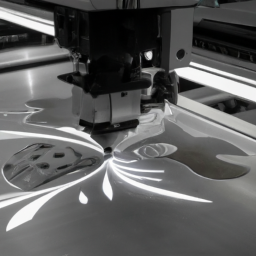

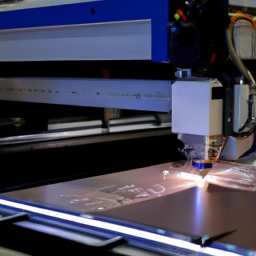

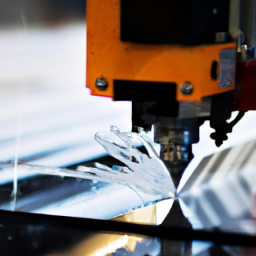

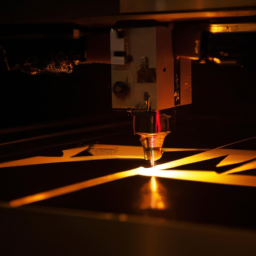

Considering the thickness of the material is crucial in determining which cutting technique will slice through it like a hot knife through butter. When it comes to material compatibility, laser cutting is more versatile as it can handle a wider range of thicknesses compared to plasma cutting.

Laser cutting is ideal for thinner acrylic sheets, typically up to 25mm thick, while plasma cutting is better suited for thicker materials, ranging from 25mm to 75mm. Heat generation is another important factor to consider. Laser cutting generates less heat, making it suitable for delicate acrylic designs that may be prone to melting or warping.

On the other hand, plasma cutting produces more heat, which can be advantageous for thicker materials but may pose challenges for thinner acrylic sheets.

Transitioning to the subsequent section about the ‘comparison of maintenance and safety,’ it is important to evaluate these factors to make an informed decision.

Comparison of Maintenance and Safety

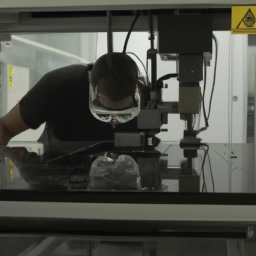

When it comes to maintaining and ensuring safety in your cutting process, you want to prioritize regular inspections and implementing safety protocols. Both laser cutting and plasma cutting methods have specific maintenance requirements and safety precautions to consider.

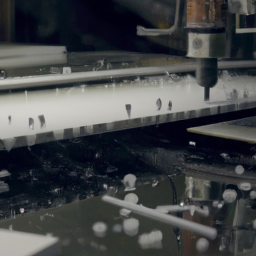

In terms of maintenance, laser cutting requires regular cleaning of the lens and mirrors to ensure optimal performance. Additionally, the laser tube may need to be replaced periodically, depending on usage.

Plasma cutting, on the other hand, requires regular inspection and replacement of consumables such as nozzles and electrodes to maintain cutting quality.

When it comes to safety precautions, laser cutting poses a potential hazard due to the high intensity of the laser beam. Safety measures such as wearing protective eyewear and ensuring proper ventilation in the workspace are crucial.

Plasma cutting, on the other hand, produces harmful fumes and requires adequate ventilation and the use of personal protective equipment (PPE) such as gloves and masks.

Both laser cutting and plasma cutting require regular maintenance and the implementation of safety precautions. It’s essential to follow the recommended maintenance guidelines and safety protocols to ensure the longevity of your equipment and the safety of your operators.

Frequently Asked Questions

Can laser cutting be used on materials other than acrylic?

Yes, laser cutting can be used on a variety of different materials. One of the advantages of laser cutting, besides acrylic, is its versatility in cutting different materials such as wood, metal, fabric, and plastic. Laser cutting offers precise and clean cuts, making it suitable for intricate designs and delicate materials. It’s also a faster and more efficient cutting method compared to traditional methods, making it a popular choice in various industries.

How does the cost of plasma cutting compare to laser cutting?

The cost comparison between plasma cutting and laser cutting is an important factor to consider when choosing a cutting method. Plasma cutting generally has lower upfront costs, as plasma cutters are typically less expensive than laser cutters.

Additionally, plasma cutting can be more cost-effective for thicker materials, as it requires less power and can cut at higher speeds. However, laser cutting offers benefits such as higher precision and cleaner cuts, which may outweigh the cost difference for some applications.

Are there any safety precautions that need to be taken when using laser cutting?

When it comes to laser cutting, safety should be your top priority. Laser beams are like the superheroes of precision cutting, but they can also be dangerous if not handled correctly. To ensure your well-being, take proper safety precautions.

This includes wearing appropriate protective gear like goggles and gloves, setting up proper ventilation to remove any harmful fumes, and ensuring the work area is clear of any potential hazards.

Remember, safety first, always.

Which method, laser cutting or plasma cutting, is better for intricate designs?

When comparing laser cutting and plasma cutting for intricate designs, precision is a key factor to consider. Laser cutting offers superior precision due to its focused beam of light, allowing for intricate and detailed designs.

On the other hand, plasma cutting may not provide the same level of precision due to the wider and less focused cutting arc. Additionally, laser cutting tends to be more efficient and faster than plasma cutting when it comes to intricate designs.

How long does it typically take to learn how to operate a laser cutting machine?

Learning how to operate a laser cutting machine involves a learning curve, but with consistent practice, you can achieve proficiency. Familiarizing yourself with the machine’s controls, software, and safety protocols is essential.

Understanding file preparation, material selection, and machine settings is crucial for precise and efficient cuts.

The time it takes to master laser cutting machine operation varies depending on individual aptitude and the complexity of the designs, but with dedication, you can become proficient in a reasonable timeframe.

Conclusion

In conclusion, when it comes to choosing between laser cutting and plasma cutting for acrylic designs, several factors need to be considered.

Laser cutting offers unparalleled precision and accuracy, ensuring flawless designs every time. Its speed and efficiency make it the ideal choice for time-sensitive projects. Additionally, laser cutting provides versatility and flexibility, allowing for intricate and complex designs.

From a cost-effectiveness standpoint, laser cutting may require a higher initial investment but proves to be more economical in the long run.

Finally, the consideration of material thickness plays a crucial role in determining the appropriate cutting method.

Overall, laser cutting emerges as the superior choice, guaranteeing impeccable acrylic designs with utmost precision and efficiency.