Are you in the metal fabrication industry and wondering which cutting method is best for your projects? Laser cutting and plasma cutting are two popular options, each with its own advantages and considerations. With so much at stake, it’s crucial to make an informed decision.

In this article, we will explore the differences between laser cutting and plasma cutting, helping you understand the technical aspects and benefits of each method. By comparing the quality of cuts, assessing safety and environmental impact, and considering other crucial factors, you can confidently choose the method that suits your needs.

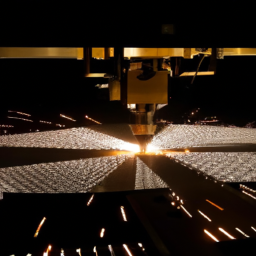

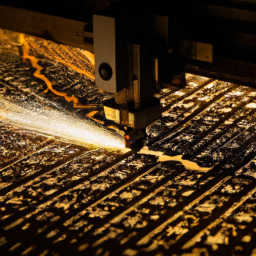

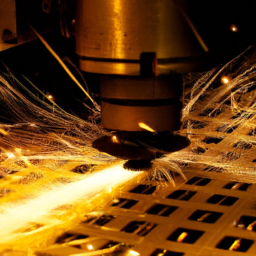

Laser cutting utilizes a high-powered laser beam to precisely cut through metal, offering exceptional accuracy and intricate detailing. Plasma cutting, on the other hand, employs a plasma torch to melt through metal, providing fast cutting speeds and versatility.

So, which method should you choose? Join us as we delve into the world of laser cutting and plasma cutting to find the answer. Let’s make the right choice together.

Key Takeaways

- Laser cutting offers exceptional accuracy and intricate detailing, making it ideal for intricate designs and complex projects.

- Plasma cutting provides fast cutting speeds and versatility, making it more suitable for thicker materials and faster cutting speeds.

- Laser cutting produces clean and smooth edge finishes with minimal kerf width, while plasma cutting tends to produce rougher edges and wider kerf widths.

- Laser cutting is considered safer and more environmentally friendly, as it generates less waste, consumes less energy, and produces minimal air pollution.

Understanding Laser Cutting

Laser cutting, with its precise and focused beam of light, offers unparalleled versatility and accuracy in metal fabrication projects. The advantages of laser cutting are numerous. Firstly, it allows for intricate and complex designs to be cut with ease, allowing for flexibility in design choices.

Additionally, laser cutting produces a clean and smooth edge finish, eliminating the need for further processing. Laser cutting is also highly efficient, with minimal material waste and quick turnaround times. However, laser cutting does have its limitations. It is not suitable for cutting thick materials, as it may result in material warping or melting. Moreover, the initial investment for laser cutting equipment can be high.

Transitioning into exploring plasma cutting, this alternative method offers its own set of advantages and limitations.

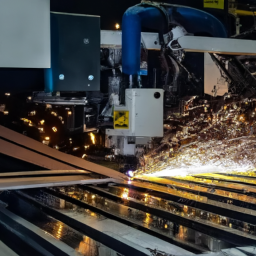

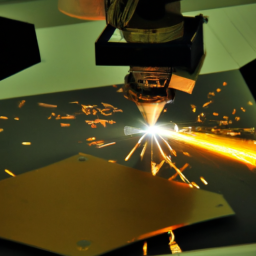

Exploring Plasma Cutting

When it comes to exploring plasma cutting, there are three key points to consider.

First, plasma cutting offers versatility in cutting thickness, allowing you to work with a wide range of materials.

Second, it’s known for its speed and productivity, making it a preferred method for many metal fabricators.

Lastly, cost comparisons show that plasma cutting can be a cost-effective option, especially for larger projects.

Versatility in Cutting Thickness

Despite its limitations, plasma cutting offers a wide range of cutting thicknesses, making it a versatile option in metal fabrication. With plasma cutting, you can achieve cutting precision within a few millimeters, allowing for intricate designs and precise cuts. This method also minimizes the heat affected zone, reducing the risk of warping or distorting the metal.

Plasma cutting can handle various thicknesses, from thin sheets to thick plates, making it suitable for a wide range of applications. However, when it comes to speed and productivity, laser cutting takes the lead.

By transitioning to the next section, we’ll explore the advantages of laser cutting in terms of speed and productivity.

Speed and Productivity

Moreover, the speed and productivity of plasma cutting can be enhanced by utilizing advanced CNC technology, allowing for efficient and accurate metal fabrication processes. When it comes to cutting speed, plasma cutting has the upper hand over laser cutting. Plasma cutting can achieve cutting speeds of up to 500 inches per minute, while laser cutting typically operates at a slower pace. This increased cutting speed directly translates to higher production efficiency, as more parts can be cut in a shorter amount of time. To illustrate this, consider the following table:

| Cutting Method | Cutting Speed (inches per minute) |

|---|---|

| Plasma Cutting | 500 |

| Laser Cutting | 200 |

As you can see, plasma cutting surpasses laser cutting in terms of cutting speed. This efficiency in production can significantly impact the overall time it takes to complete a project. With that being said, it is important to also consider the cost implications of each method, which will be discussed in the subsequent section.

Cost Comparisons

If you’re looking to save money on your metal fabrication processes, one interesting statistic to consider is that plasma cutting can be up to 50% cheaper than laser cutting. This cost efficiency makes plasma cutting a popular choice among metal fabricators.

Here are a few reasons why plasma cutting can lead to long-term savings:

-

Plasma cutting systems have a lower initial investment cost compared to laser cutting machines.

-

Plasma cutting consumes less energy, resulting in lower operational costs.

-

Consumable parts for plasma cutting, such as electrodes and nozzles, are more affordable and need to be replaced less frequently.

-

Plasma cutting can process thicker metals at a faster speed, reducing labor costs.

Considering these factors, it becomes clear that plasma cutting offers significant cost advantages over laser cutting. However, there are other important factors to consider in choosing the right method for your metal fabrication needs.

Factors to Consider in Choosing the Right Method

When considering the right method for metal fabrication, there are several factors you should take into account.

First, consider the material types and thicknesses you’ll be working with, as this will determine which method is most suitable.

Next, think about the specific requirements of your project, such as precision and intricacy. This will help you determine which method will yield the best results.

Finally, budget and cost considerations are also important, as different methods have varying costs associated with them.

Material Types and Thicknesses

Additionally, the choice between laser cutting and plasma cutting in metal fabrication depends on the types of materials and their thicknesses.

When considering material types, it’s important to note that laser cutting is well-suited for a wide range of metals, including stainless steel, aluminum, and carbon steel. On the other hand, plasma cutting is more suitable for conductive materials like steel and aluminum.

As for thicknesses, laser cutting can handle thinner materials with high precision, while plasma cutting is better for thicker materials that require faster cutting speeds.

Here are four key considerations to keep in mind when choosing between laser cutting and plasma cutting:

-

Material compatibility: Laser cutting is versatile and can work with various metal types, while plasma cutting is limited to conductive materials.

-

Precision: Laser cutting offers superior precision for thin materials, while plasma cutting is better for thicker materials.

-

Cutting speed: Plasma cutting is generally faster than laser cutting, making it ideal for time-sensitive projects.

-

Cost: Laser cutting equipment tends to be more expensive than plasma cutting equipment, so budget considerations should be taken into account.

Considering these factors, the choice between laser cutting and plasma cutting should be based on your project requirements.

Project Requirements

Considering the specific needs of your project, it is important to determine the requirements before deciding on the most suitable method for fabrication. The project complexity and the required precision are key factors to consider. Laser cutting is well-suited for intricate designs and complex projects that demand high accuracy. It utilizes specialized equipment that uses a focused beam of light to cut through the material. On the other hand, plasma cutting is ideal for projects that involve thicker materials and require faster cutting speeds. It uses a jet of ionized gas to melt and separate the metal.

To better understand the differences between laser cutting and plasma cutting, refer to the table below:

| Laser Cutting | Plasma Cutting | |

|---|---|---|

| Precision | High | Moderate |

| Speed | Moderate | High |

| Thickness | Thin | Thick |

| Complexity | Complex | Simple |

| Equipment | Specialized | Versatile |

Considering these factors will help you make an informed decision based on the requirements of your project. Moving forward, it is important to also consider the budget and cost considerations without compromising on the quality and precision of the fabrication process.

Budget and Cost Considerations

To make an informed decision about the fabrication method for your project, it’s important to take into account the budget and cost considerations. This should be done while ensuring the desired quality and precision.

Laser cutting and plasma cutting both have their own advantages and disadvantages when it comes to cost effectiveness. Laser cutting is generally more expensive due to the high cost of laser machines and maintenance. However, it offers higher precision and can be more cost effective for small or intricate projects.

On the other hand, plasma cutting is generally more affordable upfront and has lower maintenance costs. It is a suitable option for larger projects with less strict precision requirements. Considering your financial constraints, it’s essential to evaluate the cost effectiveness of each method before making a decision.

Now, let’s delve into comparing the quality of cuts.

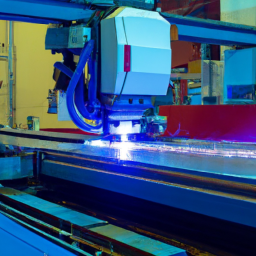

Comparing the Quality of Cuts

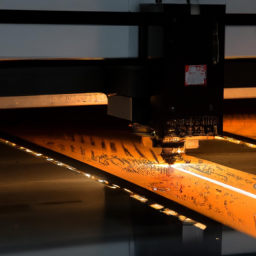

When it comes to comparing the quality of cuts between laser cutting and plasma cutting in metal fabrication, you’ll notice that laser cutting provides precise and clean cuts with minimal kerf width, while plasma cutting tends to produce rougher edges and wider kerf widths. Laser cutting uses a focused laser beam to melt or vaporize the metal, resulting in a narrow cut with minimal heat-affected zones. This method is ideal for intricate designs and high-precision cuts. On the other hand, plasma cutting uses a high-temperature plasma arc to melt through the metal, which can lead to rougher edges and wider kerf widths. While plasma cutting is faster and more cost-effective compared to laser cutting, it may not provide the same level of precision and quality. When comparing laser cutting and plasma cutting with waterjet cutting, laser cutting is known for its superior precision, while plasma cutting and waterjet cutting are more similar in terms of their wider kerf widths. Additionally, laser cutting has a minimal impact on material integrity, as it does not cause warping or distortion. However, plasma cutting can result in some heat distortion, especially on thinner materials. In summary, if you prioritize precise and clean cuts, laser cutting is the better choice, while plasma cutting may be more suitable for applications that require speed and cost-effectiveness. Moving on to the next section, assessing safety and environmental impact…

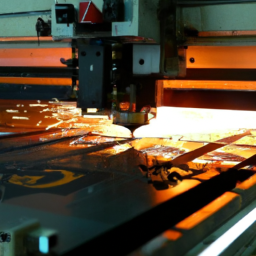

Assessing Safety and Environmental Impact

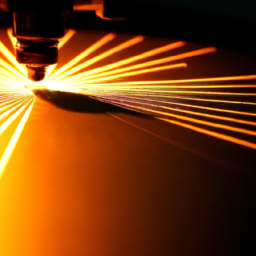

If you’re concerned about safety and the environment, it’s essential to understand the potential risks and drawbacks associated with each cutting method.

When it comes to safety regulations, laser cutting is generally considered safer than plasma cutting. Laser cutters have enclosed systems that prevent the release of hazardous fumes and reduce the risk of accidents. On the other hand, plasma cutting produces more smoke and sparks, posing a higher risk of fire and explosion if not properly managed.

In terms of environmental sustainability, laser cutting is a more eco-friendly option. Laser cutting generates less waste, consumes less energy, and produces minimal air pollution compared to plasma cutting.

Considering these factors, it is clear that laser cutting is the safer and more environmentally friendly choice in metal fabrication.

Transitioning into the subsequent section, understanding these aspects is crucial for making an informed decision.

Making an Informed Decision

Consider the safety regulations and environmental impact to confidently determine the best method for your metal fabrication needs. When comparing the benefits and evaluating the drawbacks of laser cutting and plasma cutting, it is important to have a clear understanding of the factors that can influence your decision.

In terms of safety, laser cutting offers a more precise and controlled process, reducing the risk of accidents and injuries. However, it requires proper ventilation to prevent the release of harmful fumes. On the other hand, plasma cutting produces more sparks and smoke, increasing the risk of fire hazards.

In terms of environmental impact, laser cutting is generally considered to be more environmentally friendly as it produces less waste and emits fewer pollutants. However, plasma cutting requires more energy and generates more noise pollution.

To help you make an informed decision, here is a table summarizing the safety and environmental aspects of laser cutting and plasma cutting:

| Aspect | Laser Cutting | Plasma Cutting |

|---|---|---|

| Safety | Precise and controlled process, but requires proper ventilation | More sparks and smoke, increasing fire hazards |

| Environmental Impact | Produces less waste and emits fewer pollutants | Requires more energy and generates more noise pollution |

By considering these factors, you can determine which method aligns best with your safety requirements and environmental goals in metal fabrication.

Frequently Asked Questions

Are laser cutting machines more expensive than plasma cutting machines?

When it comes to the cost comparison between laser cutting machines and plasma cutting machines, laser cutting machines are generally more expensive. This is due to the advanced technology and precision they offer.

However, it’s important to consider the efficiency analysis as well. Laser cutting machines are known for their high accuracy and clean cuts, which can result in lower material waste and reduced secondary operations.

Ultimately, the decision should be based on your specific needs and budget.

Can plasma cutting methods be used on all types of metals?

Plasma cutting methods have limitations when it comes to working with certain types of metals. While it’s suitable for cutting steel, aluminum, and stainless steel, it may struggle with non-ferrous metals like copper or brass.

On the other hand, laser cutting offers precise and clean cuts for a wide range of metals, including those that plasma cutting may struggle with. This makes laser cutting a superior choice for industries that require versatility and precision in metal fabrication.

What factors should be considered when choosing between laser cutting and plasma cutting?

When choosing between laser cutting and plasma cutting, there are two important factors to consider: cost and versatility.

Laser cutting tends to be more expensive upfront, but it offers high precision and can cut a wide range of metals.

On the other hand, plasma cutting is generally more cost-effective and can handle thicker materials, but it may not provide the same level of precision.

Ultimately, the decision should be based on your specific needs and budget.

How does the quality of cuts compare between laser cutting and plasma cutting?

When it comes to comparing the quality of cuts, laser cutting and plasma cutting are two different beasts.

Laser cutting offers precision like a surgeon’s scalpel, providing clean and accurate cuts.

On the other hand, plasma cutting may not be as precise, but it compensates with lightning-fast speed.

So, if you prioritize impeccable cuts, laser cutting is your go-to.

But if you value speed over absolute precision, plasma cutting has got your back.

What safety precautions should be taken when using laser cutting or plasma cutting methods?

When using laser cutting or plasma cutting methods, it’s crucial to prioritize safety measures. Before starting, ensure you have the appropriate protective gear, such as safety glasses, gloves, and a face shield. Be cautious of electrical hazards and always follow proper grounding procedures.

Keep the work area clear of flammable materials and have a fire extinguisher nearby. Regularly inspect and maintain the equipment to minimize the risk of accidents. Remember, safety should always be the top priority when using these cutting methods.

Conclusion

After weighing the pros and cons of laser cutting and plasma cutting, you’re now equipped to make an informed decision. Laser cutting offers unparalleled precision and accuracy, perfect for intricate designs.

On the other hand, plasma cutting is ideal for thicker materials and high-speed production.

Both methods have their strengths and weaknesses, so consider factors such as cut quality, safety, and environmental impact.

Ultimately, the choice comes down to your specific needs and requirements. Rest assured, either way, you can achieve impressive results in your metal fabrication projects.