Have you ever wondered which cutting method is more precise in metal fabrication: laser cutting or rotary cutting?

In the world of metal fabrication, accuracy is crucial, and choosing the right cutting technique can make all the difference.

Laser cutting and rotary cutting are two popular methods used in the industry, each with its own advantages and disadvantages.

In this article, we will delve into the intricacies of these cutting techniques and compare their accuracy.

By understanding the capabilities and limitations of laser cutting and rotary cutting, you will be able to make an informed decision for your metal fabrication needs.

Whether you are a professional in the field or simply curious about the intricacies of metal fabrication, this article will provide you with the technical knowledge you need to navigate the world of laser cutting and rotary cutting.

Key Takeaways

- Laser cutting offers high precision and minimal material waste, making it ideal for precise and intricate designs in industries such as automotive, aerospace, and electronics.

- Laser cutting is faster and more accurate than rotary cutting for complex designs, especially for cutting thin materials.

- Laser cutting eliminates the need for tooling changes and reduces setup time, resulting in cost savings and time efficiency in metal fabrication.

- Rotary cutting, on the other hand, is more suited for heavy-duty applications and thicker materials, providing accuracy and clean edges but limited in cutting intricate designs and may cause material distortion.

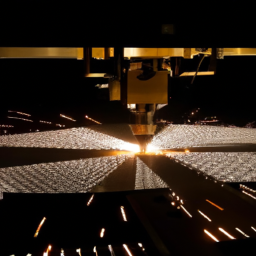

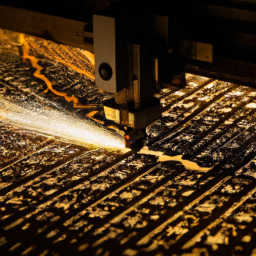

Understanding Laser Cutting

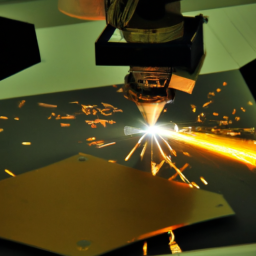

To truly comprehend laser cutting, you need to understand its intricate process and the precision it offers.

Laser cutting is a highly advanced method used in metal fabrication that utilizes a high-powered laser beam to cut through various materials with impeccable accuracy. One of the main advantages of laser cutting is its ability to produce intricate and complex designs with sharp edges and fine details. Additionally, laser cutting offers a high level of precision, ensuring minimal material waste.

However, laser cutting also has its disadvantages. It can be a costly process due to the expensive equipment and maintenance required. Moreover, laser cutting is not suitable for all materials, especially those that are highly reflective.

Moving forward, let’s explore rotary cutting and how it compares to laser cutting in terms of accuracy.

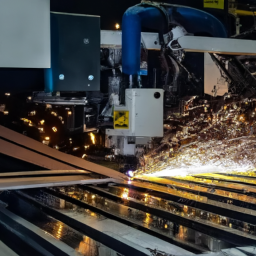

Exploring Rotary Cutting

Exploring rotary cutting gives us a chance to dive into a different method of shaping metal that can offer unique precision and charm. Rotary cutting involves the use of a rotating tool, such as a saw or grinder, to remove material from the workpiece.

One advantage of rotary cutting is its versatility, as it can be used on various types of metals and thicknesses. Additionally, rotary cutting allows for greater control and maneuverability, which is beneficial when working on complex shapes or curved surfaces. However, rotary cutting also has its disadvantages. It tends to generate more heat and produces a rougher surface finish compared to laser cutting. Furthermore, the rotary cutting process may require more time and effort due to the need for frequent tool changes.

Transitioning into the subsequent section about accuracy comparison, it is important to consider the impact of these factors on the precision of rotary cutting.

Accuracy Comparison

When comparing the accuracy of laser cutting and rotary cutting in metal fabrication, it’s important to consider the factors that can affect precision. These factors include the type of material being cut, the thickness of the material, and the complexity of the design.

Laser cutting generally offers higher precision levels than rotary cutting due to its ability to create intricate and precise cuts with minimal material loss. However, rotary cutting can still achieve a high level of precision, particularly in certain applications where speed and efficiency are prioritized over intricate details.

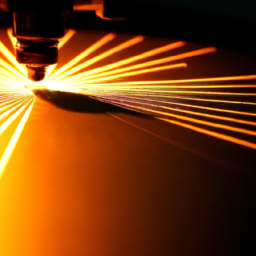

Factors Affecting Accuracy

Understanding the various factors that affect accuracy in metal fabrication, you’ll be surprised to learn that the most significant factor influencing accuracy in laser cutting is the thickness of the metal being cut. According to a study conducted by the International Journal of Machine Tools and Manufacture, to achieve optimal accuracy in laser cutting, consider the following factors:

-

Machine setup: Proper calibration and alignment of the laser cutting machine are essential for accurate cuts.

-

Material thickness: Thicker materials may require adjustments to the laser power and cutting speed to maintain accuracy.

-

Beam quality: The quality and stability of the laser beam affect the precision of the cuts.

-

Cutting speed: Adjusting the cutting speed can impact the accuracy of the laser cuts.

Understanding these factors will help you achieve precise cuts in laser fabrication.

Transitioning to the subsequent section about the precision levels of laser cutting, you will discover the capabilities and limitations of this cutting method.

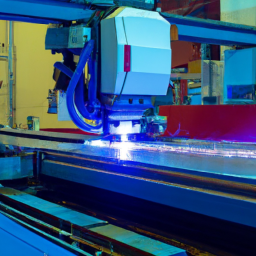

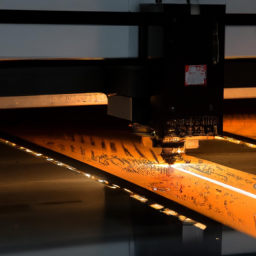

Precision Levels of Laser Cutting

Mastering the precision levels of laser cutting opens up a world of possibilities in creating intricately designed metal pieces. Laser cutting has its limitations, such as the maximum thickness it can cut and the potential for heat distortion. However, its benefits outweigh these limitations.

Laser cutting offers exceptional accuracy, with the ability to create intricate designs and complex shapes with high precision. It allows for tight tolerances and clean cuts, minimizing the need for further finishing. Laser cutting also provides minimal material wastage, as the laser beam is focused and precise. This method is ideal for projects that require intricate details and fine cuts.

Transitioning into the subsequent section about precision levels of rotary cutting, it is important to understand the advantages and limitations of both methods to determine the best approach for metal fabrication.

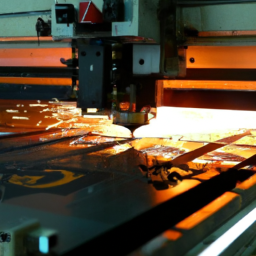

Precision Levels of Rotary Cutting

To truly appreciate the precision levels of rotary cutting, you’ll be amazed by the intricate designs and complex shapes it can effortlessly create. Rotary cutting offers a precision comparison to laser cutting, as it can achieve high levels of accuracy when cutting through various metals.

The cutting speed of rotary cutting is impressive, with the ability to swiftly and precisely cut through thick materials. This method uses a rotating cutting tool that removes material in a continuous motion, allowing for precise and clean cuts.

The precision levels achieved through rotary cutting make it an excellent choice for applications that require complex shapes and designs. Moving into the subsequent section about application considerations, it’s important to explore other factors, such as material thickness and desired finish.

Application Considerations

When considering the application of laser cutting in metal fabrication, it’s important to understand its strengths and limitations.

Laser cutting is highly suitable for precise and intricate designs, making it ideal for industries such as automotive, aerospace, and electronics.

On the other hand, rotary cutting is more suited for heavy-duty applications and thicker materials.

Factors to consider in choosing the cutting method include the desired accuracy, material thickness, production volume, and budget constraints.

Suitable Applications for Laser Cutting

If you’re looking for precise and clean cuts in metal fabrication, laser cutting is the way to go, as it can achieve accuracy levels of up to 0.1mm. Laser cutting offers several benefits, including high precision, minimal material distortion, and the ability to cut intricate shapes. However, there are some limitations to consider. Laser cutting is not suitable for all materials, such as reflective metals, and it can be slower than rotary cutting for thicker materials. To give you a better idea of the capabilities of laser cutting, here’s a comparison table:

| Laser Cutting | Rotary Cutting |

|---|---|

| High precision | Lower precision |

| Minimal material distortion | More material distortion |

| Ability to cut intricate shapes | Limited to straight cuts |

| Suitable for thin materials | Suitable for thick materials |

| Slower speed for thicker materials | Faster speed for thicker materials |

With its precision and versatility, laser cutting is ideal for a wide range of applications, including automotive parts, electronics, jewelry, and signage. In the next section, we will explore suitable applications for rotary cutting.

Suitable Applications for Rotary Cutting

For precise and efficient cutting of thicker materials, rotary cutting is the preferred method. It offers several advantages over laser cutting in certain applications.

Rotary cutting is particularly effective when working with materials such as steel, aluminum, and other metals that are thicker than what laser cutting can handle. The rotary cutting process involves the use of a rotating blade that can easily cut through these materials, providing accuracy and clean edges.

Additionally, rotary cutting is a cost-effective option for large-scale projects, as it doesn’t require the use of expensive laser equipment. However, it does have limitations, such as the inability to cut intricate designs and the potential for material distortion due to the cutting force applied.

Considering these factors, it’s essential to evaluate the requirements of your specific project when choosing the most appropriate cutting method.

Factors to Consider in Choosing the Cutting Method

To choose the most suitable cutting method, consider factors such as material thickness, project scale, and intricacy of design.

-

Cutting Speed: Laser cutting is generally faster than rotary cutting, especially for complex designs. This can save valuable time and increase productivity for large-scale projects.

-

Material Thickness: Laser cutting is more versatile and accurate when it comes to cutting thin materials, while rotary cutting is better suited for thicker materials.

These factors should be carefully evaluated to ensure the accuracy and efficiency of the cutting process. By considering the cutting speed and material thickness, you can make an informed decision that aligns with the specific requirements of your project.

Transitioning into the subsequent section about ‘cost and efficiency’, it’s important to understand how these factors impact the overall effectiveness of the cutting method.

Cost and Efficiency

Discover how laser cutting can save you time and money in metal fabrication with its unmatched accuracy and efficiency. Laser cutting is a cost-effective and time-saving method that offers precise and clean cuts, resulting in minimal material waste. Compared to rotary cutting, laser cutting eliminates the need for tooling changes and reduces setup time, making it a more efficient option. Additionally, laser cutting allows for intricate and complex designs to be achieved with ease, further enhancing its accuracy and precision.

To further illustrate the cost and efficiency benefits of laser cutting, consider the following table:

| Factor | Laser Cutting | Rotary Cutting |

|---|---|---|

| Cost | Lower | Higher |

| Setup Time | Shorter | Longer |

| Material Waste | Minimal | Significant |

| Design Flexibility | High | Limited |

| Accuracy | High | Moderate |

As shown in the table, laser cutting offers a more cost-effective and time-saving solution compared to rotary cutting in metal fabrication. Its precision and efficiency make it an ideal choice for various applications in the industry.

Frequently Asked Questions

Are there any limitations to the thickness of metal that can be cut using laser cutting?

The thickness of metal that can be cut using laser cutting is limited. The limitations of laser cutting include the ability to cut through thicker metals. Laser cutting is more suitable for thinner materials, typically up to around 25mm.

For thicker metals, rotary cutting offers advantages such as the ability to handle greater thicknesses and faster cutting speeds. However, laser cutting remains a precise and efficient method for cutting thinner metals.

What are some common applications for rotary cutting in metal fabrication?

Rotary cutting is widely used in metal fabrication for various applications. It offers precise and efficient cutting of materials such as sheet metal, pipes, and tubes.

Some common applications include the fabrication of HVAC ductwork, automotive components, and structural steel. Rotary cutting provides versatility, allowing for curved and intricate shapes to be easily achieved.

However, it’s important to note that laser cutting also has its benefits in metal fabrication, such as high precision and the ability to cut a wide range of thicknesses.

Can laser cutting be used on materials other than metal?

Laser cutting offers several advantages over rotary cutting, making it suitable for a wide range of materials beyond metal. The precision of laser cutting ensures accurate and clean cuts, reducing the need for additional finishing processes.

Additionally, laser cutting can be used on non-metal materials such as plastics, wood, acrylic, and fabric. This versatility makes laser cutting an ideal choice for various industries, including signage, automotive, aerospace, and fashion.

How does the accuracy of laser cutting compare to traditional cutting methods?

When comparing the accuracy of laser cutting to traditional cutting methods, laser cutting emerges as the epitome of precision. With laser technology, each cut is executed with utmost accuracy, leaving no room for error.

The precision achieved by laser cutting surpasses that of traditional methods, ensuring the highest degree of accuracy in the fabrication process. By harnessing the power of focused light, laser cutting sets a new standard in precision engineering.

Are there any safety considerations or precautions that need to be taken when using laser cutting in metal fabrication?

When using laser cutting in metal fabrication, there are important safety precautions that must be followed. Proper ventilation is crucial to remove fumes and smoke generated during the cutting process.

Additionally, operators should wear appropriate protective gear such as goggles, gloves, and aprons to prevent injuries. It’s also essential to have necessary equipment like fire extinguishers nearby in case of emergencies.

Following these safety measures ensures a safe working environment during laser cutting operations.

Conclusion

In conclusion, when it comes to accuracy in metal fabrication, laser cutting takes the lead. With its precise beam and computer-guided control, laser cutting offers unparalleled accuracy in intricate designs.

Rotary cutting, while effective for simpler shapes, may not deliver the same level of precision. However, it is important to consider the specific application requirements and budget constraints.

Laser cutting is undeniably efficient, but it can be costlier compared to rotary cutting. Ultimately, the choice between the two methods depends on the project’s needs and desired accuracy.