Are you a woodworking enthusiast looking to take your craft to the next level? If so, you’ve likely encountered the dilemma of choosing between laser cutting and rotary cutting techniques. These two methods offer distinct advantages, but one question remains: which is more accurate?

In this article, we will delve into the intricacies of laser cutting and rotary cutting in woodworking, providing you with the knowledge you need to make an informed decision. With laser cutting, a powerful beam of light precisely slices through the wood, offering unparalleled accuracy and precision. On the other hand, rotary cutting involves a spinning blade that swiftly cuts through the material, providing its own set of benefits.

By exploring the accuracy, speed, efficiency, and material compatibility of both techniques, we will guide you towards the ideal cutting method for your woodworking projects. So, let’s dive in and discover which method reigns supreme in the world of woodworking!

Key Takeaways

- Laser cutting offers unparalleled accuracy and precision in woodworking.

- Laser cutting excels in creating intricate designs with fine details.

- Laser cutting allows for clean and smooth edges.

- Rotary cutting may not provide the same level of precision, especially for detailed cuts.

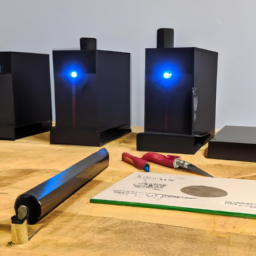

Understanding Laser Cutting

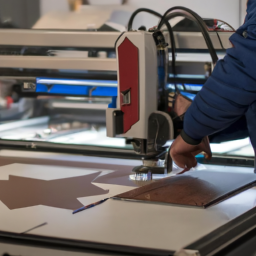

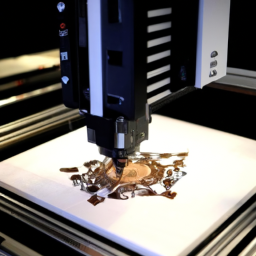

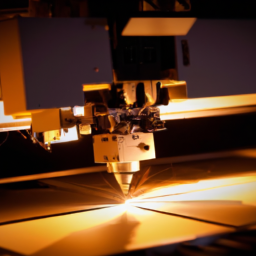

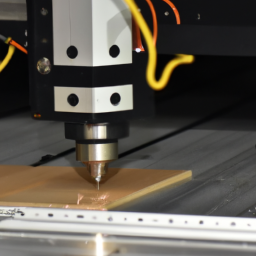

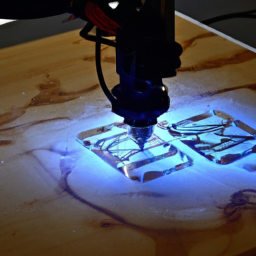

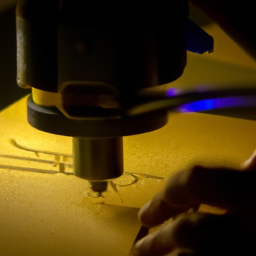

Imagine you’re standing in a woodworking workshop, and as you watch the laser cutting machine in action, you can’t help but be amazed by the precise and intricate patterns it effortlessly etches into the wood. Laser cutting offers numerous advantages that make it a popular choice for woodworking projects.

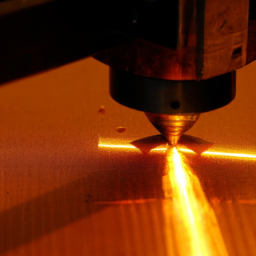

Its incredible accuracy allows for intricate designs and complex shapes that would be challenging to achieve with other cutting methods. Laser cutting also provides clean and smooth edges, reducing the need for additional finishing work. However, laser cutting does have its limitations.

It is most effective on thinner materials, and the heat generated can sometimes cause discoloration or burning on certain types of wood.

Now, let’s explore rotary cutting, another method that offers its own unique benefits.

Exploring Rotary Cutting

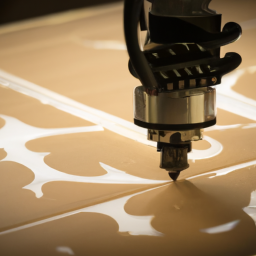

When it comes to woodworking, rotary cutting is a technique that offers a precise and efficient way to cut various materials. By using a rotating blade, this technique allows for clean and accurate cuts, resulting in smooth edges and minimal waste.

One of the advantages of rotary cutting in woodworking is its ability to cut through different types of materials, including fabric, leather, and wood, with ease. Additionally, the rotary cutting technique allows for intricate and complex patterns to be created, making it a versatile choice for woodworking projects.

Overview of Rotary Cutting Technique

To achieve precise cuts in woodworking, you can use the rotary cutting technique, which allows you to effortlessly slice through the material with a spinning blade. This technique offers several advantages and disadvantages.

| Advantages of Rotary Cutting | Disadvantages of Rotary Cutting |

|---|---|

| Accurate and precise cuts | Generates more sawdust |

| Versatile and can cut various materials | Requires proper safety precautions |

| Faster cutting speed | Limited to straight cuts |

Rotary cutting provides accurate and precise cuts, ensuring your woodworking projects are of high quality. It is a versatile technique that can cut through various materials. Additionally, it offers a faster cutting speed, allowing you to complete your projects more efficiently. However, one disadvantage is that it generates more sawdust compared to other cutting techniques. It is also important to take proper safety precautions when using rotary cutting.

Moving on to the next section about the advantages of rotary cutting in woodworking, you will discover how this technique can enhance your woodworking experience.

Advantages of Rotary Cutting in Woodworking

You’ll be amazed at how effortlessly and precisely you can slice through wood using the rotary cutting technique, enhancing your woodworking experience.

One major advantage of using a CNC machine for rotary cutting is the increased speed and efficiency it offers. With the ability to program precise measurements and patterns, you can quickly produce multiple identical pieces with ease.

Additionally, the rotary cutting technique allows for a wide range of shapes and curves to be cut accurately, thanks to the flexibility and maneuverability of the cutting tool.

On the other hand, laser cutters excel in creating intricate designs with fine details. The laser beam’s precision ensures clean and accurate cuts, especially when it comes to intricate patterns and delicate materials.

Transitioning into the next section, let’s now compare the accuracy and precision of laser cutting versus rotary cutting in woodworking.

Comparing Accuracy and Precision

Precision and accuracy are key factors to consider when comparing laser cutting and rotary cutting in woodworking. When it comes to comparing precision techniques, laser cutting takes the lead. The laser beam allows for intricate and intricate designs to be cut with utmost accuracy. The precision of laser cutting is unmatched, as it can create intricate details and complex shapes with ease. On the other hand, rotary cutting methods, while still accurate, may not be as precise as laser cutting.

However, it’s important to note that the accuracy of different cutting methods can also depend on the skill and experience of the woodworker.

Moving forward, evaluating speed and efficiency will further highlight the differences between laser cutting and rotary cutting in woodworking.

Evaluating Speed and Efficiency

Now let’s delve into evaluating the speed and efficiency of laser cutting versus rotary cutting in woodworking. This aspect is crucial as it directly impacts the overall productivity and cost-effectiveness of the process. When it comes to speed, laser cutting takes the lead. It uses a high-powered laser beam to quickly and precisely cut through the material, resulting in faster production times. On the other hand, rotary cutting involves the use of a rotating blade, which may not be as fast as laser cutting. However, rotary cutting offers its own advantages in terms of efficiency, especially when dealing with certain materials or complex designs that may not be suitable for laser cutting. Additionally, rotary cutting is generally more cost-effective than laser cutting due to lower equipment and maintenance costs. This evaluation of speed, efficiency, and cost-effectiveness is essential for woodworkers to determine the most suitable cutting method for their specific needs. Considering material compatibility, the next section will explore how laser cutting and rotary cutting differ in their ability to work with different types of materials.

Considering Material Compatibility

When considering material compatibility for laser cutting, it’s important to know that certain types of wood are better suited for this method.

Dense and hard woods such as maple, oak, and birch are ideal for laser cutting due to their ability to withstand high heat and maintain their shape.

On the other hand, softer and more porous woods like pine and cedar are better suited for rotary cutting, as they’re less likely to burn or warp under the intense heat of a laser cutter.

By understanding the specific characteristics of each type of wood, you can choose the most suitable cutting method for your woodworking project.

Types of Wood Suitable for Laser Cutting

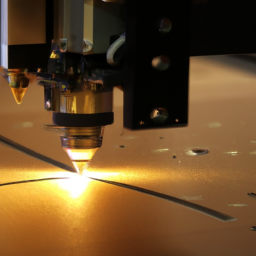

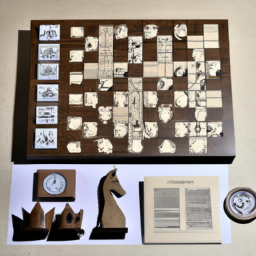

To fully appreciate the versatility of laser cutting in woodworking, you’ll be delighted to discover the wide range of wood types that can be effortlessly shaped into intricate designs. Laser cutting allows for precise and detailed cuts, making it suitable for various wood densities. Whether you’re working with softwoods like pine or hardwoods like oak, laser cutting can handle them all.

The laser’s heat melts away the wood, resulting in clean and smooth edges. Moreover, laser cutting eliminates the limitations of traditional cutting tools, allowing you to create intricate and complex designs with ease. This level of precision and accuracy is unmatched by rotary cutting methods.

Now, let’s delve into the types of wood suitable for rotary cutting and explore their unique characteristics.

Types of Wood Suitable for Rotary Cutting

One of the joys of working with a variety of wood types is the endless possibilities and unique characteristics they bring to the art of woodworking. When it comes to rotary cutting, the choice of wood is crucial.

Softwoods like pine, fir, and cedar are commonly used due to their ease of cutting and affordability. They are ideal for projects that require intricate designs and curved shapes.

Hardwoods such as oak, maple, and cherry are also suitable for rotary cutting, but they require more effort and precision. The advantage of using hardwoods is their durability and aesthetic appeal. However, they’re more expensive and may pose challenges for beginners.

Ultimately, the wood selection for rotary cutting depends on the specific project and the skill level of the woodworker.

Now, let’s explore the factors to consider when making the decision between laser cutting and rotary cutting.

Making the Decision

When it comes to woodworking projects, choosing the right cutting method is crucial for achieving accurate results.

There are several factors that you should consider in order to select the most accurate cutting technique for your specific project.

These factors include the type of wood you’re working with, the complexity of the design, and the level of precision required.

By carefully evaluating these factors, you can make an informed decision and ensure that your woodworking project turns out exactly as you envisioned.

Choosing the Right Cutting Method for Your Woodworking Projects

Although both laser cutting and rotary cutting have their advantages, it’s important to choose the right cutting method for your woodworking projects.

When deciding between laser cutting and rotary cutting, there are a few factors to consider in your cutting method selection:

-

Precision: Laser cutting offers a high level of accuracy, allowing you to achieve intricate designs with clean edges. On the other hand, rotary cutting may not provide the same level of precision, especially for detailed cuts.

-

Speed: Laser cutting is generally faster than rotary cutting, making it a great option for projects that require quick turnaround times. However, rotary cutting can still be efficient for simpler cuts.

-

Material versatility: Laser cutting is suitable for a wide range of materials, including wood, acrylic, and metal. In contrast, rotary cutting is primarily used for wood.

When choosing the right cutting method for your woodworking projects, consider these factors to ensure you select the most accurate cutting technique.

Factors to Consider in Selecting the Most Accurate Cutting Technique

Precision and speed are important factors to consider when selecting the most suitable cutting technique for your woodworking projects. When it comes to accuracy, both laser cutting and rotary cutting have their pros and cons. To help you make an informed decision, consider the following factors:

| Factors to Consider | Laser Cutting | Rotary Cutting |

|---|---|---|

| Precision | High | Moderate |

| Speed | Fast | Slow |

| Material Types | Limited | Versatile |

| Complexity | Simple | Complex |

Laser cutting offers high precision due to its focused beam, making it ideal for intricate designs. However, it may have limitations when it comes to certain materials. On the other hand, rotary cutting may not provide the same level of precision but is more versatile in handling various material types and complex shapes. Ultimately, the choice between laser cutting and rotary cutting depends on the specific requirements and intricacy of your woodworking project. Consider these factors to select the most accurate cutting technique for your needs.

Frequently Asked Questions

Can laser cutting be used on materials other than wood?

Laser cutting applications extend beyond woodworking. In fact, laser cutting is widely used in various industries due to its numerous benefits.

Did you know that lasers can cut through steel up to 25mm thick? This statistic highlights the incredible power and precision of laser cutting.

From automotive to aerospace, laser cutting is employed for its accuracy, speed, and versatility. It can handle materials like metal, plastic, fabric, and even paper, making it an invaluable tool across different sectors.

Is rotary cutting more expensive than laser cutting?

When comparing the cost of rotary cutting and laser cutting, it’s important to consider both the upfront expenses and long-term costs.

While rotary cutting may have lower upfront costs, laser cutting can provide greater precision and accuracy, resulting in less material waste and improved efficiency.

Additionally, laser cutting machines generally require less maintenance and have longer lifespans, reducing overall costs in the long run.

Therefore, although laser cutting may have a higher initial investment, it can be more cost-effective in the long term due to its precision and efficiency.

Are there any safety concerns associated with laser cutting?

When it comes to laser cutting, safety precautions should be a top priority. The intense heat and focused beam of the laser can cause serious injuries if not handled properly. It’s essential to wear protective eyewear and gloves while operating the laser cutter. Additionally, proper ventilation is important to remove harmful fumes and smoke generated during the cutting process. Adequate ventilation requirements should be followed to ensure a safe working environment.

Can laser cutting be used for intricate designs or patterns?

Laser cutting is widely used for intricate designs and patterns due to its precision and versatility. It can be applied in various industries, such as fashion, architecture, and electronics.

Laser cutting applications range from creating delicate jewelry pieces to intricate architectural models. The precision of laser cutting allows for intricate designs with fine details and smooth edges. The laser beam accurately follows the desired pattern, resulting in precise and accurate cuts.

What are the main factors to consider when choosing between laser cutting and rotary cutting?

When choosing between laser cutting and rotary cutting, there are several factors to consider.

Firstly, precision is a crucial aspect. Laser cutting offers high precision, allowing for intricate designs and patterns. On the other hand, rotary cutting may not be as precise, especially for complex shapes.

Secondly, the finish is important. Laser cutting provides a clean and smooth finish, while rotary cutting may result in rougher edges.

These factors should be carefully considered based on your specific woodworking needs.

Conclusion

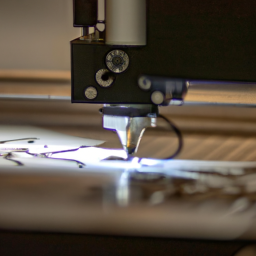

In conclusion, after careful analysis of laser cutting and rotary cutting in woodworking, it’s evident that laser cutting is the more accurate option.

With its precise beam and advanced technology, laser cutting ensures impeccable cuts, leaving no room for error.

Additionally, laser cutting offers superior speed and efficiency, allowing for quicker completion of projects.

However, it’s important to consider material compatibility when making the final decision.

As the wise saying goes, "Measure twice, cut once," laser cutting embodies this adage, ensuring impeccable precision and craftsmanship in woodworking projects.