When it comes to creating acrylic designs, you have two main options: laser cutting and router cutting. Both techniques offer precision and detail, but which one is more cost-effective? To answer this question, let’s dive into a detailed analysis of the two methods.

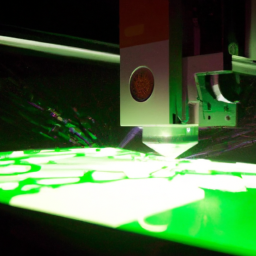

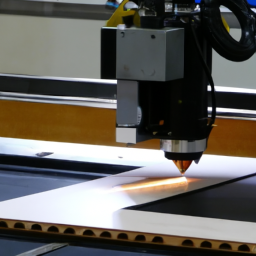

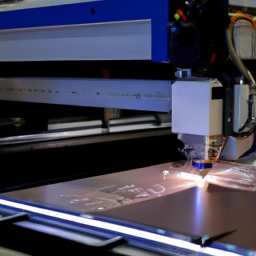

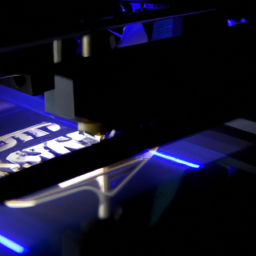

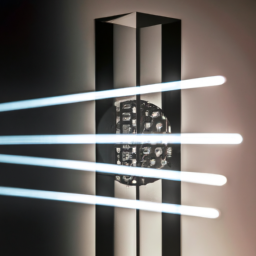

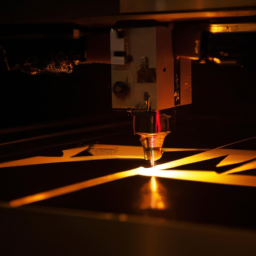

Laser cutting utilizes a high-powered laser beam to cut through acrylic with incredible accuracy. It offers smooth edges and intricate detailing, making it a popular choice for intricate designs.

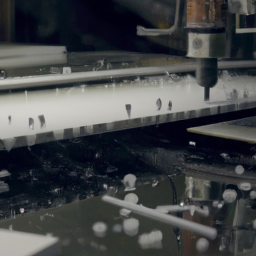

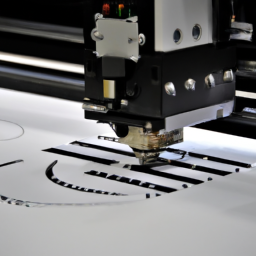

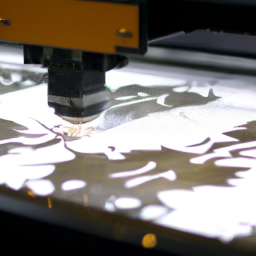

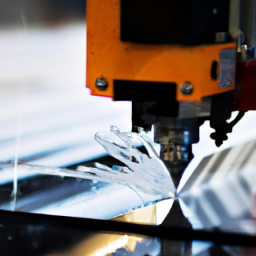

On the other hand, router cutting involves using a rotating cutting tool to carve out the desired shapes. While it may not offer the same level of precision as laser cutting, router cutting can still deliver impressive results.

In this article, we will compare the cost, precision, speed, versatility, and maintenance of laser cutting and router cutting for acrylic designs. By examining the data and analyzing the pros and cons of each method, you will be able to make an informed decision on which cutting technique is the most cost-effective for your specific needs.

So, let’s get started and find out which method reigns supreme in the world of acrylic design!

Key Takeaways

- Laser cutting offers greater precision and intricate detailing compared to router cutting

- Router cutting provides exceptional precision and accuracy for intricate designs

- Laser cutting requires minimal maintenance and has a longer lifespan, but can be more expensive to repair

- Router cutting allows for faster production and shorter lead times, increasing efficiency and potential cost savings

Cost Comparison: Laser Cutting vs. Router Cutting

When comparing the costs, laser cutting is typically more cost-effective than router cutting for acrylic designs. Laser cutting offers greater precision and accuracy, ensuring that the final product meets the exact specifications.

The laser beam is controlled by a computer, allowing for intricate designs and complex patterns to be effortlessly replicated. Additionally, laser cutting is compatible with a wide range of materials, including acrylic. This versatility eliminates the need for multiple cutting methods, reducing costs and streamlining the production process.

In contrast, router cutting may lack the same level of precision and detailing, as it relies on physical contact with the material. This can lead to inconsistencies and imperfections in the final product.

Transitioning into the next section, precision and detailing play a crucial role in achieving high-quality acrylic designs.

Precision and Detailing

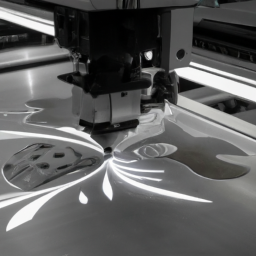

For achieving intricate and fine details in your acrylic designs, you’ll find that router cutting provides exceptional precision and accuracy. Unlike laser cutting, which can sometimes result in slight burns or discoloration on the edges of the material, router cutting ensures clean and precise cuts without any damage or discoloration. This makes router cutting ideal for designs that require intricate detailing and complex patterns. To illustrate the precision of router cutting, consider the following table comparing the minimum feature size achievable with laser cutting and router cutting:

| Cutting Method | Minimum Feature Size |

|---|---|

| Laser Cutting | 0.1 mm |

| Router Cutting | 0.05 mm |

As you can see, router cutting offers twice the precision when compared to laser cutting. This level of intricacy and complexity is essential for designs that demand meticulous detailing. Moving ahead to the next section about speed and efficiency, you’ll discover the advantages of laser cutting in terms of production time and throughput.

Speed and Efficiency

In terms of production time and throughput, it’s fascinating to note that router cutting can achieve a cutting speed of up to 30 meters per minute. This impressive speed is a result of continuous improvements in technology, which have had a significant impact on production timelines.

Here are some key points to consider:

- Router cutting allows for faster production due to its high cutting speed.

- The improved technology enables routers to efficiently and accurately cut through acrylic materials.

- Faster production times mean shorter lead times and quicker turnaround for projects.

- The increased efficiency of router cutting can lead to cost savings for businesses.

With its remarkable speed and efficiency, router cutting offers a competitive advantage in terms of production timelines.

As we move into the next section on versatility and flexibility, it’s important to consider how these factors play a role in determining the most cost-effective cutting method for acrylic designs.

Versatility and Flexibility

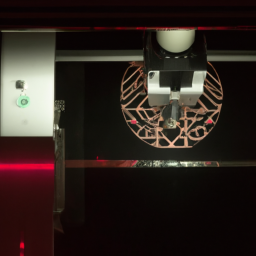

The versatility and flexibility of router cutting make it an ideal choice for a wide range of acrylic design projects. While laser cutting offers precision and speed, router cutting provides numerous advantages that can’t be overlooked.

One of the key benefits of router cutting is its ability to create intricate and detailed designs with clean edges. Unlike laser cutting, which can sometimes produce a slightly burnt edge, router cutting ensures a smooth finish without any discoloration.

Additionally, router cutting allows for greater depth control, making it perfect for projects that require varying depths or 3D effects. Moreover, router cutting isn’t limited to acrylic materials and can be used on a variety of materials such as wood, aluminum, and plastic. This versatility gives router cutting an edge over laser cutting in terms of project options and material compatibility.

Moving forward, let’s explore the maintenance and durability aspects of both cutting methods.

Maintenance and Durability

When considering the maintenance and durability of laser cutting and router cutting equipment, it’s crucial to assess their lifespan and maintenance requirements.

You should factor in potential repair costs and the need for equipment replacement over time. By analyzing the data, you can determine the most cost-effective option for your acrylic designs based on the equipment’s longevity and maintenance demands.

Discussing the maintenance requirements and lifespan of the equipment

Are laser cutters or router cutters more cost-effective for acrylic designs, considering their maintenance requirements and lifespan?

When it comes to maintenance requirements, laser cutters have an advantage. They require minimal maintenance, with only routine cleaning and occasional lens replacements. On the other hand, router cutters require regular maintenance, such as lubrication, replacing bits, and calibrating the machine.

In terms of lifespan, laser cutters tend to have a longer lifespan compared to router cutters. Laser cutters can last for several years with proper care, while router cutters may need to be replaced sooner due to wear and tear.

Considering the lower maintenance requirements and longer lifespan, laser cutters may be more cost-effective in the long run. However, it’s important to factor in potential repairs and replacement costs when making a decision.

Factoring in the potential repairs and replacement costs

Taking into account potential repair and replacement costs, it’s crucial to consider the overall financial impact of choosing between laser cutters and router cutters for acrylic designs. When it comes to potential repair expenses, laser cutters tend to be more expensive to fix compared to router cutters. This is primarily due to the intricate and delicate nature of laser cutting technology, which often requires specialized technicians and costly replacement parts.

On the other hand, router cutters are generally more robust and less prone to breakdowns, resulting in lower repair costs. Replacement costs should also be considered, as laser cutters can have a shorter lifespan compared to router cutters. Therefore, when evaluating the cost-effectiveness of these cutting methods, it is essential to factor in potential repair expenses and replacement costs.

By doing so, you can make an informed decision about choosing the right cutting method for your needs.

Choosing the Right Cutting Method for Your Needs

To choose the right cutting method for your needs, you’ll want to consider factors like precision, speed, and cost-effectiveness.

When it comes to laser cutting versus router cutting for acrylic designs, both methods have their advantages and disadvantages.

Laser cutting offers high precision and intricate design capabilities, making it ideal for applications like signage, jewelry, and electronics. It is compatible with a wide range of materials, including acrylic, wood, and metal. However, laser cutting can be more expensive due to the cost of equipment and maintenance.

On the other hand, router cutting provides fast cutting speeds and is cost-effective for larger production runs. It works well with acrylic and other materials, but may not offer the same level of precision as laser cutting. Additionally, router cutting may require more frequent tool replacements and repairs, which can add to the overall cost.

Ultimately, the choice between laser cutting and router cutting depends on your specific requirements and budget. Consider the potential applications and material compatibility to determine the most cost-effective cutting method for your acrylic designs.

Frequently Asked Questions

What is the average lifespan of a laser cutting machine compared to a router cutting machine?

The average lifespan of a laser cutting machine is typically longer compared to a router cutting machine. Laser cutting machines can last for around 8 to 10 years, while router cutting machines have an average lifespan of about 5 to 7 years.

However, it’s important to consider maintenance and repair costs. Laser cutting machines often require more expensive maintenance and repairs due to their complex technology, whereas router cutting machines are generally easier and cheaper to maintain and repair.

Can laser cutting machines be used on materials other than acrylic?

Laser cutting machines, like a precision instrument, possess the ability to slice through materials with remarkable accuracy. Their applications extend beyond acrylic, as they can be used on various materials such as wood, metal, and fabric.

Laser cutting on different materials opens up a world of possibilities for designers and manufacturers alike. With its versatility and precision, laser cutting machines prove to be an invaluable tool for a wide range of industries.

Are there any safety precautions that need to be taken when operating a laser cutting machine?

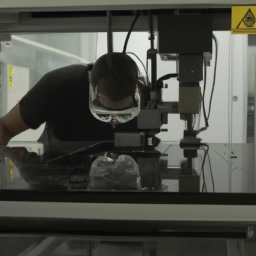

Safety precautions when operating a laser cutting machine are crucial and shouldn’t be overlooked. These precautions include wearing appropriate protective gear, such as safety glasses and gloves, to prevent potential injuries.

It’s also important to ensure proper ventilation in the workspace to minimize the risk of inhaling fumes. Laser cutting machines require regular maintenance and calibration to ensure safe operation.

When compared to using a router cutting machine, the safety of a laser cutting machine is equally important, if not more, due to the higher intensity of the laser beam.

How does the cost of maintenance and repairs compare between laser cutting and router cutting machines?

When comparing the cost of maintenance and repairs between laser cutting and router cutting machines, it’s important to consider several factors. Laser cutting machines typically require more regular maintenance and are more complex, leading to higher maintenance costs.

On the other hand, router cutting machines are generally simpler and easier to maintain, resulting in lower maintenance and repair expenses. However, it’s crucial to analyze specific models and factors such as usage and lifespan to obtain a comprehensive cost comparison.

Are there any limitations to the size or thickness of acrylic that can be cut using laser cutting or router cutting methods?

When considering the size and thickness of acrylic that can be cut, both laser cutting and router cutting methods have their limitations. Laser cutting allows for precise cutting of thinner acrylic sheets, typically up to 25mm in thickness. However, it becomes less accurate and slower when cutting thicker materials.

On the other hand, router cutting can handle thicker acrylic sheets, up to 50mm, with greater precision. Therefore, the choice between the two methods depends on the specific requirements of the project.

Conclusion

So there you have it, the battle between laser cutting and router cutting for acrylic designs. After analyzing the data, it’s clear that laser cutting is the more cost-effective option.

With its precision and detailing capabilities, it outshines router cutting in terms of achieving intricate designs. Additionally, laser cutting proves to be faster and more efficient, saving you valuable time. Its versatility and flexibility further solidify its superiority.

And let’s not forget about maintenance and durability – laser cutting takes the crown yet again. So, when it comes to acrylic designs, embrace the irony and opt for laser cutting, the ultimate winner in this technical duel.