In the world of paper crafts, the precision and intricacy of your designs can truly make them stand out. And when it comes to cutting those delicate patterns, you want to ensure you’re using the most cost-effective method. That’s where the age-old debate between laser cutting and router cutting comes into play.

Picture this: you’re sitting at your craft table, surrounded by colorful sheets of paper and a vision in your mind. You want to bring that vision to life, with every intricate detail flawlessly executed. But which cutting technique should you choose?

Laser cutting and router cutting are two popular methods used in the world of paper crafts. Each has its own unique advantages and considerations, and understanding the cost-effectiveness of these techniques is crucial in making an informed decision.

In this article, we will delve into the world of laser cutting and router cutting, comparing their cost-effectiveness for paper crafts. Whether you’re a seasoned paper craft enthusiast or just starting out, we’ll equip you with the knowledge to make the best choice for your projects.

So let’s dive in and discover the world of cost-effective cutting techniques in paper crafts!

Key Takeaways

- Laser cutting offers unmatched precision and accuracy, reducing material wastage and rework.

- Router cutting allows for the creation of intricate and detailed patterns, enhancing the overall aesthetics of paper crafts.

- Laser cutting is more cost-effective in the long run with lower operating costs and faster production times.

- Router cutting is more versatile in terms of design and customization options.

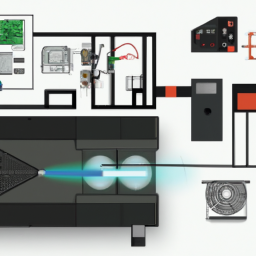

Understanding Laser Cutting

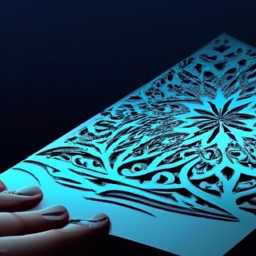

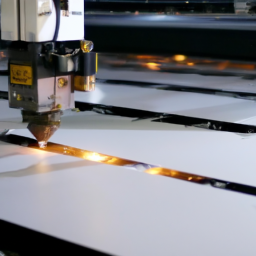

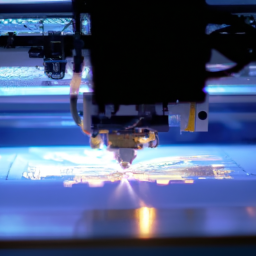

Laser cutting’s precise and swift movements make it a popular choice for paper crafts. Laser cutting techniques involve using a high-powered laser beam to cut through paper with extreme accuracy. The laser follows a pre-determined path, melting and vaporizing the paper as it goes. This technique allows for intricate designs and fine details to be cut with ease.

Laser cutting benefits include clean cuts, minimal material waste, and the ability to cut complex shapes quickly. Moreover, lasers can be programmed to cut multiple pieces at once, increasing productivity.

Now, let’s explore router cutting, another method used in paper crafts that offers its own set of advantages.

Exploring Router Cutting

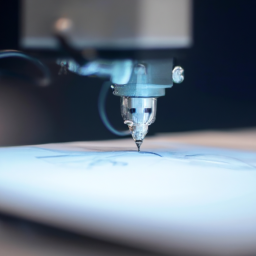

If you’re interested in exploring router cutting in paper crafts, there are a few key points to consider.

Router cutting works by using a rotating cutting tool to remove material from the paper, creating intricate designs and shapes. One advantage of router cutting in paper crafts is its ability to create precise and detailed cuts, allowing for intricate designs that may be difficult to achieve with other cutting methods.

However, it’s important to note that router cutting does have its limitations in paper crafts, as it can be time-consuming and may not be suitable for delicate or thin materials.

How Router Cutting Works

To understand how router cutting works, you need to visualize the intricate patterns and precision that can be achieved with this technique. Router cutting involves the use of a rotating cutting tool, known as a router bit, that is guided by a computer-controlled system.

The router bit moves across the surface of the material, cutting away layers to create desired shapes and designs. This technique allows for the creation of complex and detailed patterns in paper crafts. Router cutting techniques can include engraving, V-grooving, and pocketing, among others.

The applications of router cutting in paper crafts are vast, ranging from creating intricate invitations and greeting cards to designing pop-up books and three-dimensional sculptures. The advantages of router cutting in paper crafts will be explored in the next section, highlighting the unique benefits it offers over other cutting methods.

Advantages of Router Cutting in Paper Crafts

One advantage of router cutting in paper crafts is its ability to create intricate and detailed patterns, such as delicate lace-like designs, that would be difficult to achieve with traditional cutting methods. For example, imagine a wedding invitation with a beautifully intricate lace design cut out using a router, adding an elegant touch to the overall design.

Router cutting allows for precise and accurate cuts, ensuring that every detail of the design is captured flawlessly.

The versatility of router cutting enables the creation of various shapes and sizes, giving crafters the freedom to experiment with different designs and styles.

These advantages of precision and versatility in router cutting not only enhance the overall aesthetics of paper crafts but also provide endless possibilities for creativity.

However, despite these advantages, router cutting does have its limitations in paper crafts.

Limitations of Router Cutting in Paper Crafts

Despite its precision and versatility, router cutting in paper crafts has limitations that can hinder its effectiveness in certain projects. One major limitation is the inability to cut intricate and delicate designs with fine details. The router cutting process can sometimes result in rough edges and tear the paper, which is not ideal for projects that require a clean and polished finish.

Additionally, router cutting can be time-consuming and may not be suitable for large-scale or time-sensitive projects. In such cases, alternative methods such as laser cutting can offer more efficient and precise results. Laser cutting allows for intricate designs, smooth edges, and faster production times, making it a preferred choice for many paper craft enthusiasts.

Transitioning into the subsequent section about comparing cost-effectiveness, it is important to consider how these limitations may impact the overall cost-effectiveness of router cutting compared to laser cutting.

Comparing Cost-effectiveness

When considering cost-effectiveness in paper crafts, you should take into account the efficiency and precision of laser cutting compared to router cutting. Laser cutting offers several advantages that make it a more cost-effective option.

Here are four key reasons why laser cutting is a better choice for cost-conscious crafters:

-

Cost comparison: Although laser cutting machines may have a higher upfront cost, they often result in lower operating costs in the long run. Laser cutting is more energy-efficient and requires fewer consumables, such as bits or blades, reducing ongoing expenses.

-

Efficiency analysis: Laser cutting is highly efficient, allowing for faster production times and increased output. With the ability to cut intricate designs quickly and accurately, laser cutting saves both time and labor costs.

-

Precision and accuracy: Laser cutting provides unmatched precision and accuracy, ensuring clean and smooth cuts every time. This reduces material wastage and minimizes the need for rework, ultimately saving money.

-

Versatility: Laser cutting machines have the ability to cut a wide range of materials, including paper, cardstock, and even fabrics. This versatility eliminates the need for multiple tools, streamlining the crafting process and reducing costs.

Considering these cost-effective benefits, it becomes clear that laser cutting is a superior choice for paper crafts. However, when it comes to intricate designs, there are additional considerations to keep in mind.

Considerations for Intricate Designs

Now let’s delve into the considerations for intricate designs when it comes to laser cutting vs. router cutting in paper crafts. When working with intricate designs, laser cutting often offers more precision and finer details compared to router cutting. Laser cutting technology allows for intricate patterns and delicate cuts that may be difficult to achieve with a router. Additionally, laser cutting is compatible with a wide range of materials, including paper, cardstock, and even some fabrics. This versatility allows for greater design flexibility and opens up possibilities for creating unique and intricate paper crafts. To further illustrate the differences, let’s take a look at the table below:

| Criteria | Laser Cutting | Router Cutting |

|---|---|---|

| Precision | High | Moderate |

| Detail | Fine details and intricate patterns | Limited details |

| Material Compatibility | Wide range of materials, including paper and fabric | Limited to certain paper types |

As you can see, laser cutting offers several advantages when it comes to intricate designs in paper crafts. Now, let’s explore considerations for large-scale projects.

Considerations for Large-Scale Projects

For larger projects, you may want to consider the scale and complexity of the design to determine the most suitable cutting method.

When it comes to large-scale paper projects, both laser cutting and router cutting can be effective options. However, there are a few key considerations to keep in mind:

-

Material thickness: Laser cutting is generally better suited for thinner materials, while router cutting can handle thicker materials more easily.

-

Speed: Laser cutting is typically faster than router cutting, making it a more efficient choice for large-scale projects with tight deadlines.

-

Precision: Laser cutting offers higher precision and finer details, which is important for intricate designs on a larger scale.

-

Cost analysis: Laser cutting can be more expensive upfront due to the cost of the machine, while router cutting may require more time and labor.

-

Flexibility: Router cutting allows for more versatility in terms of design and customization options.

Considering these factors will help you make an informed decision about the most suitable cutting method for your large-scale paper projects.

Making an Informed Decision

When it comes to making an informed decision about whether to choose laser cutting or router cutting in paper crafts, there are a few key points to consider.

First, assess your needs and goals for the project. Determine what level of precision, speed, and complexity you require.

Next, weigh the pros and cons of each cutting method, considering factors such as cost, available materials, and the desired outcome.

Finally, consult experts and peers in the field who have experience with both techniques, as they can offer valuable insights and advice to help you make the best choice for your specific project.

Assessing Your Needs and Goals

Assessing your needs and goals is like using a magnifying glass to uncover the hidden gems of cost-effectiveness in laser cutting versus router cutting in paper crafts. To make an informed decision, it’s important to carefully evaluate what you require from the cutting process and what you hope to achieve.

Here are four key points to consider:

-

Precision: Determine the level of precision you need in your paper crafts. Laser cutting offers incredibly accurate cuts, perfect for intricate designs and delicate details.

-

Speed: Consider the time constraints you have for your projects. Router cutting is generally faster than laser cutting, making it ideal for larger volumes or time-sensitive orders.

-

Material Compatibility: Evaluate the types of materials you will be working with. Laser cutting is more versatile, capable of handling a wide range of materials, including paper, wood, and acrylic.

-

Budget: Take into account your available budget. While laser cutting machines may have a higher initial cost, they tend to have lower operating costs in the long run.

By assessing your needs and goals, you can determine which cutting method will best suit your specific requirements. With this knowledge, you can then move on to weighing the pros and cons of laser cutting versus router cutting in paper crafts.

Weighing the Pros and Cons

Considering the advantages and disadvantages can provide valuable insight into the best method for achieving your desired outcomes in paper crafts. When exploring alternatives, it’s important to compare the techniques of laser cutting and router cutting.

Laser cutting offers precision and intricate designs, allowing for detailed and complex patterns. It also provides a clean and polished finish, with minimal post-processing required.

On the other hand, router cutting is more versatile, allowing for a wider range of materials to be used. It’s also more cost-effective for small-scale projects and requires less initial investment. However, router cutting may result in rougher edges and less precise cuts compared to laser cutting.

By weighing these pros and cons, you can determine which technique aligns better with your specific needs and goals in paper crafts. Transitioning into the next section, consulting experts and peers can further assist in making an informed decision.

Consulting Experts and Peers

Now that you’ve weighed the pros and cons of laser cutting and router cutting in paper crafts, it’s time to seek advice from experienced crafters. Consulting experts and peers who have hands-on experience with both methods can provide valuable insights and tips.

They can share their personal experiences, recommend the best techniques, and help you navigate any challenges you may encounter. Additionally, when comparing the cost effectiveness of laser cutting and router cutting with other cutting methods, it’s important to gather multiple perspectives.

By reaching out to a diverse range of crafters, you can gather a variety of opinions and make a more informed decision. Don’t hesitate to ask questions and gather as much information as possible before making your final choice.

Here are some key points to consider when consulting experts and peers:

- Their preferred cutting method and the reasons behind their preference

- Any cost-saving tips or tricks they’ve discovered

- The types of projects they’ve successfully completed using laser cutting or router cutting

- Any challenges they’ve faced and how they’ve overcome them

- Their overall assessment of the cost effectiveness of laser cutting and router cutting compared to other cutting methods.

Frequently Asked Questions

Can laser cutting be used on materials other than paper?

Yes, laser cutting can be used on materials other than paper. In fact, it has numerous applications in the fashion industry. Designers are using laser cutting to create intricate patterns and unique designs on fabrics and leather.

Additionally, there is ongoing research and development exploring the potential of laser cutting in metalworking. This technology allows for precise and intricate cuts on various metals, opening up new possibilities for industries like automotive, aerospace, and jewelry.

What types of designs are best suited for router cutting?

When it comes to router cutting, intricate patterns and delicate details are a match made in heaven. Router cutting is best suited for designs that require precise and intricate cuts. For example, intricate lace patterns or delicate filigree designs. The router’s ability to make precise and detailed cuts allows for the creation of intricate and delicate designs. These designs would be difficult to achieve with other cutting methods. So, if you’re looking to create designs with intricate patterns and delicate details, router cutting is the way to go.

Are there any limitations to the size of projects that can be done with laser cutting?

When it comes to laser cutting, there are some limitations to consider. One major limitation is the size of the projects that can be done. Laser cutting machines often have a maximum cutting area, so larger projects may need to be broken down into smaller sections.

On the other hand, router cutting does not have this limitation and can handle larger projects. This is one of the advantages of router cutting over laser cutting when it comes to paper crafts.

How does the precision of laser cutting compare to router cutting?

Imagine you’re an artist delicately sculpting a masterpiece out of clay. With a steady hand and precise movements, you bring your vision to life.

In the world of paper crafts, laser cutting offers a similar level of precision. Laser cutting utilizes a focused beam of light to create intricate designs with incredible accuracy. In comparison, router cutting may lack the same level of precision, as it involves physical contact with the material.

The precision of laser cutting surpasses that of router cutting, making it the ideal choice for intricate paper crafts.

Are there any safety considerations when working with laser cutting or router cutting?

When working with laser cutting or router cutting, there are some important safety precautions to consider.

First, always wear appropriate protective gear like goggles and gloves to prevent any accidents.

Additionally, make sure to follow proper equipment maintenance to ensure the machines are in good working condition and minimize the risk of malfunctions. Regularly clean and lubricate the machines, and inspect the blades or laser components for any damage.

Following these safety measures will help ensure a safe working environment.

Conclusion

In conclusion, after thoroughly exploring the differences between laser cutting and router cutting in paper crafts, it’s clear that laser cutting is the more cost-effective option.

Not only does laser cutting offer greater precision and versatility, but it also requires less time and effort. Additionally, laser cutting allows for intricate designs to be easily achieved, making it perfect for detailed projects.

However, for large-scale projects, router cutting may be a more practical choice.

Overall, understanding these factors will help you make an informed decision and enjoy your paper crafts to the fullest.