In the world of woodworking, where precision and efficiency are paramount, the choice between laser cutting and router cutting can make all the difference. Like two master craftsmen vying for the title of supreme efficiency, these techniques bring their own unique set of strengths and weaknesses to the table.

It’s a battle between the sharp precision of the laser beam and the tried-and-true reliability of the router blade. But which one reigns supreme in terms of cost-effectiveness? In this article, we will delve into the pros and cons of laser cutting and router cutting in woodworking, exploring the factors that can impact their cost-effectiveness.

By the end, you’ll have a comprehensive understanding of the two methods and be equipped with the knowledge to make an informed decision that will optimize both your budget and your woodworking projects. So, let’s dive in and uncover the truth behind these contenders!

Key Takeaways

- Laser cutting offers precision and intricate designs, while router cutting adds a handmade touch.

- Laser cutting produces clean, smooth edges without the need for sanding or finishing, while router cutting excels in cutting larger pieces and creating smooth edges.

- Laser cutting has a high initial cost but provides long-term cost benefits with reduced material waste and increased productivity, while router cutting may have a lower setup cost but can result in more material waste.

- Laser cutting can work with a wide range of materials, reducing the need for additional equipment, while router cutting is primarily suited for wood.

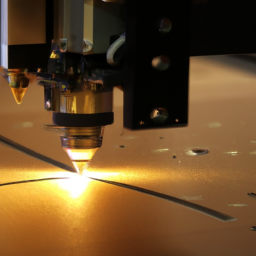

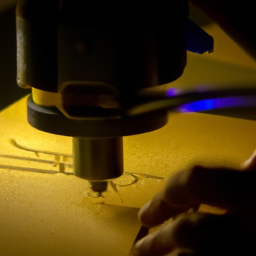

Pros and Cons of Laser Cutting in Woodworking

Laser cutting is a game-changer in woodworking, but is it really worth the hype? Absolutely.

When it comes to precision and intricacy, laser cutting has a clear advantage. With laser technology, you can achieve incredibly detailed designs that would be nearly impossible with traditional cutting methods. Additionally, laser cutting allows for clean, smooth edges without the need for sanding or finishing.

However, laser cutting does have its limitations. It’s not suitable for cutting thick or dense woods, as it can cause charring or burning. Moreover, the initial cost of purchasing a laser cutting machine can be quite high.

Transitioning to the next section about the pros and cons of router cutting, it’s important to consider that while laser cutting excels in certain areas, router cutting has its own set of advantages and disadvantages.

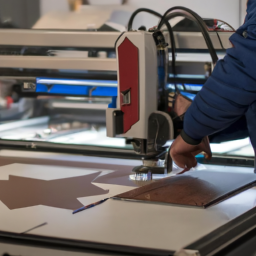

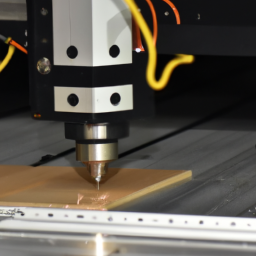

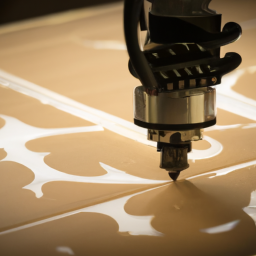

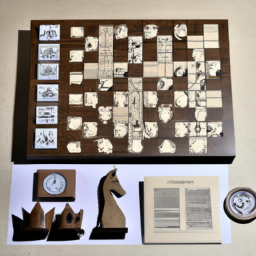

Pros and Cons of Router Cutting in Woodworking

Ironically, router cutting in woodworking may not be the quickest or most precise method, but it certainly adds a charming handmade touch to the final product. While laser cutting offers unparalleled precision, router cutting has its own unique advantages.

One of the limitations of router cutting is the inability to create intricate designs and fine details. However, it excels in cutting larger pieces and creating smooth edges. To achieve the best router cutting results, it’s crucial to use the right bits and techniques. Spiral bits are recommended for clean cuts, while straight bits are ideal for creating profiles. Additionally, using a router table ensures stability and accuracy.

Transitioning to the subsequent section about cost factors to consider, it’s important to weigh the benefits of router cutting against the potential drawbacks.

Cost Factors to Consider

Consider all the factors that can impact your budget when deciding on the best method for your woodworking projects. When it comes to router cutting, the cost of materials is a significant consideration. Depending on the type of wood you use, the price can vary greatly.

Additionally, the labor costs associated with router cutting should not be overlooked. It requires skilled operators who may charge higher fees for their expertise. These factors can add up quickly and significantly impact your overall project cost.

Now, let’s transition into discussing the cost-effectiveness of laser cutting and how it compares to router cutting.

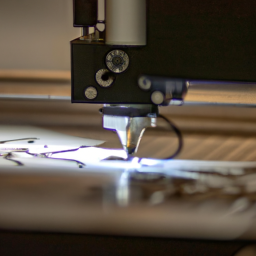

Cost-Effectiveness of Laser Cutting

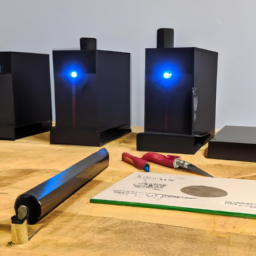

When considering the cost-effectiveness of laser cutting, there are two key points to focus on.

Firstly, you should compare the cost per cut between laser cutting and other methods to determine which option is more economical.

Additionally, it’s important to consider the long-term cost benefits of laser cutting, such as reduced material waste and increased efficiency.

By analyzing these factors, you can make an informed decision on whether laser cutting is the most cost-effective choice for your woodworking needs.

Cost per Cut Comparison

To figure out which cutting method is more cost-effective for you, let’s take a closer look at the price per cut of laser cutting compared to router cutting.

Here are four key factors to consider when evaluating the cost per cut:

-

Cost per piece: Laser cutting tends to have a higher initial setup cost, but it can produce intricate designs with minimal material waste. Router cutting, on the other hand, may have a lower setup cost but can result in more material waste due to its cutting process.

-

Cost savings: Laser cutting can provide cost savings in terms of reduced labor and increased production speed. It allows for precise and efficient cutting, which can lead to higher productivity and lower labor costs compared to router cutting.

-

Maintenance expenses: Laser cutting machines require regular maintenance and occasional replacement of consumables, which can add to the overall cost. Router cutting machines also need maintenance, but the costs are generally lower.

-

Material versatility: Laser cutting can work with a wide range of materials, including wood, acrylic, and metal, whereas router cutting is primarily suited for wood. This versatility can impact the cost per cut, depending on the specific needs of your woodworking projects.

Considering these factors, laser cutting often offers cost savings in the long run due to its higher precision, reduced material waste, and increased productivity.

Long-Term Cost Benefits

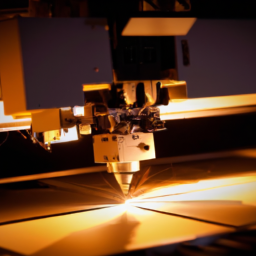

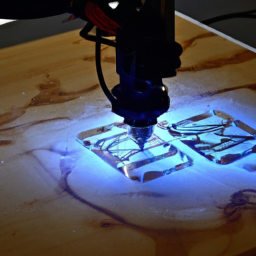

Over time, the cost benefits of laser cutting become apparent with its precision, minimal waste, and increased productivity. Laser cutting allows for precise cuts, minimizing the amount of material wasted. This results in cost savings as less material is needed for each project.

Additionally, laser cutting is a highly efficient process that can be automated, allowing for increased productivity and faster turnaround times. These factors contribute to a higher return on investment for businesses that choose laser cutting.

However, it’s important to consider the initial investment required for laser cutting equipment, which can be higher than that of router cutting. Despite this, the long-term cost benefits of laser cutting make it a cost-effective choice for woodworking projects.

In the subsequent section, we’ll explore the cost-effectiveness of router cutting.

Cost-Effectiveness of Router Cutting

When considering the cost-effectiveness of router cutting in woodworking, there are two key points to consider.

Firstly, the cost per cut comparison between laser cutting and router cutting is an important factor to take into account.

Secondly, the long-term cost benefits of using a router for cutting can have a significant impact on overall expenses.

By carefully analyzing these factors, you can make an informed decision about whether router cutting is the more cost-effective option for your woodworking needs.

Cost per Cut Comparison

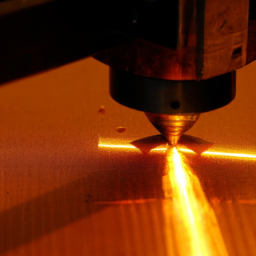

Comparing the cost per cut between laser cutting and router cutting in woodworking is like comparing the price of a sports car to a bicycle. Laser cutting is known for its precision and speed, but it comes at a higher cost per piece compared to router cutting. However, when considering the efficiency comparison, laser cutting truly shines.

Here are three reasons why laser cutting is more cost-effective in the long run:

-

Higher speed: Laser cutting machines can cut through materials at a much faster rate than router cutting, allowing for increased productivity and reduced labor costs.

-

Less material waste: Laser cutting produces minimal waste due to its narrow kerf, resulting in lower material costs.

-

Versatility: Laser cutting can handle a wider range of materials and intricate designs, eliminating the need for multiple tools and reducing setup and maintenance costs.

By considering these factors, laser cutting proves to be a more cost-effective option in the long term.

Now, let’s delve into the long-term cost benefits of laser cutting.

Long-Term Cost Benefits

One major advantage of laser cutting is its ability to handle a wider range of materials, resulting in reduced setup and maintenance costs in the long run. Laser cutting machines are capable of cutting through various materials such as wood, acrylic, metal, and even fabrics, eliminating the need for multiple tools and setups.

This versatility leads to significant cost savings as there’s no need for additional equipment or frequent maintenance for different materials. Additionally, laser cutting is known for its precision, which minimizes material waste. The laser beam follows a predetermined path, reducing the chances of errors and ensuring that cuts are made accurately, thus minimizing material waste.

This not only saves money but also contributes to a more sustainable and environmentally friendly approach to woodworking. Overall, the long-term cost benefits of laser cutting make it a cost-effective choice for woodworking projects.

Frequently Asked Questions

What are the safety precautions that need to be taken when using laser cutting in woodworking?

When using laser cutting in woodworking, it’s crucial to prioritize safety measures. To ensure your well-being, always wear appropriate protective equipment, such as safety goggles and gloves, to shield yourself from potential harm.

Additionally, make sure to follow proper operating procedures, such as keeping a safe distance from the laser beam and avoiding direct contact with the material being cut. By adhering to these safety precautions, you can minimize the risk of accidents and create a secure working environment.

Can laser cutting be used on all types of wood?

Yes, laser cutting can be used on all types of wood, which is one of its many advantages. Laser cutting offers precision and intricacy that is difficult to achieve with router cutting. It allows for intricate designs and fine details, even on delicate or exotic woods.

However, it’s important to consider the pros and cons of laser cutting versus router cutting in woodworking. While laser cutting offers accuracy and versatility, router cutting may be more cost-effective for larger-scale projects.

Are there any limitations or restrictions when using router cutting in woodworking?

When it comes to router cutting in woodworking, there are a few limitations you need to be aware of. Firstly, compared to laser cutting, router cutting may not offer the same level of precision. It can be challenging to achieve intricate designs or fine details with a router.

Additionally, router cutting may result in more waste material and require more manual labor. However, with proper skill and technique, router cutting can still be a viable and cost-effective option for many woodworking projects.

How does the cost of maintenance compare between laser cutting and router cutting machines?

Ah, the joys of maintenance! When it comes to cost comparison between laser cutting and router cutting machines, you’ll be delighted to know that they both require some tender loving care.

However, the maintenance requirements for laser cutting machines can be a bit more demanding, requiring regular cleaning and alignment. On the other hand, router cutting machines tend to be more forgiving, with less frequent maintenance needs.

So, while both options have their quirks, the router cutting machine is the maintenance champ here.

Are there any specific design or pattern limitations when using laser cutting or router cutting in woodworking?

When it comes to design flexibility, laser cutting offers a wide range of possibilities. With its high precision accuracy, intricate and complex designs can be achieved. However, router cutting also has its advantages. While it may not offer the same level of design intricacy as laser cutting, it allows for more depth and texture in the patterns.

Both methods have their own limitations, but with the right expertise, stunning and unique designs can be achieved using either technique.

Conclusion

In conclusion, both laser cutting and router cutting have their own pros and cons in woodworking. Laser cutting offers precision and intricate designs, while router cutting provides versatility and affordability.

When considering cost-effectiveness, it ultimately depends on the specific project and budget constraints. So, before making a decision, carefully evaluate the cost factors like material, labor, and equipment.

Remember, woodworking is an art that requires skill and expertise. Which cutting method will you choose to bring your woodworking creations to life?