In the world of metal fabrication, the choice between laser cutting and traditional techniques can be as complex as the intricate designs they create. Like two sides of a coin, each method presents its own advantages and considerations.

Laser cutting, akin to a surgeon’s precise incision, offers unparalleled accuracy and speed. Traditional metal fabrication techniques, on the other hand, embody the artistry of a skilled craftsman, with meticulous attention to detail.

But which approach is best suited for your project? To answer this question, you must delve into the realm of precision, efficiency, and project requirements. Are you in need of intricate designs with sharp edges? Or are you looking for the timeless charm of handcrafted metalwork? By evaluating factors such as precision and accuracy, speed and efficiency, you will be able to make an informed decision.

Join us as we embark on a journey to explore the world of laser cutting and traditional metal fabrication techniques, and discover which path will guide your project towards its ultimate success.

Key Takeaways

- Laser cutting offers unparalleled accuracy and speed, making it suitable for projects that require fine detailing and intricate designs.

- Traditional metal fabrication methods embody skilled craftsmanship and allow for unique designs and customization, making them more suitable for larger-scale productions.

- Laser cutting is faster and more efficient for smaller projects, eliminating the need for tooling changes and reducing downtime.

- When choosing between laser cutting and traditional methods, it is important to consider factors such as precision, efficiency, project requirements, cost, time, complexity, and the specific requirements of the project.

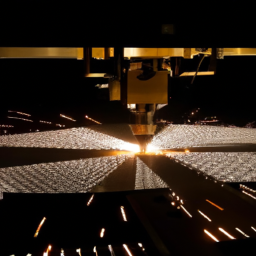

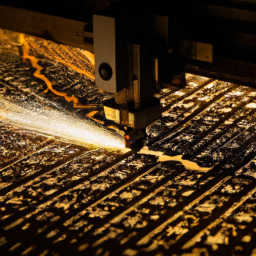

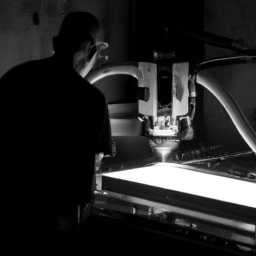

Understanding Laser Cutting

If you’re looking for a precise and efficient way to cut metal, laser cutting is the technique for you. Laser cutting offers numerous benefits that make it an ideal choice for various applications.

One of the major advantages of laser cutting is its high level of precision. The laser beam can cut through metal with exceptional accuracy, resulting in clean and precise cuts. Additionally, laser cutting is a non-contact process, meaning that there’s no physical contact between the laser and the material being cut. This eliminates the risk of damage or deformation to the metal.

Laser cutting is widely used in industries such as aerospace, automotive, and electronics, where precision and quality are paramount.

Now let’s explore traditional metal fabrication techniques.

Exploring Traditional Metal Fabrication Techniques

Exploring the various traditional methods of shaping and manipulating metal can offer a rich and time-honored approach to bringing your project to life.

Ancient metalworking methods, such as forging and casting, have been used for centuries to create intricate and durable metal structures.

Handcrafted metal fabrication has its advantages, including the ability to create unique designs that can’t be replicated by laser cutting. Additionally, handcrafted metalwork allows for a greater level of customization and attention to detail.

Skilled artisans can manipulate the metal in ways that machines simply can’t. This level of craftsmanship can add a sense of artistry and authenticity to your project.

However, it’s important to consider factors such as cost, time, and complexity when deciding between traditional metal fabrication techniques and laser cutting.

Transitioning to the next section, these factors can greatly impact the success of your project.

Factors to Consider for Your Project

Consider all the factors for your project, because making the right choice will determine the success of your metal fabrication journey. When deciding between laser cutting and traditional metal fabrication techniques, it is crucial to evaluate the cost comparison and material compatibility.

In terms of cost, laser cutting can be more cost-effective for smaller projects due to its precision and reduced waste. Traditional methods may require more manual labor and result in higher labor costs. On the other hand, laser cutting may have higher initial equipment costs.

Regarding material compatibility, laser cutting is suitable for a wide range of materials including metals, plastics, and wood. Traditional methods may have limitations when working with certain materials or complex designs.

To help visualize the differences, consider the following table:

| Factors | Laser Cutting | Traditional Methods |

|---|---|---|

| Cost | Potentially lower due to precision and reduced waste | Higher labor costs, but lower equipment costs |

| Material Compatibility | Suitable for a wide range of materials | Limitations with certain materials or complex designs |

Considering these factors will ensure that you choose the most suitable metal fabrication technique for your project. In the subsequent section, we will explore the importance of comparing precision and accuracy.

Comparing Precision and Accuracy

Take a moment to compare the precision and accuracy of different metal fabrication methods, as this can greatly impact the outcome of your project.

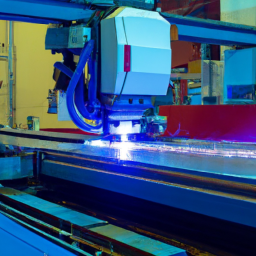

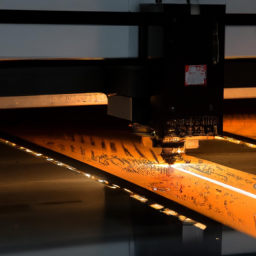

When it comes to precision comparison, laser cutting stands out as the most accurate technique. With its focused beam of light, laser cutting can achieve intricate and detailed cuts, ensuring precise dimensions and minimal material wastage.

On the other hand, traditional metal fabrication techniques such as manual cutting and machining may not offer the same level of precision due to the limitations of human control and precision tools.

Laser cutting also excels in accuracy analysis, as it can consistently reproduce the same results without human error. This makes it ideal for projects that require uniformity and exact specifications.

Moving forward, let’s evaluate the speed and efficiency of these methods without compromising on precision and accuracy.

Evaluating Speed and Efficiency

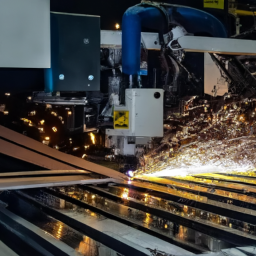

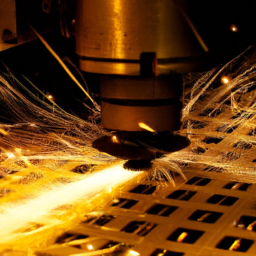

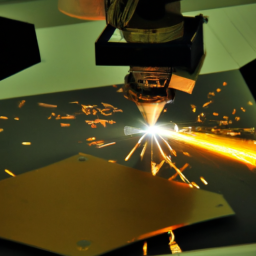

When considering the speed of laser cutting, you’ll find that it offers a significant advantage over traditional metal fabrication techniques. Laser cutting utilizes a high-powered laser beam that can cut through metal quickly and efficiently, resulting in faster production times.

In contrast, traditional metal fabrication techniques such as sawing, drilling, and grinding can be time-consuming and require multiple steps to achieve the desired outcome.

Overall, laser cutting proves to be a more efficient option when it comes to speed and productivity in metal fabrication projects.

Speed of Laser Cutting

Contrary to popular belief, laser cutting is actually faster than traditional metal fabrication techniques. Laser cutting speed is achieved through its ability to rapidly cut through metal with a high-powered laser beam. The precision and accuracy of laser cutting allow for efficient and precise cuts, resulting in increased productivity. The laser beam follows a preprogrammed path, ensuring consistency and reducing the need for manual adjustments.

Additionally, laser cutting eliminates the need for tooling changes, reducing downtime and further increasing speed. The advanced technology of laser cutting enables it to cut through a variety of metals at a faster pace compared to traditional metal fabrication techniques.

Transitioning into the subsequent section about the speed of traditional metal fabrication techniques, it is important to consider the various factors that affect their efficiency.

Speed of Traditional Metal Fabrication Techniques

While laser cutting may be faster, it’s important to consider the sluggish pace of traditional metal fabrication techniques. Traditional techniques involve processes such as sawing, shearing, and machining, which can take a considerable amount of time to complete. However, there are certain advantages to these techniques that should not be overlooked. For instance, traditional techniques allow for greater customization and flexibility in shaping metal, as well as the ability to work with a wider range of materials. Additionally, traditional techniques often yield stronger and more durable finished products due to the meticulous craftsmanship involved. By carefully weighing the benefits of traditional techniques against the speed of laser cutting, you can ensure that your project is completed with the utmost efficiency and precision. Transitioning to the subsequent section, it’s also important to consider the efficiency comparison between laser cutting and traditional metal fabrication techniques.

Efficiency Comparison

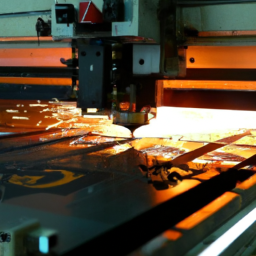

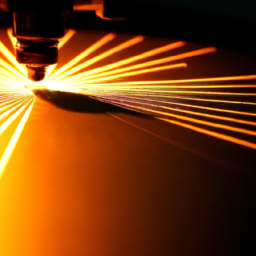

In comparing the efficiency of laser cutting and traditional metal fabrication techniques, it’s important to consider the time-consuming nature of traditional processes. Laser cutting offers significant advantages in terms of speed and efficiency, resulting in reduced production time and increased productivity.

When conducting a cost analysis, laser cutting proves to be a cost-effective method due to its high precision and minimal material wastage. Traditional techniques often require multiple steps and additional resources, leading to higher costs.

Additionally, laser cutting has a lower environmental impact compared to traditional methods. It produces less waste, requires less energy, and emits fewer harmful substances. This makes it a more sustainable option for metal fabrication projects.

Considering the efficiency, cost analysis, and environmental impact, laser cutting emerges as the superior choice for metal fabrication projects. It offers faster production times, cost savings, and a reduced environmental footprint.

Making the Decision

When making the decision between laser cutting and traditional metal fabrication techniques, it’s important to consider the specific requirements of your project and visualize how each method will bring your ideas to life.

Start by weighing the options and evaluating the complexity of your project. Laser cutting is known for its precision and ability to handle intricate designs, making it ideal for projects that require fine detailing. On the other hand, traditional metal fabrication techniques offer versatility and the ability to work with various materials and thicknesses.

Consider the scale of your project and the desired turnaround time. Laser cutting is generally faster and more efficient for smaller projects, while traditional fabrication methods may be more suitable for larger-scale productions.

Ultimately, understanding your project requirements and carefully considering the strengths and limitations of each method will help you make an informed decision.

Frequently Asked Questions

What are the typical costs associated with laser cutting compared to traditional metal fabrication techniques?

Laser cutting cost comparison is crucial when deciding between traditional metal fabrication techniques. Factors affecting laser cutting cost include material type, thickness, and complexity of the design.

Generally, laser cutting is more cost-effective for small-scale projects with intricate designs. However, for large-scale projects or simple designs, traditional metal fabrication techniques may be more economical.

Considering these factors will help you determine the most cost-efficient option for your project.

Are there any limitations to the size or thickness of metal that can be effectively cut using laser cutting?

When considering laser cutting, it’s important to understand the limitations in metal thickness and maximum size that can be effectively cut.

The thickness of metal that can be cut using lasers will depend on the power of the laser and the type of metal. Generally, lasers can effectively cut metal up to a certain thickness, beyond which the process becomes less efficient.

Similarly, the maximum size of metal that can be cut using lasers will depend on the size of the laser cutting machine.

Can laser cutting be used for intricate and complex designs, or is it better suited for simpler shapes?

Intricate designs can be effortlessly achieved with laser cutting, lending a touch of artistic finesse to your metalwork. The advantages of laser cutting lie in its precision and accuracy, allowing for intricate and complex patterns to be flawlessly reproduced. However, laser cutting does have its limitations when it comes to complex shapes. The process may struggle with certain angles and curves, making it less suitable for intricate designs that require intricate shapes.

Are there any special safety considerations or precautions that need to be taken when using laser cutting?

When using laser cutting, there are several safety considerations and precautions that need to be taken.

First, it’s important to wear appropriate personal protective equipment, such as safety glasses, gloves, and a lab coat.

Additionally, all operators should receive proper training on the safe and correct use of laser cutting equipment.

It’s crucial to follow all manufacturer guidelines and maintain a clean and well-ventilated work area to minimize the risk of accidents or exposure to hazardous fumes.

How does the quality of the finished product differ between laser cutting and traditional metal fabrication techniques?

When comparing the precision and accuracy of laser cutting and traditional metal fabrication techniques, it’s evident that laser cutting provides superior results. The laser’s focused beam allows for intricate designs and precise cuts, resulting in a higher-quality finished product.

Additionally, laser cutting is significantly faster and more efficient compared to traditional methods, reducing production time and costs.

Overall, laser cutting offers a more precise and efficient solution for metal fabrication projects.

Conclusion

In conclusion, after carefully analyzing the pros and cons of laser cutting and traditional metal fabrication techniques, you now possess the necessary knowledge to make an informed decision for your project.

While laser cutting may seem like a cutting-edge choice, it is crucial to consider the unique requirements and intricacies of your specific project.

Remember, precision and accuracy are paramount, and speed and efficiency should not be compromised.

So, choose wisely, my discerning friend, and may your metal fabrication endeavors be nothing short of sublime.