Are you contemplating the best approach for your woodworking project? Laser cutting or traditional techniques? It’s a question that many craftsmen like yourself have grappled with. Both methods have their merits, but which one is truly the best fit for your project?

In this article, we’ll delve into the world of laser cutting and traditional woodworking techniques, providing you with the knowledge and expertise to make an informed decision.

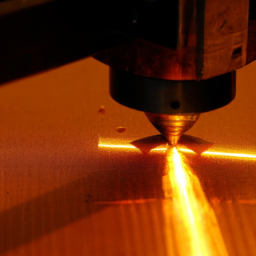

Laser cutting, a modern marvel of technology, offers unrivaled precision and accuracy. With its ability to make intricate cuts and patterns, it’s no wonder that it has gained popularity in recent years.

On the other hand, traditional woodworking techniques, steeped in tradition and craftsmanship, have stood the test of time. They provide a sense of artistry and authenticity that cannot be replicated by a machine.

But how do you decide? Consider the type of project you’re working on, the level of precision required, the time and efficiency constraints, and of course, your budget. This article will guide you through these factors, helping you navigate the decision-making process.

So, whether you’re a seasoned woodworker or just starting out, join us as we explore the world of laser cutting versus traditional woodworking techniques, and discover which approach is truly the best fit for your project.

Key Takeaways

- Laser cutting offers precision and accuracy, while traditional woodworking techniques provide artistry and authenticity.

- Factors to consider when deciding between the two methods include the type of project, level of precision required, time and efficiency constraints, and budget.

- Laser cutting allows for intricate cuts and patterns and can be used on various materials, while traditional woodworking techniques involve hand tools, craftsmanship, and joinery techniques.

- Laser cutting is faster and more productive, but may have higher upfront costs and limitations on certain materials, while traditional woodworking techniques may require less initial investment but are more time-consuming and labor-intensive.

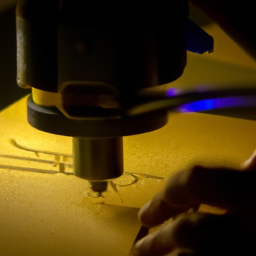

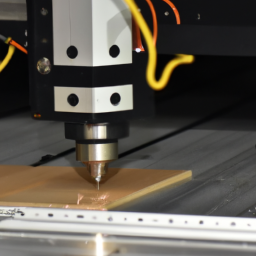

Understand the Basics of Laser Cutting

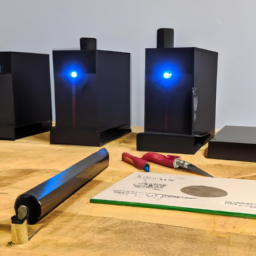

If you want to know how laser cutting can revolutionize your woodworking projects, you’re in the right place! Laser cutting offers numerous advantages that can take your craftsmanship to the next level.

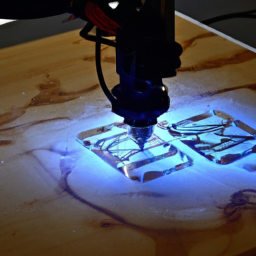

With laser cutting, you can achieve unparalleled precision and accuracy, ensuring clean and seamless cuts every time. This technique allows for intricate designs and complex shapes that would be challenging to achieve using traditional woodworking methods.

Additionally, laser cutting can be used on a wide range of materials, including wood, acrylic, leather, and even metal. The versatility of laser cutting makes it a popular choice for many craftsmen.

Now that you understand the basics and advantages of laser cutting, let’s explore traditional woodworking techniques.

Explore Traditional Woodworking Techniques

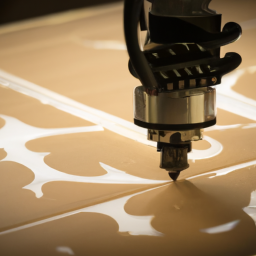

When it comes to traditional woodworking techniques, hand tools and craftsmanship play a vital role in bringing your project to life. With a keen eye for detail and a steady hand, you can achieve precise cuts and intricate designs that showcase your skill and dedication.

Additionally, mastering various joinery techniques allows you to create strong and durable connections between different pieces of wood, ensuring the longevity and stability of your finished product.

So, whether you’re a seasoned woodworker or just starting out, honing your skills in hand tools and craftsmanship, as well as learning different joinery techniques, will elevate your woodworking projects to the next level.

Hand tools and craftsmanship

Craftsmen skillfully shape wood with their hands and traditional tools, creating intricate designs and adding a touch of artistry to their projects. Hand tools are essential for this process, and their maintenance is crucial to ensure their longevity and effectiveness. Regular sharpening, cleaning, and lubricating of hand tools not only keep them in optimal condition but also enhance their performance.

The benefits of craftsmanship lie in the attention to detail and the ability to create unique, one-of-a-kind pieces. The satisfaction of working with your hands and witnessing the transformation of raw materials into a finished product is unmatched.

Joinery techniques, which involve joining two or more pieces of wood together, are an integral part of traditional woodworking. These techniques will be explored in the subsequent section, highlighting their importance in creating sturdy and durable wooden structures.

Joinery techniques

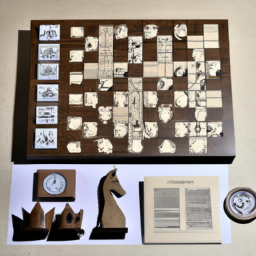

Joinery techniques are like the glue that holds together the pieces of wood, creating a strong and harmonious bond. When it comes to traditional woodworking, two of the most renowned joinery techniques are dovetail joinery and mortise and tenon techniques.

Dovetail joinery is a method that involves interlocking wedge-shaped tails and pins, creating a sturdy and aesthetically pleasing connection. This technique is commonly used in fine furniture and cabinetry, as it provides exceptional strength and durability.

On the other hand, mortise and tenon techniques involve cutting a rectangular hole (mortise) and fitting a projecting piece of wood (tenon) into it. This technique is versatile and can be used in various applications, from simple frames to complex structures.

However, when considering the type of project, it’s crucial to take into account the specific requirements and limitations of each joinery technique. Transitioning into the subsequent section, it is important to consider the type of project you have in mind.

Consider the Type of Project

For your project, you’ll want to think about the type of project you’re working on. Consideration of the customization options and material compatibility is crucial when deciding between laser cutting and traditional woodworking techniques.

Laser cutting offers a wide range of customization options, allowing you to create intricate designs and patterns with precision. It works well with various materials like wood, acrylic, and metal.

On the other hand, traditional woodworking techniques excel in creating more organic and natural-looking pieces. They are perfect for projects that require a rustic or traditional aesthetic.

Now that you understand the importance of considering the type of project, let’s delve into the next section and compare precision and accuracy between laser cutting and traditional woodworking techniques.

Compare Precision and Accuracy

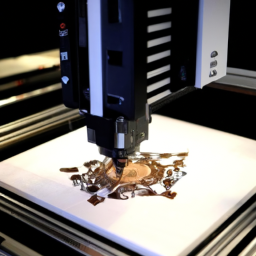

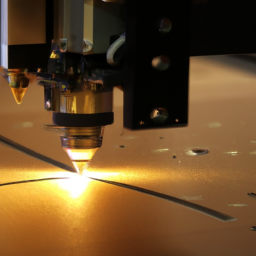

When comparing precision and accuracy, you’ll find that considering the type of project is essential in determining the most suitable technique. Laser cutting offers several advantages in terms of precision and accuracy. The laser beam is incredibly focused, allowing for intricate and detailed cuts that are difficult to achieve with traditional woodworking techniques. The computer-controlled system ensures that each cut is consistent and precise, resulting in a high level of accuracy throughout the project.

On the other hand, traditional woodworking techniques can also provide a certain level of precision and accuracy, especially when skilled craftsmen are involved. However, human error and limitations can sometimes lead to slight inconsistencies and imperfections. Overall, laser cutting excels in delivering precise and accurate results consistently.

Assessing time and efficiency will further help you determine the best technique for your project.

Assess Time and Efficiency

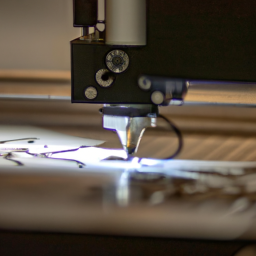

Assessing time and efficiency can be crucial when deciding between different methods of fabrication, as it can significantly impact the overall cost of a project. When comparing laser cutting and traditional woodworking techniques, it’s important to consider the speed and productivity of each method.

Laser cutting is known for its precision and ability to cut intricate designs quickly, which can save a significant amount of time compared to traditional woodworking methods. Additionally, laser cutting machines can often operate continuously, increasing productivity and reducing downtime.

However, it’s important to evaluate cost and budget as well, as laser cutting machines can be expensive to purchase and maintain.

Transitioning into the subsequent section, evaluating cost and budget is an essential step in determining the most suitable fabrication method for your project.

Evaluate Cost and Budget

To evaluate the cost and budget, you need to consider the financial aspects of the different fabrication methods.

Laser cutting and traditional woodworking techniques have their own cost factors that can significantly impact your project. Laser cutting may have a higher upfront cost, as you need to invest in the laser machine itself and the necessary software. However, it can be more cost-effective in the long run due to its precision, speed, and minimal material wastage.

On the other hand, traditional woodworking techniques may require less initial investment but can be more time-consuming and labor-intensive. Additionally, the cost of materials can vary between the two methods, with laser cutting often being limited to certain materials like wood, acrylic, and metal.

Therefore, a thorough cost comparison and assessment of material limitations is crucial to determine which method aligns best with your budget.

Frequently Asked Questions

Can laser cutting be used on materials other than wood?

Laser cutting is not limited to wood; it offers advantages on various materials. It’s like the saying goes, ‘Where there’s a will, there’s a way.’

Laser cutting can be used on materials like acrylic, leather, fabric, and even metal. It provides precise cuts, intricate designs, and smooth edges. However, it has its limitations compared to traditional woodworking techniques. For instance, it may struggle with thick or dense materials, and it can be more expensive.

What are some examples of traditional woodworking techniques?

Examples of traditional woodworking techniques include hand sawing, chiseling, carving, planing, and joinery. These methods require a high level of skill and precision.

The benefits of using these techniques are the ability to create intricate designs, unique details, and custom-made pieces. Traditional woodworking allows for a more personal touch and the satisfaction of crafting something by hand. It also allows for greater versatility in working with different types of wood and materials.

How do I determine if my project is better suited for laser cutting or traditional woodworking?

Determining the best approach for your project boils down to several key factors. Consider the intricacy and precision required – laser cutting excels in delivering fine details. On the other hand, traditional woodworking offers a more organic, handcrafted feel.

Pros of laser cutting include speed and accuracy, while traditional woodworking allows for more customization. Weigh these factors against your project’s requirements and desired aesthetic to make an informed decision.

How does laser cutting ensure precision and accuracy in comparison to traditional woodworking techniques?

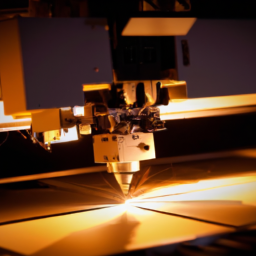

Laser cutting, when compared to CNC machining, offers superior precision and accuracy. The process involves using a high-powered laser beam to cut through the material with incredible precision, ensuring exact measurements and intricate designs.

This level of accuracy is difficult to achieve with traditional woodworking techniques, which often rely on manual skill and can be prone to human error. Additionally, laser cutting provides speed advantages over manual woodworking, making it a preferred choice for projects that require both precision and efficiency.

Are laser cutting services more expensive than traditional woodworking methods?

When it comes to cost comparison, laser cutting services may initially seem more expensive than traditional woodworking methods. However, it’s important to consider the advantages of laser cutting.

Laser cutting offers precise and accurate cuts, reducing material waste and minimizing the need for manual labor. Additionally, laser cutting allows for intricate designs and customization, resulting in a high-quality end product.

In the long run, these benefits can outweigh the initial cost difference and provide a superior outcome for your project.

Conclusion

So there you have it, my friend. After diving deep into the world of laser cutting versus traditional woodworking techniques, you now possess a wealth of knowledge to make an informed decision for your project.

Whether you choose the precision and accuracy of laser cutting or the timeless artistry of traditional woodworking, both options have their merits.

Consider the type of project, the level of precision required, the time and efficiency concerns, and of course, your budget.

With your meticulous approach, I have no doubt that you’ll create something truly remarkable. Good luck!