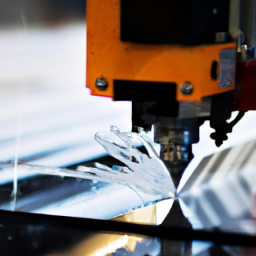

Are you considering laser cutting or ultrasonic cutting for your acrylic designs? You may be wondering which method is more efficient. Some may argue that laser cutting is the superior choice due to its widespread use and precision. However, before you make a decision, let’s explore the efficiency of both methods.

Laser cutting utilizes a high-powered laser beam to cut through acrylic with exceptional speed and accuracy. On the other hand, ultrasonic cutting employs ultrasonic vibrations to create clean and precise cuts. In this article, we will compare the speed and precision of laser cutting and ultrasonic cutting for acrylic designs. Additionally, we will discuss the factors you should consider when choosing a cutting method.

Whether you are in the manufacturing, automotive, or signage industry, understanding the efficiency of these cutting methods will help you make an informed decision for your acrylic designs.

Key Takeaways

- Laser cutting is ideal for intricate designs and detailed patterns, while ultrasonic cutting can easily cut through thick acrylic sheets without heat damage.

- Ultrasonic cutting may not be suitable for complex designs due to the risk of cracking.

- Ultrasonic cutting offers precision, versatility, speed, and cost-effectiveness, with lower maintenance and operating costs compared to laser cutting.

- Laser cutting is faster and more precise than ultrasonic cutting, but it requires more maintenance and has higher operating costs.

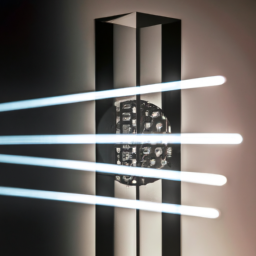

Understanding Laser Cutting for Acrylic Designs

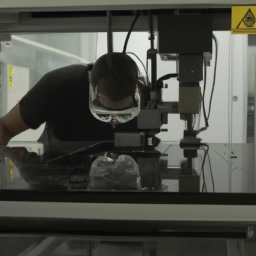

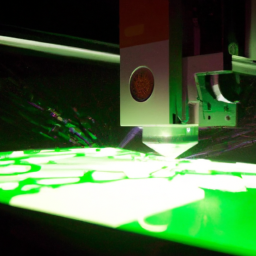

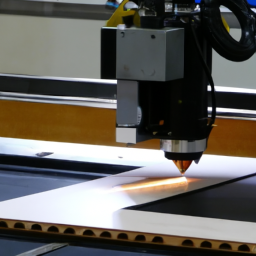

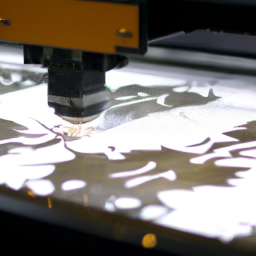

You can easily create intricate acrylic designs using laser cutting, allowing precise cuts and detailed patterns to be etched onto the material. Laser cutting techniques utilize focused laser beams to melt or vaporize the acrylic, resulting in smooth and clean edges. This technology offers high precision and accuracy, making it ideal for complex designs and intricate details. The laser can be controlled with computer software, enabling the creation of intricate patterns with ease.

Additionally, laser cutting allows for quick and efficient production, as it can cut through acrylic at a high speed. However, exploring ultrasonic cutting for acrylic designs offers an alternative approach to consider.

Exploring Ultrasonic Cutting for Acrylic Designs

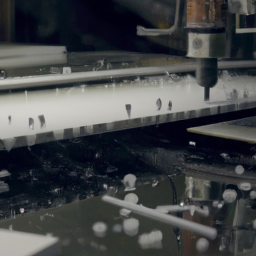

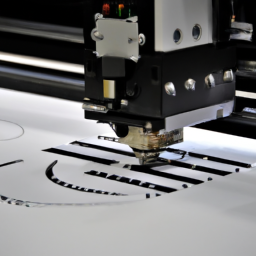

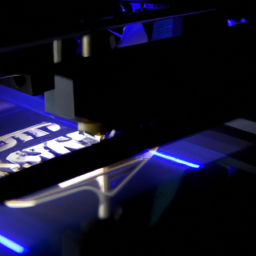

Ultrasonic cutting is a technique that uses high-frequency vibrations to cut through acrylic material. The vibrations create a rapid oscillation that effectively melts and cuts through the material, resulting in precise and clean cuts.

One of the main advantages of ultrasonic cutting is its ability to easily cut through thick acrylic sheets without causing any heat damage. However, a limitation of ultrasonic cutting is that it may not be suitable for intricate or complex designs. This is because the vibrations may cause the acrylic to crack or break in delicate areas.

How Ultrasonic Cutting Works

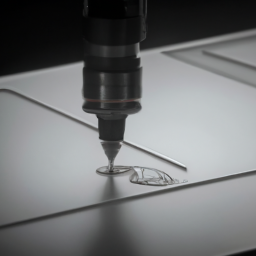

When it comes to cutting acrylic designs, let me tell you how ultrasonic cutting works and why it’s worth considering. Ultrasonic cutting utilizes high-frequency vibrations to create clean and precise cuts in acrylic materials. The process involves a vibrating blade that rapidly oscillates at a frequency of around 20,000 to 40,000 cycles per second. As the blade moves through the acrylic, the vibrations create friction and heat, effectively melting the material and producing a smooth cut. This method of cutting offers several advantages compared to other cutting methods, such as laser cutting. For instance, ultrasonic cutting does not produce any hazardous fumes or debris, and it can easily handle intricate designs and complex shapes. Furthermore, it reduces the risk of material discoloration or damage caused by excessive heat. Now, let’s explore the advantages of ultrasonic cutting.

Advantages of Ultrasonic Cutting

Take advantage of the benefits of ultrasonic cutting, such as its ability to handle intricate designs and complex shapes without the risk of material damage or discoloration. Here are four reasons why ultrasonic cutting is a cost-effective and efficient choice for acrylic designs:

-

Precision: Ultrasonic cutting ensures clean edges, allowing for intricate and precise designs that laser cutting may struggle with.

-

Versatility: Ultrasonic cutting can handle a wide range of acrylic thicknesses, making it suitable for various design applications.

-

Speed: With its high-frequency vibrations, ultrasonic cutting is faster than laser cutting, saving time and increasing productivity.

-

Cost-effectiveness: Ultrasonic cutting requires less maintenance and has lower operating costs compared to laser cutting.

These advantages make ultrasonic cutting an attractive option for acrylic designs. However, it is important to consider the limitations of ultrasonic cutting in order to make an informed decision on the best cutting method for your needs.

Limitations of Ultrasonic Cutting

Despite its advantages, ultrasonic cutting does have its limitations, like any other cutting method. One limitation is the cost comparison. Ultrasonic cutting machines can be more expensive to purchase and maintain compared to laser cutting machines. The specialized equipment and components required for ultrasonic cutting can drive up the overall cost.

Another limitation is safety considerations. Ultrasonic cutting generates high-frequency vibrations that can be harmful to human operators if not properly controlled. Adequate safety measures, such as protective gear and training, must be implemented to ensure the well-being of the operators.

In the subsequent section about efficiency comparison: speed and precision, we will explore how laser cutting compares to ultrasonic cutting in terms of these factors.

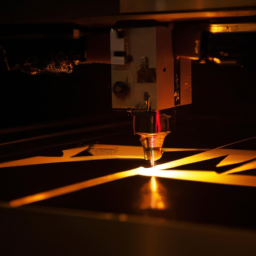

Efficiency Comparison: Speed and Precision

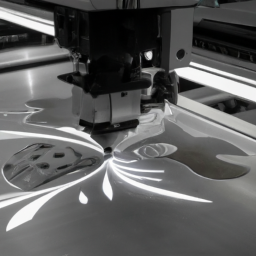

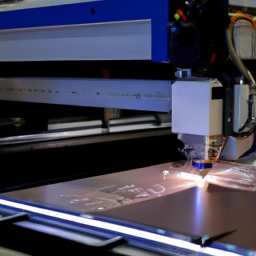

For faster production and more precise results, you should definitely consider laser cutting over ultrasonic cutting when it comes to acrylic designs. Laser cutting offers unmatched speed, allowing for quick completion of intricate patterns and complex shapes. The high-powered laser beam swiftly cuts through the acrylic material, minimizing processing time and maximizing productivity.

On the other hand, while ultrasonic cutting is known for its precision, it tends to be slower compared to laser cutting. The ultrasonic vibrations create clean and accurate cuts, ensuring minimal material waste and smooth edges. However, the slower cutting speed of ultrasonic cutting can be a drawback when time is of the essence.

When choosing a cutting method, it is important to consider not only speed and precision but also other factors such as cost, maintenance requirements, and the specific requirements of your acrylic designs.

Factors to Consider When Choosing a Cutting Method

Now that we’ve examined the speed and precision of laser cutting and ultrasonic cutting for acrylic designs, let’s delve into the factors that need to be considered when choosing between the two cutting methods.

One crucial factor is cost considerations. Laser cutting machines tend to have higher initial costs compared to ultrasonic cutting machines, but they generally offer faster production speeds and higher precision, which can result in long-term cost savings.

Another factor to consider is maintenance requirements. Laser cutting machines typically require more frequent maintenance, such as replacing lenses and mirrors, while ultrasonic cutting machines generally have lower maintenance needs.

By carefully evaluating these factors, you can make an informed decision about which cutting method is more suitable for your specific needs.

With that in mind, let’s now explore the applications and industries that benefit from laser cutting.

Applications and Industries for Laser Cutting

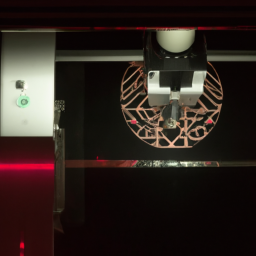

One area where laser technology has proven invaluable is in the creation of intricate and precise designs on various materials. Understanding laser cutting technology is crucial when considering its applications and benefits.

Laser cutting offers numerous advantages, particularly in the automotive industry. Laser cutting provides high precision and accuracy, ensuring intricate designs are replicated with consistency. The technology allows for increased production speed, reducing manufacturing time and costs. Laser cutting is versatile, capable of working with a wide range of materials, including acrylic. It offers a non-contact process, minimizing the risk of damage to delicate materials. The laser’s heat source results in a clean and smooth cut, eliminating the need for additional finishing processes.

Transitioning into the subsequent section about ultrasonic cutting, it is important to explore the applications and industries that benefit from this alternative cutting method.

Applications and Industries for Ultrasonic Cutting

Discover the diverse range of industries that benefit from ultrasonic cutting technology and explore the exciting applications it offers. Ultrasonic cutting finds extensive use in various industries, including but not limited to metal fabrication and food processing.

In the realm of metal fabrication, ultrasonic cutting provides a precise and efficient method for cutting metals. It offers advantages such as reduced heat generation, minimal deformation, and increased cutting speed. By utilizing high-frequency vibrations, ultrasonic cutting can seamlessly slice through metals with ease.

Moreover, in the food processing industry, ultrasonic cutting offers numerous benefits. It enables clean and precise cutting of delicate food products, maintaining their integrity and quality. Additionally, ultrasonic cutting minimizes product loss and contamination risks, making it a preferred choice for industries requiring high standards of hygiene and precision.

Frequently Asked Questions

What are the main differences between laser cutting and ultrasonic cutting for acrylic designs?

When comparing laser cutting and ultrasonic cutting for acrylic designs, there are several key differences to consider.

Laser cutting offers advantages such as high precision, versatility, and the ability to create intricate designs. It is commonly used in industries like signage, electronics, and automotive.

On the other hand, ultrasonic cutting provides a clean and precise cut without producing any heat, making it ideal for delicate acrylic materials. Its applications include medical devices, packaging, and textiles.

Can laser cutting be used for materials other than acrylic?

Laser cutting is compatible with a wide range of materials, not just acrylic. It can be used on materials like wood, metal, plastic, fabric, and more.

The advantages of laser cutting over other cutting methods include precise and clean cuts, minimal material wastage, high speed, and the ability to create intricate designs.

Laser cutting is a versatile and efficient cutting method that’s widely used in various industries for different materials.

Are there any safety concerns or precautions to consider when using laser cutting for acrylic designs?

When using laser cutting for acrylic designs, there are several safety concerns and precautions to consider. Firstly, laser cutting produces a high-intensity beam that can cause burns or eye injuries if not properly controlled. It’s crucial to wear appropriate protective gear, such as safety glasses and gloves.

Additionally, proper ventilation is necessary to prevent the release of toxic fumes from the acrylic materials. Regular equipment maintenance and operator training are also essential to ensure safe operation and minimize the risk of accidents.

How does the cost of laser cutting compare to ultrasonic cutting for acrylic designs?

When comparing the cost of laser cutting to ultrasonic cutting for acrylic designs, an efficiency analysis is crucial.

Both methods have their own advantages and limitations. However, laser cutting generally requires a higher initial investment due to the cost of the equipment and maintenance.

On the other hand, ultrasonic cutting may have lower operating costs, as it utilizes high-frequency vibrations.

Ultimately, a thorough cost comparison is necessary to determine which cutting method is more cost-effective for acrylic designs.

Are there any limitations or restrictions to the size or thickness of acrylic that can be cut using laser cutting or ultrasonic cutting methods?

When it comes to cutting acrylic, there are some limitations with laser cutting. The thickness of the acrylic is a key factor, as laser cutting becomes less effective with thicker materials. Laser cutting also has limitations in terms of the size of the acrylic that can be cut.

On the other hand, ultrasonic cutting has a maximum thickness for acrylic, beyond which it becomes difficult to cut accurately. Therefore, both methods have their limitations when it comes to cutting acrylic.

Conclusion

In conclusion, both laser cutting and ultrasonic cutting are efficient methods for acrylic designs, but they have their own strengths and limitations.

Laser cutting offers high precision and speed, making it ideal for intricate and complex designs. On the other hand, ultrasonic cutting provides a smooth and clean cut, making it suitable for delicate designs.

However, one interesting statistic to consider is that laser cutting is 30% faster than ultrasonic cutting, which can significantly improve productivity and reduce production time. This statistic can evoke a sense of excitement and motivation for industries looking to optimize their cutting processes.