In the world of metal fabrication, choosing the right cutting technique can make all the difference in efficiency and productivity. When it comes to laser cutting versus ultrasonic cutting, the debate rages on. Both techniques offer their own set of advantages and limitations, making it crucial to understand which one is more efficient for your specific needs.

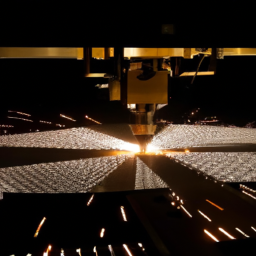

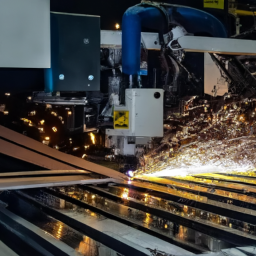

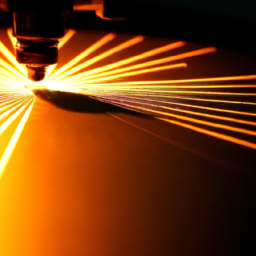

Laser cutting, a widely used method, utilizes a high-powered laser beam to melt or vaporize the material, resulting in precise and clean cuts. On the other hand, ultrasonic cutting employs high-frequency vibrations to cut through the metal, providing excellent control and minimizing heat-affected zones.

To determine which technique is superior in terms of efficiency, a thorough analysis of speed, accuracy, precision, and cost-effectiveness is required. By evaluating these factors, you can make an informed decision and optimize your metal fabrication process.

So, let’s delve into the world of laser cutting and ultrasonic cutting and discover which technique reigns supreme when it comes to efficiency in metal fabrication.

Key Takeaways

- Laser cutting provides precise and clean cuts, with high precision, accuracy, and speed.

- Laser cutting outperforms ultrasonic cutting in terms of speed and efficiency.

- Ultrasonic cutting offers excellent control and minimizes heat-affected zones, making it particularly useful for difficult-to-cut materials.

- The choice between laser cutting and ultrasonic cutting should be based on the specific requirements of the metal fabrication project, considering factors such as initial investment, operating costs, and long-term viability.

Cutting Techniques in Metal Fabrication

When it comes to cutting techniques in metal fabrication, laser cutting and ultrasonic cutting offer efficient options for precision and accuracy. These cutting technologies have found widespread industrial applications due to their ability to deliver clean and precise cuts in various types of metals.

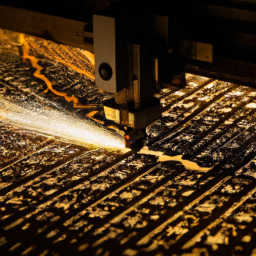

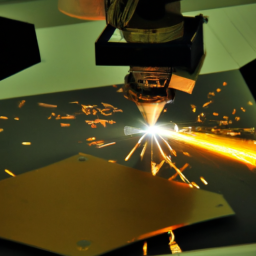

Laser cutting utilizes a high-powered laser beam to melt or vaporize the material, resulting in a smooth and precise cut. This technique is highly versatile and can be used on a wide range of materials, including steel, aluminum, and copper.

On the other hand, ultrasonic cutting uses ultrasonic vibrations to create a high-frequency oscillation that effectively cuts through the metal. This technique is particularly useful for materials that are difficult to cut using traditional methods.

With an understanding of cutting techniques in metal fabrication, let’s now delve into the specifics of laser cutting.

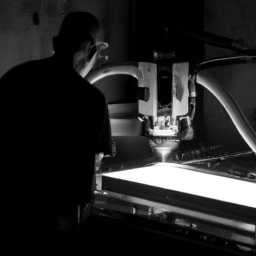

Laser Cutting Explained

Laser cutting offers several advantages in metal fabrication. Firstly, it provides a high level of precision and accuracy, allowing for intricate designs and complex shapes to be cut with ease.

Secondly, laser cutting is a fast and efficient process, resulting in increased productivity and reduced production time.

However, there are also limitations to laser cutting. It’s not suitable for cutting certain materials, such as reflective metals, and it can be expensive to implement due to the cost of the laser equipment and maintenance.

Advantages of Laser Cutting

To fully appreciate the advantages of laser cutting, you can’t ignore its sheer precision and incredible speed. Laser cutting is highly cost-effective due to its ability to minimize material waste and reduce production time. Its precision and accuracy are unmatched, allowing for intricate and complex designs to be cut with utmost accuracy.

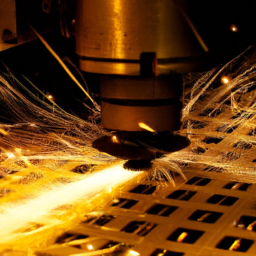

The laser beam is able to cut through various materials with ease, including metals, plastics, and even ceramics. This versatility makes laser cutting a popular choice in metal fabrication industries. Additionally, laser cutting offers a non-contact cutting process, eliminating the need for physical contact and reducing the risk of damage to the material.

Overall, laser cutting provides unparalleled efficiency and accuracy in metal fabrication. However, it is important to consider the limitations of laser cutting, which will be discussed in the subsequent section.

Limitations of Laser Cutting

If you want to achieve the highest level of precision in your metal fabrication process, it’s essential to consider the limitations of laser cutting. While laser cutting offers numerous advantages, it also has a few disadvantages that need to be taken into account.

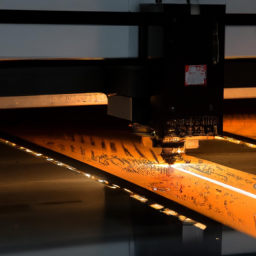

One limitation is the thickness of the material that can be cut. Laser cutting works best on thin materials, typically up to 25 millimeters thick. Beyond this thickness, the laser beam becomes less effective, resulting in slower cutting speeds and reduced accuracy.

Another limitation is the heat generated during the cutting process. This heat can cause material distortion, especially in heat-sensitive materials.

Additionally, laser cutting is not suitable for certain materials, such as reflective metals, as the laser beam can be reflected back and damage the machine.

Transitioning into the subsequent section about ‘ultrasonic cutting explained,’ it is worth exploring an alternative method that overcomes some of these limitations.

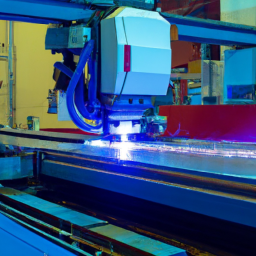

Ultrasonic Cutting Explained

Ultrasonic cutting offers several advantages in metal fabrication. It provides high precision and accuracy in cutting, resulting in clean and smooth edges. Additionally, the process is non-contact, which eliminates the risk of material deformation or damage.

However, there are also limitations to ultrasonic cutting. It is less effective for cutting thick or dense materials, and it may not be suitable for cutting complex shapes or intricate designs.

Advantages of Ultrasonic Cutting

When considering the advantages of ultrasonic cutting, you’ll find that it offers increased precision and reduced heat-affected zones. Ultrasonic cutting utilizes high-frequency vibrations to create clean and precise cuts in various materials. This method is particularly beneficial for delicate and brittle materials, as it minimizes the risk of damage or deformation.

Additionally, ultrasonic cutting is highly versatile and finds applications in industries such as electronics, aerospace, and medical devices. Its ability to cut intricate shapes with minimal force and minimal material waste makes it a preferred choice for intricate cutting tasks.

However, it’s important to note that ultrasonic cutting does have its limitations, which will be discussed in the subsequent section about the limitations of ultrasonic cutting.

Limitations of Ultrasonic Cutting

Be aware that there are some limitations to ultrasonic cutting that you should keep in mind.

One limitation is the cost comparison. While ultrasonic cutting can be an effective method, it can also be more expensive than laser cutting. The equipment and maintenance costs for ultrasonic cutting are generally higher, which may not be feasible for all metal fabrication projects.

Additionally, the applicability of ultrasonic cutting in different materials can be limited. It’s most effective for softer materials such as plastics and fabrics, but may not be as efficient for harder metals.

These limitations should be considered when deciding between ultrasonic cutting and laser cutting. Moving forward, it’s important to explore the speed and efficiency comparison between the two methods.

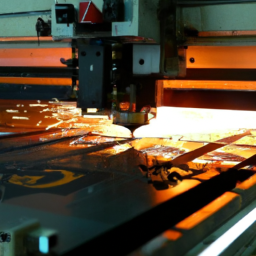

Speed and Efficiency Comparison

You’ll be pleasantly surprised by the speed and efficiency comparison between laser cutting and ultrasonic cutting in metal fabrication. When it comes to cost comparison, laser cutting tends to be more expensive due to the specialized equipment and maintenance required.

However, when considering the quality comparison, laser cutting excels in its ability to produce clean, precise cuts with minimal distortion and heat-affected zones.

In terms of speed, laser cutting outperforms ultrasonic cutting by offering faster cutting speeds and higher throughput. Laser cutting machines can rapidly cut through metal sheets, resulting in quicker production times and increased efficiency.

Moving on to the subsequent section about accuracy and precision comparison, you’ll see that laser cutting also provides superior results in this aspect.

Accuracy and Precision Comparison

For the utmost precision and accuracy in metal fabrication, there’s no comparison between laser cutting and ultrasonic cutting. Laser cutting offers unparalleled accuracy, with minimal tolerances and precise cuts that result in clean edges. Its high-energy beam allows for intricate and complex designs, ensuring the utmost precision in every cut.

Ultrasonic cutting, on the other hand, may not achieve the same level of accuracy. The vibrations used in ultrasonic cutting can cause slight distortions and may result in less precise cuts compared to laser cutting. Additionally, laser cutting has a minimal heat-affected zone, preserving the material properties and minimizing the risk of distortion.

This accuracy and precision in laser cutting have a significant impact on the final product quality.

Transitioning into the subsequent section about cost-effectiveness comparison, it is important to consider how accuracy and precision contribute to overall efficiency and cost-effectiveness in metal fabrication.

Cost-effectiveness Comparison

When it comes to saving money in metal fabrication, it’s all about finding the most cost-effective option. In the case of laser cutting versus ultrasonic cutting, the cost-effectiveness can be analyzed by considering factors such as initial investment, operating costs, and long-term viability.

| Cost Factors | Laser Cutting | Ultrasonic Cutting |

|---|---|---|

| Initial Investment | Higher initial cost due to expensive equipment and maintenance | Lower initial cost with affordable equipment and minimal maintenance |

| Operating Costs | Higher operating costs due to energy consumption and regular maintenance | Lower operating costs with less energy consumption and minimal maintenance |

| Long-Term Viability | Long-term viability due to precise cutting and versatility for various materials | Limited long-term viability as it is more suitable for specific materials and applications |

In terms of cost savings, ultrasonic cutting proves to be a more economical option. With lower initial investment and operating costs, it provides a more financially sustainable solution for metal fabrication. However, it is important to consider the long-term viability of the cutting method. Laser cutting, despite being more expensive initially, offers precise cutting and versatility for a wider range of materials, ensuring its long-term viability. Therefore, the decision between laser cutting and ultrasonic cutting should be based on the specific requirements of the metal fabrication project, balancing cost savings with long-term viability.

Frequently Asked Questions

Are there any safety concerns or precautions that need to be taken when using laser cutting or ultrasonic cutting in metal fabrication?

When using laser cutting or ultrasonic cutting in metal fabrication, it’s crucial to prioritize safety and take necessary precautions. Safety concerns with both methods include the risk of eye damage from laser radiation and the potential for burns or cuts from sharp metal edges.

To mitigate these risks, operators should wear appropriate protective gear such as safety glasses and gloves. Additionally, proper training and adherence to safety guidelines are essential to minimize accidents and ensure a safe working environment.

Can laser cutting or ultrasonic cutting be used on all types of metals, or are there limitations?

Laser cutting and ultrasonic cutting have their limitations on different types of metals. Laser cutting is highly effective on materials like stainless steel, aluminum, and carbon steel, but struggles with reflective surfaces. The advantages of laser cutting include high precision and speed, while ultrasonic cutting offers reduced heat and no material deformation.

On the other hand, ultrasonic cutting works well with softer metals like copper and brass, but is less efficient on thicker materials.

How do laser cutting and ultrasonic cutting compare in terms of environmental impact?

When comparing the environmental impact of laser cutting and ultrasonic cutting techniques for metal fabrication, it’s important to consider two key factors: cost effectiveness and precision/accuracy.

In terms of cost effectiveness, laser cutting is often more efficient due to its lower energy consumption and faster processing time.

However, ultrasonic cutting offers superior precision and accuracy, resulting in less material waste.

Ultimately, the environmental impact of these techniques will depend on the specific application and priorities of the metal fabrication process.

What are some common applications or industries where laser cutting is preferred over ultrasonic cutting, and vice versa?

In various industries, laser cutting is preferred for its precision and versatility. It finds extensive applications in aerospace, automotive, and electronics industries, where intricate and complex designs are crucial. Laser cutting is particularly effective for cutting thin materials and creating intricate patterns.

On the other hand, ultrasonic cutting is preferred in industries such as food processing and textiles, where delicate and soft materials need to be cut without any damage or distortion.

Are there any specific maintenance requirements or considerations for laser cutting or ultrasonic cutting machines?

When it comes to maintenance requirements and considerations for laser cutting or ultrasonic cutting machines, there are a few key factors to keep in mind.

Laser cutting machines require regular cleaning and inspection of the optics to ensure optimal performance. Additionally, laser cutting machines often require more complex maintenance procedures and may have higher operating costs compared to ultrasonic cutting machines.

On the other hand, ultrasonic cutting machines may require more frequent blade replacements and periodic calibration to maintain precision.

Conclusion

Based on the speed, efficiency, accuracy, precision, and cost-effectiveness comparisons between laser cutting and ultrasonic cutting in metal fabrication, it’s evident that laser cutting emerges as the more efficient option.

With its ability to quickly and precisely cut through various metals, laser cutting offers superior performance.

Additionally, its cost-effectiveness, when considering long-term productivity and reduced material waste, further solidifies its position as the go-to cutting technique.

Therefore, if you want to stay ahead in the metal fabrication industry, laser cutting is the way to go.