Welcome to the world of paper crafts, where creativity knows no bounds! As you delve into the realm of intricate designs and precise cuts, you’ll soon realize that the choice of cutting method can make all the difference. It’s like wielding a magic wand to bring your imagination to life.

In this article, we’ll explore the enchanting art of laser cutting and the mesmerizing power of ultrasonic cutting, both vying for the title of efficiency champion. Like two skilled magicians, these cutting techniques offer unique abilities that can elevate your paper craft projects to new heights.

Laser cutting, with its precise and swift movements, harnesses the power of light to effortlessly slice through paper with unparalleled accuracy. On the other hand, ultrasonic cutting, like a gentle whisper, utilizes sound waves to delicately separate the fibers of your chosen medium, ensuring a clean and flawless finish.

But which method reigns supreme in the realm of paper crafts? Join us as we embark on a journey to compare their efficiency in terms of speed, precision, cost, application, and versatility. By the end, you’ll have all the knowledge you need to make an informed decision and unlock the true potential of your paper craft creations.

So, grab your cutting tools and let’s dive in!

Key Takeaways

- Laser cutting offers unparalleled accuracy and precision compared to ultrasonic cutting.

- Ultrasonic cutting is faster and more efficient than traditional cutting methods.

- Ultrasonic cutting is ideal for delicate materials like paper, minimizing tearing or distortion.

- Laser cutting is more versatile and can be used on a wide range of materials, while ultrasonic cutting is primarily designed for cutting paper.

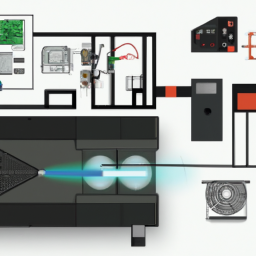

Understanding Laser Cutting in Paper Crafts

If you want to take your paper crafts to the next level, laser cutting is the technique you need to master. Laser cutting offers numerous advantages in the world of paper crafts.

Firstly, it allows for precise and intricate cuts, creating intricate and detailed designs that are difficult to achieve with other cutting techniques.

Additionally, laser cutting is a faster and more efficient process compared to traditional methods. It provides a clean and smooth edge, eliminating the need for additional finishing work.

When comparing laser cutting to ultrasonic cutting, laser cutting emerges as the more superior choice due to its versatility and precision.

Now, let’s explore ultrasonic cutting in paper crafts, and how it compares to laser cutting.

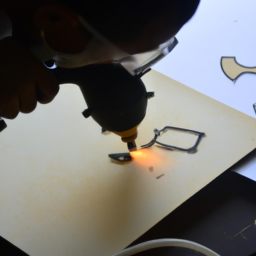

Exploring Ultrasonic Cutting in Paper Crafts

Ultrasonic cutting is a technique used in paper crafts that involves the use of high-frequency vibrations to cut through paper. This method offers several advantages, including precision cutting, minimal force required, and clean edges without fraying.

However, it also has limitations such as the inability to cut through thick materials and the potential for the vibration to cause damage to delicate designs.

What is Ultrasonic Cutting?

When it comes to paper crafts, ultrasonic cutting offers a unique and efficient way to achieve precise and clean cuts. Here are four reasons why ultrasonic cutting will revolutionize your paper crafting experience:

-

Speed: With ultrasonic cutting, you can complete intricate cuts in a fraction of the time it would take using traditional methods.

-

Precision: The ultrasonic vibrations create a clean and smooth cut, ensuring that your paper crafts look professional and polished.

-

Versatility: Ultrasonic cutting can be used on a wide range of materials, including delicate papers and cardstock, allowing you to explore various creative possibilities.

-

Less waste: Unlike other cutting techniques, ultrasonic cutting minimizes waste by producing minimal heat and avoiding unnecessary tearing or fraying.

With these advantages in mind, let’s delve into the subsequent section about the advantages of ultrasonic cutting.

Advantages of Ultrasonic Cutting

One of the key benefits of using ultrasonic cutting is its ability to achieve precise and clean cuts in a fraction of the time it would take with traditional methods. This makes it highly efficient for paper crafts and other delicate projects. Ultrasonic cutting works by using high-frequency vibrations to create a clean and accurate cut. Unlike laser cutting, which can sometimes cause discoloration or burn marks on the paper, ultrasonic cutting leaves no visible marks and maintains the integrity of the material. It is also highly versatile, allowing for intricate designs and complex shapes to be easily achieved.

| Advantages of Ultrasonic Cutting | ||

|---|---|---|

| Precise and clean cuts | Faster than traditional methods | No discoloration or burn marks on paper |

Limitations of Ultrasonic Cutting

To achieve precise and clean cuts in a fraction of the time, you’ll find that ultrasonic cutting has certain limitations. While ultrasonic cutting offers several advantages, there are challenges in implementing it in paper crafts.

Here are some limitations to consider:

-

Material Thickness: Ultrasonic cutting works best with thin materials, making it less effective for thicker papers or cardstocks.

-

Design Complexity: Intricate designs with fine details may pose difficulties for ultrasonic cutting as it may result in incomplete or uneven cuts.

-

Equipment Cost: Ultrasonic cutting machines can be expensive, making it a significant investment for crafters.

These limitations highlight the importance of considering the specific requirements of your paper craft projects before opting for ultrasonic cutting.

Moving on to the efficiency comparison: speed and precision, both laser cutting and ultrasonic cutting have their unique advantages in achieving optimal results.

Efficiency Comparison: Speed and Precision

When comparing the efficiency of laser cutting and ultrasonic cutting in paper crafts, it’s important to consider the speed and precision of each method. Laser cutting is known for its high speed, allowing for quick and efficient cutting of intricate designs.

On the other hand, ultrasonic cutting offers a different level of precision. It has the ability to cut through delicate materials with minimal damage.

Both methods have their own advantages, and it’s crucial to understand the specific requirements of your project to determine which method is more efficient for your needs.

Speed of Laser Cutting

The speed of laser cutting is like a sprinter racing towards the finish line, leaving ultrasonic cutting in the dust. Laser cutting efficiency is unmatched when it comes to speed. Here are three reasons why laser cutting is so fast:

-

High cutting speed: Laser cutting machines can move at incredibly high speeds, allowing them to swiftly cut through paper with precision. This rapid movement ensures that the job gets done in a fraction of the time compared to ultrasonic cutting.

-

Continuous cutting: Laser cutting operates using a continuous beam of light that doesn’t require frequent stops and starts. This uninterrupted process enables the laser cutter to swiftly glide through the paper without any delays, making it highly efficient.

-

Minimal setup time: Laser cutting machines have minimal setup requirements, allowing them to start cutting almost immediately. This quick setup time further adds to the overall speed and efficiency of the process.

With laser cutting’s exceptional speed, it’s no wonder that it outperforms ultrasonic cutting in terms of efficiency and productivity.

Now, let’s dive into the speed of ultrasonic cutting.

Speed of Ultrasonic Cutting

Ultrasonic cutting zooms through materials with remarkable speed and precision. When it comes to speed, ultrasonic cutting has the upper hand compared to laser cutting. The ultrasonic vibrations allow the cutting tool to quickly slice through the paper, creating clean and precise edges. The speed at which ultrasonic cutting works is due to its ability to rapidly oscillate the blade, making it glide effortlessly through the material.

To better understand the speed versus precision of these cutting techniques, let’s compare them in a table:

| Cutting Technique | Speed | Precision |

|---|---|---|

| Laser Cutting | Slower | High |

| Ultrasonic Cutting | Faster | High |

As we can see, ultrasonic cutting offers both speed and precision, making it an efficient choice for paper crafts. Now, let’s delve into the precision of laser cutting.

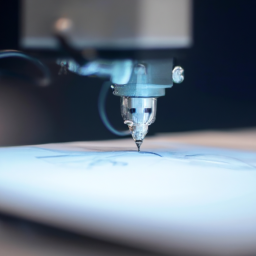

Precision of Laser Cutting

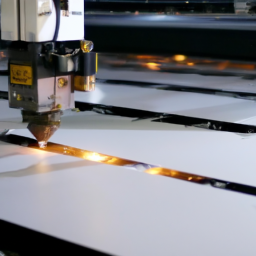

Imagine the precision you can achieve with laser cutting, allowing you to create intricate designs without any hassle. Laser cutting techniques involve using a high-powered laser beam to cut through materials with extreme accuracy. This precision is achieved by focusing the laser beam onto a small spot, resulting in clean and precise cuts.

Laser cutting is especially beneficial in paper crafts where precision is key. It allows you to create intricate and delicate designs that would be difficult to achieve with other cutting methods. With laser cutting, you can cut even the most intricate patterns with ease, ensuring that every detail is perfectly replicated. Laser cutting also minimizes the risk of tearing or damaging the paper, resulting in a cleaner and more professional finish.

Transitioning into the subsequent section about the precision of ultrasonic cutting, we can now explore the benefits of this alternative cutting method.

Precision of Ultrasonic Cutting

When it comes to precision, ultrasonic cutting is like a surgeon’s scalpel, effortlessly slicing through materials with incredible accuracy. Unlike laser cutting, which relies on a beam of light to burn through the material, ultrasonic cutting uses high-frequency vibrations to create a clean, precise cut. This method is particularly effective when working with delicate materials such as paper, as it minimizes the risk of tearing or distortion. However, it is important to note that ultrasonic cutting does have its limitations. The vibrations can cause friction, leading to heat generation, which may result in the melting or warping of certain materials. Additionally, the thickness of the material can affect the precision of the cut, with thinner materials being more susceptible to inaccuracies. Despite these limitations, ultrasonic cutting offers a comparable level of precision to laser cutting, making it a viable option for many paper craft projects. Moving on to cost considerations…

| Laser Cutting | Ultrasonic Cutting |

|---|---|

| Uses a beam of light to burn through material | Utilizes high-frequency vibrations |

| Requires precise calibration | Offers comparable precision to laser cutting |

| Ideal for intricate designs | Can cause heat generation and material melting or warping |

Now, let’s discuss the cost considerations…

Cost Considerations

When considering the cost of laser cutting, it’s important to take into account factors such as the initial investment in the machine, maintenance costs, and the cost of the laser itself.

On the other hand, ultrasonic cutting may have lower initial costs and maintenance requirements, but it may not be as precise as laser cutting.

When comparing the cost-effectiveness of these two methods, it’s crucial to weigh the benefits of precision and speed offered by laser cutting against the potentially lower costs associated with ultrasonic cutting.

Cost of Laser Cutting

To save money, you should consider the cost of laser cutting for your paper crafts. Laser cutting can be a cost-effective option due to several factors affecting cost.

Firstly, the precision of laser cutting allows for minimal material wastage, maximizing the utilization of your paper.

Secondly, laser cutting is a fast process, reducing labor costs and increasing productivity.

Additionally, the flexibility of laser cutting machines enables you to create intricate designs without the need for expensive dies or templates.

However, it’s important to note that the cost of laser cutting can vary depending on factors such as the size and thickness of the paper, complexity of the design, and the type of laser used.

These considerations will help you make an informed decision when comparing the cost of laser cutting to the cost of ultrasonic cutting.

Cost of Ultrasonic Cutting

The cost of ultrasonic cutting may initially seem higher due to the need for specialized equipment, but its efficiency and precision can ultimately lead to cost savings in the long run. Here are three reasons why ultrasonic cutting can be cost-effective and affordable:

-

Reduced material waste: Ultrasonic cutting uses high-frequency vibrations to create clean, precise cuts, which minimizes wasted materials. This means that you can maximize the use of your paper and reduce overall costs.

-

Increased production speed: Ultrasonic cutting is known for its fast cutting speed. This means that you can complete more projects in less time, increasing your productivity and potentially generating more revenue.

-

Low maintenance costs: Ultrasonic cutting machines are designed to be durable and require minimal maintenance. This translates to lower repair and replacement costs, making it a cost-effective option for long-term use.

Considering these factors, ultrasonic cutting proves to be a cost-effective choice for paper crafts.

In the subsequent section about cost-effectiveness comparison, we will explore how it compares to laser cutting in more detail.

Cost-effectiveness Comparison

If you’re looking for an affordable and efficient cutting method, considering the cost-effectiveness of ultrasonic cutting is essential. Ultrasonic cutting offers a budget-friendly solution for paper crafts, as it eliminates the need for expensive tooling or additional materials.

The cost effectiveness of ultrasonic cutting stems from its ability to cut through multiple layers of paper in a single pass, reducing production time and increasing efficiency. Additionally, the precision and accuracy of ultrasonic cutting ensure minimal material waste, further contributing to its cost-saving advantage.

When comparing the cost-effectiveness of laser cutting and ultrasonic cutting in paper crafts, it becomes evident that ultrasonic cutting provides a more economical option. This budget analysis allows crafters to allocate their resources wisely, ensuring maximum efficiency and quality in their projects.

Transitioning to the subsequent section about application and versatility, it’s important to explore the various ways ultrasonic cutting can enhance paper crafting techniques.

Application and Versatility

Imagine wielding a laser cutter or an ultrasonic cutter as your creative weapon of choice, slicing through paper with the precision of a surgeon’s scalpel. Both tools offer unique advantages when it comes to application and versatility in paper crafts.

Here are four key points to consider:

-

Application limitations: Laser cutting works best with thin materials and intricate designs, making it ideal for creating delicate paper art pieces or intricate patterns. Ultrasonic cutting, on the other hand, is better suited for thicker materials and straight cuts, making it more suitable for tasks like trimming edges or making clean, precise lines.

-

Material compatibility: Laser cutting can be used on a wide range of materials, including paper, cardboard, and even some plastics. Ultrasonic cutting, however, is primarily designed for cutting paper and may not be as effective on other materials.

-

Speed and efficiency: Laser cutting is generally faster and more efficient than ultrasonic cutting, allowing you to complete your projects more quickly. Ultrasonic cutting, while not as fast, offers the advantage of producing less heat, which can be beneficial when working with sensitive materials.

-

Versatility: Laser cutting machines often come with additional features like engraving and etching capabilities, allowing for more diverse creative possibilities. Ultrasonic cutters, on the other hand, are more specialized tools focused solely on cutting.

Understanding the application limitations and material compatibility of laser cutting and ultrasonic cutting is crucial in making the right choice for your paper crafting needs.

Transitioning into the next section, let’s explore the factors to consider when determining the most efficient cutting method for your specific projects.

Making the Right Choice

When it comes to choosing the best method for your paper crafting projects, it’s important to consider factors like application limitations, material compatibility, speed and efficiency, and versatility. Making the right choice between laser cutting and ultrasonic cutting depends on your specific needs and preferences.

Laser cutting is known for its precision and ability to create intricate designs. It is a great choice for projects that require intricate details and fine cuts. However, laser cutting may not be suitable for all types of paper and can sometimes cause scorching or burning.

On the other hand, ultrasonic cutting uses high-frequency vibrations to cut through the paper. It is a versatile option that can handle various types of paper and is less likely to cause damage. However, it may not provide the same level of precision as laser cutting.

To help you make an informed decision, here is a comparison table highlighting the key factors to consider when choosing between laser cutting and ultrasonic cutting for your paper crafts:

| Factors to Consider | Laser Cutting | Ultrasonic Cutting |

|---|---|---|

| Precision | High | Moderate |

| Material Compatibility | Limited | Wide Range |

| Speed and Efficiency | Fast | Moderate |

| Versatility | Limited | High |

Consider your specific project requirements and weigh the pros and cons of each method to make the right choice for your paper crafting needs.

Frequently Asked Questions

Are there any safety concerns associated with laser cutting in paper crafts?

When it comes to laser cutting in paper crafts, there are a few safety concerns to keep in mind. One major concern is the potential for burns or fires if the laser isn’t used properly.

Additionally, laser cutting can release toxic fumes, so proper ventilation is essential. However, laser cutting does have its advantages, such as precise and intricate cuts.

It’s important to weigh these safety concerns against the benefits before using laser cutting in your paper crafts.

What types of materials can be cut using ultrasonic cutting in paper crafts?

Ultrasonic cutting in paper crafts offers a wide range of materials that can be cut with precision. This method is suitable for cutting materials like paper, cardboard, fabric, and foam. The advantages of ultrasonic cutting in paper crafts over traditional methods are numerous.

It provides cleaner cuts, reduces fraying, and minimizes the risk of damage to delicate materials. Additionally, ultrasonic cutting allows for faster and more efficient production, making it a preferred choice for many crafters.

How does the speed of laser cutting compare to ultrasonic cutting in paper crafts?

When comparing the laser cutting speed with ultrasonic cutting in paper crafts, the former is generally faster. Laser cutting operates at a high speed, allowing for precise and efficient cuts.

In contrast, ultrasonic cutting can be slower due to the nature of the process, which involves vibrations to cut through the material.

While both methods have their advantages, laser cutting is often favored for its quicker speed, making it a popular choice in paper craft applications.

Are there any limitations to the precision of laser cutting in paper crafts?

When it comes to the precision of laser cutting in paper crafts, there are some limitations to keep in mind. Laser cutting is incredibly precise, but it can struggle with intricate designs or thin materials because the heat from the laser can cause them to warp or burn. On the other hand, ultrasonic cutting offers benefits such as clean cuts and minimal heat, making it ideal for delicate projects. So, depending on your specific needs, ultrasonic cutting may be a better choice for achieving precise results in paper crafts.

How does the cost of laser cutting compare to ultrasonic cutting in paper crafts?

When comparing the cost of laser cutting and ultrasonic cutting in paper crafts, a cost comparison and efficiency analysis is important.

Laser cutting often requires expensive equipment and maintenance costs, which can make it more costly upfront. On the other hand, ultrasonic cutting typically involves lower equipment and maintenance costs.

However, it’s important to consider the efficiency of each method as well, as laser cutting may offer faster and more precise results, potentially reducing overall production costs in the long run.

Conclusion

So, when it comes to laser cutting vs. ultrasonic cutting in paper crafts, the choice ultimately depends on your specific needs and preferences. Both methods offer unique advantages and can produce precise and intricate cuts.

While laser cutting may be faster and more widely available, ultrasonic cutting provides a quieter and more gentle approach. Cost considerations also play a role, with laser cutting typically being more expensive upfront.

However, it’s important to remember that the versatility and application of both methods make them valuable tools in the world of paper crafts. So, don’t be afraid to embrace either technique and let your creativity soar!