In the realm of paper crafts, where precision and efficiency are paramount, the choice between laser cutting and ultrasonic cutting can be as delicate as the materials themselves. Like two skilled artisans wielding their tools, these cutting methods each possess unique qualities that set them apart.

Imagine, if you will, the laser as a meticulous conductor, its beam of light orchestrating intricate cuts with surgical precision. On the other hand, the ultrasonic cutter acts as a nimble sculptor, its vibrating blade effortlessly gliding through layers of paper with finesse.

As you embark on your paper crafting journey, it is essential to understand the nuances of these cutting techniques and their impact on efficiency. This article aims to unravel the intricacies of laser cutting and ultrasonic cutting, comparing their speed, precision, cost considerations, safety, and environmental impact.

Armed with this knowledge, you will be equipped to make an informed decision and elevate your paper crafting endeavors to new heights.

Key Takeaways

- Laser cutting offers precise and intricate designs with clean and accurate cuts, while ultrasonic cutting generates delicate cuts with no burnt edges.

- Laser cutting is faster and more efficient than ultrasonic cutting, with cutting speeds measured in meters per second compared to centimeters per second for ultrasonic cutting.

- Laser cutting provides unparalleled precision with minimal material waste, but it can be expensive and generate heat. Ultrasonic cutting, on the other hand, is versatile and can handle a wide range of materials but may not be suitable for thick or hard materials.

- Laser cutting produces toxic fumes and generates waste in the form of offcuts and debris, while ultrasonic cutting does not release harmful gases or fumes and produces minimal waste.

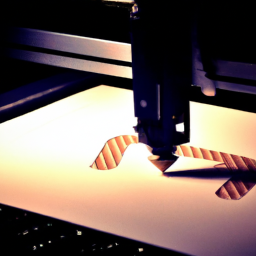

Understanding Laser Cutting in Paper Crafts

If you want to take your paper crafts to the next level, laser cutting is the game-changing technique you need to know about. Laser cutting offers several advantages in paper crafts.

Firstly, it allows for precise and intricate designs, ensuring clean and accurate cuts every time. The laser beam can easily navigate corners and curves, resulting in a polished finished product.

Additionally, laser cutting is a fast and efficient process, saving both time and effort. However, there are some disadvantages to consider. Laser cutting can be expensive, as the equipment and maintenance costs are high. Moreover, the laser can generate heat, which may cause the paper to warp or burn if not handled properly.

Despite these drawbacks, laser cutting remains a popular choice for paper craft enthusiasts.

Now, let’s explore ultrasonic cutting in paper crafts.

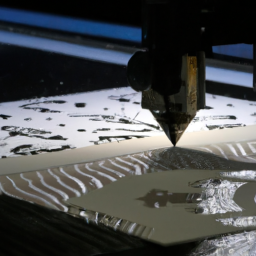

Exploring Ultrasonic Cutting in Paper Crafts

In this discussion, we’ll explore the key points of ultrasonic cutting in paper crafts. You’ll learn about how ultrasonic cutting works and the pros and cons of using this technique. We’ll also discuss the various applications it has in the world of paper crafts. Understanding the intricacies of ultrasonic cutting will help you make informed decisions about its efficiency and suitability for your specific paper craft projects.

How Ultrasonic Cutting Works

To understand how ultrasonic cutting works, picture yourself as a paper artist wielding a magical blade that effortlessly glides through sheets of paper with the precision of a surgeon. Ultrasonic cutting offers several advantages over other cutting methods, particularly in the realm of paper crafts. Here are some key points to consider:

-

Reduced heat transfer: Ultrasonic cutting generates less heat compared to laser cutting, resulting in minimal distortion or discoloration of the paper.

-

Delicate cuts: The ultrasonic vibrations create clean and precise cuts, even on intricate designs, ensuring high cutting quality.

-

No burnt edges: Unlike laser cutting, ultrasonic cutting does not leave behind any burnt edges, preserving the aesthetic appeal of the paper craft.

-

Versatile cutting capabilities: Ultrasonic cutting can handle a wide range of materials, including delicate papers and fabrics, expanding the possibilities for creative designs.

Understanding the advantages of ultrasonic cutting sets the stage for a comprehensive evaluation of its pros and cons in the subsequent section.

Pros and Cons of Ultrasonic Cutting

Ultrasonic cutting offers both advantages and disadvantages, so it’s important to weigh the pros and cons before deciding if it’s the right cutting method for your creative projects.

One major advantage of ultrasonic cutting is its ability to cut through various materials with precision and speed. It produces clean and smooth edges, reducing the need for additional finishing.

However, there are limitations to consider. Ultrasonic cutting is not suitable for thick or hard materials, as it may cause chipping or damage. It also requires a specific setup and can be costly compared to other cutting methods.

Despite these limitations, ultrasonic cutting has various applications in paper crafts. Transitioning into the subsequent section, let’s explore the applications of ultrasonic cutting in paper crafts.

Applications of Ultrasonic Cutting in Paper Crafts

With the gentle touch of an artist’s hand, the ultrasonic blade dances through delicate paper, creating intricate designs that seem to come alive on the page. The advantages of ultrasonic cutting in paper crafts are numerous.

Firstly, the ultrasonic vibrations allow for precise and intricate cuts, enabling the creation of complex designs that would be difficult to achieve with other cutting methods.

Additionally, the non-contact nature of ultrasonic cutting eliminates the risk of damage or distortion to the paper, ensuring a clean and flawless result.

Furthermore, ultrasonic cutting techniques can be used to create embossed patterns, adding texture and depth to paper crafts.

Transitioning into the subsequent section about efficiency comparison, the speed and precision of ultrasonic cutting make it a highly efficient choice for paper crafts.

Efficiency Comparison: Speed and Precision

When comparing laser cutting and ultrasonic cutting in paper crafts, it’s important to consider the speed and precision of each method.

Laser cutting is known for its high speed, allowing for quick and efficient cuts in paper.

On the other hand, ultrasonic cutting offers superior precision, ensuring clean and accurate cuts.

Additionally, there are several factors that can affect the efficiency of these cutting methods in paper crafts, such as the type of paper being used, the thickness of the material, and the complexity of the design.

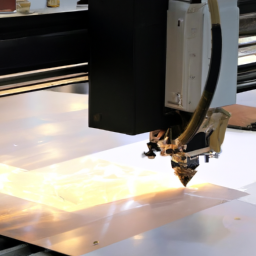

Speed of Laser Cutting vs. Ultrasonic Cutting

Imagine how much time you can save by using laser cutting instead of ultrasonic cutting in your paper crafts. The speed of laser cutting far surpasses that of ultrasonic cutting, making it a more efficient option.

Let’s compare the cutting speeds:

-

Laser cutting speed: Laser cutting machines are capable of cutting at incredibly high speeds, often reaching up to several meters per second. This rapid cutting speed allows for efficient production, especially when dealing with large quantities of paper crafts.

-

Ultrasonic cutting speed: On the other hand, ultrasonic cutting operates at a relatively slower pace. While it’s still faster than traditional manual cutting methods, it can’t match the speed of laser cutting. The cutting speed of ultrasonic cutting machines is typically measured in centimeters per second.

-

Comparison of cutting speeds: When comparing the cutting speeds of laser cutting and ultrasonic cutting, laser cutting clearly emerges as the winner in terms of efficiency and time-saving capabilities.

As we transition into the subsequent section about the precision of laser cutting vs. ultrasonic cutting, it’s important to consider how these two methods differ in terms of accuracy and intricacy.

Precision of Laser Cutting vs. Ultrasonic Cutting

Now that you have a clear understanding of the speed differences between laser cutting and ultrasonic cutting, let’s delve into the precision aspect.

Laser cutting offers unparalleled precision due to its focused beam of light, which can achieve intricate and complex designs with remarkable accuracy. The laser cutting process ensures clean and precise cuts, resulting in minimal material waste.

On the other hand, ultrasonic cutting also provides a high level of precision, but it may not match the accuracy of laser cutting when it comes to intricate designs. Despite this, ultrasonic cutting offers its own advantages, such as the ability to cut through multiple layers of paper at once and the absence of heat, which eliminates the risk of burnt edges.

Transitioning into the subsequent section about factors affecting efficiency in paper crafts, we will explore the impact of material thickness and complexity on the cutting process.

Factors Affecting Efficiency in Paper Crafts

To maximize efficiency in your paper crafts, it’s important to consider the impact of material thickness and complexity on the cutting process. These factors can significantly affect the speed and accuracy of both laser cutting and ultrasonic cutting techniques. With recent technology advancements, both methods have become more efficient, but understanding the factors that influence their efficiency is crucial.

In the table below, we compare the impact of material thickness and complexity on the efficiency of laser cutting and ultrasonic cutting in paper crafts:

| Factors | Laser Cutting | Ultrasonic Cutting |

|---|---|---|

| Material Thickness | Effective for thin to medium thicknesses | Suitable for thin to thick thicknesses |

| Complexity | Excellent for intricate designs | Limited by the complexity of the design |

As shown in the table, laser cutting is more effective for thin to medium thicknesses, while ultrasonic cutting is suitable for a wider range of thicknesses. Laser cutting excels in handling intricate designs, whereas ultrasonic cutting is limited by the complexity of the design.

Considering these factors affecting efficiency and the impact of technology advancements, it is essential to take into account the cost considerations of equipment and maintenance in the subsequent section.

Cost Considerations: Equipment and Maintenance

When it comes to cost considerations, you’ll be delighted to know that laser cutting and ultrasonic cutting in paper crafts offer affordable equipment and low maintenance requirements.

Equipment cost is a significant factor to consider when choosing a cutting method for paper crafts. Laser cutting machines can range in price depending on the power and features, but there are affordable options available for hobbyists and small businesses. Ultrasonic cutting equipment is also relatively affordable, making it accessible to a wide range of users.

Additionally, both methods have low maintenance requirements, which helps reduce ongoing costs. This makes laser cutting and ultrasonic cutting cost-effective choices for paper craft enthusiasts.

Moving forward, it is important to consider the safety and environmental impact of these cutting methods.

Safety and Environmental Impact

When it comes to laser cutting, safety measures are crucial to ensure the well-being of operators and prevent accidents. These measures include wearing protective eyewear and clothing, as well as implementing proper ventilation systems to control the release of fumes and particles.

Similarly, ultrasonic cutting also requires safety precautions such as using gloves and protective gear to prevent injuries, and ensuring proper ventilation to minimize exposure to airborne particles.

In terms of environmental considerations, both methods have their impact, with laser cutting producing toxic fumes and ultrasonic cutting generating noise pollution.

Safety Measures for Laser Cutting

One important aspect to consider when discussing safety measures for laser cutting is the use of protective eyewear. Laser beams can cause severe eye injuries, so it is crucial to wear appropriate eyewear that provides adequate protection. Additionally, operators should receive proper training on laser safety, including understanding the potential hazards and how to operate the equipment safely. Another important safety measure is ensuring proper ventilation in the laser cutting area. Laser cutting produces smoke and fumes, which can be harmful if inhaled. Adequate ventilation systems should be in place to remove these pollutants from the air.

| Safety Measures for Laser Cutting | |

|---|---|

| Use protective eyewear | Receive proper training on laser safety |

| Ensure proper ventilation in the cutting area |

It is essential to implement these safety measures to minimize the risks associated with laser cutting. Moving forward, let’s explore the safety measures for ultrasonic cutting.

Safety Measures for Ultrasonic Cutting

To ensure a safe and efficient process, it’s crucial to implement specific safety measures when using ultrasonic cutting technology.

Safety precautions must be taken to protect both the operator and the surrounding environment. First and foremost, proper training is essential to ensure that operators are knowledgeable about the equipment and its potential risks.

Additionally, the use of protective gear is vital. This includes wearing safety glasses to protect the eyes from flying debris and earplugs to minimize exposure to loud noises.

It’s also important to have a well-ventilated workspace to prevent the accumulation of fumes or dust particles. These safety measures will help mitigate any potential hazards associated with ultrasonic cutting.

Moving on to environmental considerations for both methods, it’s important to address the impact of these cutting technologies on the surrounding ecosystem.

Environmental Considerations for Both Methods

Now that you understand the safety measures required for ultrasonic cutting, let’s delve into the environmental considerations for both laser cutting and ultrasonic cutting methods.

When it comes to laser cutting, one must consider the environmental impact it poses. The process emits harmful gases and fumes, which can contribute to air pollution. Additionally, laser cutting generates waste in the form of offcuts and debris, which can be difficult to dispose of responsibly.

On the other hand, ultrasonic cutting offers a more environmentally-friendly alternative. This method produces minimal waste due to its precise cutting, resulting in reduced material consumption. Furthermore, ultrasonic cutting does not release harmful gases or fumes, making it a cleaner option.

With these environmental factors in mind, you can now make an informed decision on which method aligns best with your paper crafting needs.

Making an Informed Decision

When it comes to making an informed decision about laser cutting vs. ultrasonic cutting in paper crafts, you need to consider various factors.

One of the most important factors is making a cost-effective choice. Laser cutting machines are generally more expensive than ultrasonic cutting machines, both in terms of initial investment and ongoing maintenance costs. However, laser cutting offers higher precision and speed, which can result in increased productivity and potentially offset the initial investment.

Additionally, factors such as the desired level of intricacy in the paper cuts, the materials being used, and the volume of production should be considered before deciding between laser cutting and ultrasonic cutting.

By carefully evaluating these factors, you can make an informed decision that aligns with your budget and requirements.

Frequently Asked Questions

What are the main differences between laser cutting and ultrasonic cutting in paper crafts?

When comparing laser cutting and ultrasonic cutting in paper crafts, the main differences lie in their pros, cons, and benefits.

Laser cutting offers precise and intricate designs, but it can cause paper discoloration and burn edges.

On the other hand, ultrasonic cutting excels in delicate and intricate paper designs, without any heat or discoloration issues.

Both techniques have their advantages, so choosing one depends on the specific requirements of your paper craft project.

Does laser cutting produce cleaner and more precise cuts compared to ultrasonic cutting?

Laser cutting offers significant advantages over ultrasonic cutting when it comes to producing cleaner and more precise cuts. The precision of laser cutting is unmatched, as it uses a focused laser beam to melt or vaporize the material with extreme accuracy. On the other hand, ultrasonic cutting relies on vibrations to create cuts, which can result in less precise edges.

Therefore, if you prioritize clean and precise cuts, laser cutting is the superior choice.

Are there any specific types of paper or materials that are better suited for laser cutting or ultrasonic cutting?

When it comes to laser cutting or ultrasonic cutting in paper crafts, it’s important to consider the types of paper or materials that are better suited for each technique.

Laser cutting is highly effective on materials such as cardstock, cardboard, and thin papers, as it provides clean and precise cuts.

On the other hand, ultrasonic cutting is more suitable for thicker materials like foam board or corrugated cardboard, offering efficient and accurate results.

Both techniques have their own benefits and applications in paper crafts.

How expensive is the equipment required for laser cutting and ultrasonic cutting in paper crafts?

The cost comparison of laser cutting and ultrasonic cutting equipment in paper crafts depends on various factors. Laser cutting machines are generally more expensive upfront, ranging from a few thousand dollars to tens of thousands of dollars. However, they offer high precision and versatility, making them suitable for intricate designs.

On the other hand, ultrasonic cutting equipment is typically more affordable, with prices starting from a few hundred dollars. While it may not offer the same level of precision, it is effective for cutting through thicker materials.

Overall, the cost of the equipment for both methods should be considered alongside the specific requirements and budget of the user.

What are the safety precautions that need to be taken when using laser cutting or ultrasonic cutting in paper crafts?

When using laser cutting or ultrasonic cutting in paper crafts, it’s important to take certain safety precautions. For laser cutting, you should always wear protective eyewear to shield your eyes from the intense laser beam. Additionally, ensure that the work area is well-ventilated to prevent the accumulation of harmful fumes.

When using ultrasonic cutting, be cautious of the high-frequency vibrations and avoid touching the cutting blade directly to prevent injuries. It’s crucial to follow these safety measures to avoid any accidents or harm while working with these cutting techniques.

Now, let’s compare laser cutting and ultrasonic cutting in paper crafts in terms of efficiency.

Conclusion

Based on the efficiency comparison, cost considerations, and safety and environmental impact, it’s clear that laser cutting is the more efficient choice for paper crafts.

With its precise and rapid cutting capability, laser cutting outshines ultrasonic cutting in terms of speed and precision.

Additionally, the lower equipment and maintenance costs make laser cutting a more financially viable option.

Moreover, laser cutting’s minimal impact on the environment and its safety features make it a responsible choice for crafters.

So, when it comes to paper crafts, laser cutting is the shining star, cutting through the competition like a finely tuned scalpel through delicate paper.