Are you tired of the same old methods of cutting wood in your woodworking projects? Well, fret no more! We have a riveting comparison for you that will surely leave you on the edge of your seat.

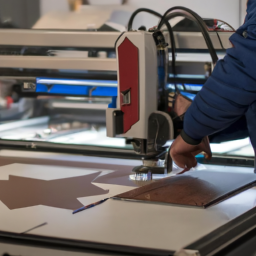

Introducing laser cutting and ultrasonic cutting, two cutting-edge techniques that are revolutionizing the woodworking industry.

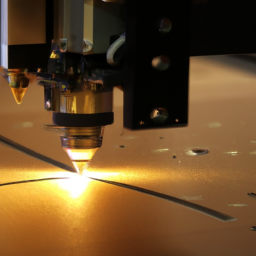

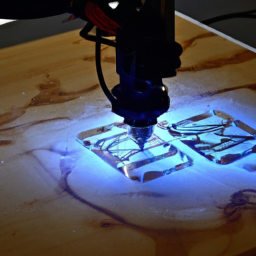

Laser cutting, the superhero of precision, uses a high-powered laser beam to effortlessly slice through wood with utmost accuracy.

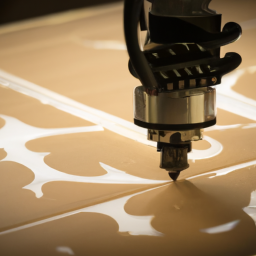

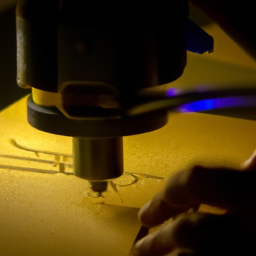

On the other hand, ultrasonic cutting, the stealthy ninja, utilizes high-frequency vibrations to seamlessly glide through any wooden material.

But which technique reigns supreme in terms of efficiency? In this epic battle, we will explore the intricacies of laser cutting and ultrasonic cutting, comparing their efficiency, cost-effectiveness, and application considerations.

So buckle up and prepare to be amazed as we delve into the captivating world of laser cutting vs. ultrasonic cutting in woodworking. Get ready to witness woodworking at its finest!

Key Takeaways

- Laser cutting offers unmatched precision and can cut through wood, plastic, and metal.

- Ultrasonic cutting can handle delicate and intricate designs without causing damage.

- Laser cutting is faster and more precise than ultrasonic cutting.

- Ultrasonic cutting produces clean and smooth edges, eliminating the need for additional finishing work.

Understanding Laser Cutting

If you’re looking for a precise and fast cutting method, laser cutting is the way to go. Laser cutting offers numerous advantages that make it a popular choice in woodworking.

One major advantage is its unmatched precision. With laser cutting, you can achieve incredibly fine details and intricate designs that would be difficult to achieve with other cutting methods. Additionally, laser cutting is highly efficient and can cut through various materials with ease, including wood, plastic, and metal. This makes it a versatile tool for a wide range of woodworking applications.

Whether you need to create intricate patterns or make precise cuts, laser cutting provides the accuracy and speed you need.

Now, let’s explore ultrasonic cutting and see how it compares to laser cutting.

Exploring Ultrasonic Cutting

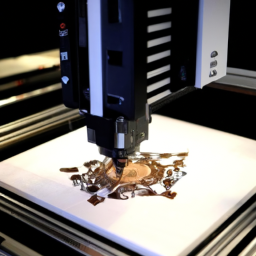

To explore ultrasonic cutting, you’ll be amazed by the precision and speed it offers in the world of woodworking. Ultrasonic cutting utilizes high-frequency vibrations to cut through various materials with incredible accuracy.

One of the major advantages of ultrasonic cutting is its ability to handle delicate and intricate designs with ease. It can effortlessly cut through materials like wood, plastics, and even foam without causing any damage or distortion. Additionally, ultrasonic cutting produces clean, smooth edges, eliminating the need for additional finishing work.

However, it does have some limitations. Ultrasonic cutting is not suitable for cutting thick materials, as it may struggle to penetrate them effectively. Furthermore, it may not be as effective when working with certain types of hardwood.

Transitioning to the subsequent section about comparing efficiency, it’s important to consider these advantages and limitations when evaluating the efficiency of ultrasonic cutting.

Comparing Efficiency

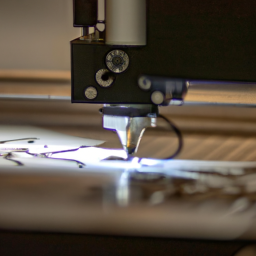

When comparing the efficiency of laser cutting and ultrasonic cutting in woodworking, it’s important to consider the speed and precision of each method.

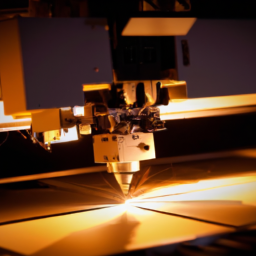

Laser cutting is known for its high speed and precise cuts, as it uses a laser beam to melt or burn through the material.

On the other hand, ultrasonic cutting utilizes high-frequency vibrations to slice through the wood, offering a different level of speed and precision.

Factors such as the type of wood, thickness, and desired outcome should also be taken into account when determining the efficiency of these cutting methods.

Speed and Precision of Laser Cutting

For faster and more precise woodworking cuts, laser cutting outperforms ultrasonic cutting every time. Here’s why:

-

Laser cutting techniques allow for intricate and detailed designs to be easily achieved, thanks to the high precision of the laser beam.

-

The speed of laser cutting is unmatched, as it can cut through wood with incredible efficiency, reducing production time significantly.

-

Laser cutting minimizes the risk of material damage, as the heat generated is localized and controlled, preventing warping or charring.

-

With laser cutting, there’s no need for additional finishing processes, such as sanding or smoothing, as the cuts are clean and precise.

With these advantages, laser cutting proves to be the superior choice for woodworking when it comes to speed and precision. However, let’s now explore the speed and precision of ultrasonic cutting to gain a comprehensive understanding of both methods.

Speed and Precision of Ultrasonic Cutting

Experience the incredible speed and precision of ultrasonic cutting, revolutionizing the world of woodworking with its unparalleled efficiency and accuracy.

Ultrasonic cutting offers several advantages over laser cutting. Firstly, it operates at high speeds, allowing for faster production times and increased productivity. Additionally, the ultrasonic cutting technology ensures precise and clean cuts, resulting in minimal material waste and reduced need for post-processing.

However, it is important to note that ultrasonic cutting does have its limitations. It is best suited for cutting softer materials such as wood and foam, as it may struggle with harder materials. Furthermore, the cutting depth is limited compared to laser cutting, which may be a factor to consider in certain applications.

Transitioning into the subsequent section about factors to consider in efficiency, it is important to assess the specific requirements and materials involved in woodworking projects.

Factors to Consider in Efficiency

Now that you understand the speed and precision of ultrasonic cutting, let’s delve into the factors to consider in efficiency.

When it comes to choosing between laser cutting and ultrasonic cutting in woodworking, there are several key elements to take into account. First, the type of material being cut plays a crucial role in determining the optimal cutting method.

Second, the complexity of the design and the intricacy of the cuts required can also impact the efficiency of each technique.

Lastly, the desired production volume needs to be considered to ensure that the chosen method can meet the required output.

By carefully evaluating these factors and selecting the optimal cutting conditions, you can maximize the efficiency of your woodworking process.

Now, let’s move on to the next section and explore the cost comparison between laser cutting and ultrasonic cutting.

Cost Comparison

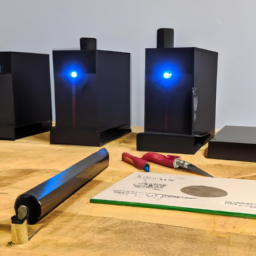

Ultimately, laser cutting proves to be more cost-efficient than ultrasonic cutting in woodworking. While the initial investment for laser cutting equipment may be higher, the long-term savings outweigh the initial cost. Laser cutting machines have a longer lifespan and require less maintenance compared to ultrasonic cutting machines. Additionally, laser cutting is more precise and can produce intricate designs with minimal material waste, reducing overall production costs. To illustrate the cost comparison, consider the following table:

| Factor | Laser Cutting | Ultrasonic Cutting |

|---|---|---|

| Initial Investment | High | Moderate |

| Maintenance Costs | Low | Moderate |

| Material Waste | Low | High |

| Longevity | High | Moderate |

As seen in the table, laser cutting offers cost effectiveness and long-term savings in woodworking. Moving forward, it is important to consider application considerations when deciding between laser cutting and ultrasonic cutting methods.

Application Considerations

When considering the application of laser cutting or ultrasonic cutting in woodworking, there are several key points to take into account.

Firstly, it is important to determine the suitable wood types for each cutting method. Laser cutting is generally more suitable for woods that are non-reflective and have a consistent density, while ultrasonic cutting can be used on a wider range of wood types.

Additionally, complex designs and intricate cuts can be achieved with both methods, but the level of precision and intricacy may vary.

Suitable Wood Types for Laser Cutting

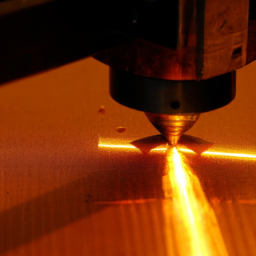

Choose the right wood types for laser cutting, and you’ll unlock a world of endless possibilities and intricate designs. When it comes to laser cutting, wood density and moisture content are crucial factors to consider.

Wood with a lower density, such as balsa or pine, is generally easier to cut with a laser due to its softer composition. On the other hand, woods with higher density, like oak or mahogany, may require more power and slower cutting speeds to achieve clean cuts.

Additionally, it is important to ensure that the wood has an appropriate moisture content, as excessively dry or wet wood can cause issues during laser cutting.

With the right wood types, laser cutting can produce precise and intricate designs effortlessly.

Now, let’s explore the suitable wood types for ultrasonic cutting.

Suitable Wood Types for Ultrasonic Cutting

Ready to explore the types of wood that work best for ultrasonic cutting? Let’s dive in and discover the perfect materials for your crafting projects!

Ultrasonic cutting, as compared to traditional cutting methods, offers several advantages in woodworking. One of the key benefits is that it can be used on a wide range of wood types. Whether you’re working with softwoods like pine and cedar, or hardwoods like oak and mahogany, ultrasonic cutting can effectively handle them all.

The precise and controlled vibrations produced by ultrasonic cutting allow for clean and precise cuts, making it suitable for intricate designs and complex patterns. This makes it a versatile option for woodworkers who want to achieve intricate cuts without compromising on efficiency.

Now, let’s move on to the next section and explore how ultrasonic cutting performs with complex designs and intricate cuts.

Complex Designs and Intricate Cuts

If you’re looking to create intricate designs and achieve precise cuts in your woodworking projects, ultrasonic cutting is the way to go!

Did you know that ultrasonic cutting can achieve a cutting accuracy of up to 0.1mm, ensuring that your intricate patterns come out flawlessly? Ultrasonic cutting is particularly well-suited for artistic projects that require intricate designs and delicate cuts. It allows you to create complex patterns and shapes with ease, making it a popular choice for artists and designers.

On the other hand, laser cutting is more commonly used in furniture making, where precision and speed are crucial. While laser cutting can also achieve precise cuts, it may not be as suitable for intricate designs as ultrasonic cutting.

So, if you’re looking to create intricate patterns and achieve flawless cuts, ultrasonic cutting is the perfect choice for your woodworking projects.

Frequently Asked Questions

What are the safety precautions that need to be taken when using laser cutting in woodworking?

To ensure safety when using laser cutting in woodworking, there are several important precautions to take. First, always wear appropriate personal protective equipment, including safety glasses and gloves.

Additionally, ensure that the work area is well-ventilated to prevent the buildup of fumes. It is crucial to follow the manufacturer’s guidelines and properly maintain the equipment.

Regular inspections and training for operators are also essential. By adhering to these safety measures and equipment requirements, you can minimize the risk of accidents and injuries.

Can laser cutting be used on all types of wood?

Yes, laser cutting can be used on a wide range of wood types, making it a versatile choice for woodworking. However, it’s important to note that not all woods are suitable for laser cutting applications.

Dense hardwoods like oak and maple are ideal for laser cutting, as they provide clean and precise cuts. Softer woods like pine and cedar can also be used, but they may require adjustments in the laser settings to avoid charring or burning.

How does ultrasonic cutting differ from traditional sawing methods?

Ultrasonic cutting differs from traditional sawing methods in several ways. Firstly, it offers significant advantages over sawing in terms of precision and speed. Ultrasonic cutting uses high-frequency vibrations to create clean, precise cuts, resulting in minimal material waste.

Additionally, it operates at a much higher speed compared to traditional sawing methods, allowing for faster production times. These factors make ultrasonic cutting a superior choice for industries that require high precision and efficiency in their cutting processes.

Are there any limitations to the thickness of wood that can be cut using ultrasonic cutting?

When it comes to ultrasonic cutting in woodworking, there are indeed limitations to the thickness of wood that can be cut. Ultrasonic cutting is best suited for thinner materials, typically up to 25mm in thickness.

This is due to the nature of the technology, which relies on high-frequency vibrations to cut through materials. On the other hand, laser cutting offers certain advantages in woodworking, such as the ability to cut through thicker materials and a higher precision in intricate designs.

What are some other industries where laser cutting and ultrasonic cutting are commonly used?

In the medical field, laser cutting and ultrasonic cutting are commonly used for various applications. Laser cutting is used in surgeries to precisely cut tissues and remove tumors. Ultrasonic cutting, on the other hand, is used in dental procedures to cut through hard materials like bone.

In the automotive industry, laser cutting is used to fabricate precise and intricate components, while ultrasonic cutting is used for trimming and cutting materials like plastic and fabric.

Both technologies offer efficient and precise cutting solutions in these industries.

Conclusion

In conclusion, when it comes to laser cutting vs. ultrasonic cutting in woodworking, laser cutting takes the crown for efficiency. It makes woodworking a breeze with its precise and thorough cuts. Plus, the cost comparison is a no-brainer, as laser cutting proves to be more cost-effective in the long run.

While ultrasonic cutting has its merits, it simply can’t compete with the power and speed of laser cutting. So why settle for anything less than the most efficient option? Choose laser cutting and experience woodworking like never before.