Did you know that acrylic is one of the most popular materials for creating intricate designs? It’s true, and if you’re considering acrylic for your next project, you’ll need to decide between laser cutting and waterjet cutting. Both methods offer precise and detailed results, but which one is right for you?

According to recent statistics, laser cutting is the preferred choice for 75% of acrylic design projects. Laser cutting uses a high-powered laser to vaporize or melt the acrylic, resulting in clean and precise cuts.

On the other hand, waterjet cutting uses a high-pressure stream of water mixed with abrasive materials to cut through the acrylic. This method is known for its ability to cut through thick materials and create intricate shapes.

In this article, we will explore the basics of laser cutting and the benefits of waterjet cutting, consider your project requirements, compare speed and efficiency, evaluate cost factors, and help you make an informed decision about which method is right for your acrylic designs.

Key Takeaways

- Laser cutting is preferred for 75% of acrylic design projects due to its precision and efficiency.

- Waterjet cutting is ideal for thicker and more intricate acrylic designs.

- Laser cutting offers higher precision and detail, making it suitable for thin sheets and intricate designs.

- Laser cutting is generally faster and more cost-effective, while waterjet cutting can handle thicker materials but may take longer and generate more waste.

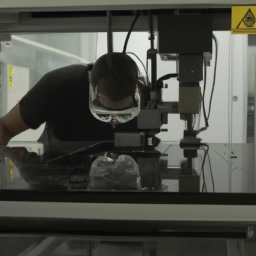

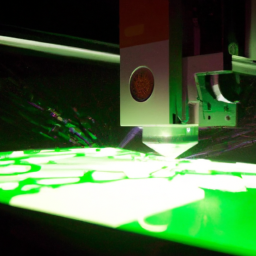

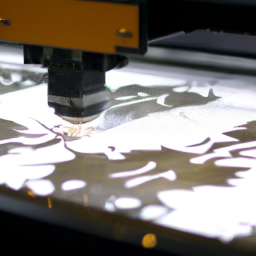

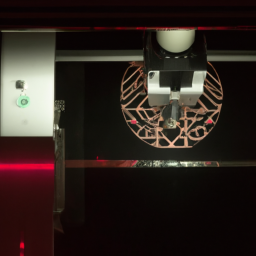

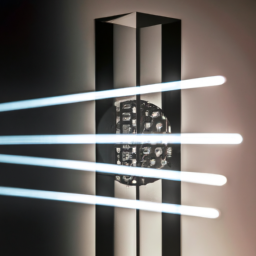

Understand the Basics of Laser Cutting

Laser cutting is a highly precise and efficient method for cutting acrylic designs. It uses laser cutting techniques to direct a high-powered laser beam onto the acrylic material. The laser melts and vaporizes the material along the desired cutting path, resulting in clean, smooth edges with minimal heat-affected zones. Laser cutting has a wide range of applications, including signage, architectural models, and custom jewelry. It is particularly popular in the art and design industry due to its ability to produce intricate designs and fine details. Additionally, laser cutting offers quick turnaround times and high production rates, making it a cost-effective option for large-scale projects.

Now, let’s explore the benefits of waterjet cutting, another popular method for cutting acrylic designs.

Explore the Benefits of Waterjet Cutting

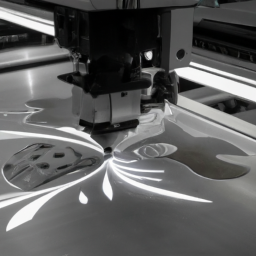

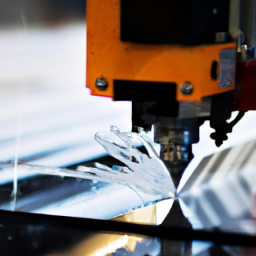

Waterjet cutting is a highly efficient method that utilizes a high-pressure stream of water mixed with an abrasive material to cut through various materials, including acrylic. This process involves the use of a computer-controlled system that directs the waterjet to precisely cut the desired shape or design.

One of the major advantages of waterjet cutting is its ability to produce intricate and detailed cuts with high precision, making it ideal for complex acrylic designs. However, it’s important to note that waterjet cutting may not be the fastest method and can be more expensive than other cutting methods.

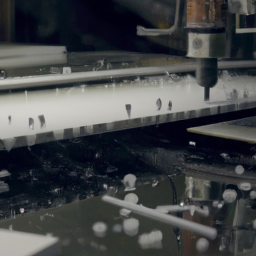

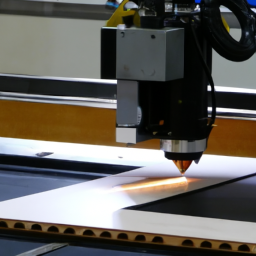

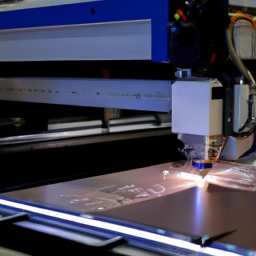

How Waterjet Cutting Works

Flowing like a mighty river, the powerful stream of water expertly sculpts and shapes acrylic designs with precision. Waterjet cutting works by pressurizing water to high levels and then propelling it through a small nozzle at an incredibly fast speed. This process offers several advantages over laser cutting for acrylic designs.

-

No Heat Affected Zone: Waterjet cutting doesn’t generate heat, eliminating the risk of warping or discoloration in the acrylic material.

-

Versatility: Waterjets can cut through thicker acrylic materials compared to lasers, making it suitable for a wider range of design options.

-

Complex Shapes: With waterjet cutting, intricate and precise designs can be achieved, allowing for more creative possibilities.

However, waterjet cutting also has its disadvantages. It’s a slower process compared to laser cutting, which can affect production time. Additionally, the high-pressure water jet can result in more material wastage.

Transitioning into the subsequent section about the pros and cons of waterjet cutting, it’s important to consider the advantages and disadvantages when selecting the ideal cutting method for your acrylic designs.

Pros and Cons of Waterjet Cutting

One of the benefits of waterjet cutting is its ability to achieve intricate and precise designs, allowing for endless creative possibilities. Waterjet cutting uses a high-pressure stream of water mixed with an abrasive substance to cut through materials like acrylic. This method is highly accurate, with a narrow cutting width and minimal material wastage.

Additionally, waterjet cutting can handle thicker materials compared to laser cutting, making it suitable for projects that require greater thicknesses. However, there are some drawbacks to consider. Waterjet cutting can be slower than laser cutting, especially for intricate designs. It also requires a larger upfront investment and higher maintenance costs.

On the other hand, laser cutting offers faster speeds and is more cost-effective for simpler designs. Consider your project requirements as you weigh the pros and cons of waterjet cutting before making a decision.

Consider Your Project Requirements

When considering your project requirements for acrylic designs, there are two key points to focus on:

- The thickness and complexity of the design, and the precision and detail needed.

The thickness and complexity of the acrylic design will determine which cutting method, either laser cutting or waterjet cutting, is more suitable for your project. Laser cutting is better suited for thinner and less complex designs, while waterjet cutting is ideal for thicker and more intricate designs.

- Additionally, the precision and detail needed in your project will also play a significant role in determining the appropriate cutting method, as laser cutting offers a higher level of precision and detail compared to waterjet cutting.

Thickness and Complexity of the Acrylic Design

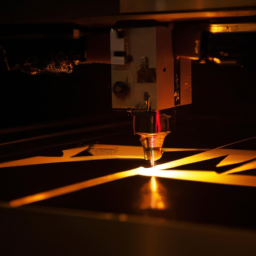

For acrylic designs, the thickness and complexity play a crucial role in determining whether laser cutting or waterjet cutting is more suitable. Laser cutting is the preferred choice for designs with a thickness of less than 1 inch due to its precision and speed.

When it comes to acrylic thickness, laser cutting is highly effective as it can easily handle thin sheets without causing any damage or warping. Additionally, laser cutting is ideal for intricate designs as it can create intricate shapes and patterns with high accuracy. The precision and detail needed for complex acrylic designs can be achieved through laser cutting, which provides clean and precise cuts. This method ensures that even the most intricate details are accurately replicated in the final product.

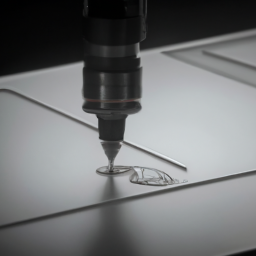

Precision and Detail Needed

To achieve the precision and detail required for complex acrylic designs, you must carefully consider the thickness and intricacy of the design. When deciding between laser cutting and waterjet cutting, it is important to weigh the trade-offs between precision and speed, as well as cost and quality. Laser cutting offers exceptional precision and the ability to create intricate details, thanks to its focused beam of light. On the other hand, waterjet cutting may not offer the same level of precision, but it can handle thicker materials and is ideal for complex designs.

To better understand the differences between laser cutting and waterjet cutting, let’s compare their precision and detail capabilities:

| Laser Cutting | Waterjet Cutting | |

|---|---|---|

| Precision | High | Moderate |

| Detail | Excellent | Good |

| Thickness Range | Thin | Thick |

When deciding which cutting method to choose, consider the precision and detail needed for your acrylic design. If you require the highest level of precision and intricate details, laser cutting may be the better option. However, if the design is complex and the thickness of the acrylic is a concern, waterjet cutting may be the more suitable choice.

Now, let’s compare the speed and efficiency of laser cutting and waterjet cutting to further determine the best option for your acrylic designs.

Compare Speed and Efficiency

When considering laser cutting versus waterjet cutting for acrylic designs, it’s important to compare the speed and efficiency of these two methods.

Laser cutting generally requires less time to complete a cut compared to waterjet cutting due to its high cutting speed. On the other hand, waterjet cutting may take longer as it involves the use of pressurized water to cut through the material.

Both methods have their own advantages, and it’s crucial to analyze your project requirements to determine which option is best suited for you.

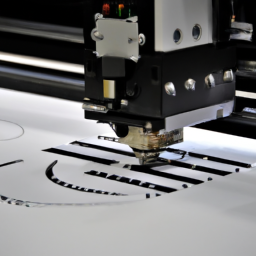

Time Required for Laser Cutting

Save time on your acrylic designs with laser cutting or waterjet cutting. When comparing the speed of these two methods, laser cutting comes out on top. The laser cutting process is incredibly fast and efficient, allowing you to quickly produce intricate designs with precision.

With laser cutting, the laser beam melts or vaporizes the acrylic material, creating clean and accurate cuts in a matter of seconds. This speed advantage is especially beneficial when working on large-scale projects or when time is of the essence.

However, it’s important to note that laser cutting is not the only option. In the next section, we’ll explore the time required for waterjet cutting and how it compares to laser cutting in terms of efficiency and speed.

Time Required for Waterjet Cutting

Waterjet cutting, on the other hand, offers a different approach to achieving accurate and precise cuts in acrylic materials. Unlike laser cutting, which uses a focused beam of light to melt and vaporize the material, waterjet cutting relies on a high-pressure stream of water mixed with an abrasive material to erode the acrylic. This process allows for the cutting of thicker materials and eliminates the risk of heat-induced distortion. However, waterjet cutting does have some drawbacks in terms of time required. The speed of waterjet cutting is affected by several factors, including the thickness of the acrylic, the complexity of the design, and the speed at which the waterjet can move. These factors can significantly increase the time required for waterjet cutting compared to laser cutting. Moving forward, it is important to consider these time factors as you evaluate cost factors for your acrylic cutting needs.

Evaluate Cost Factors

One important aspect to consider is the overall cost of the laser cutting and waterjet cutting processes. When comparing the cost of these two methods, it’s crucial to take into account the cost of materials and the amount of waste generated.

Laser cutting tends to be more cost-effective than waterjet cutting because it requires less material and produces minimal waste. The precision of laser cutting allows for efficient use of materials, resulting in reduced costs. On the other hand, waterjet cutting can be more expensive due to the high cost of the equipment and the need for abrasive materials. Additionally, waterjet cutting generates more waste, which can increase disposal costs.

Evaluating the cost factors is essential to make an informed decision about which cutting method is right for your acrylic designs.

Make an Informed Decision

When it comes to deciding between laser cutting and waterjet cutting for your acrylic designs, it’s important to weigh the pros and cons to ensure you’re making a well-informed choice. Here are three factors to consider when weighing your options:

-

Precision: Laser cutting offers high precision and intricate detailing, making it ideal for intricate designs. Waterjet cutting, on the other hand, may result in slightly rougher edges and less intricate cuts.

-

Material Thickness: Laser cutting is more suitable for thinner acrylic sheets, while waterjet cutting can handle thicker materials with ease.

-

Speed: Laser cutting is generally faster than waterjet cutting, making it a preferred choice for projects with tight deadlines.

By carefully weighing these options and considering factors such as precision, material thickness, and speed, you can make an informed decision that best suits your acrylic design needs.

Frequently Asked Questions

Can laser cutting or waterjet cutting be used for materials other than acrylic?

Other materials suitable for laser cutting or waterjet cutting include wood, metal, plastic, and fabric. When comparing cutting speed and precision for different materials, laser cutting is generally faster and more precise than waterjet cutting. Laser cutting uses a focused laser beam to vaporize or melt the material, while waterjet cutting uses a high-pressure stream of water mixed with abrasive particles.

Ultimately, the choice between laser cutting and waterjet cutting depends on the specific material and desired outcome.

What are the potential safety hazards associated with laser cutting and waterjet cutting?

When it comes to laser cutting and waterjet cutting, there are potential safety hazards to consider. Both methods involve intense heat and high-pressure streams, which can pose risks if not properly managed.

Safety precautions, such as wearing protective eyewear and gloves, are essential to prevent injuries. Additionally, proper ventilation and fire safety measures should be in place.

By prioritizing safety and following the necessary precautions, you can minimize the potential hazards associated with laser cutting and waterjet cutting.

Are there any limitations to the complexity of designs that can be achieved through laser cutting or waterjet cutting?

There are limitations to the complexity of designs that can be achieved through laser cutting or waterjet cutting. Laser cutting offers greater precision and is capable of achieving intricate designs with fine details, but it may have limitations when it comes to cutting thicker materials. On the other hand, waterjet cutting can handle thicker materials, but it may not provide the same level of precision as laser cutting. The choice between the two methods depends on the specific requirements of your design.

Can laser cutting or waterjet cutting be used for both small-scale and large-scale projects?

Both laser cutting and waterjet cutting can be used for both small-scale and large-scale projects. Laser cutting is a precise and efficient method that is suitable for a wide range of materials, including acrylic. It uses a high-powered laser to cut through the material with extreme accuracy.

On the other hand, waterjet cutting uses a high-pressure stream of water mixed with abrasive materials to cut through materials. It is also capable of cutting acrylic and is particularly useful for projects that require intricate designs and thick materials.

How do laser cutting and waterjet cutting compare in terms of environmental impact?

When it comes to environmental sustainability, laser cutting and waterjet cutting couldn’t be more different. While laser cutting may seem like the obvious choice for energy consumption due to its precise and efficient nature, it ironically leaves a larger environmental impact. The high energy consumption of laser cutting machines results in increased carbon emissions and electricity usage.

On the other hand, waterjet cutting uses significantly less energy and is considered more environmentally friendly.

Conclusion

When it comes to choosing between laser cutting and waterjet cutting for acrylic designs, it’s important to consider your specific project requirements and budget.

Laser cutting offers precise and efficient results, while waterjet cutting provides versatility and the ability to work with thicker materials.

Both methods have their advantages and limitations, so it’s crucial to evaluate the speed, efficiency, and cost factors before making a decision.

Symbolizing the intricacies of your project, this decision will shape the outcome of your acrylic designs. Choose wisely.