Are you ready to cut through the noise and make the right choice for your metal fabrication needs?

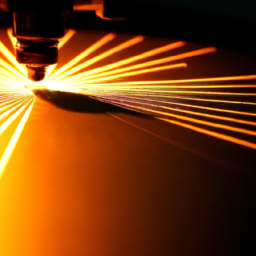

Laser cutting and waterjet cutting are two powerful techniques that can shape and transform metal with precision. Like a surgeon’s scalpel, laser cutting uses a concentrated beam of light to slice through materials, while waterjet cutting, akin to a mighty torrent, employs a high-pressure stream of water mixed with abrasive particles to erode metal.

But which is the perfect tool for your project? In this article, we will dive deep into the world of laser cutting and waterjet cutting, examining their applications and exploring the factors you should consider when making your decision.

By the end, you will be equipped with the knowledge to choose the method that suits your needs, like a master craftsman selecting the perfect chisel for their masterpiece.

So, let’s embark on this journey of metal fabrication and discover which path leads to your perfect cut.

Key Takeaways

- Laser cutting offers high precision and intricate designs with clean and smooth finishes.

- Laser cutting is efficient and suitable for a wide range of metals, but may not be suitable for thick metals due to slower cutting speed and potential distortion.

- Waterjet cutting is versatile and compatible with various materials, offering precise cutting capabilities without generating heat or causing material distortion.

- Factors to consider when choosing between laser cutting and waterjet cutting include precision, narrow kerf width, material compatibility, edge quality, and automation.

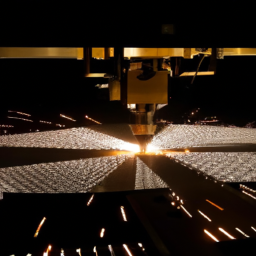

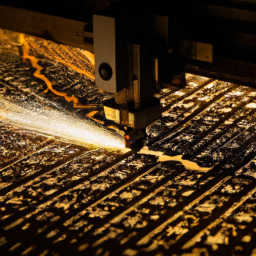

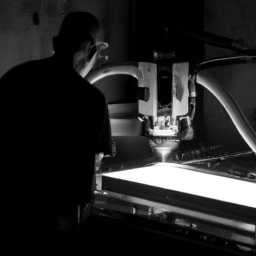

Understanding Laser Cutting

Laser cutting is a mind-blowing technique that can effortlessly slice through metal with precision and finesse. It offers numerous advantages in metal fabrication.

First and foremost, laser cutting allows for intricate and complex designs to be easily achieved, thanks to its high level of accuracy. Additionally, this method provides a clean and smooth finish, eliminating the need for further processing.

Laser cutting is also highly efficient, as it can cut through a wide range of metals at a rapid pace. However, like any technique, it does have its limitations. For example, laser cutting is not suitable for thick metals, as it may result in a slower cutting speed and potential distortion.

Now, let’s explore waterjet cutting to see how it compares.

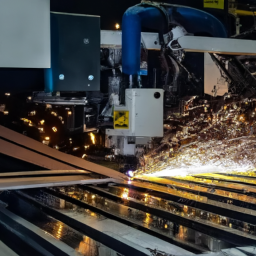

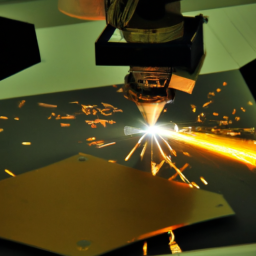

Exploring Waterjet Cutting

Waterjet cutting is a versatile cutting method that provides compatibility with a wide range of materials, including metals, plastics, composites, and even fragile materials like glass and ceramics. The cold cutting process of waterjet cutting avoids the generation of heat, minimizing the risk of material distortion or damage.

However, it’s important to note that waterjet cutting tends to have a slower cutting speed compared to laser cutting, which may affect production efficiency for certain projects.

Versatile Material Compatibility

With versatile material compatibility, you can explore endless possibilities and create stunning metal fabrications that will leave you in awe.

Waterjet cutting offers a wide range of material options, from metals like steel and aluminum to more delicate materials like glass and ceramics. Unlike laser cutting, waterjet cutting does not have material limitations, allowing you to work with a diverse range of materials for your projects.

Additionally, waterjet cutting provides precise cutting capabilities, ensuring clean and accurate cuts every time. This precision is especially important when working with intricate designs or complex shapes.

As we move into the next section on the cold cutting process, you’ll see how waterjet cutting’s versatility and precision make it a top choice in metal fabrication.

Cold Cutting Process

When it comes to metal fabrication, you’ll be amazed at the precision and versatility of the cold cutting process. Unlike other methods that generate heat, cold cutting uses techniques such as laser cutting and waterjet cutting to cut through metal without altering its properties. This makes it ideal for materials that are sensitive to high temperatures or require a clean edge finish.

To better understand the advantages and limitations of the cold cutting process, let’s take a look at the following table:

| Advantages | Limitations |

|---|---|

| High precision | Material thickness limitations |

| Versatility in material compatibility | Slower cutting speed |

| Clean edge finish | Higher cost |

| Minimal heat-affected zone | Limited ability for complex shapes |

| Reduced risk of warping | Waterjet cutting may cause material erosion |

As you can see, cold cutting offers numerous benefits, such as high precision, versatility, and clean edge finishes. However, it does have some limitations, including slower cutting speeds and higher costs. Nonetheless, the next section will discuss the slower cutting speed in more detail, allowing you to make an informed decision about which cutting method is right for you.

Slower Cutting Speed

If you’re looking for a cutting process that offers precision and versatility, you’ll want to know about the slower cutting speed. When it comes to laser cutting versus waterjet cutting in metal fabrication, one key difference is the speed at which the materials are cut.

Waterjet cutting is generally slower compared to laser cutting. However, this slower cutting speed comes with its advantages. The slower speed allows for higher precision in cutting complex shapes and intricate designs. It also reduces heat distortion, which is essential for maintaining the integrity of the metal being cut.

So, while waterjet cutting may be slower, the benefits of higher precision and reduced heat distortion make it a preferred choice for certain applications.

Now, let’s move on to the factors to consider when deciding between laser cutting and waterjet cutting.

Factors to Consider

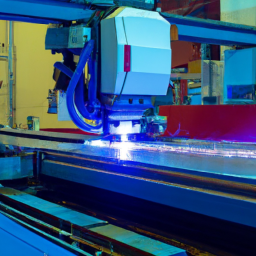

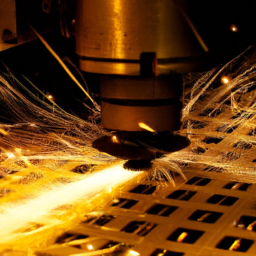

One major factor to consider when choosing between laser cutting and waterjet cutting is the incredible precision and accuracy that laser cutting offers. Laser cutting uses a focused beam of light to melt or vaporize the material, resulting in clean, precise cuts.

Here are five key aspects to consider when it comes to laser cutting:

- Laser cutting offers a high level of precision, allowing for intricate and detailed designs.

- The laser beam is extremely focused, resulting in narrow kerf width and minimal material wastage.

- Laser cutting is suitable for a wide range of materials, including metals, plastics, and wood.

- It provides excellent edge quality, with minimal burrs or roughness.

- Laser cutting machines are highly automated and can be programmed to cut complex shapes with ease.

Considering these factors, laser cutting is a popular choice for applications requiring precise cuts and intricate designs.

Applications of Laser Cutting

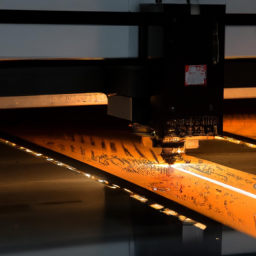

In industrial manufacturing, laser cutting is widely used for its precision and efficiency in cutting various materials such as metal sheets and tubes.

The automotive industry also benefits from laser cutting as it allows for intricate designs and precise cuts in the production of car parts.

In the electronics and technology sector, laser cutting is essential for creating intricate circuit boards and precise components.

Industrial Manufacturing

Choose laser cutting or waterjet cutting for your industrial manufacturing needs and experience the precision and efficiency that these methods offer. Laser cutting, with its numerous advantages, is widely used in industrial manufacturing. Here are three reasons why laser cutting is the preferred choice:

-

High precision: Laser cutting offers exceptional precision, allowing for intricate and complex cuts with minimal material wastage. This accuracy is crucial in industries where precision is paramount, such as aerospace and electronics.

-

Speed and efficiency: Laser cutting is incredibly fast, allowing for quick turnaround times and increased productivity. Additionally, the automated nature of laser cutting ensures consistent and repetitive cuts, enhancing efficiency in industrial manufacturing processes.

-

Versatility: Laser cutting can be used on a wide range of materials, including metals, plastics, and fabrics. This versatility makes it a preferred method in industries where different materials need to be cut for various applications.

By understanding the advantages of laser cutting and the disadvantages of waterjet cutting, you can make an informed decision for your industrial manufacturing needs.

Transitioning into the subsequent section about the automotive industry, let’s explore how laser cutting is revolutionizing the way automobiles are manufactured.

Automotive Industry

Get ready to discover how the automotive industry is being revolutionized by the precision and efficiency of laser cutting. Laser cutting has become an integral part of automotive design and manufacturing processes, allowing for the creation of intricate and precise components. By using a high-powered laser beam, automotive manufacturers can cut through various materials with ease, including metals and alloys commonly used in the industry. This technology enables the production of complex shapes and designs, enhancing the overall aesthetics and functionality of vehicles. Laser cutting in the automotive industry is not limited to body components but also extends to interior parts, such as dashboard panels and seat frames. With its accuracy and speed, laser cutting has significantly improved the manufacturing process, leading to higher productivity and cost-effectiveness. As we transition to the next section about electronics and technology, you will see how laser cutting continues to shape various industries.

Electronics and Technology

Discover how the precision and efficiency of laser cutting are revolutionizing the electronics and technology industry, enhancing the production of intricate components and improving overall functionality.

Advancements in electronics require intricate designs and precise cuts, and laser cutting provides the perfect solution. With its focused beam of high-energy light, laser cutting can accurately cut through various materials used in electronics, such as metals and plastics. This technology allows for the creation of intricate circuit boards, microchips, and other components with minimal waste and maximum precision.

The impact of laser cutting on technology is undeniable, as it enables the production of smaller, more powerful, and more efficient electronic devices. Laser cutting is leading the way in the electronics and technology industry, setting new standards for precision and quality.

As we transition to discuss the applications of waterjet cutting, it’s important to recognize the significant role that laser cutting plays in advancing the field.

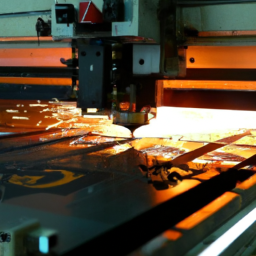

Applications of Waterjet Cutting

When considering metal fabrication, it’s remarkable how waterjet cutting can create intricate designs that leave a lasting impression. With the use of an abrasive waterjet, this method offers precision cutting that is highly accurate and efficient.

The high-pressure water stream, combined with abrasive particles, allows for the ability to cut through various types of materials, including metals, with ease. The waterjet cutting process eliminates the need for heat, which reduces the risk of warping or distortion in the material.

Additionally, waterjet cutting can produce intricate shapes and sharp corners that may be challenging to achieve with other cutting methods. When it comes to making the right choice between laser cutting and waterjet cutting, understanding the unique capabilities of each method is crucial for achieving the desired results.

Making the Right Choice

Choosing between laser cutting and waterjet cutting can be a challenging decision, but understanding the unique capabilities of each method is crucial for achieving exceptional results in metal fabrication. When weighing options, cost considerations play a significant role in making the right choice.

Here are some key factors to consider:

- Initial Investment: Laser cutting machines typically have a higher upfront cost compared to waterjet cutting machines.

- Operating Costs: Laser cutting requires a continuous supply of gases and regular maintenance, while waterjet cutting requires abrasive materials and periodic nozzle replacement.

- Material Flexibility: Laser cutting is better suited for thinner materials, while waterjet cutting can handle thicker and harder materials more effectively.

- Precision: Laser cutting offers higher precision and finer details, while waterjet cutting provides a smoother and burr-free edge.

- Environmental Impact: Laser cutting produces fumes and requires proper ventilation, while waterjet cutting is a cleaner and more environmentally friendly option.

Considering these factors and your specific needs will help you make an informed decision that maximizes both quality and cost efficiency in your metal fabrication projects.

Frequently Asked Questions

What is the cost comparison between laser cutting and waterjet cutting in metal fabrication?

The cost difference between laser cutting and waterjet cutting in metal fabrication depends on various factors.

Laser cutting generally has lower initial setup costs and higher cutting speeds, making it more cost-effective for large production runs.

On the other hand, waterjet cutting is known for its precision and versatility, but it can be more expensive due to higher maintenance and operational costs.

Consider your specific requirements and budget when choosing between the two methods.

Are there any limitations to the thickness of metal that can be cut using laser cutting?

Oh, the mighty laser cutting! It can slice through metal with such precision and finesse…as long as it’s not too thick. Yes, there are limitations to the thickness of metal that can be cut using laser cutting. The laser’s heat can only penetrate so far, making it less effective for thicker materials.

This is where waterjet cutting swoops in with its advantage. Waterjet cutting can handle thicker metals with ease, thanks to its high-pressure jet of water mixed with abrasive particles. So, when it comes to cutting thick metal, waterjet cutting is the way to go.

How does the speed of laser cutting compare to waterjet cutting?

When comparing cutting speeds, laser cutting is generally faster than waterjet cutting. This is due to the high intensity of the laser beam, which can rapidly heat and vaporize the material. Factors that can affect cutting speeds in laser cutting include the thickness and type of material, as well as the power of the laser.

In waterjet cutting, the cutting speed can be influenced by factors such as the pressure and velocity of the waterjet, as well as the type of abrasive used.

Are there any safety considerations when using laser cutting or waterjet cutting?

To ensure safe operations when using laser cutting or waterjet cutting, certain safety precautions must be taken.

For laser cutting, it’s crucial to wear appropriate protective gear, such as safety glasses and gloves, to prevent injuries from laser beams and sparks. Regular equipment maintenance, including checking and cleaning the laser system, is also important.

Similarly, for waterjet cutting, operators should wear safety gear and maintain the equipment to prevent any accidents or malfunctions.

Can both laser cutting and waterjet cutting be used for intricate designs and complex shapes?

Both laser cutting and waterjet cutting can be used for intricate designs and complex shapes. Laser cutting is suitable for materials such as metal, wood, and plastic, while waterjet cutting is ideal for cutting materials like stone, glass, and ceramics.

Laser cutting offers the advantage of high precision and speed, but it may cause thermal distortion. On the other hand, waterjet cutting provides a smooth finish with no heat-affected zones, but it is slower and may not be suitable for very thick materials.

Conclusion

In conclusion, when it comes to metal fabrication, the choice between laser cutting and waterjet cutting depends on various factors.

Laser cutting offers precise and efficient results, perfect for intricate designs.

Conversely, waterjet cutting provides versatility and can handle a wide range of materials.

To make the right choice, consider the complexity of your project and the material you’re working with.

So, whether you opt for the laser’s lightning-fast precision or the waterjet’s wide-ranging capabilities, choose wisely to craft a flawless masterpiece!