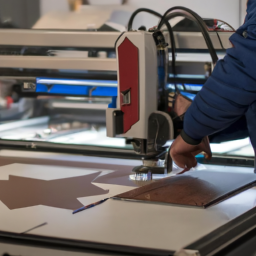

Are you looking to give your woodworking projects a cutting edge? When it comes to precision and efficiency, laser cutting and waterjet cutting are two popular options that can take your craftsmanship to the next level.

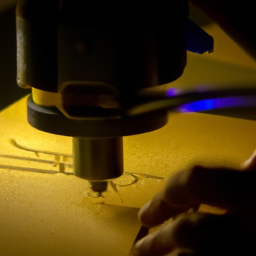

Like two skilled artists with different techniques, each method has its own unique advantages and considerations. Laser cutting, akin to a surgeon’s precision, uses a high-powered laser beam to slice through wood with incredible accuracy.

On the other hand, waterjet cutting, like a gentle cascade, employs a high-pressure stream of water mixed with abrasive materials to smoothly carve intricate designs.

As you embark on your woodworking journey, it’s crucial to understand the differences between these two techniques and choose the one that best suits your needs. In this article, we will explore the ins and outs of laser cutting and waterjet cutting, comparing cost, efficiency, project requirements, and safety. By the end, you will have the knowledge and confidence to make an informed decision and bring your woodworking dreams to life.

Key Takeaways

- Laser cutting offers unmatched precision and clean cuts, making it suitable for intricate designs and fine details in woodworking.

- Waterjet cutting is more versatile and can cut through almost any material, making it ideal for thick or delicate materials in woodworking.

- Laser cutting has lower upfront costs and operating costs compared to waterjet cutting, making it more cost-effective in the long run.

- When choosing between laser cutting and waterjet cutting in woodworking, factors to consider include project requirements, wood thickness, desired precision, project specifications, safety and maintenance, and desired outcome in woodworking projects.

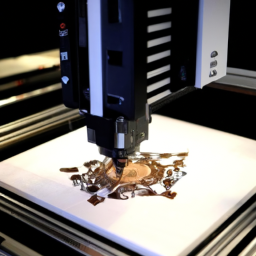

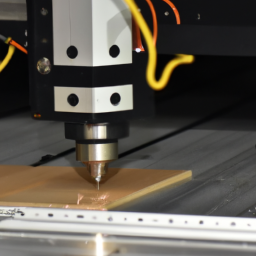

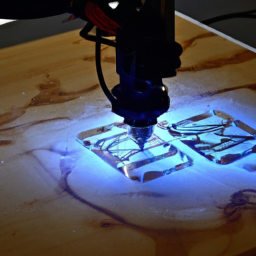

Understanding Laser Cutting in Woodworking

If you’re a woodworking enthusiast, you’ll be amazed by the precision and versatility that laser cutting brings to the table. Laser cutting offers a multitude of advantages in woodworking.

Firstly, it provides unmatched precision, allowing for intricate and detailed designs that would be difficult to achieve using traditional cutting methods. Laser cutting also offers clean and precise cuts, minimizing the need for additional finishing work.

Additionally, laser cutting can be used on a wide range of materials, including wood, acrylic, and even metal, making it a versatile tool in the woodworking industry. From creating intricate patterns and designs to cutting out complex shapes, laser cutting offers endless possibilities for woodworking projects.

Now, let’s dive into exploring waterjet cutting in woodworking, another fascinating technique that has its own set of advantages.

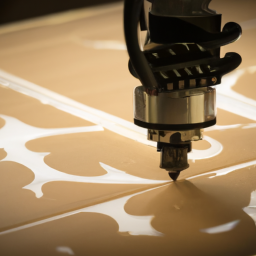

Exploring Waterjet Cutting in Woodworking

When it comes to waterjet cutting in woodworking, there are several key points to consider.

Firstly, waterjet cutting offers high cutting speeds, allowing you to complete your projects efficiently.

Secondly, there is no heat-affected zone when using waterjet cutting, which means you don’t have to worry about damaging the material due to excessive heat.

Lastly, waterjet cutting is compatible with a wide range of materials and thicknesses, making it a versatile option for your woodworking needs.

High Cutting Speeds

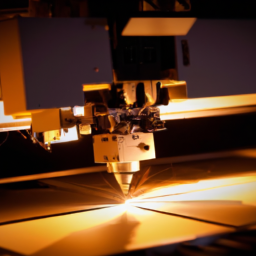

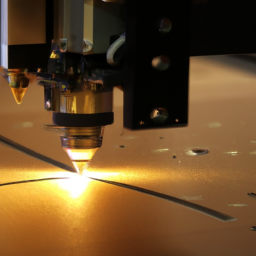

With its lightning-fast cutting speeds, laser cutting zips through wood like a hot knife through butter. This high-speed cutting is made possible by advanced laser cutting technology, which utilizes a concentrated beam of light to precisely cut through the wood with incredible speed and accuracy. Imagine the laser swiftly moving across the wood, leaving behind a perfectly cut edge. It’s like a dance, as the laser effortlessly glides through the material, creating intricate designs and shapes. Take a look at the table below to understand the difference in cutting speeds between laser cutting and waterjet cutting. As we dive into the next section about the "no heat-affected zone," you’ll see how laser cutting’s high speed is not the only advantage it has over waterjet cutting.

No Heat-Affected Zone

Experience the precision and perfection of laser cutting as it leaves behind a flawlessly cut edge with no heat-affected zone. Unlike waterjet cutting, which can generate heat during the cutting process, laser cutting uses a high-powered laser beam to precisely and accurately cut through wood without causing any thermal damage.

This means that there is no heat-affected zone, ensuring that the material remains unaffected by heat and maintains its original properties. Laser cutting provides a clean and smooth cut, eliminating the need for additional finishing or sanding.

Now that you understand the benefits of laser cutting in woodworking, let’s explore its compatibility with different materials and thicknesses.

Material Compatibility and Thickness

One fascinating fact to consider is that laser cutting is compatible with a wide range of materials, including metals, plastics, and textiles, allowing for endless possibilities in various industries. However, it is important to note that there are some material limitations.

For instance, certain metals with high reflectivity, such as copper and aluminum, may not be suitable for laser cutting. Additionally, laser cutting may not be the best choice for certain materials that release toxic fumes when heated, like PVC.

On the other hand, waterjet cutting proves to be more versatile in terms of material compatibility, as it can cut through almost any material, including thick metals and non-reflective materials. Moreover, waterjet cutting offers exceptional cutting precision, ensuring intricate designs with minimal material wastage.

As we move into comparing the cost and efficiency of these two methods, it is essential to consider the unique material capabilities and limitations they offer.

Comparing the Cost and Efficiency

Although laser cutting may initially seem more cost-effective, waterjet cutting can provide greater efficiency and precision in woodworking projects.

When it comes to cost comparison, laser cutting may have lower upfront costs due to the lower equipment and maintenance expenses. However, waterjet cutting can be more efficient in terms of material usage, as it does not produce a heat-affected zone and does not require additional finishing processes.

Waterjet cutting also offers higher precision and accuracy, allowing for intricate designs and smooth edges. Additionally, the versatility of waterjet cutting allows for the use of a wider range of materials, including metals and composites, expanding the possibilities for woodworking projects.

When considering project requirements and complexity, waterjet cutting’s efficiency and precision make it a compelling choice for woodworking projects.

Considering Project Requirements and Complexity

When considering project requirements and complexity, there are several key points to take into account.

First, if your woodworking project involves intricate designs and fine details, laser cutting may be the better choice for you. Laser cutting allows for precise and detailed cuts that can achieve intricate patterns and designs.

Second, if your project involves working with thick or delicate materials, waterjet cutting may be the more suitable option. Waterjet cutting can handle thicker materials like wood, as well as delicate materials that may be damaged by the heat generated by laser cutting.

Lastly, if you have production volume and time constraints, laser cutting is typically faster than waterjet cutting. Laser cutting can be more efficient for large production volumes, as it can quickly cut multiple pieces at once. However, it’s important to consider the specific requirements of your project to determine which method will best meet your needs.

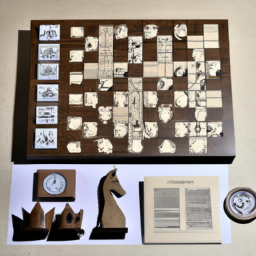

Intricate Designs and Fine Details

For woodworkers looking to create intricate designs and fine details, laser cutting may be the preferred choice due to its ability to achieve precision cuts with a tolerance as low as 0.1mm.

Laser cutting utilizes a high-powered laser beam to vaporize or melt away the material, resulting in clean and precise cuts. This technique is especially advantageous for woodworking projects that require intricate patterns, delicate filigree work, or intricate inlays. The laser cutting process allows woodworkers to achieve a level of precision that would be difficult to achieve with other woodworking techniques.

However, when working with thick or delicate materials, waterjet cutting may be a better option. Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through materials, allowing for greater flexibility and versatility.

Thick or Delicate Materials

To achieve the highest level of precision and flexibility in working with thick or delicate materials, the preferred choice would be waterjet cutting due to its ability to utilize a high-pressure stream of water mixed with abrasive particles. Here are four reasons why waterjet cutting is the ideal option for such materials:

-

Thick materials: Waterjet cutting can effortlessly slice through thick materials like hardwood or metal, providing clean and accurate cuts without any heat-affected zones or warping.

-

Delicate materials: Waterjet cutting is gentle enough to handle delicate materials such as veneers or thin acrylic sheets, ensuring minimal distortion or damage during the cutting process.

-

Versatility: Waterjet cutting can be adjusted to accommodate various thicknesses, making it suitable for a wide range of materials, from thick blocks to fragile ornaments.

-

Intricate designs: The precise nature of waterjet cutting allows for intricate and detailed designs on both thick and delicate materials, giving woodworkers the freedom to create stunning and complex pieces.

Transitioning into the next section about ‘production volume and time constraints,’ it’s important to consider these factors when deciding between laser cutting and waterjet cutting.

Production Volume and Time Constraints

Maximize your production volume and meet tight time constraints with the right cutting method. When it comes to production efficiency, both laser cutting and waterjet cutting offer advantages. Laser cutting is known for its high cutting speed and precision, making it ideal for large production volumes. On the other hand, waterjet cutting is more versatile and can handle a wider range of materials, including thick and delicate ones.

To give you a clearer picture, let’s compare the two methods using a cost analysis:

| Criteria | Laser Cutting | Waterjet Cutting |

|---|---|---|

| Cutting Speed | Very fast | Slower than laser cutting |

| Material Versatility | Limited to certain materials | Can handle a wide range of materials |

| Cost | Lower operating cost | Higher operating cost |

By considering these factors, you can determine which method aligns better with your production goals and constraints. Once you have maximized your production volume and met your time constraints, it is important to evaluate safety and maintenance to ensure smooth operations.

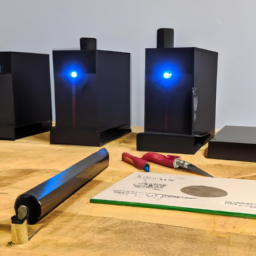

Evaluating Safety and Maintenance

Ensure your woodworking workspace remains safe and well-maintained by considering the benefits of laser cutting and waterjet cutting.

When evaluating the cost effectiveness of these cutting methods, it’s important to also consider the safety and maintenance aspects.

Laser cutting requires regular maintenance to ensure the machine is operating efficiently and to prevent any potential safety hazards. Cleaning the lenses, checking for any loose or damaged parts, and ensuring proper ventilation are all crucial for maintaining a safe laser cutting workspace.

On the other hand, waterjet cutting requires minimal maintenance and poses fewer safety risks.

By evaluating the safety and maintenance requirements of both methods, you can make an informed decision about which cutting method is best suited for your woodworking projects.

With this knowledge, you can proceed to make the right choice for your woodworking projects without compromising safety or maintenance.

Making the Right Choice for Your Woodworking Projects

When it comes to choosing the ideal method for your woodworking projects, it’s crucial to consider the unique qualities and advantages of both laser and waterjet cutting techniques.

Each method has its own set of benefits and it’s important to understand your project specifications before making a decision.

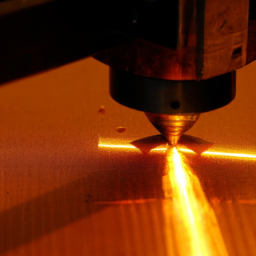

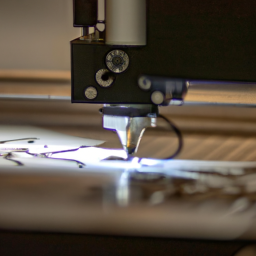

Laser cutting is known for its precision and speed. It uses a focused laser beam to cut through wood with accuracy, allowing for intricate designs and detailed cuts. Laser cutting is also great for cutting thicker materials and can produce clean edges.

On the other hand, waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through wood. This method is ideal for projects that require a softer touch, as it doesn’t produce heat or put pressure on the wood. Waterjet cutting is also versatile, able to cut through a wide range of materials with ease.

When choosing appropriate tools for your woodworking projects, take into consideration the complexity of your designs, the thickness of the wood, and the desired precision. Understanding your project specifications will help you make the right choice between laser cutting and waterjet cutting.

Frequently Asked Questions

Can laser cutting or waterjet cutting be used on other materials besides wood in woodworking projects?

When it comes to alternative applications, laser cutting and waterjet cutting can be used on various materials besides wood. Laser cutting is versatile and can be used on materials like metal, plastic, and fabric, offering precise and intricate cuts.

On the other hand, waterjet cutting is ideal for materials that may be sensitive to heat, such as glass or foam. Both methods have their pros and cons, so it’s important to consider the specific material and project requirements before making a decision.

How long does it take for laser cutting or waterjet cutting to complete a woodworking project?

When comparing the speed of laser cutting and waterjet cutting in woodworking projects, several factors come into play. The complexity and size of the project, as well as the material being cut, can influence completion time.

Laser cutting tends to be faster than waterjet cutting due to its high precision and ability to cut through materials quickly. However, waterjet cutting may be preferred for certain projects that require intricate designs or the ability to cut through thick materials.

Ultimately, the completion time will vary depending on these factors.

Are there any environmental considerations when choosing between laser cutting and waterjet cutting in woodworking?

When considering the environmental impact of laser cutting versus waterjet cutting in woodworking, it’s crucial to understand the differences.

Laser cutting uses a focused beam of light to cut through materials, resulting in minimal material waste and energy consumption.

On the other hand, waterjet cutting uses a high-pressure stream of water mixed with abrasive materials, which can lead to more water usage and potential contamination.

Additionally, laser cutting tends to be more cost-effective due to lower maintenance and operating costs.

Can laser cutting or waterjet cutting be used for intricate designs or detailed patterns in woodworking projects?

When it comes to intricate designs or detailed patterns in woodworking projects, both laser cutting and waterjet cutting have their pros and cons.

Laser cutting offers precise and intricate cuts with smooth edges, making it ideal for delicate designs. However, it can be limited to certain materials like wood, acrylic, and plastics.

On the other hand, waterjet cutting can handle a wider range of materials including metal, glass, and stone, but may not achieve the same level of precision as laser cutting.

What are the limitations or restrictions when using laser cutting or waterjet cutting in woodworking projects?

When it comes to laser cutting in woodworking, there are a few limitations to consider. It excels at intricate designs and detailed patterns, but it struggles with thicker materials and may leave a darkened edge.

On the other hand, waterjet cutting has its own set of restrictions. It’s not ideal for delicate or small pieces as it may cause splintering or damage. Additionally, it’s less precise than laser cutting and may require additional finishing.

Conclusion

In conclusion, after investigating the truth of the theory and considering various factors, you can now confidently make the right choice for your woodworking projects.

Both laser cutting and waterjet cutting have their advantages and disadvantages, but ultimately, it depends on your specific requirements and project complexity.

By evaluating the cost, efficiency, safety, and maintenance aspects, you can determine which method is best suited for your needs.

With this knowledge and experience, you can now embark on your woodworking journey with precision and confidence.