Did you know that Nd:YAG laser cutters are widely used in a variety of industries, including manufacturing, aerospace, and medical? These powerful machines offer precise and efficient cutting capabilities, making them an essential tool for many professionals.

In this article, we will delve into the basics of Nd:YAG laser cutters, providing you with a comprehensive understanding of how they work, their applications, and the advantages they offer. We will also discuss important factors to consider when choosing an Nd:YAG laser cutter and highlight safety considerations for laser cutting.

Additionally, we will explore future developments and innovations in Nd:YAG laser cutting technology. Whether you are a business owner looking to invest in a laser cutter or simply curious about this fascinating technology, this article will serve as your guide to Nd:YAG laser cutters.

So, let’s dive in and uncover the world of laser cutting!

Key Takeaways

- Nd:YAG laser cutters are widely used in manufacturing, aerospace, and medical industries for precise and efficient cutting capabilities.

- The key component of Nd:YAG laser cutters is the neodymium-doped yttrium aluminum garnet crystal.

- Nd:YAG laser cutters can cut a wide range of materials, including metals, plastics, ceramics, and composites.

- Factors to consider when choosing an Nd:YAG laser cutter include power and energy levels, beam quality and stability, and maintenance and support.

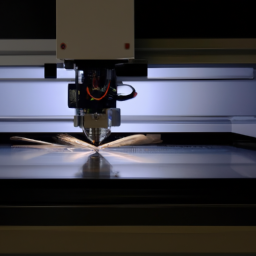

How Nd:YAG Laser Cutters Work

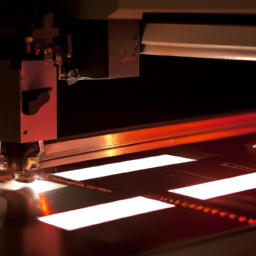

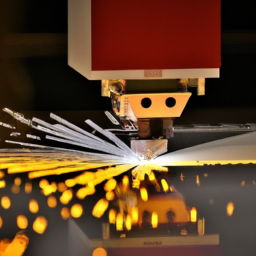

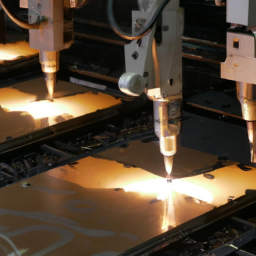

You may be surprised by how effortlessly Nd:YAG laser cutters slice through tough materials, leaving you in awe of their incredible precision and power. These remarkable machines operate on the principle of selective absorption of laser energy by the material being cut.

The key component in Nd:YAG laser cutters is the neodymium-doped yttrium aluminum garnet crystal, which emits high-energy light when stimulated by a flash lamp or diode laser. This light is then focused into a beam and directed onto the workpiece.

As the intense laser beam strikes the material, it rapidly heats and vaporizes the targeted area, creating a narrow kerf. This process repeats as the laser beam moves across the workpiece, resulting in clean, precise cuts.

Understanding the working principles and key components of Nd:YAG laser cutters sets the stage for exploring their diverse applications in various industries.

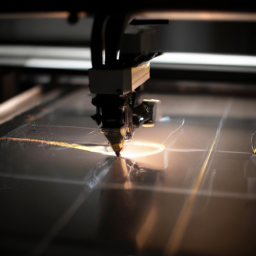

Applications of Nd:YAG Laser Cutters

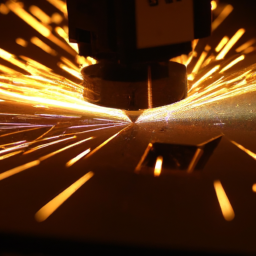

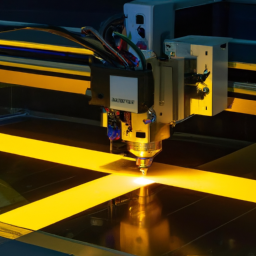

Have you ever wondered what types of materials can be easily and precisely cut using this advanced technology? Nd:YAG laser cutters are versatile machines that can cut a wide range of materials with high precision and accuracy. They are commonly used in various industrial applications, such as metal fabrication, automotive manufacturing, electronics production, and aerospace engineering.

These laser cutters can effortlessly cut materials like stainless steel, aluminum, copper, brass, titanium, and even non-metallic materials like ceramics, plastics, and composites. The ability to cut through such a diverse range of materials makes Nd:YAG laser cutters a popular choice in many industries.

In the next section, we will explore the advantages of Nd:YAG laser cutters and why they are preferred over other cutting methods.

Advantages of Nd:YAG Laser Cutters

When it comes to Nd:YAG laser cutters, you can expect precision and accuracy in every cut. These machines are known for their ability to produce precise and clean cuts, making them ideal for applications that require high levels of accuracy.

Additionally, Nd:YAG laser cutters offer versatility and flexibility, allowing you to work with a wide range of materials and thicknesses.

Lastly, the non-contact process of Nd:YAG laser cutting ensures that there’s no physical contact between the laser and the material, minimizing the risk of damage or contamination.

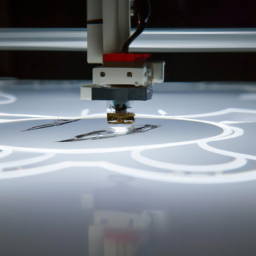

Precision and Accuracy

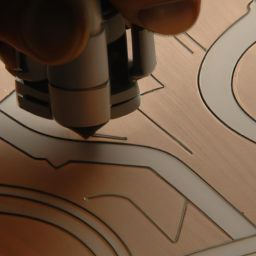

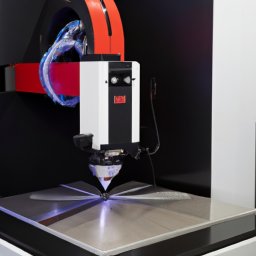

To truly appreciate the capabilities of nd:yag laser cutters, it’s crucial to grasp the significance of precision and accuracy in achieving flawless results.

Precision is the ability of a laser cutter to consistently produce exact and fine cuts, while speed refers to the rate at which these cuts are made. Nd:YAG laser cutters excel in striking a balance between precision and speed, making them highly efficient.

Laser cutting techniques, such as beam focusing and pulse duration control, contribute to the precision achieved by nd:yag laser cutters. These techniques ensure that the laser beam is concentrated and the pulse duration is optimized for the material being cut, resulting in clean and accurate cuts. This precision and accuracy allows for intricate and complex designs to be executed flawlessly.

Transitioning into the next section about versatility and flexibility, nd:yag laser cutters also offer a wide range of capabilities beyond just precise cutting.

Versatility and Flexibility

Imagine the possibilities of what you can create with the wide range of capabilities and flexibility offered by nd:yag laser cutters – they can handle various materials with ease, including metals, plastics, ceramics, and even diamonds. This versatility and flexibility make nd:yag laser cutters a cost-effective and efficient solution for a wide range of applications.

Not only can they achieve intricate and precise cuts, but they can also engrave and mark materials with exceptional accuracy. The ability to work with different materials without the need for additional tooling or setup changes saves both time and money. Additionally, the non-contact process of laser cutting eliminates the risk of material damage or contamination, ensuring high-quality results.

Transitioning into the next section about the ‘non-contact process’, you’ll discover how this feature further enhances the capabilities of nd:yag laser cutters.

Non-contact Process

The non-contact process of laser cutting with nd:yag laser cutters ensures high-quality results and eliminates the risk of material damage or contamination. One of the advantages of this non-contact process is that it allows for precise and intricate cuts without physically touching the material. This is especially beneficial when working with delicate or sensitive materials, as it reduces the chances of distortion or warping.

Additionally, the non-contact nature of laser cutting eliminates the need for clamping or holding down the material, saving time and effort. However, it’s important to note that there are limitations to the non-contact process. For example, it may not be suitable for materials that are highly reflective or transparent, as the laser energy may be reflected or absorbed instead of cutting through the material.

Considerations such as these will be discussed in the subsequent section about factors to consider when choosing an nd:yag laser cutter.

Factors to Consider When Choosing an Nd:YAG Laser Cutter

When choosing an Nd:YAG laser cutter, there are three key factors you need to consider: power and energy levels, beam quality and stability, and maintenance and support.

The power and energy levels of the laser cutter determine its cutting capabilities and speed, so it’s crucial to choose one that meets your specific needs.

Beam quality and stability are essential for achieving precise and accurate cuts, ensuring consistent performance.

Lastly, considering the maintenance and support provided by the manufacturer is important to ensure the longevity and reliability of your Nd:YAG laser cutter.

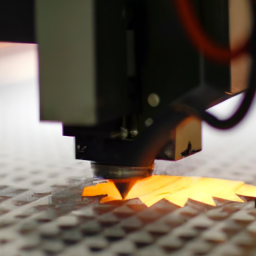

Power and Energy Levels

Get ready to feel the pulse of power and energy as you step into the world of nd:yag laser cutters. These machines offer a wide range of power and energy levels to suit different laser cutting techniques and applications.

When choosing an Nd:YAG laser cutter, it’s important to consider the power and energy levels that will be required for your specific needs.

Here are two key factors to consider:

-

Laser Cutting Techniques:

- Different laser cutting techniques require different power and energy levels. For example, if you’re cutting thin materials, you may require lower power and energy levels. On the other hand, if you’re cutting thicker materials or need faster cutting speeds, higher power and energy levels may be necessary.

-

Beam Delivery Systems:

- The power and energy levels of an Nd:YAG laser cutter are closely tied to the beam delivery system. Different beam delivery systems can handle different power and energy levels. It’s important to choose a system that can handle the specific power and energy requirements of your application.

As you delve deeper into the world of nd:yag laser cutters, you’ll soon explore the next section about ‘beam quality and stability’ without missing a beat.

Beam Quality and Stability

Immerse yourself in the world of nd:yag laser cutters as you discover the remarkable beam quality and stability that will take your laser cutting experience to new heights. When it comes to laser cutting, beam quality refers to the characteristics of the laser beam, such as its focusability and uniformity. A high-quality beam ensures precise and clean cuts, resulting in superior finished products. Stability, on the other hand, refers to the consistency of the laser beam over time. A stable beam is essential for maintaining accuracy and repeatability in your laser cutting applications. Achieving both beam quality and stability requires careful consideration of factors such as beam delivery systems and thermal management. By optimizing these aspects, you can ensure optimal performance and longevity of your nd:yag laser cutter. In the next section on maintenance and support, we will explore how you can keep your laser cutter running smoothly and efficiently.

Maintenance and Support

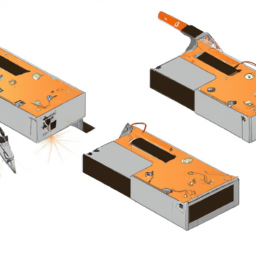

Now that you understand the importance of beam quality and stability in nd:YAG laser cutters, let’s delve into the crucial aspect of maintenance and support.

Regular maintenance procedures are essential to ensure the longevity and optimal performance of your laser cutter. This includes routine cleaning and inspection of the optics, as well as checking and replacing any worn-out components.

Additionally, it is vital to familiarize yourself with troubleshooting techniques in case any issues arise during operation. This may involve diagnosing and resolving problems related to power supply, cooling systems, or beam alignment.

By following proper maintenance procedures and being equipped with troubleshooting techniques, you can minimize downtime and keep your nd:YAG laser cutter operating at its best.

Now, let’s move on to the next section, where we will discuss safety considerations for nd:YAG laser cutting.

Safety Considerations for Nd:YAG Laser Cutting

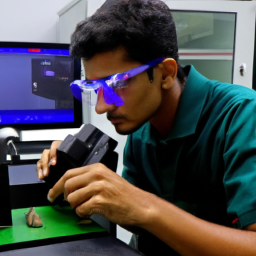

To ensure your safety when using an Nd:YAG laser cutter, it’s crucial to remember that just like a surgeon’s steady hand, your cautious and precise movements are essential in avoiding accidents. However, it’s not just your actions that contribute to safety; the use of proper safety equipment is equally important.

Ensure you have access to protective eyewear, gloves, and clothing that can shield you from laser radiation and potential sparks or debris. Additionally, receiving proper training and certifications in laser safety protocols is essential to minimize risks. Knowing how to operate the laser cutter safely, understand emergency procedures, and identify potential hazards is crucial.

By prioritizing safety equipment and obtaining the necessary training, you can confidently operate the Nd:YAG laser cutter.

Looking ahead, let’s explore the future developments and innovations in Nd:YAG laser cutting.

Future Developments and Innovations in Nd:YAG Laser Cutting

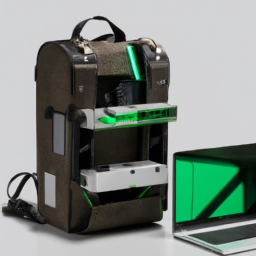

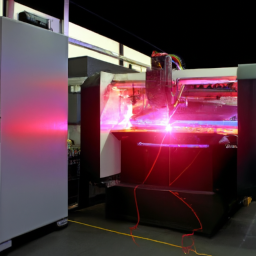

The future of Nd:YAG laser cutting holds exciting possibilities for advancements and breakthroughs. As technology continues to evolve, so does the potential for improved performance and increased efficiency in laser cutting processes.

One area of focus for future advancements is the development of higher power lasers, which would allow for faster and more precise cutting. Additionally, emerging technologies such as beam shaping and adaptive optics have the potential to enhance the quality of laser cutting by improving beam control and reducing thermal distortion.

Another area of interest is the integration of artificial intelligence and machine learning algorithms, which could optimize cutting parameters and improve overall process efficiency.

With these future developments on the horizon, Nd:YAG laser cutting is poised to become even more versatile and effective in a wide range of applications.

Frequently Asked Questions

What is the cost range of Nd:YAG laser cutters?

The cost range of nd:yag laser cutters varies depending on the specific model and features. Compared to other types of laser cutters, nd:yag laser cutters generally have a higher upfront cost. However, they offer advantages such as higher power output, versatility in cutting various materials, and the ability to engrave and mark surfaces.

Some disadvantages include higher maintenance costs and the need for specialized training to operate the equipment effectively.

Can Nd:YAG laser cutters be used on all types of materials?

Nd:YAG laser cutters have certain limitations when it comes to the types of materials they can be used on. They work best on metals, ceramics, and certain plastics. However, they aren’t suitable for cutting transparent materials or highly reflective surfaces.

Despite these limitations, there are several advantages to using Nd:YAG laser cutters. They provide high precision, clean cuts, and can be used for various applications such as marking, engraving, and welding.

How long does it take to learn how to operate an Nd:YAG laser cutter?

It typically takes a few weeks to several months to become proficient in operating an nd:yag laser cutter. The learning curve depends on your prior experience with similar equipment and your ability to grasp technical concepts quickly. To expedite the learning process, specialized training programs are available that provide comprehensive instruction on operating nd:yag laser cutters. These courses cover topics such as machine setup, safety protocols, material compatibility, and troubleshooting techniques.

Are there any maintenance requirements for Nd:YAG laser cutters?

Maintenance requirements for nd:yag laser cutters include regular cleaning of the optics, checking and replacing the flash lamp, and ensuring proper cooling and ventilation. Common issues faced in nd:yag laser cutters include beam misalignment, power fluctuations, and contamination of the optics. Regular maintenance is essential to prevent these issues and ensure optimal performance.

It’s recommended to follow the manufacturer’s guidelines for maintenance and consult a professional technician for any complex repairs or troubleshooting.

Can Nd:YAG laser cutters be used for engraving or marking materials?

Nd:YAG laser engraving applications open up a world of possibilities. Imagine a beam of light delicately etching intricate designs onto various materials. With Nd:YAG laser marking, you can achieve precise and permanent markings on metals, plastics, ceramics, and more.

The benefits of using Nd:YAG laser marking include high-speed operation, non-contact process, and exceptional durability. Whether it’s industrial applications or artistic creations, Nd:YAG lasers are a versatile tool for engraving and marking materials.

Conclusion

In conclusion, Nd:YAG laser cutters are a highly efficient and versatile tool for precision cutting in various industries. They have become an essential tool in manufacturing and fabrication processes due to their ability to cut through a wide range of materials and their high level of precision.

One interesting statistic to note is that Nd:YAG laser cutters have an average cutting speed of 200 inches per minute, making them significantly faster than traditional cutting methods.

As technology continues to advance, we can expect to see even more innovations and improvements in Nd:YAG laser cutting, further enhancing its capabilities and applications.