Have you ever watched a skilled chef effortlessly slicing through ingredients with a precision knife, marveling at their expertise? Just like the chef’s knife, the tools you choose for your business can greatly impact your cutting operations.

Nd:YAG laser cutters and CNC routers are two popular options, each with their own unique strengths.

Imagine you have a carpentry business, and you need to cut intricate designs out of various materials like wood, acrylic, or metal. You may be torn between the precision of an Nd:YAG laser cutter and the versatility of a CNC router. To help you make an informed decision, let’s delve into the key differences and considerations.

In this article, we will explore the technical aspects, analyze the precision and efficiency of Nd:YAG laser cutters, and assess the versatility and flexibility of CNC routers. We will also compare the cost and maintenance requirements of both machines. By the end, you will have the knowledge and insights needed to determine which tool is better suited for your business’s specific cutting needs.

So, let’s dive in and find the perfect cutting companion for your business.

Key Takeaways

- Nd:YAG laser cutters offer high cutting speed and minimal material wastage, making them ideal for businesses requiring fast and precise cutting operations.

- CNC routers are versatile and flexible, suitable for a wider range of industries and applications, including woodworking, plastic fabrication, and signage.

- Nd:YAG laser cutters are more expensive and require specialized maintenance, while CNC routers are more affordable and easier to maintain.

- Businesses should consider their specific cutting needs, material compatibility, and customization options to make an informed decision between Nd:YAG laser cutters and CNC routers.

Understand the Differences Between Nd:YAG Laser Cutters and CNC Routers

Now, let’s dive into understanding the differences between Nd:YAG laser cutters and CNC routers so you can confidently choose the best option for your business!

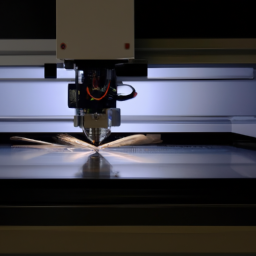

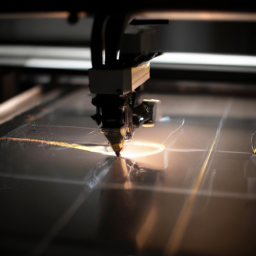

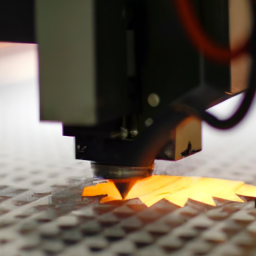

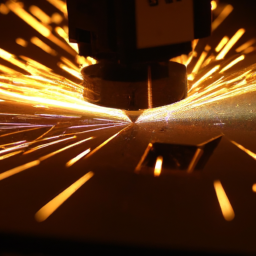

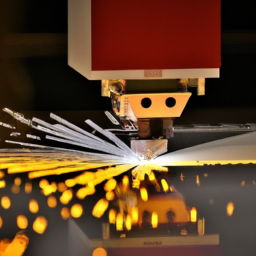

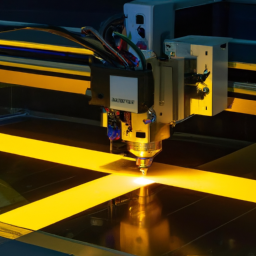

Nd:YAG laser cutters are highly efficient machines that use a solid-state laser to cut through a variety of materials with precision. They offer advantages such as high cutting speed, minimal material wastage, and the ability to cut intricate shapes. However, they have a limited range of applications, mainly in industries like electronics and jewelry.

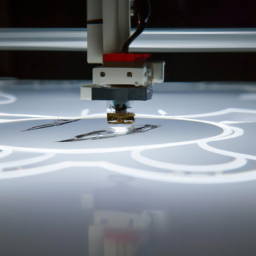

On the other hand, CNC routers use computer-controlled movements to cut materials using various tools. They have a wider range of applications in industries like woodworking, plastic fabrication, and signage. While CNC routers are versatile, they may have lower cutting speeds compared to Nd:YAG laser cutters.

Consider your business’s cutting needs and objectives as you determine which machine will work best for you.

Consider Your Business’s Cutting Needs and Objectives

Consider your business’s cutting needs and objectives, and you’ll be amazed to learn that a recent study found that businesses that invest in the right cutting technology can experience a 30% increase in productivity. When choosing between Nd:YAG laser cutters and CNC routers, it’s crucial to evaluate the cutting speed and material compatibility.

Nd:YAG laser cutters offer exceptional cutting speed, allowing for quick and efficient processing of various materials, including metals, plastics, and ceramics. This speed can significantly reduce production time and increase output. Additionally, Nd:YAG lasers exhibit excellent material compatibility, enabling precise and clean cuts on a wide range of materials.

With this understanding of cutting speed and material compatibility, we can now delve into evaluating the precision and efficiency of Nd:YAG laser cutters.

Evaluate the Precision and Efficiency of Nd:YAG Laser Cutters

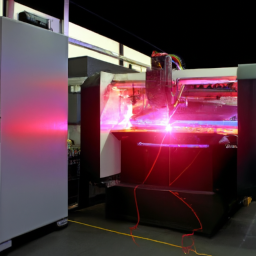

When evaluating the precision and efficiency of Nd:YAG laser cutters, it’s crucial to assess their ability to deliver accurate and rapid cuts on a wide range of materials.

Nd:YAG laser cutters offer several advantages, including high precision and accuracy due to their focused beam and small spot size. These cutters can achieve intricate and complex designs with minimal material waste. Additionally, Nd:YAG laser cutters are known for their efficiency, as they can cut through various materials quickly and with minimal heat-affected zones.

However, it’s important to consider the limitations of Nd:YAG laser cutters as well. They may not be suitable for cutting certain materials like reflective metals, and they may have lower cutting speeds compared to other laser cutting methods.

As you assess the precision and efficiency of Nd:YAG laser cutters, it’s important to transition into the subsequent section about assessing the versatility and flexibility of CNC routers.

Assess the Versatility and Flexibility of CNC Routers

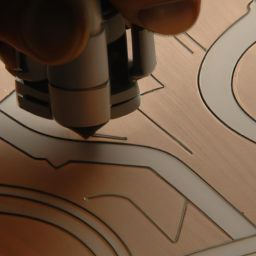

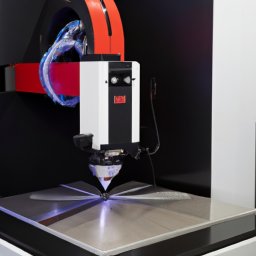

The versatility and flexibility of CNC routers make them a valuable tool for a wide range of industries and applications. CNC routers offer several advantages in different industries.

In woodworking, they allow for precise cutting and shaping of various materials, including solid wood, plywood, and MDF boards.

In the automotive industry, CNC routers are used for fabricating interior trim components and cutting out intricate designs on dashboards. They are also widely used in the signage industry to create customized and detailed signs.

One of the main benefits of CNC routers is their ability to explore creative possibilities. With the use of advanced software, intricate and complex designs can be easily programmed and executed. However, there are some limitations to consider.

CNC routers may not be suitable for industries that require extremely high precision, such as aerospace or medical device manufacturing.

Transitioning into the next section about comparing the cost and maintenance of both machines, it is important to evaluate these factors when deciding between Nd:YAG laser cutters and CNC routers.

Compare the Cost and Maintenance of Both Machines

Comparing the cost and maintenance of both machines is like weighing the price of a delicate, high-maintenance sports car against a reliable, low-maintenance sedan.

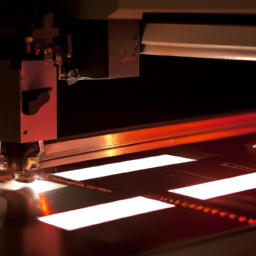

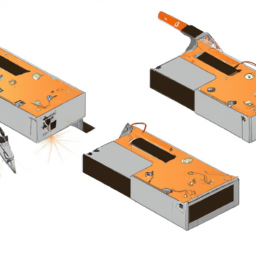

When it comes to cost, CNC routers are generally more affordable than ND:YAG laser cutters. The initial investment for a CNC router is typically lower, and the ongoing costs, such as electricity and consumables, are also comparatively lower. On the other hand, ND:YAG laser cutters are known for their higher price tags, both in terms of purchase and maintenance. These machines require regular maintenance and calibration to ensure optimal performance, which can add to the overall cost.

Regarding maintenance, CNC routers are relatively easier to maintain with routine checks and occasional part replacements. In contrast, ND:YAG laser cutters demand specialized maintenance and expert technical assistance.

To make an informed decision based on your business’s specific requirements, consider the cost comparison and maintenance comparison of both machines.

Make an Informed Decision Based on Your Business’s Specific Requirements

To make the best choice for your business, carefully consider your specific requirements and find the machine that perfectly suits your needs.

When comparing nd:YAG laser cutters and CNC routers, it’s crucial to evaluate their customization options and material compatibility.

Nd:YAG laser cutters offer high precision and are ideal for cutting intricate designs on a variety of materials such as metal, plastic, and wood. However, they may not be suitable for thick materials or those that are highly reflective.

On the other hand, CNC routers are versatile and can handle a wider range of materials, including thick and reflective ones. They are excellent for carving and engraving, providing greater flexibility in terms of design.

By assessing your business’s requirements for customization and material compatibility, you can make an informed decision between nd:YAG laser cutters and CNC routers.

Frequently Asked Questions

What are the main differences between Nd:YAG laser cutters and CNC routers?

Nd:YAG laser cutters and CNC routers have distinct differences. Laser cutters use a high-powered laser beam to cut through materials, while routers use rotating cutting tools. Laser cutters offer precise and intricate cuts, making them ideal for delicate designs. However, they are limited in the materials they can cut.

On the other hand, CNC routers are versatile and can work on a wide range of materials, but they may not achieve the same level of precision as laser cutters. Each option has its pros and cons, so choose based on your business needs.

How do I determine my business’s cutting needs and objectives?

To determine your business’s cutting needs and evaluate objectives, start by understanding the materials you work with and the desired precision and speed. Consider factors such as production volume, material thickness, and design complexity.

Evaluate your business objectives by identifying the desired level of automation, scalability, and cost-effectiveness. Assessing these factors will help you make an informed decision on which cutting technology, whether it be Nd:YAG laser cutters or CNC routers, aligns best with your business’s requirements.

What factors should I consider when evaluating the precision and efficiency of Nd:YAG laser cutters?

When evaluating the precision and efficiency of Nd:YAG laser cutters, there are several factors to consider.

Firstly, look at the laser power and beam quality, as these will directly impact the cutting precision.

Additionally, consider the cutting speed and repetition rate, which determine the efficiency of the cutter.

Other important factors include the control software, cooling system, and maintenance requirements.

By thoroughly evaluating these factors, you can make an informed decision about the precision and efficiency of Nd:YAG laser cutters for your business.

How can I assess the versatility and flexibility of CNC routers?

Assessing the versatility and flexibility of CNC routers requires a meticulous evaluation process.

To begin, consider the range of materials the router can handle, examining its compatibility with various densities and sizes.

Assess the router’s adaptability by analyzing its software capabilities, such as the ability to import different file formats and perform complex operations.

Additionally, evaluate the router’s speed and precision when executing different tasks, ensuring efficiency across a range of projects.

What are the costs associated with the maintenance of Nd:YAG laser cutters and CNC routers?

When conducting a comparison analysis of maintenance costs between Nd:YAG laser cutters and CNC routers, it’s essential to consider various factors. Maintenance costs for Nd:YAG laser cutters typically include regular calibration, replacement of flash lamps, and periodic cleaning of optics.

On the other hand, CNC routers require maintenance such as lubrication, replacing worn-out cutting tools, and regular inspection of drive systems. Both machines have associated costs, but the specific expenses may vary depending on factors like machine usage, complexity, and the availability of skilled technicians.

Conclusion

In conclusion, when deciding between Nd:YAG laser cutters and CNC routers for your business, it’s crucial to assess your cutting needs and objectives.

While Nd:YAG laser cutters offer precision and efficiency, CNC routers provide versatility and flexibility.

Additionally, considering the cost and maintenance of both machines is essential.

Remember the old adage, "Choose the right tool for the job."

By carefully evaluating your business’s specific requirements, you can make an informed decision that will optimize productivity and success.