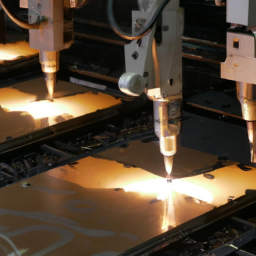

Are you in search of the ultimate laser cutting machine that will revolutionize your manufacturing processes? Look no further, as we present to you the epic battle between Nd:YAG laser cutters and CO2 laser cutters. These cutting-edge technologies have taken the industrial world by storm, offering unparalleled precision and efficiency.

Prepare to be amazed as we delve into the realm of laser cutting, exploring the capabilities, power, and cost of these mighty machines.

In this electrifying showdown, we will compare the cutting capabilities of Nd:YAG and CO2 laser cutters, assessing their power and speed to determine which one reigns supreme.

Brace yourself for an in-depth analysis of the cost and maintenance requirements of each laser cutter, ensuring you make an informed decision for your business.

We will leave no stone unturned as we examine the precision and accuracy of these laser cutters, uncovering the secrets behind their flawless cuts.

So, gear up and join us on this journey to discover which laser cutter is the perfect match for your specific needs. Get ready for a battle of epic proportions – Nd:YAG versus CO2 – which one will emerge victorious? Let the laser cutting games begin!

Key Takeaways

- Nd:YAG laser cutters are highly precise and suitable for thinner and delicate materials, while CO2 laser cutters are versatile and ideal for cutting thicker and tougher materials.

- Nd:YAG laser cutters have a longer lifespan and lower maintenance costs, while CO2 laser cutters have lower initial costs but may require more frequent maintenance and consumable replacements.

- Nd:YAG laser cutters offer slower cutting speeds but provide more precision and accuracy, while CO2 laser cutters have faster cutting speeds and excel in high-volume production.

- Nd:YAG laser cutters are suitable for engraving on metals, ceramics, and plastics, while CO2 laser cutters are great for cutting and engraving organic materials like wood, paper, and fabric.

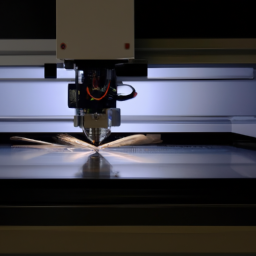

Understanding the Basics of Laser Cutting Technology

If you’re looking to dive into the world of laser cutting, get ready to be amazed by the mind-blowing capabilities that this technology can offer you. Laser cutting has revolutionized the manufacturing industry with its precision and efficiency.

One of the key advantages of fiber laser cutters is their ability to cut through a wide range of materials, including metals, plastics, and composites. They offer superior beam quality, which results in cleaner cuts and reduced material waste. Understanding beam quality in laser cutting is crucial, as it directly affects the cut edge quality and overall efficiency of the process.

Now, let’s transition into comparing the cutting capabilities of nd:yag and co2 laser cutters, where we will explore their differences and help you decide which one is right for you.

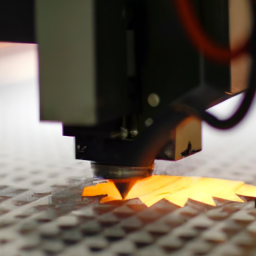

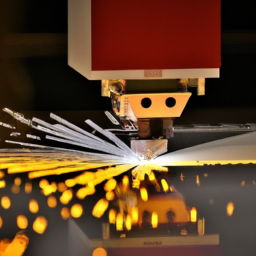

Comparing the Cutting Capabilities of Nd:YAG and CO2 Laser Cutters

When comparing the cutting capabilities, it’s important to consider the unique strengths and limitations of both Nd:YAG and CO2 laser cutters.

Nd:YAG laser cutters offer several advantages. They are highly precise and can cut through a wide range of materials, including metals, ceramics, and plastics. Additionally, they have a smaller heat-affected zone, which reduces the risk of material distortion. However, Nd:YAG laser cutters also have some disadvantages. They are generally slower and less powerful than CO2 laser cutters, limiting their efficiency for large-scale projects.

On the other hand, CO2 laser cutters are known for their versatility. They can cut through a variety of materials, including wood, acrylic, and fabric, at high speeds.

In conclusion, understanding the advantages and disadvantages of Nd:YAG and CO2 laser cutters is essential in assessing the power and speed of each laser cutter.

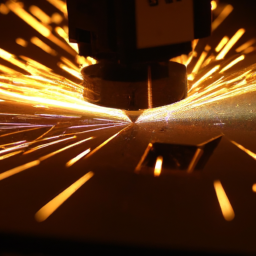

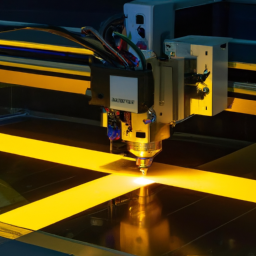

Assessing the Power and Speed of Each Laser Cutter

Assessing the power and speed of each laser cutter reveals their unique capabilities and efficiency for various cutting tasks. When evaluating material compatibility, it is essential to consider the power and speed of the laser cutter. Nd:YAG laser cutters typically have lower power levels, making them suitable for thinner and more delicate materials such as plastics and fabrics. On the other hand, CO2 laser cutters have higher power levels, enabling them to cut through thicker and tougher materials like metals and wood. The speed of the laser cutter also plays a crucial role in determining its efficiency. Nd:YAG laser cutters are generally slower, providing more precision and accuracy, while CO2 laser cutters are faster, making them ideal for high-volume production. Additionally, analyzing the environmental impact is important. Nd:YAG laser cutters produce less waste and consume less energy, making them more environmentally friendly. Transitioning into the subsequent section about considering the cost and maintenance requirements, it is crucial to factor in these aspects when making a decision.

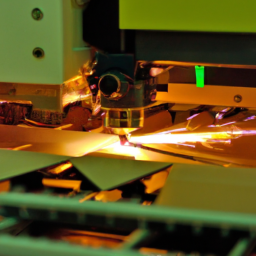

Considering the Cost and Maintenance Requirements

Considering the cost and maintenance requirements, it’s important to factor in these aspects when making a decision about which laser cutter is best for you.

Cost effectiveness is a key consideration when comparing ND:YAG laser cutters and CO2 laser cutters. ND:YAG laser cutters tend to have a higher upfront cost compared to CO2 laser cutters. However, they offer a longer lifespan and lower maintenance costs in the long run.

CO2 laser cutters, on the other hand, have a lower initial cost but may require more frequent maintenance and replacement of consumables.

Maintenance considerations also play a role in the decision-making process. ND:YAG laser cutters require less maintenance due to their solid-state design, while CO2 laser cutters require more frequent cleaning and alignment.

In conclusion, when considering the cost effectiveness and maintenance requirements, it is important to weigh these factors against the precision and accuracy of the laser cutters.

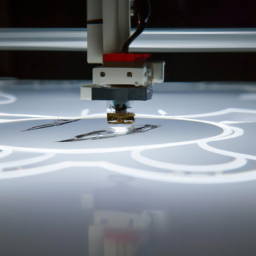

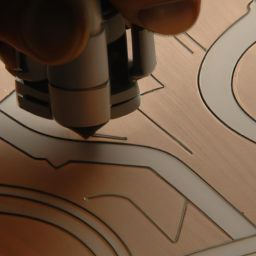

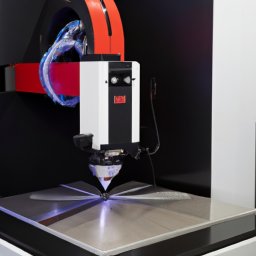

Examining the Precision and Accuracy of the Laser Cutters

Take a moment to marvel at the incredible precision and accuracy that these laser cutting machines possess. When evaluating the impact of material thickness on laser cutting precision, it’s crucial to consider the capabilities of both Nd:YAG and CO2 laser cutters.

Nd:YAG laser cutters are known for their ability to cut through thicker materials with high precision, making them suitable for heavy-duty applications. On the other hand, CO2 laser cutters excel in providing precise cuts on thinner materials.

Additionally, analyzing the effect of different cutting speeds on accuracy is essential. Nd:YAG laser cutters offer faster cutting speeds, resulting in increased productivity and efficiency. CO2 laser cutters, however, provide slower cutting speeds, which can be advantageous when intricate detailing and higher accuracy are required.

Evaluating these factors will help you determine the best laser cutter for your specific needs without compromising precision and accuracy.

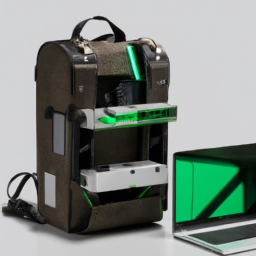

Determining the Best Laser Cutter for Your Specific Needs

To determine the best laser cutter for your specific needs, imagine yourself effortlessly creating precise and intricate designs with the perfect balance of speed and accuracy. When considering customization options, both the Nd:YAG laser cutter and CO2 laser cutter offer a range of possibilities.

The Nd:YAG laser cutter allows for engraving on a variety of materials, including metals, ceramics, and plastics, while the CO2 laser cutter excels in cutting and engraving organic materials like wood, paper, and fabric.

Safety features are of utmost importance when working with laser cutters. Both options come equipped with safety measures such as a protective enclosure, emergency stop buttons, and interlock systems to prevent accidents. However, it’s crucial to carefully evaluate the specific safety features offered by each laser cutter to ensure they meet your requirements.

Overall, considering both customization options and safety features will help you determine the best laser cutter for your specific needs.

Frequently Asked Questions

Can Nd:YAG laser cutters be used on all types of materials, or are they limited to specific ones?

Not every material is made for a Nd:YAG laser cutter. Its limited applicability means it can only work efficiently on certain types of materials.

On the other hand, CO2 laser cutters offer a wider range of applications. They have the advantage of being able to cut through various materials, such as wood, acrylic, and fabric, with precision and accuracy. Therefore, if you require versatility in material cutting, CO2 laser cutters are the way to go.

How long does it take to learn how to operate a CO2 laser cutter?

The learning curve for operating a CO2 laser cutter can vary depending on your prior experience with similar machinery. However, on average, it takes about a week of training to become proficient in operating a CO2 laser cutter.

During this time, you’ll learn how to set up the machine, adjust the laser settings, and operate it safely. Familiarity with computer software and design programs can also expedite the learning process.

Continuous practice and hands-on experience will further enhance your skills.

Are there any safety precautions that need to be taken when using Nd:YAG laser cutters?

When using nd:yag laser cutters, it’s important to take certain safety precautions. Always wear appropriate protective eyewear to shield your eyes from the intense laser beam.

Ensure that the work area is well-ventilated to prevent the buildup of potentially harmful fumes.

Additionally, it’s crucial to have a clear understanding of the common materials used with nd:yag laser cutters, such as metals, ceramics, and plastics, to ensure proper handling and avoid any potential hazards.

Can CO2 laser cutters be used for engraving purposes as well?

Co2 laser cutters aren’t just for cutting; they can also be used for engraving! Unlike Nd:YAG laser cutters, Co2 lasers have the capability to etch designs onto various materials. This is due to their higher power and longer wavelength.

However, when it comes to precision and versatility, Nd:YAG lasers have the upper hand. With their shorter wavelength and ability to work with a wider range of materials, Nd:YAG laser cutters offer distinct advantages over Co2 lasers for all your cutting and engraving needs.

What is the expected lifespan of a typical Nd:YAG laser cutter?

The expected lifespan of a typical Nd:YAG laser cutter depends on various factors. With proper maintenance and regular servicing, it can last for several years. However, the actual lifespan can vary based on usage, intensity, and operating conditions.

Regular maintenance requirements include cleaning the optics, checking and replacing consumables, and ensuring proper alignment. Adhering to these maintenance procedures can maximize the lifespan of your Nd:YAG laser cutter and optimize its performance.

Conclusion

So, after all the technical analysis and comparisons, you’re still wondering which laser cutter is right for you? Well, fear not, dear reader, for the answer lies within your specific needs and requirements.

While the Nd:YAG laser cutter may offer impressive cutting capabilities and the CO2 laser cutter boasts power and speed, it ultimately comes down to what you value most. Consider the cost and maintenance, precision and accuracy, and make a decision that suits your unique circumstances.

In the end, the best laser cutter for you is the one that cuts through all the noise and delivers exactly what you need. Happy laser cutting!