When it comes to choosing the right cutting tool for your business, the decision can be overwhelming.

Nd:YAG laser cutters and die cutters are two popular options, each with their own set of advantages and disadvantages. To make an informed decision, it’s important to understand the intricacies of both technologies.

Nd:YAG laser cutters are known for their precision and versatility. They use a high-powered laser beam to cut through various materials with incredible accuracy.

On the other hand, die cutters offer a more traditional approach, using a specially designed blade to cut shapes into materials.

In this article, we will explore the advantages and disadvantages of Nd:YAG laser cutters and die cutters, helping you determine which one is the better investment for your business.

By comparing factors such as cost, speed, versatility, and maintenance requirements, you will be able to make a well-informed decision that aligns with your specific needs and goals.

So let’s dive in and find out which cutting tool reigns supreme in the battle of Nd:YAG laser cutters versus die cutters.

Key Takeaways

- Nd:YAG laser cutters are known for their precision and versatility, as they can cut through metals, plastics, and ceramics.

- Die cutters are cost-effective and can handle a wider range of materials, but have limitations in precision and material compatibility.

- Nd:YAG laser cutters require safety precautions and proper ventilation, as they can potentially cause thermal damage to materials.

- Die cutters have a slower production speed compared to Nd:YAG laser cutters and struggle to cut through metal or thick plastics.

Understanding the Nd:YAG Laser Cutter

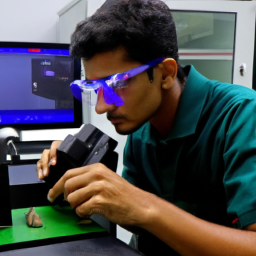

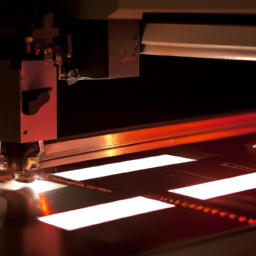

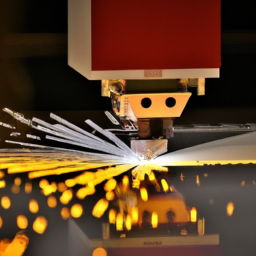

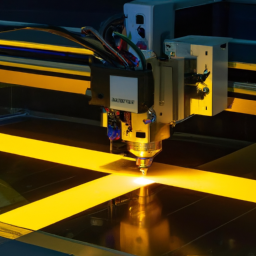

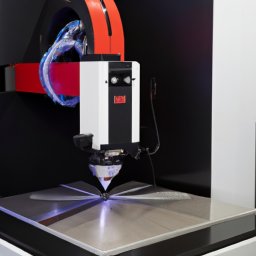

If you really want to understand the Nd:YAG Laser Cutter, you’re going to be blown away by its precision and power. This laser cutting machine utilizes a crystal rod of neodymium-doped yttrium aluminum garnet (Nd:YAG) as the lasing medium, which emits high-intensity laser beams.

The Nd:YAG laser cutter is widely used in various industries due to its versatility in applications. It can effortlessly cut through materials like metals, plastics, and ceramics with remarkable accuracy, making it ideal for intricate designs and precise cuts.

However, it’s crucial to adhere to strict safety precautions when operating this machine. This includes wearing protective eyewear and ensuring proper ventilation to prevent exposure to harmful fumes.

Now, let’s delve into exploring the die cutter and its capabilities.

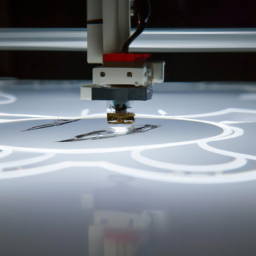

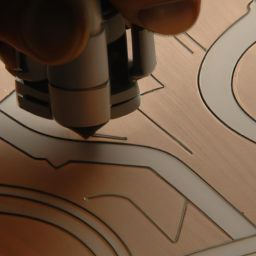

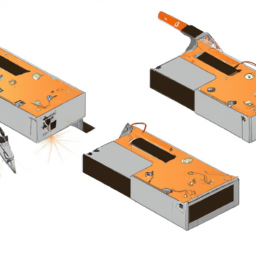

Exploring the Die Cutter

Although die cutters may initially seem like a less advanced choice compared to their laser counterparts, their versatility and ability to handle a wider range of materials make them a valuable investment in the long run. Die cutters offer a variety of applications, including cutting, embossing, and creasing materials such as paper, cardboard, fabric, and even metal. The precision of die cutters is unmatched, ensuring accurate and consistent results every time. With the ability to create intricate designs and precise shapes, die cutters are essential in industries like packaging, signage, and manufacturing. Additionally, die cutters are cost-effective, as they eliminate the need for expensive laser consumables and maintenance. Transitioning into the subsequent section, it is important to consider the advantages of Nd:YAG laser cutters in order to make an informed decision.

Advantages of Nd:YAG Laser Cutters

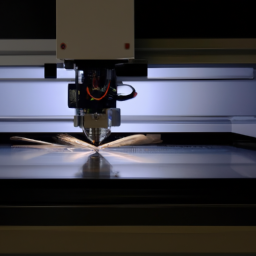

When it comes to choosing the right equipment for your needs, you’ll quickly discover the advantages of using Nd:YAG laser cutters. These cutting-edge machines offer precision cutting that is unmatched by other methods, ensuring that your products are made to exact specifications.

Nd:YAG laser cutters are known for their versatility, as they can be used on a wide range of materials, including metals, plastics, and ceramics. This makes them ideal for a variety of applications, from fabricating intricate components for electronics to creating custom signage.

The laser beam is highly focused, allowing for intricate and detailed cuts that would be difficult to achieve with other methods. With Nd:YAG laser cutters, you can achieve the precision and versatility needed for your projects. However, it’s important to consider the advantages of die cutters as well.

Advantages of Die Cutters

One of the compelling advantages of die cutters is their ability to deliver precise and consistent cuts, ensuring impeccable craftsmanship in your projects. Here are four reasons why die cutters are a worthwhile investment:

-

Efficiency: Die cutters are known for their high-speed operation, allowing you to complete projects in a shorter amount of time compared to other cutting methods.

-

Precision: Die cutters utilize sharp blades or steel rule dies that can be customized to cut intricate shapes with utmost accuracy. This precision ensures that your final products have clean edges and a professional finish.

-

Consistency: Die cutters offer consistent results with every cut, eliminating variations that can occur with manual cutting methods. This level of consistency guarantees that your projects will have a uniform appearance.

-

Versatility: Die cutters can handle a wide range of materials, including paper, cardboard, fabric, and even certain plastics. This versatility allows you to explore various creative possibilities without limitations.

Transitioning into the next section, let’s now examine the disadvantages of Nd:YAG laser cutters.

Disadvantages of Nd:YAG Laser Cutters

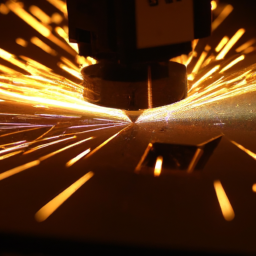

When considering the disadvantages of Nd:YAG laser cutters, there are a few key points to keep in mind.

Firstly, these machines require a higher initial investment compared to traditional die cutters.

Additionally, Nd:YAG laser cutters have a limited thickness capability for certain materials, which can be a drawback for industries that work with thicker materials.

Lastly, there is a potential risk for thermal damage when using Nd:YAG laser cutters, as the intense heat generated during the cutting process can sometimes affect the structural integrity of the material.

Higher Initial Investment

Although the upfront cost may be steeper, opting for an nd:yag laser cutter can prove to be a more advantageous investment. When considering the cost comparison between nd:yag laser cutters and die cutters, it’s important to take into account the long-term benefits.

While die cutters may have a lower initial investment, their limitations in terms of versatility and precision can result in additional costs over time. Nd:yag laser cutters, on the other hand, offer a wide range of capabilities. They can cut intricate designs and handle various materials with ease. This increased flexibility can lead to higher productivity and increased customer satisfaction.

Transitioning into the subsequent section about ‘limited thickness for certain materials’, it’s important to note that nd:yag laser cutters do have certain limitations in terms of thickness for certain materials.

Limited Thickness for Certain Materials

When considering the higher initial investment of ‘nd:yag laser cutters vs. die cutters’, it’s important to also take into account the limited thickness for certain materials. While die cutters can handle thicker materials with ease, ‘nd:yag laser cutters’ have their limitations.

Thicker materials such as metals and certain types of plastics may require alternative cutting methods. In terms of thickness capacity, die cutters offer a greater range of options compared to ‘nd:yag laser cutters’. This is due to the nature of the cutting mechanism and the power limitations of laser cutters. Therefore, if your project involves working with thicker materials, a die cutter may be the more suitable investment.

Moving forward, it’s essential to also consider the potential for thermal damage when comparing these two cutting methods.

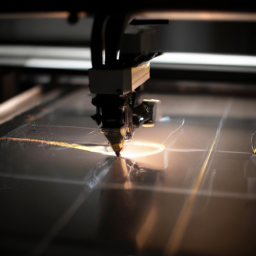

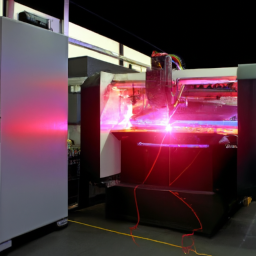

Potential for Thermal Damage

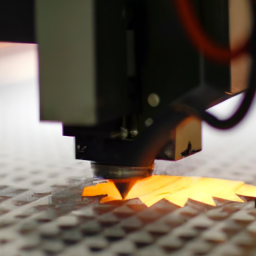

One important factor to consider is the potential for thermal damage when comparing these two cutting methods. When using an ND:YAG laser cutter, there’s a possibility of thermal damage to the material being cut. This can occur due to the high temperatures generated by the laser beam. However, laser cutter safety measures can be implemented to minimize this risk. For instance, cooling systems can be used to regulate the temperature and prevent overheating.

Additionally, precision cutting is a major advantage of ND:YAG laser cutters. The laser beam can be controlled with great accuracy, allowing for intricate and detailed cuts. This precision is crucial in industries that require fine finishing and high-quality results.

Transitioning into the next section about the disadvantages of die cutters, it’s important to note that thermal damage is less of a concern with die cutters due to the absence of heat.

Disadvantages of Die Cutters

You’ll regret choosing a die cutter because of its limitations and higher costs compared to an nd:yag laser cutter. Die cutters have several disadvantages that make them a less favorable investment option.

Firstly, die cutters have limited precision when it comes to intricate designs and fine details. This can result in imperfect cuts and inaccurate shapes, compromising the overall quality of the finished product.

Secondly, die cutters require the creation and maintenance of physical dies, which can be time-consuming and costly.

Additionally, die cutters are limited in their material compatibility, often being unable to effectively cut through certain materials such as metal or thick plastics.

Lastly, die cutters have a slower production speed compared to nd:yag laser cutters, leading to decreased efficiency and increased production time.

Frequently Asked Questions

Can a Nd:YAG laser cutter be used on all types of materials?

When considering the use of Nd:YAG laser cutters on different materials, there are several advantages to take into account.

Nd:YAG laser cutters offer high power output, allowing for efficient cutting on a variety of materials including metals, plastics, ceramics, and more.

Factors to consider when choosing a laser cutter for specific materials include the thickness and type of material, as well as the desired precision and speed of the cutting process.

Are die cutters more cost-effective than Nd:YAG laser cutters in the long run?

Die cutters are generally more cost-effective than Nd:YAG laser cutters in the long run. When considering cost comparison, die cutters have lower initial investment costs and maintenance expenses compared to Nd:YAG laser cutters.

Additionally, die cutters have higher efficiency in terms of production speed and material usage. They can handle a wide range of materials efficiently, making them a preferred choice for many industries.

Therefore, die cutters are a more cost-effective option in the long run.

How long does it take to set up and calibrate a Nd:YAG laser cutter?

Setting up and calibrating an nd:yag laser cutter typically takes a few hours. This process involves ensuring the laser is properly aligned, adjusting power settings, and calibrating the focal length.

Regular maintenance is crucial to keep the machine operating efficiently. However, the benefits of using an nd:yag laser cutter outweigh the setup time and maintenance requirements. It offers precise and clean cuts, versatility in materials, and increased productivity, making it a valuable investment for various industries.

Can die cutters produce intricate designs and shapes like Nd:YAG laser cutters?

Die cutters have distinct advantages over Nd:YAG laser cutters when it comes to producing intricate designs and shapes. While Nd:YAG laser cutters are highly precise, they have limitations in terms of intricate detailing due to their beam diameter and heat affected zone.

On the other hand, die cutters can achieve intricate designs with sharp edges and fine details. This makes die cutters a better choice for applications requiring complex shapes and intricate designs.

What safety precautions should be taken when operating a Nd:YAG laser cutter?

When operating an Nd:YAG laser cutter, it’s important to prioritize safety precautions. Proper eye protection, such as laser safety goggles, should always be worn to prevent potential eye damage. Regular maintenance is also crucial to ensure the machine’s optimal performance. This includes cleaning the lens, checking for any loose or damaged parts, and monitoring the cooling system. By adhering to these safety measures and maintaining the laser cutter, you can prevent accidents and prolong its lifespan.

Conclusion

In conclusion, when deciding between an Nd:YAG laser cutter and a die cutter, it’s essential to weigh their respective advantages and disadvantages.

While the Nd:YAG laser cutter offers precise and efficient cutting capabilities, the die cutter provides versatility and cost-effectiveness.

Ultimately, the better investment depends on your specific needs and priorities. So, whether you prioritize accuracy or flexibility, make an informed decision based on your requirements.

Remember, investing wisely ensures long-term success.