Imagine you’re in a workshop, surrounded by the hum of machinery and the smell of freshly cut materials. You have a project in mind, and you need a cutter that can deliver precision and speed. But with so many options available, how do you choose the right one?

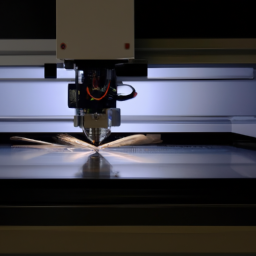

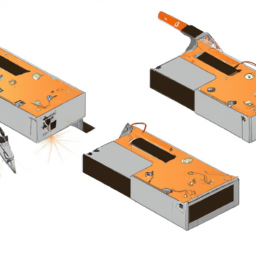

In this article, we will delve into the world of cutting technology and compare two popular choices: Nd:YAG laser cutters and electric cutters. These cutting-edge tools offer unique advantages, but which one is more convenient for your needs?

By examining factors such as cutting precision, versatility of materials, maintenance requirements, cost, and overall user experience, we will help you make an informed decision. So, whether you’re a hobbyist or a professional seeking the perfect cutter, join us as we explore the fascinating realm of Nd:YAG laser cutters and electric cutters to determine which one will truly elevate your cutting experience.

Key Takeaways

- Nd:YAG laser cutters offer higher cutting precision, versatile material capabilities, and faster cutting speeds compared to electric cutters.

- Nd:YAG laser cutters require less maintenance and have fewer breakdowns, resulting in long-term cost savings.

- Nd:YAG laser cutters provide a more convenient user experience with automated features and intuitive interfaces.

- Nd:YAG laser cutters have superior safety features with enclosed cutting areas and protective shields, reducing the risk of accidents.

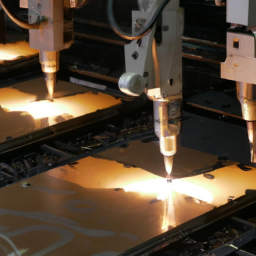

Understanding the Basics of Nd:YAG Laser Cutters and Electric Cutters

When it comes to understanding the basics of Nd:YAG laser cutters and electric cutters, it’s important to know the key differences.

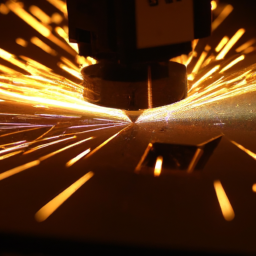

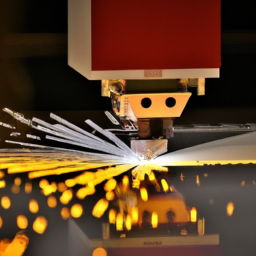

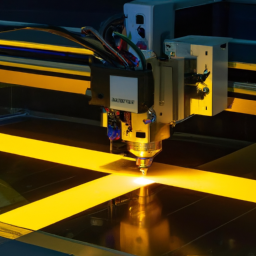

Nd:YAG laser cutters, also known as solid-state lasers, use a neodymium-doped yttrium aluminum garnet crystal as the active medium. They offer several advantages, such as high power output, precise cutting capabilities, and the ability to cut a wide range of materials, including metals.

On the other hand, electric cutters rely on a motor-driven blade to cut through materials. While they’re generally more affordable, electric cutters have some disadvantages, such as limited cutting precision and slower cutting speed compared to Nd:YAG laser cutters.

Moving on to comparing cutting precision and speed…

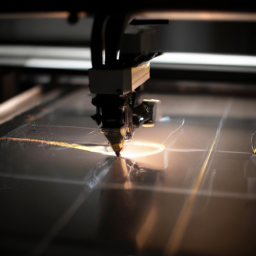

Comparing Cutting Precision and Speed

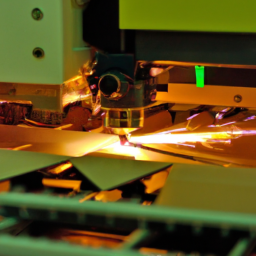

Surprisingly, electric cutters can sometimes outperform their high-tech counterparts in terms of cutting precision and speed. When analyzing efficiency, electric cutters have proven to be quite accurate, even though they lack the advanced technology of Nd:YAG laser cutters. The precision of electric cutters is attributed to their ability to make multiple cuts in a single pass, allowing for smaller and more intricate designs.

Additionally, electric cutters often have faster cutting speeds compared to Nd:YAG laser cutters, as they don’t require the time-consuming process of focusing the laser beam. This combination of accuracy and speed makes electric cutters a convenient choice for projects that prioritize efficiency.

Moving on to the next section, we’ll examine the versatility of materials and how each type of cutter handles different substances.

Examining the Versatility of Materials

Exploring the range of materials that can be effortlessly handled by both electric and high-tech cutters is crucial when assessing their compatibility and cutting quality. These versatile tools are capable of working with a wide array of materials, including:

-

Metals: Both electric and high-tech cutters can easily handle various types of metals, such as aluminum, stainless steel, and copper.

-

Plastics: From acrylic and polycarbonate to PVC and ABS, these cutters provide precise and clean cuts on different plastic materials.

-

Woods: Electric and high-tech cutters can effortlessly work with different types of wood, including plywood, MDF, and hardwood.

-

Fabrics: Whether it’s delicate silk or thick canvas, these cutters ensure accurate cutting without fraying or damaging the fabric.

-

Paper: Both electric and high-tech cutters can handle different types and thicknesses of paper, ensuring clean and precise cuts.

Examining the versatility of materials helps in evaluating the maintenance requirements of these cutters, which will be discussed in the subsequent section.

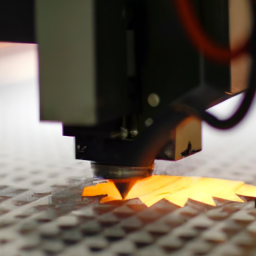

Evaluating the Maintenance Requirements

Maintaining these versatile cutters is like tending to a well-oiled machine, ensuring smooth and precise cuts for years to come. When evaluating maintenance costs, it’s important to consider both the frequency of downtime and the associated expenses.

ND:YAG laser cutters generally require less maintenance compared to electric cutters. The laser technology used in ND:YAG cutters is highly efficient and less prone to breakdowns, resulting in reduced downtime. Additionally, laser cutters have fewer moving parts, reducing the need for regular repairs and replacements. This not only saves on maintenance costs but also minimizes production interruptions.

By comparing downtime frequency and maintenance costs, it becomes evident that ND:YAG laser cutters offer a higher level of convenience.

Transitioning into the subsequent section about considering cost and affordability, it’s important to weigh these factors against the initial investment.

Considering Cost and Affordability

When it comes to cost and affordability, it’s important to consider the initial investment required for each type of cutter. When evaluating the cost effectiveness of ND:YAG laser cutters versus electric cutters, there are several key factors to take into account:

-

Initial Purchase Price: ND:YAG laser cutters tend to have a higher initial purchase price compared to electric cutters.

-

Maintenance Costs: Electric cutters typically have higher maintenance costs due to the need for regular blade replacements and other upkeep expenses.

-

Long-Term Savings: Despite the higher initial investment, ND:YAG laser cutters can provide long-term savings through reduced material waste, increased precision, and faster cutting speeds.

Considering these factors can help you determine which cutter option offers the best cost effectiveness and long-term savings for your needs.

Moving on to determining the overall convenience and user experience…

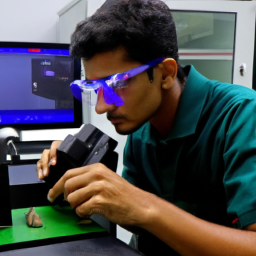

Determining the Overall Convenience and User Experience

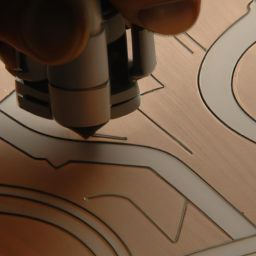

Now that we have discussed the cost and affordability of ‘nd:yag laser cutters vs. electric cutters, let’s move on to determining the overall convenience and user experience. When evaluating ease of use, it is important to consider factors such as setup time, programming complexity, and user-friendly interfaces. Electric cutters often require more manual adjustments and can be time-consuming to set up, whereas ‘nd:yag laser cutters typically have automated features and intuitive interfaces that make them easier to operate. Additionally, analyzing safety features is crucial in any cutting machine. Electric cutters may pose a higher risk of accidents due to their exposed blades, while ‘nd:yag laser cutters offer a safer option with their enclosed cutting area and protective shields. In the table below, we compare the convenience and safety aspects of these two types of cutters:

| Factors | ‘nd:yag Laser Cutters | Electric Cutters |

|---|---|---|

| Setup Time | Less time required | More time required |

| Programming Complexity | Intuitive interfaces | Manual adjustments |

| Safety Features | Enclosed cutting area, protective shields | Exposed blades, higher risk of accidents |

By carefully evaluating these aspects, we can determine which type of cutter offers a more convenient and user-friendly experience.

Frequently Asked Questions

Are Nd:YAG laser cutters more expensive to purchase compared to electric cutters?

Nd:YAG laser cutters are indeed more expensive to purchase compared to electric cutters. According to a cost comparison study, the average price of an Nd:YAG laser cutter is $50,000, while electric cutters cost around $10,000.

However, this higher upfront cost is offset by the efficiency analysis. Nd:YAG laser cutters have a higher cutting speed and precision, resulting in reduced material waste and increased productivity.

So, despite the higher initial investment, Nd:YAG laser cutters offer long-term cost savings.

Can Nd:YAG laser cutters be used on delicate materials such as fabrics or thin plastics?

Yes, nd:yag laser cutters can be used on delicate materials such as fabrics or thin plastics. Their precise beam and controlled heat allow for accurate and clean cuts without damaging the material. This makes nd:yag laser cutters ideal for applications like textile manufacturing or intricate plastic designs.

However, it’s worth noting that electric cutters also have their advantages, such as being more cost-effective and suitable for a wider range of materials.

How often do electric cutters require blade replacements?

Electric cutters generally require blade replacements at regular intervals, depending on the usage and the specific brand/model. However, the longevity of electric cutter blades can be extended by proper maintenance and handling.

One of the benefits of using electric cutters is their versatility in cutting different materials, including delicate fabrics and thin plastics. Their precision and control make them an ideal choice for various applications, providing efficient and accurate results.

Do Nd:YAG laser cutters produce harmful fumes or emissions?

When it comes to safety, nd:yag laser cutters are a great choice. They produce minimal fumes and emissions, making them safer for operators and the environment. In fact, studies have shown that nd:yag laser cutters emit up to 90% less fumes compared to other types of laser cutters.

On the other hand, electric cutters require proper ventilation and safety precautions to avoid harmful fumes. Therefore, nd:yag laser cutters are a safer and more convenient option.

What safety precautions should be taken when operating an electric cutter?

When operating an electric cutter, it’s crucial to follow specific operating procedures to ensure safety. Always wear appropriate protective equipment, such as safety glasses and gloves, to protect against potential hazards. Familiarize yourself with the cutter’s user manual to understand its features and limitations.

Additionally, make sure the work area is well-ventilated to prevent the buildup of potentially harmful fumes. By adhering to these safety precautions, you can minimize the risk of accidents and injuries while operating an electric cutter.

Conclusion

In conclusion, when considering the convenience of Nd:YAG laser cutters versus electric cutters, it’s evident that the former offers a superior user experience. The precision and speed of laser cutting technology outshine electric cutters, allowing for intricate and efficient cuts.

Additionally, Nd:YAG laser cutters exhibit remarkable versatility, accommodating a wide range of materials. While maintenance requirements may be higher, the benefits of precision and versatility outweigh this drawback.

Ultimately, if you’re seeking a convenient and efficient cutting solution, Nd:YAG laser cutters are the way to go.