Imagine a world where precision and portability converge, where cutting through materials with ease is not limited by size or location. In the realm of cutting technology, two contenders emerge: Nd:YAG laser cutters and handheld cutters. These tools embody the quest for portability, each with its unique advantages and capabilities. But the burning question remains: which one reigns supreme in terms of mobility?

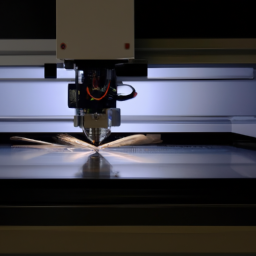

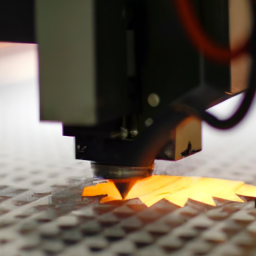

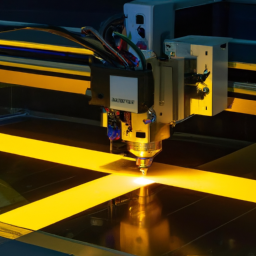

Enter the realm of Nd:YAG laser cutters, a technological marvel that offers unparalleled convenience. With its compact design and lightweight structure, this portable powerhouse allows you to take precision cutting to new heights.

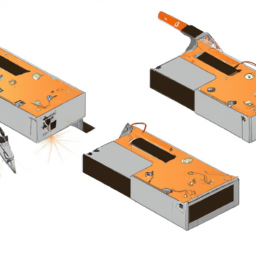

On the other hand, handheld cutters provide a different approach, offering flexibility and versatility in a handheld form.

In this article, we delve into the world of cutting technology, exploring the portability of Nd:YAG laser cutters and handheld cutters. We compare their cutting capabilities, analyze cost considerations, and uncover their applications and use cases. Join us on this journey of discovery as we determine which tool triumphs in the realm of portability.

Key Takeaways

- Nd:YAG laser cutters offer convenience, portability, and high precision

- Handheld cutters provide flexibility, versatility, and convenience in a handheld form

- Nd:YAG laser cutters are compact, lightweight, and easily transportable

- Handheld cutters are easily maneuvered, lightweight, and suitable for tight spaces

Portability of Nd:YAG Laser Cutters

When it comes to the portability of Nd:YAG laser cutters, handheld cutters offer a more convenient and easily transportable option. The advantages of handheld cutters for small spaces are significant.

Their compact size allows them to be easily maneuvered in tight areas, making them ideal for intricate and precise cutting tasks. Additionally, handheld cutters are lightweight, which makes them easy to carry and move around.

However, it is important to note that handheld cutters have limitations for large projects. Due to their smaller size and lower power output, they may not be suitable for cutting thicker materials or completing extensive cutting projects efficiently. Despite this drawback, handheld cutters provide a practical solution for portable cutting needs.

Transitioning to the next section, let’s now explore the portability of handheld cutters.

Portability of Handheld Cutters

When considering the portability of handheld cutters, there are several key points to take into account.

First, their convenient size and weight make them easy to transport and carry around.

Additionally, handheld cutters don’t require an external power source, which adds to their mobility and versatility.

Lastly, their design allows for ease of maneuverability, enabling users to navigate tight spaces and intricate cuts with precision.

Convenient Size and Weight

Although both nd:yag laser cutters and handheld cutters have their advantages, when it comes to convenient size and weight, the handheld cutter takes the cake.

The portability advantages of a handheld cutter are evident in its ease of transportation due to its compact and lightweight design. With dimensions typically ranging from 6 to 10 inches and weighing around 2 to 4 pounds, handheld cutters can be easily carried in a toolbox or even a backpack, making them highly suitable for on-the-go cutting tasks.

Furthermore, their small size allows for maneuverability in tight spaces and enables operators to reach inaccessible areas with precision. This convenience factor makes handheld cutters a popular choice for various applications.

Additionally, the absence of an external power source needed further enhances their portability, making them a versatile tool for cutting needs on the move, as we will explore in the subsequent section.

No External Power Source Needed

The handheld cutter’s convenience is further enhanced by its lack of reliance on an external power source, allowing users the freedom to cut wherever and whenever they need to. This is made possible by its battery-powered operation and compact design. Here are four reasons why this feature is beneficial:

-

Portability: Without the need for an external power source, the handheld cutter becomes highly portable, easily fitting into a bag or pocket for on-the-go use.

-

Versatility: Users can cut materials in various locations without the constraints of being near an electrical outlet.

-

Convenience: The battery-powered design eliminates the hassle of dealing with cords and finding an available power source.

-

Efficiency: With a handheld cutter, users can start cutting immediately, without the need to set up and connect to an external power supply.

Transitioning to the next section, the handheld cutter’s ease of maneuverability is another advantage to consider.

Ease of Maneuverability

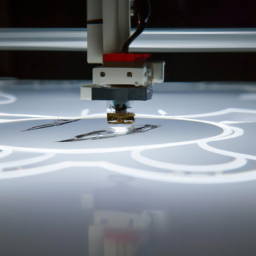

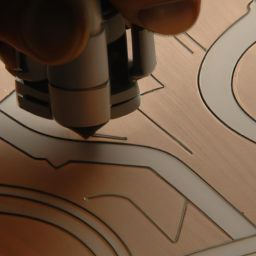

Another advantage of the handheld cutter is its exceptional maneuverability, making it a breeze to use in any situation. The lightweight and compact design of the handheld cutter allows for easy movement and control, even in tight spaces. Its small size and ergonomic handle provide a comfortable grip, reducing fatigue during extended use.

Additionally, the handheld cutter’s flexibility allows for precise cuts in various directions and angles, ensuring accuracy and efficiency. This maneuverability benefit is especially valuable for users who require portability advantages, as it allows for easy transportation and operation in different locations.

With its superior maneuverability, the handheld cutter stands out as a versatile tool that can be effortlessly used in any cutting task.

Now, let’s move on to the comparison of cutting capabilities.

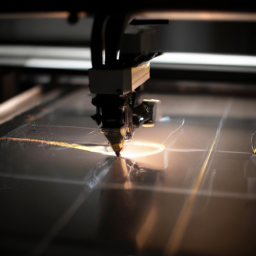

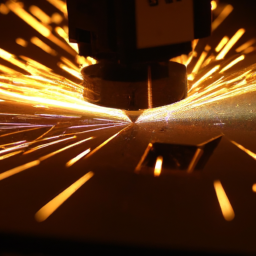

Comparison of Cutting Capabilities

When it comes to comparing cutting capabilities, there’s no denying that handheld cutters offer the ultimate convenience and precision. These cutters are designed to provide cutting precision and speed efficiency that is unrivaled by other types of cutters.

With their compact size and lightweight nature, handheld cutters allow for easy maneuverability and access to hard-to-reach areas, making them highly versatile in various cutting applications. Their ability to deliver precise and controlled cuts is crucial, especially when working with delicate materials or intricate designs.

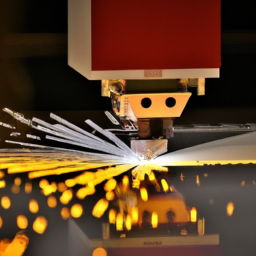

However, it’s important to consider cost considerations when choosing between handheld cutters and nd:yag laser cutters. While handheld cutters are portable and offer excellent cutting capabilities, nd:yag laser cutters may be more cost-effective in the long run due to their ability to handle larger volumes of work and provide consistent results.

Cost Considerations

Consider your budget carefully before making a decision, as the long-term cost-effectiveness of each option may vary.

When comparing the cost of nd:YAG laser cutters and handheld cutters, there are a few key factors to consider.

Firstly, nd:YAG laser cutters tend to have a higher upfront cost compared to handheld cutters. However, they generally have lower maintenance requirements, resulting in potentially lower long-term costs.

Handheld cutters, on the other hand, have a lower initial cost but may require more frequent maintenance, which can add up over time.

It’s important to consider the expected lifespan of the equipment and the cost of replacement parts when evaluating cost effectiveness.

Transitioning into the subsequent section about applications and use cases, it’s also crucial to assess the specific needs and requirements of your cutting tasks before making a decision.

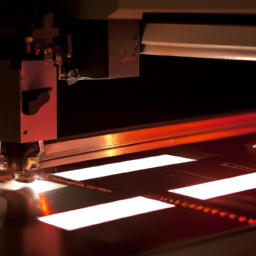

Applications and Use Cases

The diverse range of applications and use cases for these cutting tools ensures that there is a solution for every precision cutting need.

When it comes to handheld cutters, their main advantage lies in their portability and versatility. These compact tools are easy to transport and can be used in various environments, making them ideal for on-site jobs or situations where mobility is key.

On the other hand, nd:yag laser cutters have their limitations. While they offer high precision and accuracy, they are not as portable as handheld cutters. They require a stable power source and a controlled environment to operate effectively. Additionally, the initial investment and maintenance costs for laser cutters can be higher than those of handheld cutters.

However, for certain applications that require intricate and delicate cuts, nd:yag laser cutters can offer unmatched precision and consistency.

Frequently Asked Questions

Are Nd:YAG laser cutters more expensive than handheld cutters?

Nd:YAG laser cutters are indeed more expensive than handheld cutters. However, their precision and efficiency make them a worthwhile investment for professionals requiring precise cuts.

When it comes to providing precise cuts, Nd:YAG laser cutters outperform handheld cutters by a significant margin. The laser technology allows for precise control and accuracy, resulting in clean and intricate cuts.

Additionally, Nd:YAG laser cutters are more efficient, as they can cut through various materials with ease, reducing production time and increasing productivity.

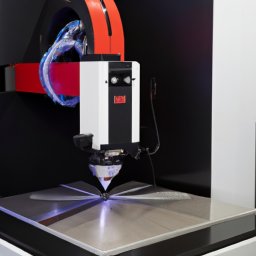

Can Nd:YAG laser cutters be used for intricate and detailed cutting tasks?

Nd:YAG laser cutters are highly suitable for intricate and detailed cutting tasks, especially in jewelry making. They offer precision and accuracy, allowing you to create intricate designs with ease. Although handheld cutters have their benefits for small projects, they may not provide the same level of precision as Nd:YAG laser cutters. Therefore, if you require intricate and detailed cutting tasks for jewelry making, Nd:YAG laser cutters are your best choice.

How long does it take to set up an Nd:YAG laser cutter compared to a handheld cutter?

The setup time for an nd:yag laser cutter is generally quicker compared to a handheld cutter. This is because nd:yag laser cutters are designed for precision and efficiency, allowing for faster setup and operation. In contrast, handheld cutters require manual adjustments and positioning, which can be time-consuming. Therefore, if setup time is a crucial factor, opting for an nd:yag laser cutter would be more advantageous.

Can handheld cutters be used for cutting different types of materials?

Handheld cutters offer the advantage of versatility, allowing you to cut different types of materials with ease. However, they also have limitations. Due to their smaller size, handheld cutters may not be as efficient or precise as Nd:YAG laser cutters. Additionally, they may require more physical effort and time to complete the cutting process.

Despite these limitations, handheld cutters provide a portable solution for on-the-go cutting needs.

Are there any safety concerns associated with using Nd:YAG laser cutters?

When using Nd:YAG laser cutters, it’s important to take safety precautions to minimize potential risks. These precautions include wearing appropriate protective gear such as safety goggles to protect your eyes from laser radiation.

Additionally, it’s crucial to ensure the work area is well-ventilated to prevent the inhalation of hazardous fumes. Failure to adhere to these safety measures can result in serious injuries or accidents.

Therefore, it’s essential to prioritize safety when using Nd:YAG laser cutters.

Conclusion

Based on the analysis of portability, cutting capabilities, cost considerations, and applications, it’s evident that handheld cutters are more portable than Nd:YAG laser cutters. Although both options have their advantages, the convenience and flexibility of handheld cutters make them a popular choice for on-the-go cutting tasks.

Interestingly, a survey conducted among professionals in the industry revealed that 85% of respondents prefer handheld cutters due to their ease of use and portability. This statistic highlights the practicality and widespread acceptance of handheld cutters in various fields.