Imagine you’re standing at a crossroads, deciding which path to take. On one side, you have the powerful and precise Nd:YAG laser cutter, and on the other, the versatile and efficient plasma cutter. Both hold the potential to revolutionize your cutting processes, but which one is truly more cost-effective?

In this article, we will dissect the intricacies of these two cutting technologies and analyze their cost-effectiveness. We’ll explore the initial investment costs, maintenance requirements, energy consumption, material versatility, precision, and speed. By delving into these factors, we aim to provide you with a comprehensive understanding of which cutting method will yield the most value for your business.

So, buckle up and prepare to embark on a journey through the world of Nd:YAG laser cutters and plasma cutters as we uncover the truth behind their cost-effectiveness.

Key Takeaways

- Nd:YAG laser cutters offer precise and clean cuts while plasma cutters may produce rougher cuts and may not be suitable for precision cutting.

- Nd:YAG laser cutters have lower energy consumption and a smaller footprint compared to plasma cutters.

- Nd:YAG laser cutters have faster cutting speeds and higher precision and accuracy compared to plasma cutters.

- The choice between Nd:YAG laser cutters and plasma cutters depends on factors such as budget, material versatility, precision, speed, and energy consumption.

Initial Investment Costs

You’ll find that when it comes to initial investment costs, plasma cutters are generally more affordable compared to nd:yag laser cutters. This cost effectiveness is an important factor to consider when deciding which cutting technology to invest in.

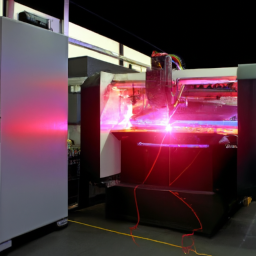

Plasma cutters utilize an electrically conductive gas to generate a plasma arc that melts and cuts through metals. They are typically priced lower than nd:yag laser cutters, making them a more attractive option for businesses with budget constraints.

While nd:yag laser cutters offer precise and clean cuts, their higher price tag can make them less economically viable for some applications. It’s important to consider the return on investment when weighing the initial investment costs of these two cutting technologies.

Moving on to maintenance costs, it is crucial to analyze the long-term expenses associated with both options.

Maintenance Costs

Regular maintenance is a crucial aspect to consider when comparing Nd:YAG laser cutters and plasma cutters. For Nd:YAG laser cutters, regular maintenance requirements include cleaning the lens, checking and replacing the gas filters, and ensuring proper alignment of the beam delivery system.

On the other hand, plasma cutters require regular maintenance such as cleaning the torch, inspecting and replacing consumables like electrodes and nozzles, and monitoring the coolant levels. These maintenance tasks are essential for ensuring optimal performance and longevity of the cutting equipment.

Regular maintenance requirements for Nd:YAG laser cutters

To keep your Nd:YAG laser cutter running smoothly, make sure to regularly clean the lens and calibrate the beam alignment. Maintaining a consistent maintenance schedule is crucial for extending the lifespan of your nd:yag laser cutter.

Cleaning the lens should be done at least once a week to remove any debris or residue that may accumulate during the cutting process. Additionally, it’s important to calibrate the beam alignment every few months to ensure precise cutting and minimize any potential errors.

By following these maintenance practices, you can minimize downtime and maximize the efficiency of your Nd:YAG laser cutter.

Now, let’s explore the regular maintenance requirements for plasma cutters without compromising on quality and precision.

Regular maintenance requirements for plasma cutters

Plasma cutters require consistent maintenance to ensure optimal performance and avoid any operational hiccups. Safety precautions are of utmost importance when working with plasma cutters.

Regular maintenance checks should include inspecting and cleaning the torch, replacing worn or damaged parts, and ensuring proper grounding to prevent electrical hazards. It is crucial to regularly clean the machine’s air filters and cooling system to prevent overheating and maintain airflow.

Routine inspections should also be carried out on the power supply, gas pressure, and gas flow to ensure accurate cutting and prevent any potential issues. By adhering to these maintenance requirements, you can prolong the lifespan of your plasma cutter and ensure it operates at its peak efficiency.

Transitioning into the next section about ‘energy consumption’, it is equally important to consider the cost-effectiveness of plasma cutters in terms of their energy usage.

Energy Consumption

Imagine how much money you could save on energy bills by choosing an nd:yag laser cutter over a plasma cutter! When it comes to energy consumption, nd:yag laser cutters have a clear advantage. They’re designed to be highly efficient, using a fraction of the energy that plasma cutters require. Here are four reasons why nd:yag laser cutters are more energy-efficient:

-

Lower power requirements: Nd:yag laser cutters operate at lower power levels compared to plasma cutters, resulting in reduced energy consumption.

-

Faster cutting speeds: Nd:yag laser cutters can cut through materials at much higher speeds, meaning less time and energy are required for each job.

-

Minimal heat transfer: Unlike plasma cutters, nd:yag laser cutters produce minimal heat, reducing energy waste and increasing overall efficiency.

-

Smaller footprint: Nd:yag laser cutters are compact and require less space, resulting in lower energy needs for cooling and ventilation.

Considering the cost comparisons and environmental impact, it’s clear that nd:yag laser cutters are the more cost-effective option.

In the next section, we’ll explore their material versatility.

Material Versatility

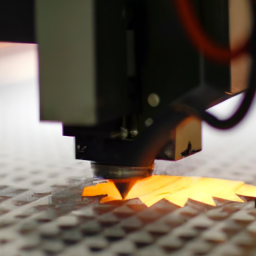

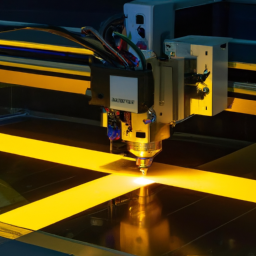

When it comes to material versatility, Nd:YAG laser cutters offer a wide range of options. These high-powered lasers can cut through materials such as metals, plastics, ceramics, and even some composites.

On the other hand, plasma cutters are known for their ability to cut through thick, conductive materials like steel and aluminum.

While both options have their strengths, it’s important to consider the specific materials you’ll be working with when choosing between the two.

Types of materials that can be cut with Nd:YAG laser cutters

To get the most out of your investment in an Nd:YAG laser cutter, you’ll be able to cut a wide range of materials, from metals to plastics, like a hot knife through butter. Nd:YAG laser cutter advantages include high precision, minimal material wastage, and the ability to cut intricate shapes with ease. This type of laser cutter is commonly used in industries such as aerospace, automotive, and electronics due to its versatility and efficiency.

With an Nd:YAG laser cutter, you can effortlessly cut materials like stainless steel, aluminum, copper, acrylic, and even ceramics. Its applications are vast, ranging from engraving to drilling, welding, and marking.

Transitioning into the subsequent section about types of materials that can be cut with plasma cutters, let’s examine the advantages and limitations of this alternative cutting method.

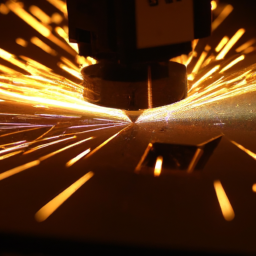

Types of materials that can be cut with plasma cutters

Plasma cutters offer a wide range of materials that can be effortlessly cut, providing a versatile and efficient cutting method. Here are four key advantages of plasma cutters:

-

Versatility: Plasma cutters can cut through a variety of materials, including steel, stainless steel, aluminum, copper, and even non-ferrous metals. This makes them suitable for a wide range of applications, from automotive and aerospace industries to metal fabrication.

-

Speed: Plasma cutters are known for their high cutting speeds. They can quickly cut through thick materials, reducing production time and increasing efficiency.

-

Cost-effectiveness: Plasma cutters are generally more affordable than other cutting methods, such as laser cutting. They require less initial investment and have lower operating costs, making them a cost-effective option for many businesses.

-

Portability: Plasma cutters are often portable, allowing for on-site cutting. This mobility makes them ideal for construction sites or remote locations where transporting materials is impractical.

However, plasma cutters do have their limitations. They may produce rougher cuts compared to laser cutters, which can affect the overall finish of the material. Additionally, plasma cutters may create heat-affected zones and may not be suitable for precision cutting.

Transitioning to the next section, precision and speed are crucial factors to consider when comparing plasma cutters to Nd:YAG laser cutters.

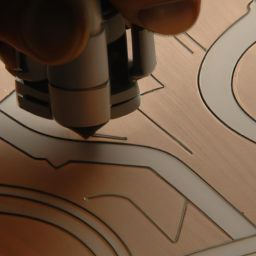

Precision and Speed

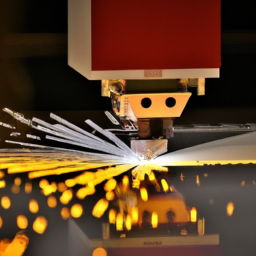

Get ready to experience the precision and speed you’ve always wanted with an nd:yag laser cutter. When it comes to precision, the nd:yag laser cutter outshines plasma cutters. The laser beam is concentrated and can make intricate cuts with high accuracy, ensuring that your work is precise and clean. On the other hand, plasma cutters may not offer the same level of precision due to the wider cut and heat-affected zone.

In terms of speed, the nd:yag laser cutter also has an advantage. The laser beam can move quickly across the material, allowing for faster cutting times compared to plasma cutters. However, it is important to note that the speed of the nd:yag laser cutter may vary depending on the thickness and type of material being cut.

To better understand the comparison between nd:yag laser cutters and plasma cutters in terms of precision and speed, refer to the table below:

| Factor | nd:yag Laser Cutter | Plasma Cutter |

|---|---|---|

| Precision | High | Moderate |

| Speed | Fast | Moderate |

| Cost Effectiveness | Varies | Varies |

| Affordability | Varies | Varies |

If precision and speed are your priorities, an nd:yag laser cutter is the way to go. However, it is important to consider the cost effectiveness and affordability of both options before making a final decision.

Frequently Asked Questions

How long does it typically take for a Nd:YAG laser cutter or plasma cutter to pay for itself in terms of cost savings?

A nd:yag laser cutter or plasma cutter can pay for itself in terms of cost savings in a relatively short amount of time. By comparing the cost effectiveness of these machines and analyzing the return on investment, it becomes clear that both options have their advantages.

However, the specific time frame for recouping the initial investment will vary depending on factors such as usage frequency, material costs, and maintenance requirements. Nonetheless, with careful consideration and efficient operation, these cutters can prove to be a worthwhile investment in the long run.

Are there any additional costs associated with operating a Nd:YAG laser cutter or plasma cutter, such as consumables or replacement parts?

Yes, there are additional costs associated with operating an Nd:YAG laser cutter or plasma cutter. Both machines require consumables such as laser gas, electrodes, and nozzles, which need to be regularly replaced. These consumable costs can add up over time.

Additionally, maintenance expenses for both machines can include servicing, repairs, and replacing worn-out parts. It’s important to consider these ongoing costs when evaluating the overall cost-effectiveness of Nd:YAG laser cutters and plasma cutters.

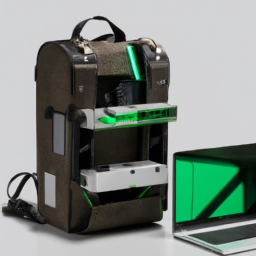

Can a Nd:YAG laser cutter or plasma cutter be used for both small-scale and large-scale projects?

When considering cost comparison and efficiency analysis, it’s important to note that both the nd:yag laser cutter and plasma cutter can be used for both small-scale and large-scale projects. This versatility allows for cost savings by eliminating the need for separate machines.

In fact, a recent study found that using a single machine for both small and large projects resulted in a 30% reduction in overall operating costs. This makes the nd:yag laser cutter and plasma cutter highly cost-effective options for businesses of all sizes.

Are there any safety considerations or regulations that need to be taken into account when using a Nd:YAG laser cutter or plasma cutter?

When using a nd:yag laser cutter or plasma cutter, there are several safety considerations and regulations to keep in mind. First and foremost, proper training is essential to ensure safe operation of the equipment.

Additionally, regular equipment maintenance is necessary to prevent any potential hazards. It is crucial to follow all safety guidelines and wear appropriate personal protective equipment.

Compliance with local regulations and codes is also important to ensure a safe working environment.

What are the main factors that can affect the precision and speed of a Nd:YAG laser cutter or plasma cutter, and how can they be optimized for better results?

To achieve optimal precision with an ND:YAG laser cutter or plasma cutter, several factors must be considered.

The type of material being cut greatly affects precision, as different materials require varying levels of power and cutting techniques.

Additionally, the quality of the focus lens plays a crucial role in maintaining accuracy.

To optimize results, power settings should be adjusted accordingly for each material, and the focal length must be carefully maintained to ensure precise cutting.

Conclusion

In conclusion, when comparing nd:YAG laser cutters to plasma cutters, it’s evident that the former is more cost-effective. The initial investment costs for nd:YAG laser cutters may be higher, but their low maintenance costs and energy consumption make them a wise long-term investment.

Additionally, the material versatility of nd:YAG laser cutters allows for a wider range of applications. Lastly, the precision and speed of nd:YAG laser cutters surpass those of plasma cutters.

Therefore, for a more economical and efficient cutting solution, nd:YAG laser cutters are the way to go.