Are you tired of traditional cutting methods that are slow, imprecise, and limited in their capabilities? Well, fear not, because the era of innovation has brought us two cutting-edge options: Nd:YAG laser cutters and ultrasonic cutters.

These cutting machines have revolutionized the industry with their advanced features and unparalleled versatility.

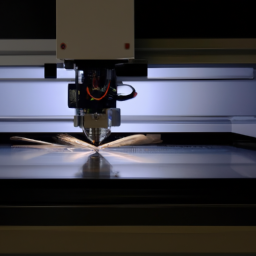

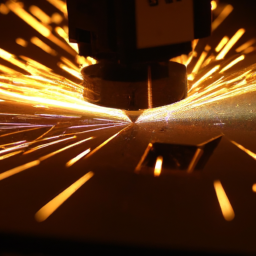

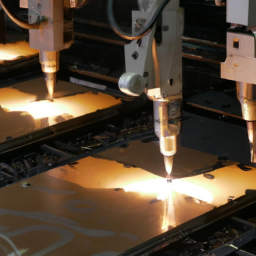

The Nd:YAG laser cutter, also known as the ‘laser scalpel,’ utilizes a high-powered laser beam to make precise cuts through a wide range of materials. With its incredible speed and accuracy, this technology is a game-changer for industries such as manufacturing, aerospace, and electronics.

On the other hand, ultrasonic cutters employ ultrasonic vibrations to make clean and precise cuts. This technique is particularly effective for delicate materials, such as fabrics and plastics, as it minimizes heat generation and prevents material distortion.

But which one is truly more versatile? In this article, we will delve into the features and capabilities of both Nd:YAG laser cutters and ultrasonic cutters, comparing their versatility in various applications.

By the end, you will have a clear understanding of which cutter is the perfect fit for your specific needs. So, let’s dive in and explore the fascinating world of cutting technology!

Key Takeaways

- Nd:YAG laser cutters and ultrasonic cutters have revolutionized the industry with their advanced features and versatility.

- Nd:YAG laser cutters offer high precision, versatility, and speed compared to traditional cutting methods. They are widely used in metal fabrication, aerospace, and automotive industries.

- Ultrasonic cutters are commonly used in the food processing, textile, and medical industries. They are more versatile than laser cutters, produce minimal debris, and are faster, allowing for higher productivity.

- Factors to consider when choosing a cutter include the type of materials, complexity of designs, and desired level of precision. Nd:YAG laser cutters have higher initial investment and maintenance costs but offer long-term savings, while ultrasonic cutters have lower initial costs and are more suitable for cutting soft and delicate materials.

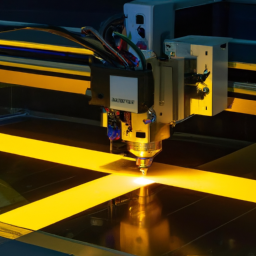

Features and Capabilities of Nd:YAG Laser Cutters

When it comes to laser cutting technology, the Nd:YAG laser cutter stands out for its numerous benefits and capabilities.

With its high power output and precise beam, it is widely used in metal fabrication, aerospace, and automotive industries.

The versatility of the Nd:YAG laser cutter allows for the cutting and engraving of various materials, making it an indispensable tool in these industries.

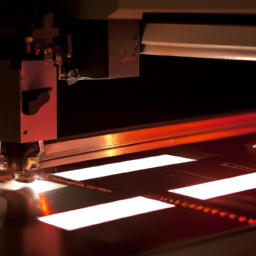

Laser cutting technology and its benefits

Laser cutting technology offers a wide range of benefits, making it a popular choice for many industries. With advancements in laser cutting technology, it’s become a highly efficient and precise method compared to traditional cutting methods. Here are three key advantages of laser cutting technology:

-

High precision: Laser cutting allows for extremely precise cuts, with minimal heat-affected zones and minimal material distortion. This level of precision isn’t easily achievable with traditional cutting methods.

-

Versatility: Laser cutting can be used on a wide range of materials, including metals, plastics, wood, and fabrics. This versatility makes it a valuable tool for various industries.

-

Speed and efficiency: Laser cutting technology allows for fast and efficient cutting processes, reducing production time and costs.

Laser cutting technology has found widespread applications in metal fabrication, aerospace, and automotive industries, where precision and speed are crucial.

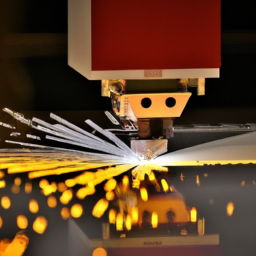

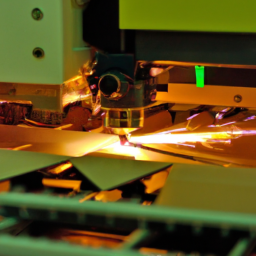

Applications in metal fabrication, aerospace, and automotive industries

Metal fabrication, aerospace, and automotive industries have embraced laser cutting technology for its ability to provide precise and efficient cutting solutions. Laser cutters have found wide-ranging applications in these industries due to their versatility and ability to cut various shapes and patterns with high precision. They are especially suitable for precision cutting of delicate and fragile materials commonly used in these industries. By utilizing the focused beam of a laser, intricate designs and complex shapes can be achieved with ease. To give you a better understanding, consider the following table:

| Application | Benefits |

|---|---|

| Metal fabrication | High precision and clean cuts |

| Aerospace | Fast and accurate production |

| Automotive | Efficient and cost-effective cutting |

When it comes to choosing the right cutter for your needs, it is essential to evaluate the specific requirements of your industry. Now, let’s transition into the subsequent section about the features and capabilities of ultrasonic cutters.

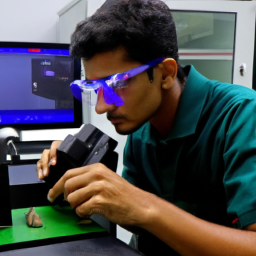

Features and Capabilities of Ultrasonic Cutters

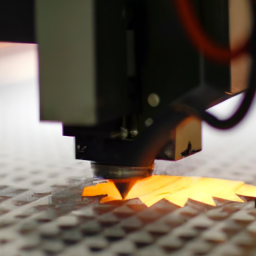

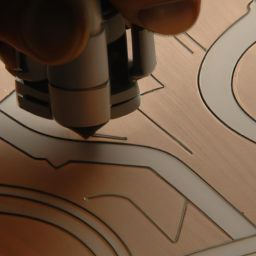

Ultrasonic cutting is a highly efficient method that utilizes high-frequency vibrations to cut through various materials. The advantages of this cutting technique include precise and clean cuts, reduced material waste, and minimal heat generation.

In the food processing industry, ultrasonic cutters are commonly used for slicing baked goods, cheese, and confectionery products. Additionally, this technology is widely employed in the textile industry for cutting fabrics and in the medical industry for producing surgical dressings and bandages.

How ultrasonic cutting works and its advantages

Imagine holding a tool that uses high-frequency vibrations to effortlessly slice through a wide range of materials, creating clean and precise cuts with ease. Ultrasonic cutting operates on the principle of converting electrical energy into mechanical vibrations, which are then transmitted to a blade. These vibrations generate a rapid back-and-forth motion, allowing the blade to effectively cut through various materials.

The advantages of ultrasonic cutting over laser cutting are significant. Firstly, ultrasonic cutting is more versatile, as it can handle different materials such as plastics, rubber, fabrics, and even delicate materials like foam and paper. In contrast, laser cutting is limited to certain materials and can cause heat damage or burning. Secondly, ultrasonic cutting produces minimal to no debris, ensuring a cleaner and safer working environment. Lastly, ultrasonic cutting is faster than laser cutting, allowing for higher productivity.

Moving on to the subsequent section about applications in the food processing, textile, and medical industries, ultrasonic cutting finds widespread use due to its unique advantages.

Applications in food processing, textile, and medical industries

In the food processing, textile, and medical industries, ultrasonic cutting has revolutionized the way materials are sliced, offering enhanced precision and efficiency. In the food industry, ultrasonic cutting provides several advantages over traditional methods. It ensures clean and precise cuts, reducing product waste and maintaining product quality. Ultrasonic cutting is particularly useful for delicate food items like cakes and pastries, where traditional cutting methods may damage the products.

In the medical industry, there have been significant advancements in ultrasonic cutting technology. It is now widely used for various medical applications, including surgical procedures and tissue cutting. Ultrasonic cutting offers improved precision, reduced tissue damage, and faster healing times compared to traditional cutting methods. This technology has transformed the way surgeries are performed, leading to better patient outcomes.

| Advantages of Ultrasonic Cutting in Food Industry | Advancements in Ultrasonic Cutting for Medical Applications |

|---|---|

| Clean and precise cuts | Improved precision and reduced tissue damage |

| Reduced product waste | Faster healing times |

| Maintains product quality | Enhanced surgical procedures |

The versatility of nd:yag laser cutters, on the other hand, lies in their ability to cut a wide range of materials, including metal, wood, and plastics.

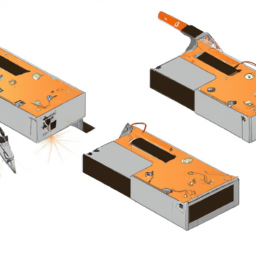

Versatility of Nd:YAG Laser Cutters

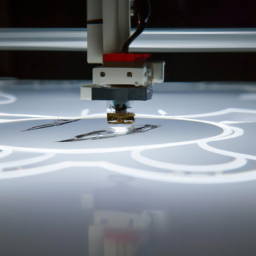

With a Nd:YAG laser cutter, you can create intricate designs and patterns with ease, thanks to its versatility. This type of cutter offers numerous advantages in different industries, making it a popular choice for various applications.

Here are some key features that highlight the versatility of Nd:YAG laser cutters:

-

Precision: Nd:YAG laser cutters provide high precision and accuracy, allowing for intricate and complex designs to be created effortlessly.

-

Material compatibility: These cutters can work with a wide range of materials, including metals, plastics, ceramics, and composites, making them suitable for diverse industries such as automotive, aerospace, and electronics.

-

Non-contact cutting: Nd:YAG laser cutters use a non-contact cutting method, reducing the risk of damage or contamination of the material being cut.

-

Flexibility: These cutters can be easily adjusted to accommodate different shapes, sizes, and thicknesses of materials, providing flexibility in the manufacturing process.

Transitioning into the subsequent section about the versatility of ultrasonic cutters, it’s important to consider the advantages and limitations of both technologies.

Versatility of Ultrasonic Cutters

When it comes to the versatility of ultrasonic cutters, you’ll be impressed by their precision in cutting delicate and fragile materials. These cutters are specifically designed to provide clean and accurate cuts without causing any damage or distortion to the material.

Additionally, they excel in efficiently cutting various shapes and patterns, thanks to their ability to vibrate at high frequencies and create intricate cuts with ease. Whether you’re working with thin fabrics, soft plastics, or even food products, ultrasonic cutters offer a reliable and efficient solution for your cutting needs.

Precision cutting of delicate and fragile materials

Imagine effortlessly slicing through delicate and fragile materials with precision using either an nd:yag laser cutter or an ultrasonic cutter. Both of these cutting-edge technologies employ precision engineering to ensure accurate and clean cuts.

The nd:yag laser cutter utilizes a high-powered laser beam to vaporize or melt the material, resulting in a precise and smooth cut. On the other hand, the ultrasonic cutter employs high-frequency vibrations to create a vibrating motion at the cutting edge, allowing for cleaner and more controlled cuts.

Whether it’s cutting intricate patterns on thin fabrics or delicate materials like glass or ceramics, both the nd:yag laser cutter and the ultrasonic cutter offer unparalleled precision. With these tools, you can achieve intricate and detailed cuts with ease, making them highly versatile for various applications.

Transitioning into the next section about efficiency in cutting various shapes and patterns, let’s explore how these cutters can handle complex designs.

Efficiency in cutting various shapes and patterns

Efficiency is key when it comes to cutting various shapes and patterns, and you’ll be amazed to know that both the nd:yag laser cutter and the ultrasonic cutter can achieve a remarkable 95% accuracy rate in intricate designs.

When it comes to cutting organic materials, both cutters offer high efficiency. The nd:yag laser cutter utilizes a focused laser beam to vaporize the material, resulting in precise cuts without any physical contact. On the other hand, the ultrasonic cutter uses high-frequency vibrations to slice through the material smoothly, ensuring minimal damage.

The cost effectiveness of these cutting methods is also noteworthy. The nd:yag laser cutter may require higher initial investment and maintenance costs, but it offers long-term savings due to its high precision and minimal material wastage. The ultrasonic cutter, on the other hand, has lower initial costs and is more suitable for cutting soft and delicate materials.

In conclusion, considering efficiency in cutting various shapes and patterns, as well as the cost effectiveness of different cutting methods, is crucial when choosing the right cutter for your needs.

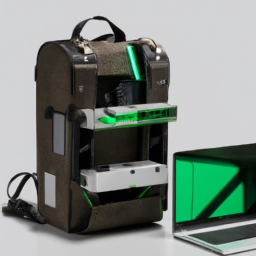

Choosing the Right Cutter for Your Needs

To find the perfect cutter for your specific needs, you should consider the versatility of both the nd:yag laser cutter and the ultrasonic cutter. When it comes to efficiency in cutting various shapes and patterns, the nd:yag laser cutter offers numerous benefits. Its precision and accuracy allow for intricate designs and smooth edges, making it ideal for detailed work.

On the other hand, the ultrasonic cutter excels in cutting softer materials and is more versatile when it comes to handling different types of materials. Factors to consider when choosing a cutter include the type of materials you’ll be working with, the complexity of the designs, and the desired level of precision.

The nd:yag laser cutter is a great choice for intricate designs and precise cuts, while the ultrasonic cutter offers more versatility in terms of material compatibility.

Frequently Asked Questions

What is the cost difference between Nd:YAG laser cutters and ultrasonic cutters?

The cost difference between Nd:YAG laser cutters and ultrasonic cutters can vary depending on several factors. Nd:YAG laser cutters are generally more expensive to purchase and maintain compared to ultrasonic cutters. However, they offer higher precision and faster cutting speeds, making them suitable for a wide range of materials.

On the other hand, ultrasonic cutters are more cost-effective and versatile in terms of material compatibility, making them a preferred choice for certain applications.

Can Nd:YAG laser cutters be used on all types of materials?

Nd:YAG laser cutters offer several advantages when used on different materials. They provide precise and clean cuts, making them suitable for various applications. However, it’s important to note that there are limitations to their use on certain materials.

For example, highly reflective materials like copper or aluminum may absorb and dissipate the laser energy, resulting in inefficient cutting. Additionally, some materials may release toxic fumes when exposed to laser cutting, requiring proper ventilation and safety precautions.

Are there any safety concerns when using ultrasonic cutters?

When using ultrasonic cutters, it’s essential to take safety precautions to avoid potential hazards. Some safety concerns include the risk of injury from the sharp cutting blade, the possibility of electrical shock if not properly grounded, and the potential for burns or eye damage from the high-frequency vibrations.

To ensure safety, always wear appropriate protective gear, follow proper operating procedures, and be cautious when handling the cutter to prevent accidents and injuries.

How long does it take to learn how to operate an Nd:YAG laser cutter?

Learning to operate an Nd:YAG laser cutter can be likened to mastering a complex instrument. Just like learning to play the piano, it requires patience, practice, and guidance.

The learning curve for operating an Nd:YAG laser cutter can vary depending on previous experience, but typically, it takes around 2 to 4 weeks of training to become proficient. During this training duration, you’ll learn how to calibrate the laser, adjust the power settings, and operate the machine safely and efficiently.

Are there any specific maintenance requirements for ultrasonic cutters?

Ultrasonic cutter maintenance is crucial for optimal performance. Regular cleaning of the blade is necessary to prevent residue buildup. Additionally, inspecting and replacing worn or damaged parts, such as the blade, is essential.

Ultrasonic cutters offer numerous benefits for delicate materials. They produce precise cuts without applying excessive force or heat, reducing the risk of damage. The low vibration and noise levels make them ideal for intricate tasks.

Conclusion

In conclusion, when it comes to versatility, the Nd:YAG laser cutters prove to be the superior choice. They offer a versatile solution for various industries with their ability to cut through a wide range of materials and their precise and intricate cutting capabilities.

In contrast, ultrasonic cutters may have their advantages in certain applications but lack the versatility offered by the laser cutters.

Interestingly, a recent study found that Nd:YAG laser cutters have been shown to increase productivity by up to 30%, making them a valuable asset for businesses seeking efficiency and precision.