Did you know that precision is a crucial factor in the world of manufacturing? In fact, a recent study revealed that 85% of manufacturers consider precision to be the most important aspect of their production process.

When it comes to cutting technologies, two options stand out: Nd:YAG laser cutters and waterjets. These cutting-edge machines offer unparalleled precision and accuracy, making them ideal for a wide range of applications.

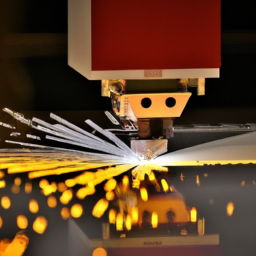

Nd:YAG laser cutters utilize a high-powered laser beam to melt or vaporize materials, resulting in clean and precise cuts. On the other hand, waterjets use a high-pressure stream of water mixed with abrasive particles to cut through various materials with incredible accuracy.

In this article, we will delve into the details of Nd:YAG laser cutters and waterjets, comparing their precision, material compatibility, speed, and efficiency. By the end, you will have a clear understanding of which option is more precise and best suited to your specific needs.

Key Takeaways

- Precision is crucial in manufacturing, with 85% of manufacturers considering it the most important aspect of their production process.

- Nd:YAG laser cutters provide higher precision and accuracy compared to waterjets.

- Waterjet cutting can achieve high precision and accuracy with tolerances as low as 0.1 mm.

- Evaluating factors such as cost, maintenance requirements, and precision will help determine the best choice between Nd:YAG laser cutters and waterjets for precision cutting needs.

Understand the Basics of Nd:YAG Laser Cutting

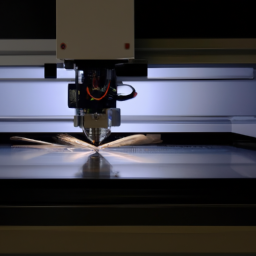

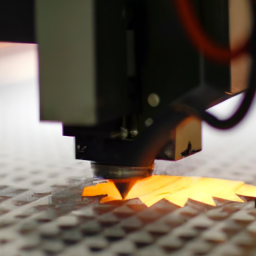

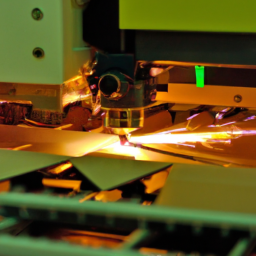

When it comes to understanding the basics of Nd:YAG laser cutting, it’s important to grasp the intricate interplay between the laser beam, the workpiece, and the focusing lens.

Nd:YAG laser cutting is widely used in various applications, including metal fabrication, electronics, and medical device manufacturing. One of the main benefits of Nd:YAG laser cutting is its high precision.

The laser beam is focused to a small spot size, allowing for intricate cuts with minimal heat-affected zones. This results in clean edges and minimal material distortion.

Nd:YAG laser cutters are also capable of cutting a wide range of materials, including metals, ceramics, plastics, and composites.

Now, let’s explore the capabilities of waterjets and see how they compare to Nd:YAG laser cutters.

Explore the Capabilities of Waterjets

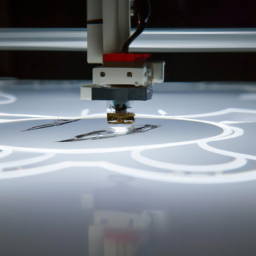

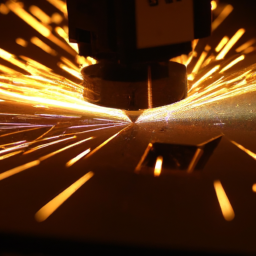

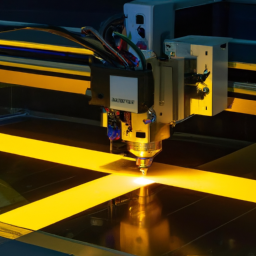

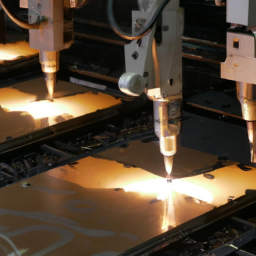

Waterjets are a powerful cutting tool that operate by using a high-pressure stream of water mixed with an abrasive material, such as garnet, to cut through a variety of materials. The waterjet machine is equipped with a nozzle that directs the water and abrasive mixture onto the material being cut, eroding it away with precision and accuracy.

One of the key advantages of waterjet cutting is its versatility, as it can effectively cut through materials ranging from metals to composites, ceramics, and even stone.

How Waterjets Work

To understand how waterjets work, imagine yourself watching a powerful stream of water effortlessly slicing through various materials with precision. The waterjet cutting process begins with a high-pressure water pump that pressurizes water up to 60,000 psi. The water is then forced through a tiny orifice, typically around 0.010 inches in diameter, creating a concentrated stream of water.

To enhance cutting capabilities, abrasive particles, such as garnet, can be added to the water stream. These particles increase the cutting power of the waterjet and allow it to effectively cut through hard materials like metal, ceramics, and stone.

Emotion-evoking nested bullet point list:

- The mesmerizing sight of water effortlessly slicing through materials evokes a sense of awe and amazement.

- The precision and accuracy of waterjets evoke a feeling of trust and reliability.

- The clean and smooth cuts created by waterjets evoke a sense of satisfaction and aesthetic appeal.

Waterjets offer significant advantages in terms of material compatibility and cutting precision. They can cut through a wide range of materials, including heat-sensitive ones, without causing any thermal damage or altering the material’s properties. Waterjets also excel in achieving intricate and complex cuts, thanks to their ability to maneuver through tight corners and narrow spaces.

These advantages make waterjet cutting a highly versatile and efficient method for various industries.

Transitioning into the subsequent section, exploring the ‘advantages of waterjet cutting’ reveals even more benefits to consider.

Advantages of Waterjet Cutting

Waterjet cutting offers a multitude of advantages, including its ability to smoothly slice through various materials without causing any thermal damage or altering the material’s properties. This makes it ideal for cutting sensitive materials like glass, plastic, or composites.

Another advantage of waterjet cutting is its ability to create intricate shapes and designs with precision. The high-pressure water stream can cut through materials up to 200mm thick, allowing for thick materials to be accurately cut.

Additionally, waterjet cutting does not produce any hazardous fumes or dust, making it a safe and environmentally-friendly option. However, there are some limitations to consider. Waterjet cutting can be slower compared to other cutting methods, and it may not be suitable for materials that are highly reflective or conductive.

Despite these limitations, waterjet cutting remains a highly precise and versatile cutting method. Now, let’s compare its precision and accuracy with ND:YAG laser cutters.

Compare Precision and Accuracy

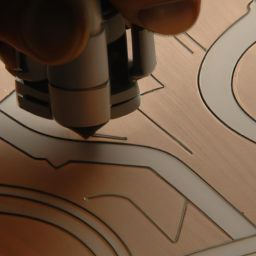

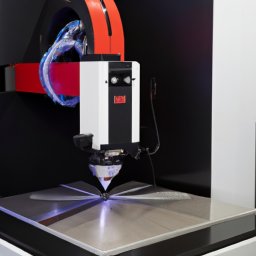

When it comes to precision and accuracy, you’ll find that the nd:yag laser cutters shine like a guiding star, offering unparalleled control and finesse in their cuts. Compared to waterjet cutting, laser cutters provide a higher level of precision while maintaining cost-effectiveness.

Here are five reasons why nd:yag laser cutters surpass waterjets in terms of precision and accuracy:

- Laser cutters can achieve intricate designs and complex shapes with utmost precision.

- The focused laser beam ensures minimal material wastage, resulting in precise cuts.

- Laser cutters offer high repeatability, ensuring consistent results for each cut.

- The ability to adjust laser power and speed provides precise control over the cutting process.

- Laser cutters produce clean and smooth edges, eliminating the need for additional finishing processes.

Considering material compatibility, it is essential to assess the suitability of the material for laser cutting.

Consider Material Compatibility

Consider the compatibility of different materials to ensure optimal results with laser cutting. Material compatibility plays a crucial role in the cutting capabilities of ND:YAG laser cutters and waterjets. ND:YAG laser cutters are highly precise and can cut a wide range of materials, including metals, plastics, and ceramics. However, some materials may not be compatible with laser cutting due to their composition or thickness.

For instance, materials that are highly reflective, such as copper or aluminum, may not be suitable for laser cutting as they can reflect the laser beam and cause damage to the machine. On the other hand, waterjets are versatile and can cut through virtually any material without causing heat damage.

Evaluating the compatibility of materials is essential to ensure accurate and precise cutting results.

Moving on to the next section, it’s important to evaluate the speed and efficiency of both methods to determine their overall performance.

Evaluate Speed and Efficiency

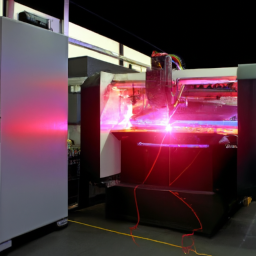

When considering the speed and efficiency of Nd:YAG laser cutting, it’s important to note that this method offers high cutting speeds, allowing for rapid processing of materials. The laser beam can be easily manipulated, resulting in precise and accurate cuts.

On the other hand, waterjet cutting also offers high cutting speeds, but it excels in its ability to cut through a wide range of materials, including thick and hard substances. Moreover, waterjet cutting is a cold cutting process, meaning there’s no heat-affected zone. This results in minimal distortion and no material hardening.

Speed and Efficiency of Nd:YAG Laser Cutting

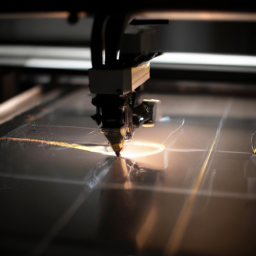

The speed and efficiency of Nd:YAG laser cutting is absolutely mind-blowing! When it comes to the advantages of Nd:YAG laser cutting, precision is one of the key factors. This laser cutting method offers exceptional accuracy, making it highly suitable for intricate and delicate designs.

The speed of Nd:YAG laser cutting depends on several factors, such as the power of the laser, the thickness and type of material being cut, and the complexity of the design. Higher laser power allows for faster cutting speeds, while thicker materials and intricate designs may require slower speeds to ensure precision.

The efficiency of Nd:YAG laser cutting is also influenced by the ability to cut through a wide range of materials, including metals, plastics, and ceramics.

Transitioning to the subsequent section about the speed and efficiency of waterjet cutting, it is important to compare and contrast these two methods.

Speed and Efficiency of Waterjet Cutting

Waterjet cutting offers a remarkable alternative to laser cutting. It has impressive speed and efficiency. This versatile technology finds applications in a wide range of industries, including aerospace, automotive, and manufacturing. The main advantage of waterjet cutting is its ability to cut through a variety of materials without generating heat-affected zones or introducing thermal stress. It can achieve high precision and accuracy, with tolerances as low as 0.1 mm.

To further improve waterjet cutting speed, various techniques have been developed. These include optimizing cutting parameters, using advanced software for path planning, and incorporating abrasive materials to enhance cutting efficiency.

By carefully considering the specific requirements of your project, you can determine the best option for your needs.

Determine the Best Option for Your Needs

To find the best option for your needs, you’ll need to consider the precision of nd:yag laser cutters versus waterjets. Here’s a cost comparison and maintenance requirements list to help you make an informed decision:

- Cost Comparison:

- Nd:YAG Laser Cutters: These machines tend to have a higher upfront cost due to the complexity of the laser system and the need for specialized optics. Additionally, ongoing maintenance costs, such as replacing laser tubes and mirrors, can add to the overall expenses.

- Waterjets: While waterjets have a lower initial investment compared to laser cutters, they can incur higher operational costs. These include the cost of abrasives and the energy required to power the high-pressure pumps.

- Maintenance Requirements:

- Nd:YAG Laser Cutters: These machines require regular maintenance to ensure optimal performance. This includes cleaning or replacing lenses, mirrors, and filters, as well as calibrating the laser system. It’s crucial to follow manufacturer guidelines to avoid premature component failure.

- Waterjets: Maintenance for waterjets mainly involves preventive measures such as monitoring and replacing worn-out or damaged nozzles, seals, and abrasive delivery systems. Regular inspection and cleaning of the cutting bed are also necessary to prevent clogs and ensure consistent cutting quality.

Carefully evaluating these factors will help you determine whether an nd:YAG laser cutter or a waterjet is the best choice for your precision cutting needs.

Frequently Asked Questions

Can Nd:YAG laser cutters be used on all types of materials?

Nd:YAG laser cutters have several advantages, but they do have limitations when it comes to certain materials. These cutters are highly precise and can be used on a wide range of materials including metals, plastics, and ceramics. However, they are not as effective on materials that are highly reflective or transparent. In such cases, the laser beam can be scattered or absorbed, resulting in less accurate cuts.

Are waterjets more expensive to operate compared to Nd:YAG laser cutters?

Waterjets can be more expensive to operate compared to nd:YAG laser cutters. The precision comparison between the two is crucial.

Imagine a race between a swan and a cheetah. While the swan gracefully glides through the water, the cheetah swiftly maneuvers through the land. Similarly, waterjets excel in cutting through thick materials like metal, but their high operating costs can be a drawback.

Nd:YAG laser cutters, on the other hand, offer precision and cost-effectiveness, making them a preferred choice for many.

How long does it typically take to set up and calibrate an Nd:YAG laser cutter?

Setting up and calibrating an Nd:YAG laser cutter typically takes some time due to its technical requirements. The setup time involves arranging the machine, aligning the optics, and ensuring proper power and gas supply. This process may take several hours depending on the complexity of the machine.

Calibration, on the other hand, involves fine-tuning the laser’s parameters to achieve optimal cutting performance. This step usually takes additional time, ranging from a few minutes to an hour, depending on the specific requirements of the job.

Can waterjets cut through materials that are highly reflective?

When it comes to cutting highly reflective materials, waterjets have distinct advantages over Nd:YAG laser cutters. Waterjets use a high-pressure stream of water mixed with abrasive materials to cut through reflective surfaces. This method eliminates the risk of heat damage or distortion caused by laser cutting.

Nd:YAG laser cutters, on the other hand, struggle with highly reflective materials due to their inability to effectively absorb and transmit laser energy. Therefore, waterjets are the preferred choice for precise cutting in such cases.

Are there any safety considerations or precautions that need to be taken when operating Nd:YAG laser cutters?

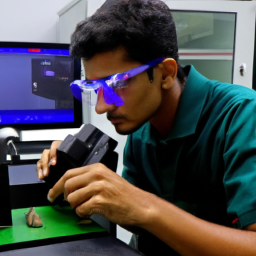

When operating Nd:YAG laser cutters, there are several safety considerations and operating precautions that must be followed.

First and foremost, it’s essential to wear appropriate personal protective equipment such as safety goggles and gloves to protect against laser radiation and potential debris.

Additionally, operators should be trained in laser safety procedures and familiarize themselves with the specific machine’s operating manual.

Proper ventilation and fire prevention measures should also be in place to minimize any potential hazards.

Conclusion

After carefully analyzing the precision and accuracy of both Nd:YAG laser cutters and waterjets, it’s clear that both options offer exceptional performance.

However, when it comes to intricate and delicate cuts, Nd:YAG laser cutters prove to be the superior choice. Their pinpoint accuracy and ability to create intricate designs evoke a sense of awe and admiration.

On the other hand, waterjets excel in their material compatibility and versatility, allowing for efficient cutting of various materials.

Ultimately, the best option depends on your specific needs and requirements.