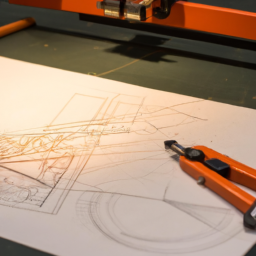

Did you know that laser cutting is 10 times faster than traditional CNC cutting? When it comes to optimizing your designs for cutting, choosing the right method can make all the difference. In this article, we will explore the benefits and considerations of laser cutting versus CNC cutting, helping you determine which option is best for your needs.

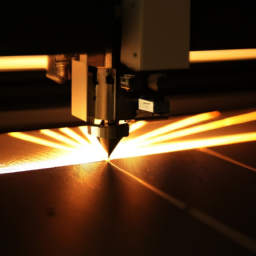

Laser cutting utilizes a high-powered laser beam to precisely cut through materials, resulting in clean and intricate designs. On the other hand, CNC cutting uses a computer-controlled machine to cut through various materials, offering flexibility and accuracy.

Factors to consider when deciding between the two methods include the complexity of your design, material type, budget, and desired turnaround time. While laser cutting may be more expensive, it offers faster and more efficient results, making it ideal for intricate designs and time-sensitive projects. CNC cutting, on the other hand, provides versatility and cost-effectiveness for simpler designs.

By understanding the differences and weighing the factors, you can make an informed decision on whether laser cutting or CNC cutting is the right choice for your project.

So, let’s dive in and find out which method will help you achieve your design goals with precision and efficiency.

Key Takeaways

- Laser cutting is 10 times faster than traditional CNC cutting, offering faster and more efficient results.

- CNC cutting is more versatile and cost-effective for simpler designs, making it suitable for a broader range of materials.

- Laser cutting provides precise cutting with smooth edges and increased precision in intricate designs, making it ideal for complex and detailed patterns.

- CNC cutting offers greater flexibility in design iterations and customization options, making it a versatile option for future product expansion and experimentation.

Understanding Laser Cutting

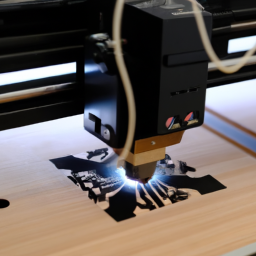

Laser cutting offers precise and intricate cutting capabilities, allowing for the creation of complex designs with incredible detail. The laser beam melts, burns, or vaporizes the material being cut, resulting in clean and accurate edges. This process is ideal for projects that require fine details or sharp corners.

Laser cutting can also handle a wide range of materials, including wood, acrylic, metal, and fabric. One of the advantages of laser cutting is its ability to create intricate patterns and shapes without the need for additional tools or equipment. It’s also a faster and more efficient method compared to traditional cutting techniques.

Now, let’s delve into the next section and explore the world of CNC cutting.

Understanding CNC Cutting

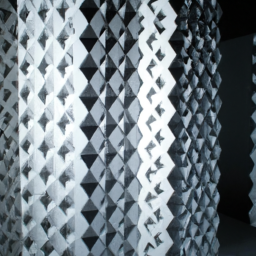

When it comes to CNC cutting, you’re like a sculptor shaping clay with precision and control. CNC cutting techniques utilize computer-controlled machines to accurately cut through various materials, such as wood, metal, and plastic.

These machines can perform intricate cuts and create complex shapes, making them ideal for detailed designs. CNC cutting applications are vast and diverse, ranging from architectural models and signage to aerospace components and industrial parts.

With CNC cutting, you have the ability to achieve high levels of accuracy, consistency, and repeatability in your designs. However, before diving into the world of CNC cutting, there are several factors to consider. By understanding these factors, you can ensure that you make the right choice for your specific project needs.

Factors to Consider

One important aspect to consider is the type of material you’ll be working with and its compatibility with CNC cutting techniques. CNC cutting is suitable for a wide range of materials, including wood, plastic, metal, and foam. However, the design complexity of your project can also affect the suitability of CNC cutting. Intricate designs with fine details may require more advanced CNC machines and tools to achieve the desired results.

Additionally, some materials may not be compatible with CNC cutting due to their composition or properties. It’s important to research and understand the limitations and capabilities of CNC cutting for different materials before making a decision. Considering these factors will help you determine whether CNC cutting is the right choice for your project.

Next, let’s discuss the cost comparison between laser cutting and CNC cutting techniques.

Cost Comparison

When comparing the cost of laser cutting and CNC cutting, there are several key points to consider.

Firstly, the initial investment for laser cutting equipment is typically higher than CNC cutting equipment.

Secondly, operating costs for laser cutting may be higher due to the need for electricity and gas.

Lastly, maintenance and upkeep costs for laser cutting machines can also be higher compared to CNC cutting machines.

Initial Investment

If you’re looking to minimize your initial investment, laser cutting is the way to go. Laser cutting machines tend to have a lower upfront cost compared to CNC cutting machines. This is especially beneficial for small businesses or individuals who are just starting and have limited funds.

With laser cutting, you can save on the cost of purchasing and maintaining a CNC machine, which can be quite expensive. When considering the initial investment, it’s important to also take into account the long term benefits. Laser cutting machines are known for their precision and versatility, allowing you to create intricate designs with ease. This can lead to increased productivity and customer satisfaction, ultimately resulting in higher profits.

Additionally, laser cutting machines require less maintenance compared to CNC machines, reducing ongoing costs and saving you money in the long run.

Now, let’s move on to the next section and explore the operating costs of laser cutting versus CNC cutting.

Operating Costs

To truly understand the impact on your wallet, let’s delve into the realm of operating costs and discover the financial implications of laser cutting versus CNC cutting.

When it comes to cost analysis, laser cutting tends to have higher operating costs compared to CNC cutting. The main reason for this is the expense of laser gas and electricity needed to power the laser cutter. On the other hand, CNC cutting machines generally have lower operating costs as they primarily rely on electricity.

However, it’s important to note that laser cutting can offer long-term savings due to its higher cutting speed and greater precision, which can result in reduced material waste and increased production efficiency.

Transitioning to the subsequent section about maintenance and upkeep, it’s crucial to consider these factors alongside the operating costs.

Maintenance and Upkeep

Maintaining and managing the machinery becomes a meticulous and meaningful mission. When it comes to maintenance requirements, both laser cutting and CNC cutting systems have their own set of needs.

For laser cutting, regular cleaning of the lens and mirrors is crucial to ensure optimal performance. Additionally, the cooling system and gas supply must be checked and maintained regularly.

On the other hand, CNC cutting machines require routine lubrication of moving parts, such as the ball screws and linear guides, to prevent wear and tear.

When it comes to troubleshooting, laser cutting systems may require more specialized knowledge and expertise, whereas CNC cutting machines can be easier to diagnose and fix.

By staying on top of maintenance and promptly addressing issues, you can minimize downtime and maximize productivity.

Transitioning into the subsequent section about ‘speed and efficiency’, it’s important to understand how maintenance can impact these factors.

Speed and Efficiency

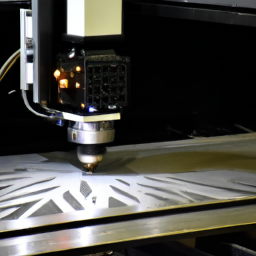

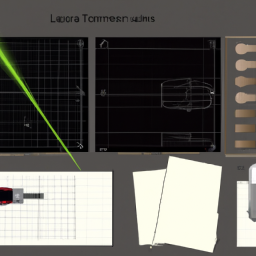

When considering laser cutting or CNC cutting, it’s important to prioritize speed and efficiency to ensure optimal results for your designs. Here are three key factors to consider:

-

Speed vs. Accuracy: Laser cutting is known for its high speed, allowing for quick production of intricate designs. CNC cutting, on the other hand, offers greater accuracy, making it ideal for projects that require precise dimensions.

-

Material Compatibility: Laser cutting is suitable for a wide range of materials, including metals and plastics. CNC cutting, however, is more versatile and can handle a broader spectrum of materials, such as wood, foam, and even glass.

-

Workflow Efficiency: Laser cutting requires less setup time, as it directly processes the design files. CNC cutting, on the other hand, involves the creation of toolpaths, which can be time-consuming.

Considering these factors, you can make an informed decision on whether laser cutting or CNC cutting is the right choice for your specific project.

Making the Decision

One important factor to consider is the material compatibility of laser cutting and CNC cutting, with CNC cutting being more versatile and able to handle a broader spectrum of materials, such as wood, foam, and even glass. When weighing options between laser cutting and CNC cutting, it’s crucial to think about the long-term benefits. While laser cutting may be faster and more efficient for certain materials, CNC cutting offers the advantage of being able to work with a wider range of materials. This versatility can be beneficial if you plan on expanding your product offerings or experimenting with different materials in the future. By choosing CNC cutting, you are investing in a technology that can adapt and grow with your business, providing more opportunities for innovation and creativity.

| Laser Cutting | CNC Cutting | |||

|---|---|---|---|---|

| Faster cutting speeds | Slower cutting speeds | |||

| Limited material compatibility | Versatile material compatibility | |||

| Precise cutting with smooth edges | Precise cutting with options for different finishes | Increased precision in intricate designs | Expanded range of design possibilities | |

| Enhanced efficiency in production processes | Improved customization options | |||

| Reduced waste and material consumption | Greater flexibility in design iterations | |||

| Integration with computer-aided design (CAD) software | Integration with 3D printing technology | |||

| Potential for automation and unmanned operation | Potential for integration with robotics | |||

| Ability to create complex and detailed patterns | Ability to create multi-layered and textured designs | |||

| Opportunity for cost savings in manufacturing | Opportunity for rapid prototyping and product development | |||

| Potential for creating unique and personalized products | Potential for creating intricate and artistic pieces | |||

| Ability to work with a wide range of materials | Ability to create precise and intricate joinery | |||

| Potential for creating lightweight and durable structures | Potential for creating complex and functional geometries |

Frequently Asked Questions

Can laser cutting be used on all types of materials?

Laser cutting can be used on a wide range of materials, making it a versatile choice. It is suitable for materials such as wood, acrylic, paper, fabric, and even metal. The advantages of laser cutting over CNC cutting include its precision, speed, and ability to create intricate designs. With laser cutting, you can achieve clean, smooth cuts with minimal material waste. It’s a great option for various applications, from crafting to industrial manufacturing.

What are the common limitations or drawbacks of CNC cutting?

When it comes to CNC cutting, limitations abound! It’s like trying to cut through a thick slab of concrete with a butter knife. The precision is lacking, and the edges are rougher than a gravel road.

But fear not, laser cutting is here to save the day! With its precision and smooth edges, it’s like a hot knife through butter. Say goodbye to limitations and hello to the advantages of laser cutting.

Is there a maximum thickness that laser cutting can handle?

There is a maximum thickness that laser cutting can handle. The maximum thickness depends on the power of the laser and the materials compatibility.

Laser cutting is typically more suitable for thinner materials, as the laser beam can only penetrate a certain depth. Thicker materials may require multiple passes or alternative cutting methods.

It’s important to consider the maximum thickness and materials compatibility when deciding between laser cutting and CNC cutting.

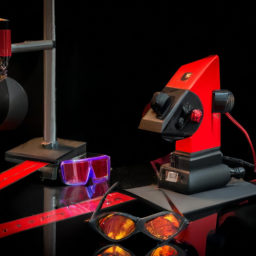

Are there any safety concerns specific to laser cutting or CNC cutting?

When it comes to laser cutting safety, there are a few concerns to be aware of. The main issue is the potential for eye damage due to the intense laser beam. It’s essential to wear appropriate protective eyewear when operating or being near a laser cutting machine.

On the other hand, CNC cutting safety is more focused on preventing accidents caused by moving parts and sharp tools. Proper training and safety protocols are crucial to ensure a safe working environment.

How does the level of intricacy or complexity of a design affect the choice between laser cutting and CNC cutting?

When it comes to choosing between laser cutting and CNC cutting, the level of intricacy or complexity of your design plays a crucial role. Laser cutting is ideal for intricate designs that require high precision and fine details. Its narrow laser beam allows for precise cuts and intricate patterns.

On the other hand, CNC cutting is better suited for less intricate designs that require more cutting precision. It utilizes a rotating cutting tool to achieve accurate and consistent cuts.

Conclusion

So now that you have all the information about laser cutting and CNC cutting, it’s time to make a decision.

Remember, both methods have their own advantages and it ultimately depends on your specific needs and preferences.

For example, let’s say you’re a small business owner looking to create intricate designs for jewelry. Laser cutting might be the perfect choice for you, as it offers precise and detailed cuts that will enhance the beauty of your products.

Ultimately, the choice is yours to make based on what will best suit your project and budget.