Are you looking to optimize your designs for cutting processes? Whether you are a manufacturer or a designer, understanding the cost-effectiveness of different cutting methods is crucial. Let’s consider a hypothetical case study: Imagine you are designing intricate patterns for a product made of acrylic. You have two options: laser cutting or die cutting. Which one should you choose to ensure cost-effectiveness?

In this article, we will explore the differences between laser cutting and die cutting, and help you determine which method is more suitable for your specific design needs. We will consider factors such as material and design complexity, production volume, time constraints, and tooling and setup costs.

By optimizing your designs for laser cutting or die cutting, you can make informed decisions that not only save you money but also enhance the overall quality of your products.

So, if you want to maximize cost-efficiency without compromising on design intricacy, read on to discover the best approach for your cutting needs.

Key Takeaways

- Laser cutting offers high precision and flexibility with material choices, suitable for intricate designs and complex detailing.

- Die cutting is more cost-effective for large production runs, compatible with a wide range of materials, and allows for high-speed and high-volume production.

- Optimizing designs for laser cutting saves time and money, minimizing material waste and improving cutting efficiency.

- Die cutting maximizes production efficiency, reduces waste and lower material costs, and achieves precise and consistent cuts.

Understand the Differences between Laser Cutting and Die Cutting

If you’re looking to understand the differences between laser cutting and die cutting, you’re in for an enlightening ride! Let’s dive into the pros and cons of both methods.

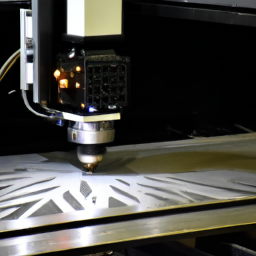

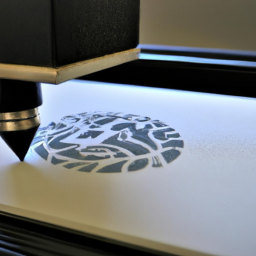

Laser cutting offers several advantages over die cutting. First off, laser cutting can handle intricate designs with high precision, making it ideal for complex projects. It also allows for greater flexibility in terms of material choices, as it can cut through various materials like wood, metal, and acrylic.

On the other hand, die cutting relies on a physical die, which limits the design complexity and material options. However, die cutting is often more cost-effective for large production runs. So, when considering the material and design complexity, it’s important to weigh the pros and cons of each method.

Consider the Material and Design Complexity

When considering the material and design complexity for laser cutting and die cutting, there are a few key points to keep in mind.

First, you need to consider the material compatibility with laser cutting, as certain materials may not be suitable for this method. Similarly, you should also consider the material compatibility with die cutting, as some materials may not work well with this technique.

Lastly, design complexity and intricacy should be taken into account, as both laser cutting and die cutting have limitations when it comes to intricate designs.

Material Compatibility with Laser Cutting

To ensure material compatibility with laser cutting, you’ll want to select materials that are as precise and consistent as a well-tuned orchestra. Laser cutting offers numerous benefits such as high precision, intricate designs, and clean edges. However, it also has its limitations, including material thickness restrictions and the potential for heat damage.

When choosing materials for laser cutting, keep in mind the following:

- Opt for materials that have a high melting temperature, such as metals or acrylics.

- Choose materials that are free from impurities or contaminants that could interfere with the laser cutting process.

- Consider the thickness of the material, as laser cutting is most effective for thin to medium thicknesses.

- Ensure the material is not prone to warping or melting under the heat generated by the laser.

- Check if the material is compatible with the specific wavelength of the laser being used.

Considering these factors will help you select materials that are compatible with laser cutting. However, it’s also essential to consider material compatibility with die cutting, which we will explore in the next section.

Material Compatibility with Die Cutting

Discover the perfect materials for your project by considering their compatibility with die cutting. When comparing the cost effectiveness of laser cutting and die cutting, it’s important to take into account the materials that can be used with die cutting.

Die cutting is compatible with a wide range of materials, including paper, cardboard, fabric, leather, and plastics. This versatility allows for greater flexibility in choosing the most cost-effective option for your project. However, it’s worth noting that certain materials may have limitations when it comes to die cutting, such as thicker materials that may require more force to cut.

Understanding the advantages and disadvantages of each material when it comes to die cutting can help you make an informed decision. Transitioning into the next section about design complexity and intricacy, it’s important to consider how these factors can also impact the cost-effectiveness of die cutting.

Design Complexity and Intricacy

Design complexity and intricacy play a crucial role in determining the best choice for your project, as they can significantly impact the final cost and effectiveness of die cutting. When it comes to intricate detailing and design flexibility, laser cutting tends to have the upper hand. Laser cutting allows for greater precision and can easily handle intricate patterns, intricate detailing, and complex designs. This level of precision is not easily achievable with die cutting, which relies on physical dies that may struggle with intricate designs. Thus, if your project requires a high level of design complexity and intricate detailing, laser cutting may be more cost-effective and efficient for your needs.

Now, let’s transition into the next section to evaluate production volume and time constraints.

Evaluate Production Volume and Time Constraints

Consider the production volume and time constraints when deciding between laser cutting and die cutting, as it’ll determine the most cost-effective option. Conduct a thorough production volume analysis to determine the quantity of materials that need to be cut.

Laser cutting is more efficient for smaller production volumes, as it allows for quick setup and minimal tooling costs. On the other hand, die cutting is more suitable for larger production volumes, as it can cut multiple materials simultaneously, reducing production time.

Additionally, evaluate the time constraints of your project. Laser cutting offers faster turnaround times, making it ideal for projects with tight deadlines. As you consider these factors, keep in mind that laser cutting may be the best option for lower production volumes and shorter time constraints.

Transitioning into the next section, factor in tooling and setup costs to further analyze the cost-effectiveness of each method.

Factor in Tooling and Setup Costs

When considering tooling and setup costs for your project, it’s important to factor in the initial investment for laser cutting and die cutting. Laser cutting typically requires a higher initial investment due to the cost of the laser cutting machine and software. On the other hand, die cutting may have a lower initial investment since it involves using pre-made dies.

Additionally, conducting a cost analysis for tooling and setup will help you determine the most cost-effective option for your specific project.

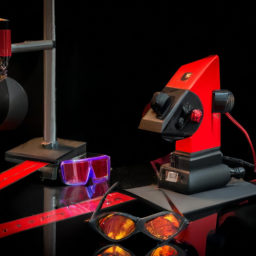

Initial Investment for Laser Cutting

The initial investment for laser cutting can be daunting, but it’s worth it for the precision and versatility it offers. Here are a few things to consider when thinking about the initial investment for laser cutting:

-

High-quality laser cutting machine: Laser cutting machines can be expensive, but they offer precise and efficient cutting capabilities.

-

Maintenance and repairs: Like any equipment, laser cutting machines require regular maintenance and occasional repairs, which should be factored into the initial investment.

-

Training and expertise: Operating a laser cutting machine requires specialized knowledge and skills, so training employees or hiring experts may be necessary.

-

Consumables and materials: Laser cutting requires specific consumables like gas and laser lenses, as well as materials to be cut.

-

Safety equipment and regulations: To ensure a safe working environment, investing in proper safety equipment and complying with regulations is essential.

Considering these factors, it’s important to conduct an initial investment comparison and cost-effectiveness analysis before making a decision.

Now, let’s move on to discussing the initial investment for die cutting.

Initial Investment for Die Cutting

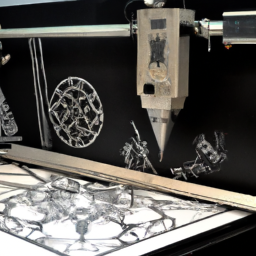

If you’re looking to expand your business and increase production efficiency, die cutting may be the game-changer you’ve been searching for. While laser cutting has its advantages, die cutting offers significant cost benefits and long-term savings.

The initial investment for die cutting equipment may be higher than laser cutting, but the cost per unit decreases significantly over time. Die cutting allows for high-speed and high-volume production, resulting in lower labor costs and faster turnaround times. Additionally, die cutting is compatible with a wide range of materials, including paper, cardboard, plastics, and metals. This versatility further contributes to cost savings by eliminating the need for multiple cutting methods.

With die cutting, you can achieve precise and consistent cuts while maximizing your production efficiency. Transitioning into the next section on cost analysis for tooling and setup, let’s explore how die cutting can provide even more cost-effective solutions for your business.

Cost Analysis for Tooling and Setup

Maximize your savings and streamline your production process with a thorough cost analysis of tooling and setup for die cutting. When comparing the cost of tooling and setup for die cutting versus laser cutting, it’s important to consider the long-term benefits and potential cost savings. While die cutting may require a higher initial investment, the cost per unit decreases significantly as the volume of production increases. This is due to the fact that die cutting allows for faster processing times and higher production rates compared to laser cutting. Additionally, die cutting offers greater precision and consistency, resulting in less waste and lower material costs. To illustrate this cost comparison, consider the following table:

| Cost Analysis | Die Cutting | Laser Cutting |

|---|---|---|

| Initial Investment | Higher | Lower |

| Cost per Unit | Decreases | Remains constant |

By conducting a cost analysis, you can make an informed decision based on your specific production needs and budget. Once you’ve optimized your die cutting process, you can further enhance your cost savings by optimizing your designs for laser cutting, which we will explore in the next section.

Optimize Designs for Laser Cutting

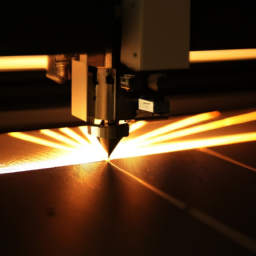

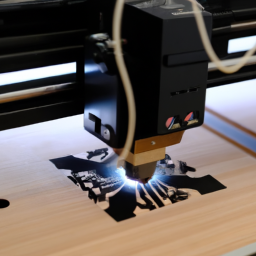

Imagine how much time and money you could save by optimizing your designs for laser cutting. With the right design software and understanding of laser parameters, you can create designs that are perfectly tailored for laser cutting.

Design software allows you to easily manipulate shapes and create intricate designs that can be cut with precision. By optimizing your designs for laser cutting, you can minimize material waste and improve cutting efficiency, ultimately reducing costs.

Laser cutting also offers the advantage of being able to cut a wide range of materials, from metals to plastics, allowing for versatility in your designs. However, it’s important to note that optimizing designs for laser cutting is just one aspect of the cost-effective manufacturing process.

Now let’s transition to the next section and explore how to optimize designs for die cutting.

Optimize Designs for Die Cutting

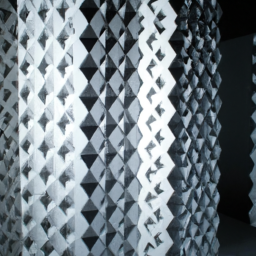

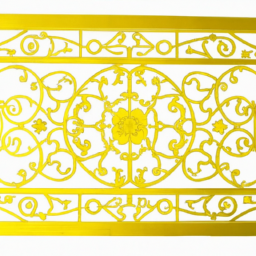

Now that you’ve learned how to optimize designs for laser cutting, let’s dive into optimizing designs for die cutting. Design optimization is crucial for die cutting to ensure cost-effectiveness and efficiency. By implementing the right die cutting techniques, you can maximize material usage and minimize production time. Here are three key techniques to consider:

-

Nesting: Arrange multiple designs within a single die to minimize waste and increase productivity.

-

Bridge cutting: Utilize bridges or tabs to maintain the integrity of delicate designs during the cutting process.

-

Rule optimization: Optimize the placement and size of the cutting rule to reduce material waste and improve cutting precision.

By incorporating these design optimization strategies, you can achieve cost-effective and high-quality die-cut products.

Frequently Asked Questions

Can laser cutting be used for all types of materials, or are there limitations?

Laser cutting has its limitations when it comes to the types of materials it can be used on. While it is versatile and can cut through a wide range of materials like wood, plastic, and metal, some materials such as reflective surfaces or certain types of glass may not be suitable for laser cutting.

Despite these limitations, laser cutting offers several advantages such as precision, flexibility, and the ability to create intricate designs, making it a popular choice for many applications.

Are there any design restrictions when it comes to laser cutting?

When it comes to laser cutting, there are indeed some design restrictions you need to consider.

Pay attention to design considerations and think about material compatibility. Laser cutting allows for intricate and precise designs, but keep in mind the limitations of the machine.

Make sure your design can be effectively cut without compromising the material. By understanding these factors, you can create designs that are both visually stunning and perfectly suited for laser cutting.

How does production volume affect the cost-effectiveness of laser cutting and die cutting?

The production volume plays a significant role in determining the cost-effectiveness of laser cutting and die cutting. As the production volume increases, the cost per unit decreases for laser cutting due to its high speed and automation capabilities.

However, die cutting offers advantages in high volume production as it can be more cost-effective and efficient for repetitive tasks. Therefore, considering the impact of production volume is crucial in determining the most cost-effective cutting method.

Are there any specific time constraints to consider when choosing between laser cutting and die cutting?

When choosing between laser cutting and die cutting, it’s important to consider time constraints and project deadlines.

Laser cutting is generally faster than die cutting, making it a better choice when there is limited time available. Laser cutting machines can quickly cut through materials, reducing production time and allowing for faster completion of projects.

So, if meeting project deadlines is a priority, laser cutting may be the more suitable option.

What are some additional costs associated with die cutting that may not be present in laser cutting?

When it comes to die cutting, there are a few extra costs that you need to consider. Unlike laser cutting, die cutting requires the creation of custom dies, which can be quite expensive.

Additionally, die cutting is limited in terms of the materials it can work with, whereas laser cutting has more flexibility. So, while laser cutting may have its own set of material limitations, die cutting definitely comes with its fair share of additional costs.

Conclusion

In conclusion, when it comes to choosing between laser cutting and die cutting, cost-effectiveness is key. By understanding the differences between these two methods and considering factors like material, design complexity, production volume, and time constraints, you can make an informed decision.

Optimizing your designs for either laser cutting or die cutting can help you achieve the desired outcome. Just like a skilled artist delicately carving intricate patterns, choosing the right cutting method will ensure your designs come to life with precision and finesse.