Are you tired of the old saw and chisel routine? It’s time to step into the future of precision cutting with laser cutting and milling. These cutting-edge techniques have revolutionized the manufacturing industry, offering unparalleled precision and efficiency.

But which method is more precise? In this article, we will delve into the world of laser cutting and milling, exploring their basics and factors affecting precision. We will compare the two methods, highlighting their advantages and limitations.

Whether you are a DIY enthusiast or a professional designer, choosing the right method for your project is crucial. So, grab your safety goggles and join us on this journey to discover which method reigns supreme in the realm of precision cutting.

Key Takeaways

- Laser cutting offers superior accuracy compared to milling.

- Laser cutting is more precise for intricate designs, while milling may be better for simpler shapes.

- Laser cutting is faster and more cost-effective for small to medium-sized projects.

- Laser cutting allows for material optimization and minimizes waste.

Understanding the Basics of Laser Cutting and Milling

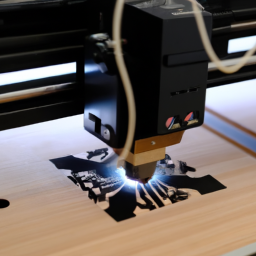

Laser cutting and milling, two popular methods for designing precision parts, offer distinct advantages when it comes to creating intricate and detailed designs.

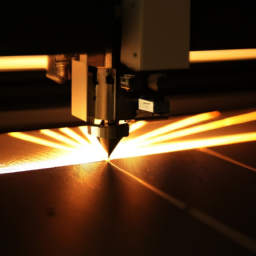

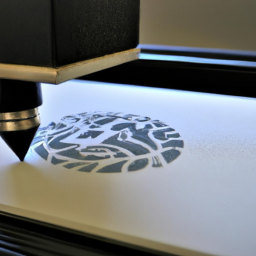

Laser cutting, known for its high level of precision and accuracy, uses a focused laser beam to cut through materials with extreme precision. It is especially effective for thin materials and can produce complex shapes with tight tolerances.

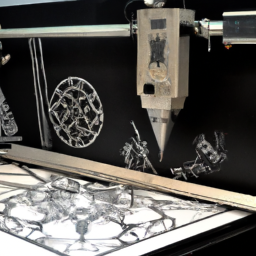

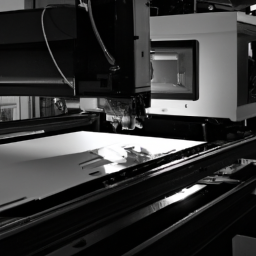

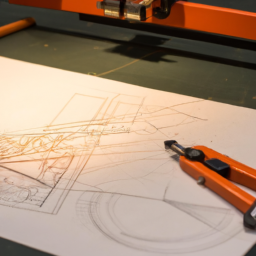

On the other hand, CNC machining, commonly referred to as milling, utilizes rotating cutting tools to remove material and create the desired shape. While it may not be as precise as laser cutting, milling offers the advantage of being able to work with a wider range of materials, including metals and plastics.

Factors such as material properties and design complexity can affect the precision in both laser cutting and milling. Understanding these factors is crucial for optimizing designs and achieving the desired precision in manufacturing.

Factors Affecting Precision in Laser Cutting and Milling

When it comes to precision, there are numerous factors that can greatly impact the quality of both laser cutting and milling. In the case of laser cutting, the factors affecting precision include the power and focus of the laser beam, the speed at which the beam moves across the material, and the type and thickness of the material being cut. Additionally, the importance of software and programming can’t be overstated, as they determine the path and speed of the laser beam, ensuring accuracy and consistency.

On the other hand, milling precision is influenced by factors such as the quality of the cutting tools, the rigidity of the milling machine, and the stability of the workpiece. These factors, combined with the skill of the operator, determine the level of precision that can be achieved.

Transitioning into the subsequent section about comparing precision in laser cutting and milling, it’s important to consider these factors when evaluating the precision capabilities of each method.

Comparing Precision in Laser Cutting and Milling

To achieve a higher level of precision, you should consider the various factors that impact the quality of both laser cutting and milling.

When it comes to precision comparison, laser cutting generally offers superior accuracy compared to milling. Laser cutting utilizes a high-energy laser beam that can make incredibly precise cuts with minimal material loss. The laser beam follows a predetermined path, resulting in precise and consistent cuts.

On the other hand, milling involves physically removing material using rotating cutting tools, which can introduce more variability and potential for errors. While milling can still achieve high levels of precision, laser cutting tends to be more accurate.

This precision comparison is crucial when deciding between the two techniques for your specific project.

Moving forward, let’s explore the advantages and limitations of laser cutting.

Advantages and Limitations of Laser Cutting

If you’re looking for a method that offers precise and consistent cuts, laser cutting has advantages and limitations worth considering.

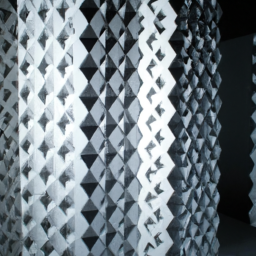

Laser cutting is known for its exceptional precision, allowing for intricate and detailed designs to be accurately replicated. The use of a focused laser beam ensures minimal material wastage and precise cuts along the desired path. This method also offers high repeatability, ensuring that each cut is identical to the previous one.

However, laser cutting does have some limitations. It may not be suitable for cutting certain materials, such as thick metals, as it may result in excessive heat and distortion. Additionally, the precision in laser cutting may not be as high as that achieved through milling, especially for complex designs with tight tolerances.

Despite these limitations, laser cutting remains a popular choice for many applications.

Speaking of precision in milling…

Advantages and Limitations of Milling

Milling offers a wide range of advantages and limitations that should be taken into consideration when choosing a fabrication method. One of the key advantages of milling is its high accuracy. With advancements in milling technology, precision levels have significantly improved, allowing for intricate and complex designs to be achieved with great accuracy. Milling also offers the flexibility to work with a variety of materials, including metals, plastics, and wood. However, there are limitations to milling as well. It can be a slower process compared to laser cutting, and the cost of equipment and maintenance can be relatively high. Additionally, milling may produce more waste material compared to laser cutting. When choosing the right method for your project, it’s important to weigh these advantages and limitations to ensure optimal results. Transitioning into the subsequent section about choosing the right method for your project, it is crucial to consider various factors to make an informed decision.

Choosing the Right Method for Your Project

When choosing the right method for your project, there are several key considerations to keep in mind.

Firstly, you need to consider the complexity of your design. Laser cutting is generally more precise for intricate designs, while milling may be better suited for simpler shapes.

Secondly, material selection and thickness play a crucial role in determining the appropriate method. Laser cutting is ideal for various materials, including metals and plastics, while milling works best with harder materials like wood and aluminum.

Lastly, cost and time constraints should be taken into account. Laser cutting is usually faster and more cost-effective for small to medium-sized projects, while milling may be more suitable for larger and more intricate designs.

Considerations for Design Complexity

To truly unlock the potential of your design, intricate details and complex patterns can be elegantly brought to life through the precision of laser cutting. When designing for intricate patterns, laser cutting offers a level of accuracy that is difficult to achieve with milling. The use of design software plays a crucial role in ensuring precision, as it allows for intricate designs to be created and translated into machine-readable formats. This ensures that every detail of your design is accurately replicated during the laser cutting process.

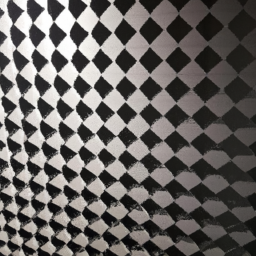

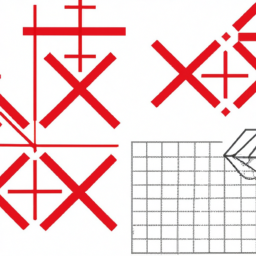

In order to illustrate the impact of design complexity on precision, consider the following table:

| Design Complexity | Laser Cutting Precision | Milling Precision |

|---|---|---|

| Low | High | Medium |

| Medium | Very High | Low |

| High | Extremely High | Very Low |

As you can see, laser cutting consistently provides higher precision, especially when dealing with complex designs. This precision is key when bringing intricate patterns to life.

When considering material selection and thickness, there are additional factors to take into account. [Transition to next section here].

Material Selection and Thickness

Now that you’ve considered the complexity of your design, let’s move on to the next important factor: material selection and thickness.

When optimizing designs for laser cutting or milling, it’s crucial to choose materials that are compatible with the chosen manufacturing method. Laser cutting works best with materials such as acrylic, wood, and thin metals, while milling is more suitable for harder materials like aluminum or steel.

Additionally, the thickness of the material also plays a role in the precision of the process. Thicker materials may require more machining time and can affect the surface finish of the final product. So, it’s important to carefully consider the material compatibility and thickness to ensure the desired precision and surface finish.

Now, let’s transition into the subsequent section about cost and time constraints.

Cost and Time Constraints

Considering cost and time constraints is crucial when choosing materials and thickness for your design. Not only do you want to create a precise and high-quality product, but you also need to manage your project efficiently.

When it comes to cost estimation, laser cutting tends to be more cost-effective than milling. Laser cutting is a quicker process, resulting in reduced labor costs and faster turnaround times. Additionally, laser cutting allows for material optimization, minimizing waste and further reducing expenses.

On the other hand, milling can be more time-consuming and expensive due to the need for specialized equipment and skilled operators. Therefore, if your priority is to optimize cost and time, laser cutting is generally the preferred choice.

However, it’s essential to evaluate your specific project requirements and consult with professionals to determine the best approach. Good project management is key to achieving precision while staying within budget and schedule.

Frequently Asked Questions

What materials can be used for laser cutting and milling?

To enjoy this answer, remember that variety is the spice of life. When it comes to laser cutting and milling, you have a wide range of materials to choose from.

Wood, acrylic, metal alloys, foam, leather, fabric, paper, and cardboard can all be used for both processes. These versatile materials offer endless possibilities for creating precise and intricate designs.

So, whether you’re working with wood or fabric, laser cutting and milling can help bring your ideas to life.

How does the cost of laser cutting compare to milling?

The cost comparison between laser cutting and milling depends on various factors such as material type, complexity of the design, and quantity.

Generally, laser cutting is more cost-effective for small to medium-sized projects due to its faster processing time and minimal tooling requirements. However, for larger or more intricate designs, milling may be preferred despite the higher costs associated with setup and labor.

A precision analysis should be conducted to determine the most suitable option based on your specific requirements.

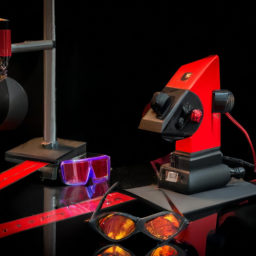

Are there any safety concerns associated with laser cutting or milling?

Laser cutting and milling both have safety concerns that need to be addressed. Safety precautions, such as wearing protective eyewear and following proper operating procedures, are necessary to prevent potential hazards. The intense heat and high power of lasers can cause burns or fire, while milling machines can pose risks of flying debris or entanglement.

It’s essential to prioritize safety in both processes to ensure the well-being of operators and prevent accidents.

Can laser cutting or milling be used for 3D designs?

Laser cutting is advantageous for 3D designs because it allows for precise and intricate cuts, resulting in clean and detailed finished products. It is especially useful for complex geometric shapes and delicate materials. On the other hand, milling has limitations when it comes to 3D designs. It’s not as precise as laser cutting and can struggle with intricate details. Additionally, milling may require multiple passes to achieve the desired shape, increasing production time.

Are there any specific design considerations when using laser cutting or milling?

When using laser cutting, you need to consider the accuracy and complexity of your design. Laser cutting can achieve incredibly precise cuts, allowing for intricate and detailed designs. However, it’s important to be mindful of the limits of the material and the complexity of the design to ensure optimal results.

On the other hand, when using milling, you should focus on material selection and surface finish. Milling allows for more versatility in material options and offers a wide range of surface finishes to choose from.

Conclusion

So, when it comes to precision, laser cutting takes the crown. Its ability to create intricate designs with minimal material waste is unmatched. However, don’t underestimate the power of milling. It still holds its ground in certain situations, providing a different level of precision.

Ultimately, the choice between laser cutting and milling depends on your specific project needs. Just like a master chef carefully selects the perfect tool for each dish, you too must choose wisely to achieve the best results in your designs.