Are you tired of the same old methods for cutting designs? Looking for a more efficient and precise way to bring your ideas to life? Well, we’ve got just the solution for you!

In this article, we will explore the fascinating world of laser cutting and plasma cutting, two cutting-edge techniques that are revolutionizing the design industry. These methods offer a plethora of benefits, including faster production times and more intricate designs. But which one is right for you? That’s where optimization comes into play.

By optimizing your designs specifically for laser cutting or plasma cutting, you can ensure maximum efficiency and cost-effectiveness. So, whether you’re a seasoned designer or just starting out, join us as we delve into the world of optimizing designs for laser cutting vs. plasma cutting, and discover the method that will take your projects to the next level.

Key Takeaways

- Laser cutting is ideal for intricate designs and precise cuts, while plasma cutting is better for thicker materials and larger projects.

- Factors to consider when choosing between laser cutting and plasma cutting include precision, versatility, equipment costs, and ability to cut reflective materials.

- Laser cutting requires a higher initial investment but offers increased accuracy and versatility.

- The size and quantity of projects influence the choice of cutting method.

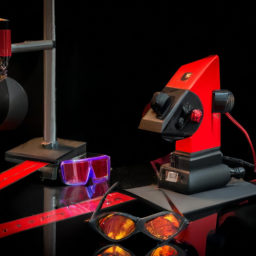

Understanding the Basics of Laser Cutting and Plasma Cutting

Let’s dive into the basics of laser cutting and plasma cutting and discover which method is right for your design needs!

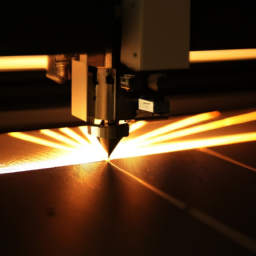

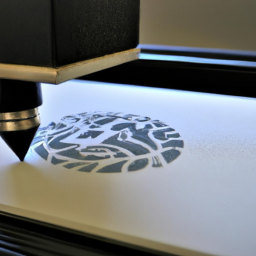

When it comes to cutting edge technology in laser and plasma cutting, understanding the difference between raster graphics and vector graphics is essential. Laser cutting utilizes a high-powered laser beam to precisely cut through materials, while plasma cutting uses a stream of ionized gas to melt and sever metal.

Laser cutting is ideal for intricate designs and precise cuts, as it can easily handle vector graphics. On the other hand, plasma cutting is better suited for thicker materials and larger projects that require faster cutting speeds.

Now that you have a grasp on the basics, let’s explore the factors to consider when choosing between laser cutting and plasma cutting.

Factors to Consider When Choosing Between Laser Cutting and Plasma Cutting

When deciding between laser cutting and plasma cutting, it’s important to consider various factors.

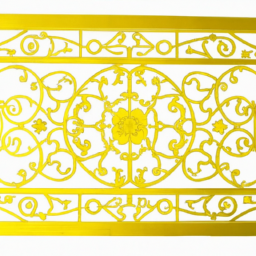

Laser cutting offers precision and versatility, making it ideal for intricate designs and fine materials. On the other hand, plasma cutting is known for its ability to handle thick materials and its lower equipment costs. It also has an advantage over laser cutting when it comes to cutting reflective materials, as lasers can struggle with these surfaces.

Additionally, plasma cutting can be faster and more cost-effective for certain applications. However, if you require high precision and smooth edges, laser cutting might be the better choice.

Considering these factors will help you determine the optimal method for your specific needs.

Moving forward to optimizing designs for laser cutting, let’s explore some key strategies for achieving the best results.

Optimizing Designs for Laser Cutting

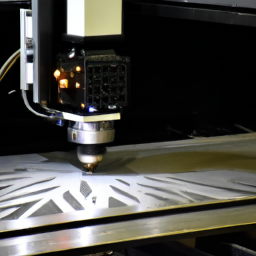

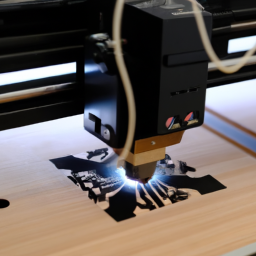

To achieve the best results with laser cutting, you’ll want to consider a few key strategies.

First, when designing for laser cutting, it’s important to keep in mind the limitations of the process. Laser cutting works best with thin materials, so try to avoid designs that require cutting through thick or dense materials.

Secondly, material selection plays a crucial role in optimizing your designs for laser cutting. Choose materials that are compatible with laser cutting, such as metals, plastics, or wood. Avoid materials that may produce harmful fumes or have a high risk of catching fire during the cutting process.

By following these strategies, you can ensure that your designs are suitable for laser cutting and achieve the desired results.

Now, let’s explore how to optimize designs for plasma cutting.

Optimizing Designs for Plasma Cutting

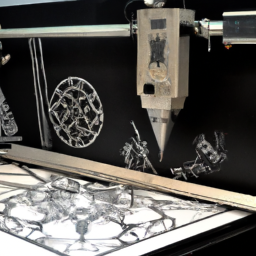

When optimizing designs for plasma cutting, there are three key points to consider.

First, designing with raster graphics allows for greater control over intricate details and complex shapes.

Second, adjusting cutting speed and power ensures precise and efficient cutting based on the material being used.

Lastly, handling piercing and beveling requires careful planning and execution to achieve desired results.

By taking these factors into account, you can optimize your designs for plasma cutting and achieve high-quality results.

Designing with Raster Graphics

If you want to achieve the best results when designing with raster graphics, you should consider the limitations and advantages of both laser cutting and plasma cutting.

When it comes to raster graphic limitations, it’s important to remember that plasma cutting is not as precise as laser cutting. This means that intricate details and fine lines may not be accurately reproduced with plasma cutting. However, plasma cutting can handle thicker materials compared to laser cutting.

To optimize your designs for plasma cutting, it is recommended to use larger, bold designs with clear edges and avoid intricate details. Additionally, it’s important to adjust the cutting speed and power settings to ensure clean and precise cuts.

By considering these best practices, you can create designs that are suitable for plasma cutting and transition smoothly into the subsequent section about adjusting cutting speed and power.

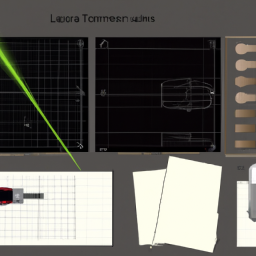

Adjusting Cutting Speed and Power

Adjusting the cutting speed and power can make a world of difference in achieving the most precise and flawless cuts for your designs.

When working with laser cutting or plasma cutting, it’s important to find the right balance between cutting speed and power to ensure optimal results. By adjusting the cutting speed, you can control the pace at which the laser or plasma cuts through the material. This is especially useful when working with different cutting thicknesses.

Additionally, adjusting the power of the laser or plasma can help achieve clean and accurate cuts, particularly when dealing with materials of varying compatibility. With the right adjustments, you can ensure that the cuts are smooth and precise, resulting in a high-quality final product.

Speaking of achieving flawless cuts, let’s dive into the next section about handling piercing and beveling.

Handling Piercing and Beveling

To handle piercing and beveling, you’ll want to pay close attention to the thickness of the material you’re working with. Studies show that thinner materials require different piercing techniques compared to thicker ones. For thin materials, it’s crucial to use piercing techniques that prevent warping or distortion. This can be achieved by using lower power settings and shorter piercing durations.

On the other hand, thicker materials require higher power and longer piercing durations to ensure a clean cut. When it comes to beveling, laser cutting offers more precise and accurate results compared to plasma cutting. Laser cutting allows for intricate and complex beveling methods, while plasma cutting may result in rougher edges.

Now, let’s move on to the next section about cost comparison and budget considerations.

Cost Comparison and Budget Considerations

When comparing the cost of laser cutting and plasma cutting, there are several key points to consider.

Firstly, you need to factor in the initial equipment cost, which can vary significantly between the two methods.

Secondly, maintenance and operating costs should be taken into account, as these can have a significant impact on your budget over time.

Lastly, the scale and volume of your projects should be considered, as this can affect the cost effectiveness of each method.

Initial Equipment Cost

Considering initial equipment cost, you’ll find that laser cutting requires a higher investment compared to plasma cutting, but the precision and versatility it offers make it a worthwhile choice.

Laser cutting machines are generally more expensive upfront due to their advanced technology and higher precision capabilities. However, this initial investment can be justified by the increased accuracy and ability to cut a wide range of materials with laser cutting. Additionally, laser cutting often results in cleaner cuts and eliminates the need for secondary finishing processes.

While plasma cutting equipment may have a lower initial cost, it may require more maintenance and consumables, which can add to the overall operating costs.

Transitioning into the next section about maintenance and operating costs, it’s important to consider these factors when deciding between laser cutting and plasma cutting.

Maintenance and Operating Costs

If you want to keep your expenses in check, it’s crucial to factor in the costs of maintenance and operation for both laser cutting and plasma cutting. While the initial equipment cost may be a consideration, the ongoing maintenance and operating costs can greatly impact your overall budget.

When it comes to maintenance costs, laser cutting requires regular maintenance to ensure the machine operates efficiently and accurately. This can include cleaning the lenses, replacing consumables, and conducting routine inspections. On the other hand, plasma cutting machines generally have lower maintenance requirements, as they don’t rely on delicate optics or consumables.

To determine the cost efficiency of each method, consider the following factors:

- Energy consumption: Laser cutting machines tend to use more energy than plasma cutting machines.

- Consumables: Laser cutting may require more frequent replacement of consumables such as lenses and nozzles.

- Downtime: Laser cutting machines may experience more downtime due to maintenance needs.

By considering these maintenance costs and cost efficiency factors, you can make an informed decision on which cutting method is most suitable for your project.

Moving on to the next section about project scale and volume, the size and quantity of your projects will also play a crucial role in determining the ideal cutting method.

Project Scale and Volume

The size and quantity of your projects will greatly influence the cutting method that’s most suitable for you.

When it comes to project scale and volume, both laser cutting and plasma cutting have their advantages and considerations.

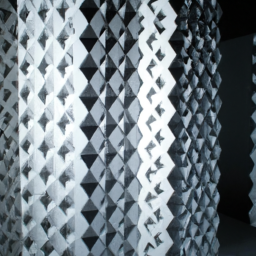

Laser cutting is ideal for smaller projects with intricate designs and high precision requirements. Its narrow kerf allows for intricate details, making it perfect for project complexity.

On the other hand, plasma cutting is better suited for large-scale projects that require cutting through thicker materials. It offers faster cutting speeds and can handle a wider range of material compatibility.

Ultimately, the decision on which cutting method to choose will depend on the specific needs of your project. Making the right choice for your project involves carefully considering the project scale, complexity, and material compatibility.

Transitioning into the next section, these factors will help you determine the most suitable cutting method for your needs.

Making the Right Choice for Your Project

Deciding on the perfect process for your project requires careful consideration and a clear concept. When it comes to choosing between laser cutting and plasma cutting, you need to evaluate your project requirements.

Here are three key factors to consider:

-

Precision: Laser cutting offers high precision with intricate designs, while plasma cutting is better suited for thicker materials that don’t require fine details.

-

Material: Laser cutting works well with a variety of materials, including metal, wood, and acrylic. Plasma cutting is primarily used for metal fabrication.

-

Cost: Laser cutting is generally more expensive due to the high precision and advanced technology involved. Plasma cutting, on the other hand, is a more cost-effective option for larger-scale projects.

By considering these factors and weighing them against your project requirements, you can make an informed decision on whether laser cutting or plasma cutting is the right choice for you.

Frequently Asked Questions

What are the main differences between laser cutting and plasma cutting?

When comparing laser cutting and plasma cutting, there are key differences to consider.

Laser cutting offers several advantages over plasma cutting, such as higher precision and accuracy, cleaner cuts, and the ability to cut a wider range of materials.

However, it’s important to note that laser cutting can be more expensive than plasma cutting, especially for thicker materials. Therefore, cost considerations should be factored in when deciding between the two methods.

Can laser cutting and plasma cutting be used for the same types of materials?

Oh, the joys of material compatibility! Laser cutting and plasma cutting definitely have their differences when it comes to the types of materials they can handle.

Laser cutting is a bit of a snob, preferring delicate materials like wood, plastic, and thin metals.

Plasma cutting, on the other hand, is more of a tough guy, tackling thick metals with ease.

As for cost effectiveness, laser cutting can be a bit pricey, especially for thick metals, while plasma cutting tends to be more budget-friendly.

So, choose wisely based on your material and budget constraints!

Are there any limitations to the complexity of designs that can be achieved with laser cutting?

There are some limitations to the complexity of designs that can be achieved with laser cutting. Laser cutting is extremely precise and can create intricate designs, but there are certain design elements that may be difficult to achieve.

For example, extremely small details or sharp angles may not be possible due to the limitations of the laser cutting process. However, with careful planning and consideration, many complex designs can still be successfully executed using laser cutting.

How does the speed of cutting differ between laser cutting and plasma cutting?

When comparing the cutting speeds between laser cutting and plasma cutting, several factors come into play. In laser cutting, the cutting speed is influenced by factors such as the power of the laser, the material being cut, and the thickness of the material.

On the other hand, plasma cutting’s speed is determined by the power of the plasma torch and the type of gas used.

Overall, laser cutting tends to have faster cutting speeds compared to plasma cutting due to its precision and ability to cut through various materials.

Can laser cutting or plasma cutting be used for both small-scale and large-scale projects?

Laser cutting and plasma cutting are both versatile methods for cutting materials, but when it comes to cost-effectiveness, laser cutting takes the cake. It’s like a magical precision wand that effortlessly slices through materials with incredible speed and accuracy.

For small-scale projects, laser cutting has distinct advantages, such as its ability to handle intricate designs and produce clean edges. So, whether it’s a tiny prototype or a massive undertaking, laser cutting is the way to go.

Conclusion

So, when it comes to choosing between laser cutting and plasma cutting, it’s clear that both methods have their advantages and considerations.

However, after investigating the truth behind the theory, it can be concluded that laser cutting is the more precise and efficient option for optimizing designs. With its ability to achieve intricate details and high-quality cuts, laser cutting is the ideal choice for projects that require utmost precision.

While plasma cutting may be more cost-effective for thicker materials, laser cutting offers superior results for many applications.