Imagine a precision instrument delicately carving intricate patterns into a material, with each cut as precise as the stroke of a master painter’s brush. Laser cutting and router cutting are two techniques that offer this level of accuracy, and choosing the right method can make all the difference in your design projects.

In this article, we will delve into the world of laser cutting and router cutting, exploring their unique characteristics and capabilities. We will also examine the factors that affect their accuracy, and ultimately answer the burning question: which method is more accurate?

Whether you are a seasoned designer or a curious enthusiast, understanding the nuances of these techniques will empower you to optimize your designs for maximum precision. So, grab your imagination and let’s embark on a journey to discover the artistry of optimizing designs for laser cutting versus router cutting.

Key Takeaways

- Laser cutting offers high accuracy and versatility, while router cutting allows for more flexibility in materials.

- Laser cutting minimizes material waste, but may cause heat distortion or discoloration, while router cutting has slower cutting speed and may not be as accurate for intricate details.

- Factors affecting accuracy in both methods include material selection, machine calibration, and operator skill.

- Design optimization for accuracy requires understanding the capabilities and limitations of the cutting methods, paying attention to details like tolerances and material thickness, and making small adjustments in the design to improve accuracy.

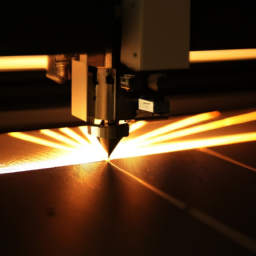

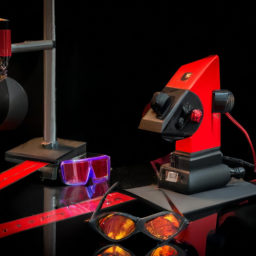

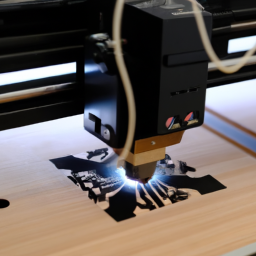

Understanding Laser Cutting

Laser cutting is a fascinating process that allows for incredibly precise and intricate designs to be created with ease. The advantages of laser cutting are numerous. Firstly, it offers exceptional accuracy, allowing for tight tolerances and intricate details to be achieved.

Additionally, laser cutting is incredibly versatile, capable of cutting various materials such as wood, metal, and plastic. It also produces clean cuts with minimal material waste, making it a cost-effective option. However, laser cutting does have its limitations. It is not suitable for cutting thick materials, as the laser beam may struggle to penetrate them effectively. Moreover, laser cutting can sometimes cause heat distortion or discoloration on certain materials.

Now that you understand the advantages and limitations of laser cutting, let’s explore the alternative method of router cutting.

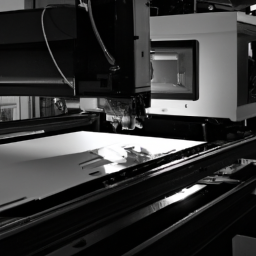

Exploring Router Cutting

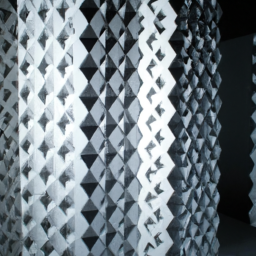

Imagine you’re standing in front of a powerful router, watching as it effortlessly slices through a sheet of material with precision and finesse. Router cutting techniques involve using a spinning bit to remove material and create intricate designs. Unlike laser cutting, which uses a focused beam of light, router cutting allows for more flexibility in the type of materials that can be cut. However, it does have its limitations.

The cutting speed of a router is slower compared to laser cutting, and it may not be as accurate when it comes to intricate details. Factors such as the type of bit used, the speed of the router, and the skill of the operator can all affect the accuracy of the cuts.

Now, let’s delve into the factors affecting accuracy in both laser cutting and router cutting.

Factors Affecting Accuracy

To achieve precise cuts, you need to consider factors such as the choice of materials, the speed of the router, and your own level of expertise.

When it comes to material selection, certain materials may be more prone to inaccuracies due to their composition or thickness. It is important to choose materials that are suitable for router cutting and can maintain their structural integrity during the process.

Additionally, machine calibration plays a crucial role in achieving accuracy. Proper calibration ensures that the router moves in a precise and consistent manner. Regular maintenance and calibration checks are necessary to avoid any deviations in cutting accuracy.

By taking these factors into account, you can optimize your designs for router cutting and ensure high levels of accuracy in your final product.

Now, let’s compare the accuracy of router cutting with laser cutting.

Comparing Accuracy

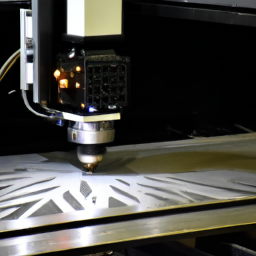

When it comes to achieving precise cuts, one important aspect to consider is comparing the accuracy of router cutting with laser cutting.

Measuring accuracy in manufacturing processes is crucial to ensure the final product meets the required specifications. Both router cutting and laser cutting have their own advantages and limitations when it comes to accuracy.

Laser cutting is known for its high precision, as it uses a concentrated beam of light to cut through materials. However, the accuracy of laser cutting can be affected by the properties of the material being cut, such as thickness and reflectivity.

On the other hand, router cutting can also achieve accurate cuts, especially when using advanced computer numerical control (CNC) systems. The impact of material properties on cutting accuracy should be taken into account when choosing the right method for your project.

In the subsequent section about choosing the right method, you will learn more about the factors to consider in order to make an informed decision.

Choosing the Right Method

To make the best choice for your project, you need to carefully consider the factors that will help you choose the right method for achieving precise cuts in manufacturing.

One important factor to consider is the material selection. Different materials may have different requirements when it comes to cutting accuracy. For example, certain materials may be better suited for laser cutting due to their ability to withstand high heat, while others may be more suitable for router cutting.

Another factor to consider is the impact of machine calibration. Both laser cutting and router cutting machines require regular calibration to ensure accurate and precise cuts. Neglecting machine calibration can result in errors and inconsistencies in the final product.

By considering the importance of material selection and the impact of machine calibration, you can make an informed decision on the right method for achieving accurate cuts in your manufacturing process.

Now, let’s move on to optimizing design for accuracy.

Optimizing Design for Accuracy

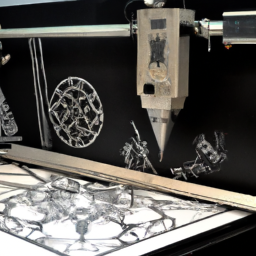

Creating precise cuts in manufacturing requires careful consideration of design elements to ensure accuracy in the final product. When optimizing a design for accuracy, there are a few key factors to keep in mind.

First, it’s crucial to understand the capabilities and limitations of the cutting method being used, whether it’s laser cutting or router cutting. This knowledge will help you make informed decisions about the design elements that can improve precision.

Additionally, paying attention to details such as tolerances and material thickness can greatly impact the accuracy of the final cut. By fine-tuning these parameters and adjusting the design accordingly, you can achieve exactness in your manufacturing process.

Remember that even small adjustments in design can make a significant difference in the accuracy of the cuts, so it’s worth investing time and effort in optimizing the design for precision.

Frequently Asked Questions

Can laser cutting and router cutting be used interchangeably for all types of materials?

Laser cutting and router cutting cannot be used interchangeably for all types of materials. Laser cutting has limitations when it comes to certain materials like thick metals or reflective surfaces. On the other hand, router cutting has advantages for intricate designs, as it can achieve more intricate and detailed cuts compared to laser cutting.

For example, when working with delicate wood carvings, router cutting is preferred for its precision and ability to create intricate patterns.

Is laser cutting or router cutting more cost-effective for small-scale projects?

When considering cost comparison for small-scale projects, it’s important to analyze both laser cutting and router cutting.

Laser cutting may have higher upfront costs due to the need for specialized equipment, but it can offer greater precision and faster production times.

On the other hand, router cutting may have lower initial costs, but it may require additional finishing work to achieve the desired precision.

Ultimately, the best option depends on the specific requirements of the project and budget constraints.

Are there any limitations or restrictions on the size of designs that can be cut using laser cutting or router cutting?

While laser cutting offers precise and intricate designs, it does have limitations in terms of size. Large designs may require multiple cuts or specialized equipment.

On the other hand, router cutting doesn’t have size restrictions, but it is limited by material compatibility. Certain materials may not be suitable for router cutting, such as fragile or heat-sensitive ones.

So, when considering the size of your design, it’s important to take into account the limitations of laser cutting and the material compatibility for router cutting.

What are the main differences in the cutting speed between laser cutting and router cutting?

The main differences in cutting speed between laser cutting and router cutting depend on factors like the material being cut and the design complexity.

Laser cutting generally has a faster cutting speed due to the high precision and efficiency of the laser beam. However, router cutting can be faster for certain materials or designs.

It’s important to consider that laser cutting often has lower energy consumption compared to router cutting, making it a more environmentally friendly choice.

Are there any specific design considerations that need to be taken into account when preparing a file for laser cutting or router cutting?

When preparing a file for laser cutting or router cutting, there are some design considerations you need to keep in mind. For laser cutting, factors like material thickness, kerf width, and cutting speed can affect the cut quality.

On the other hand, for router cutting, the design should consider factors like bit diameter, cutting depth, and feed rate. These factors play a crucial role in determining the accuracy and quality of the cuts.

Conclusion

So, you’ve reached the end of our enlightening journey comparing laser cutting and router cutting for accuracy. Now, I know you’re dying to know which method reigns supreme. Well, my friend, the truth is, both have their strengths and weaknesses.

It all boils down to your specific needs and preferences. So, go forth and optimize your designs accordingly! Just remember, in the world of precision cutting, accuracy is the name of the game. Happy crafting!