‘Measure twice, cut once.’ This age-old adage is the mantra of every designer, reminding us of the importance of precision and efficiency in our craft.

When it comes to optimizing designs for laser cutting versus traditional design techniques, the choice is not always clear-cut. Laser cutting offers numerous advantages, such as intricate detailing and faster production times, while traditional techniques provide the tactile experience and flexibility that some designs require.

In this article, we will delve into the world of laser cutting, exploring its advantages and limitations. Additionally, we will dive into the realm of traditional design techniques, examining how they can be maximized for optimal results.

By understanding the considerations for choosing the right technique and learning how to optimize designs, you can make an informed decision that best suits your project’s unique needs.

So, let’s explore the world of design and discover which technique reigns supreme: laser cutting or traditional design methods.

Key Takeaways

- Laser cutting offers advantages such as intricate detailing, faster production times, accuracy and precision, wide range of materials, design flexibility, cost-effectiveness, and reduction in manual labor and time.

- Traditional design techniques provide benefits such as a tactile experience, flexibility, handcrafted and artistic results, unique charm and authenticity, customization, enhancement of craftsmanship, and intricate detailing.

- When comparing laser cutting and traditional design techniques, laser cutting excels in precision, efficiency, and cost, while traditional design techniques excel in flexibility and intricacy.

- Factors to consider when choosing the right technique include material selection, cost effectiveness, precision and accuracy, time efficiency, specific project requirements, and intricacy and timeline of the project.

Understanding Laser Cutting: Advantages and Limitations

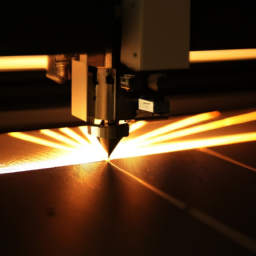

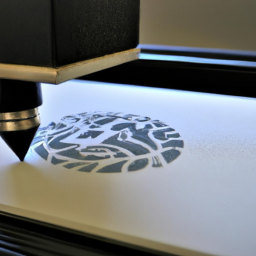

Laser cutting offers a plethora of advantages, allowing designers to create intricate and precise designs with ease. The accuracy and precision of laser cutting are unmatched, enabling designers to achieve intricate details and fine cuts that would be difficult or impossible with traditional techniques.

Laser cutting also provides versatility, as it can be used on a wide range of materials, including metals, wood, and plastics. However, it’s important to be aware of the limitations of laser cutting.

For instance, laser cutting can be expensive, especially for large-scale projects. Additionally, laser cutting has certain constraints, such as limitations on the thickness of materials that can be cut.

Despite these limitations, laser cutting remains a powerful tool for designers.

Now, let’s explore traditional design techniques and their role in the creative process.

Exploring Traditional Design Techniques

When exploring traditional design techniques, you’ll discover the handcrafted and artistic approach that sets them apart.

These techniques offer a level of flexibility and customization that’s hard to achieve with laser cutting. However, it’s important to note that traditional design techniques can be time and labor-intensive, requiring skilled craftsmen and a longer production process.

Handcrafted and Artistic Approach

Embrace your creative side and let your artistic instincts guide you as you explore the handcrafted approach to design.

In a world dominated by machine-made products, there’s something special about creating something with your own hands. Handcrafted designs offer a unique charm and authenticity that can’t be replicated by a machine. It allows for a level of creativity and personal expression that’s often lacking in precision-driven techniques.

While machines excel in precision, the human touch brings a sense of warmth and imperfection that adds character to a design. However, it’s important to note that the handcrafted approach does have its limitations when it comes to flexibility and customization.

This is where laser cutting and other modern techniques come into play, providing the perfect balance between creativity and precision.

Flexibility and Customization

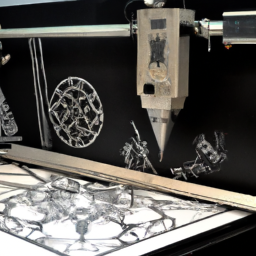

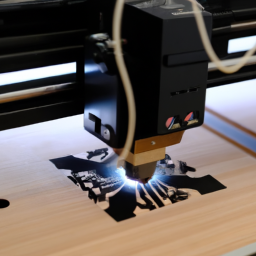

The key to unlocking endless possibilities lies within the realm of customization, allowing your design to reflect your unique identity and personal style. Laser cutting offers a wide range of customization options that traditional design techniques simply cannot match.

With laser cutting, you have the freedom to create intricate and detailed designs that are tailored specifically to your vision. The design flexibility afforded by laser cutting enables you to experiment with different shapes, sizes, and patterns, pushing the boundaries of what is possible. Furthermore, laser cutting allows for precise and accurate cuts, ensuring a high level of craftsmanship in your final product.

So, why settle for limitations when you can have complete control over your design? Embrace the power of customization and let your creativity soar. With laser cutting, the possibilities are truly endless.

Transitioning into the next section, let’s explore how laser cutting can save you from the time and labor-intensive process of traditional design techniques.

Time and Labor Intensive

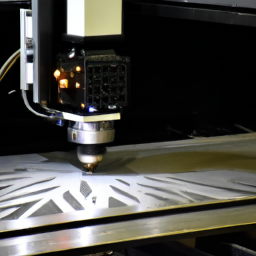

By streamlining the design process, laser cutting offers a more efficient and effective alternative to labor-intensive traditional techniques. With laser cutting, you can achieve precise cuts and intricate designs with minimal effort. This makes it a cost-effective option, as it reduces the need for manual labor and saves time. Laser cutting also allows for greater flexibility in customization, as it can easily adapt to different materials and thicknesses. To illustrate the benefits of laser cutting, consider the following table:

| Traditional Design Techniques | Laser Cutting |

|---|---|

| Labor-intensive | Cost-effective |

| Time-consuming | Precision cutting |

| Limited customization | Flexibility |

| Prone to human error | Efficient |

| Inconsistent results | Effective |

As you can see, laser cutting offers significant advantages over traditional techniques. In the next section, we will discuss considerations for choosing the right technique, taking into account factors such as material, complexity, and budget.

Considerations for Choosing the Right Technique

Consider the factors that’ll help you determine the best technique for your design, while keeping in mind the adage ‘measure twice, cut once.’

Here are four key considerations for choosing between traditional design techniques and optimizing designs for laser cutting:

-

Material selection: Laser cutting works well with a wide range of materials such as wood, acrylic, and metal, while traditional techniques may be limited to certain materials.

-

Cost effectiveness: Laser cutting can be more cost-effective for intricate designs and small production runs, as it eliminates the need for complex tooling and reduces material waste.

-

Precision and accuracy: Laser cutting offers precise and accurate cuts, allowing for intricate designs and tight tolerances that may be difficult to achieve with traditional techniques.

-

Time efficiency: Laser cutting is generally faster than traditional techniques, as it eliminates the need for manual labor and reduces production time.

Considering these factors, it’s clear that optimizing designs for laser cutting can provide numerous benefits over traditional techniques.

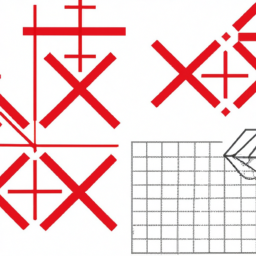

Optimizing Designs for Laser Cutting

When choosing a technique for your design, keep in mind the benefits of creating intricate and precise designs with laser cutting. Laser cutting offers precision cutting that allows for the creation of highly detailed and accurate designs.

The laser beam can cut through a wide range of materials, including wood, acrylic, metal, and fabric. This versatility in material selection allows for endless design possibilities.

Laser cutting also eliminates the need for complex tooling or set-up, resulting in faster production times and reduced costs. Additionally, the laser cutting process produces clean and smooth edges, minimizing the need for post-processing.

By optimizing your designs for laser cutting, you can achieve the highest level of precision and quality.

Transitioning into the subsequent section, maximizing results with traditional design techniques offers alternative approaches to consider.

Maximizing Results with Traditional Design Techniques

Now that you’ve learned about optimizing designs for laser cutting, let’s explore how you can maximize results with traditional design techniques.

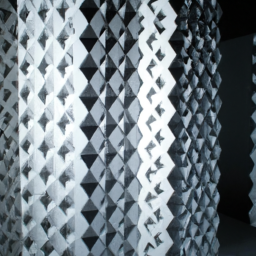

While laser cutting offers precision and efficiency, traditional design methods have their own merits. By employing traditional techniques, you can enhance craftsmanship and create unique, handcrafted pieces that showcase your artistic abilities.

Traditional design methods allow for more intricate detailing and can add a personal touch to your projects. From intricate woodwork to delicate metal engravings, traditional design methods provide a level of artistry that laser cutting may not be able to replicate.

However, when it comes to making the best choice for your project, you need to carefully consider the specific requirements, intricacy, and timeline of your design.

Transitioning into the subsequent section, let’s examine how you can determine the optimal approach for your project.

Making the Best Choice for Your Project

To determine the most suitable approach for your project, carefully assess the specific requirements, intricacy, and timeline while envisioning the final outcome. When weighing your options, consider the cost comparison between optimizing designs for laser cutting and utilizing traditional design techniques. While traditional design techniques may offer more flexibility and allow for intricate details, optimizing designs for laser cutting can provide greater precision and efficiency. To help you make the best choice, here is a comparison table:

| Traditional Design Techniques | Optimizing Designs for Laser Cutting | |

|---|---|---|

| Precision | Moderate | High |

| Flexibility | High | Limited |

| Intricacy | High | Moderate |

| Efficiency | Moderate | High |

| Cost | Varies | Generally higher |

Consider these factors and prioritize what matters most for your project to make an informed decision.

Frequently Asked Questions

What are the main advantages of laser cutting compared to traditional design techniques?

The advantages of laser cutting compared to traditional design techniques are numerous.

Laser cutting offers precise and accurate cuts, resulting in high-quality finished products. It allows for intricate and complex designs to be created with ease.

Laser cutting is also a faster and more efficient process, reducing production time and costs. Additionally, it offers the flexibility to work with a variety of materials, including metals, plastics, and wood, making it a versatile option for designers.

What are the limitations or drawbacks of laser cutting?

When it comes to laser cutting, there are a few limitations and challenges to consider.

One limitation is the thickness of the material that can be cut. Laser cutting is more suitable for thin materials, and thicker ones may require multiple passes or other methods.

Additionally, laser cutting can result in heat-affected zones and potential warping of the material.

Another challenge is the cost of the equipment and maintenance, which can be quite expensive.

How do traditional design techniques differ from laser cutting in terms of process and outcome?

Traditional design techniques differ from laser cutting in terms of process and outcome. When using traditional design techniques, you rely on manual tools and skills to create your design. This can be time-consuming and may require more effort to achieve precision.

On the other hand, laser cutting is a more efficient process that uses computer-controlled lasers to cut through materials with extreme precision. This results in a cleaner and more accurate outcome, with less room for error.

What are some key factors to consider when deciding whether to use laser cutting or traditional design techniques?

When deciding whether to use laser cutting or traditional design techniques, there are several key factors to consider.

Design considerations play a crucial role, as laser cutting allows for more intricate and precise designs compared to traditional methods.

Additionally, cost comparison is important, as laser cutting can be more expensive upfront but may save money in the long run due to increased efficiency and reduced material waste.

Can you provide any tips or best practices for optimizing designs specifically for laser cutting?

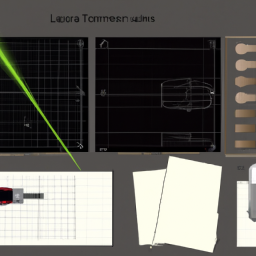

To optimize your designs for laser cutting, there are a few tips and best practices you can follow.

First, make sure to use laser cutting software that allows you to create precise and accurate designs.

Additionally, consider the material you’re working with and adjust your design accordingly to avoid any complications during the cutting process.

Finally, always double-check your design before sending it for laser cutting to ensure it meets all the necessary requirements.

Conclusion

So, after weighing the advantages and limitations of both laser cutting and traditional design techniques, it’s time to make a decision.

In this modern world where time is of the essence, laser cutting seems like the way to go. Its precision and efficiency can’t be beat.

However, don’t discount the tried and true methods of traditional design. Sometimes a little old-fashioned craftsmanship can add that extra touch of authenticity to your project.

Ultimately, it’s up to you to choose what suits your needs and preferences. Happy designing, and may the force be with you!