Are you ready to cut through the clutter and create stunning designs? When it comes to optimizing your designs, it’s crucial to choose the right cutting method. Just like a master chef carefully selects the perfect knife for each ingredient, you need to choose between laser cutting and vinyl cutting to ensure the versatility and precision your project demands.

In this article, we will explore the world of laser cutting and vinyl cutting, comparing their advantages and helping you make an informed decision.

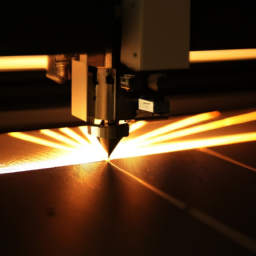

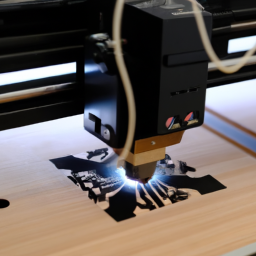

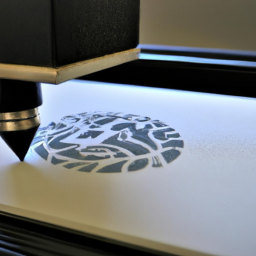

Laser cutting, like a skilled surgeon, uses a highly concentrated beam of light to effortlessly slice through materials with unparalleled accuracy.

On the other hand, vinyl cutting, like a nimble artist’s brush, delicately carves intricate designs on adhesive vinyl sheets, offering flexibility and creativity.

By understanding the basics and exploring the advantages of each method, you can confidently navigate the world of cutting techniques.

Whether you’re a DIY enthusiast or a professional designer, this article will provide you with the insights you need to optimize your designs for laser cutting or vinyl cutting.

So, let’s dive in and uncover the secrets to unleashing your creativity and versatility!

Key Takeaways

- Laser cutting is versatile and can be used on various materials like wood, acrylic, leather, and metal.

- Vinyl cutting is best for thin and flexible materials like adhesive vinyl or heat transfer vinyl.

- Laser cutting allows for intricate and detailed designs with clean edges and smooth finishes.

- Vinyl cutting offers scalability, allowing for designs of different sizes.

Understanding the Basics of Laser Cutting

Now that you’ve grasped the basics of laser cutting, you’ll be able to unlock a whole new world of design possibilities. Laser cutting offers numerous advantages over other cutting methods, making it a versatile option for designers.

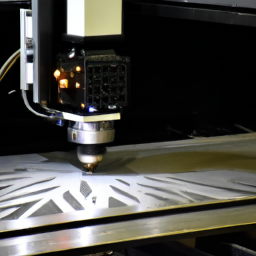

One of the main advantages is the precision and accuracy it provides. Laser cutting allows you to create intricate and detailed designs with clean edges and smooth finishes. Additionally, laser cutting can be used on a wide range of materials, including wood, acrylic, leather, and metal, giving you the flexibility to work with different mediums.

When designing for laser cutting, there are a few considerations to keep in mind, such as the minimum and maximum thickness of the material and the size limitations of the laser bed. With these design considerations in mind, you’ll be able to fully explore the advantages of laser cutting and create stunning designs.

Exploring the Advantages of Laser Cutting

Contractions allow for greater precision and intricacy in creating designs, leading to an emotional connection with the audience. When it comes to laser cutting, there are numerous advantages that make it a preferred choice over other cutting methods. Laser cutting provides a level of versatility that is unmatched, allowing for the creation of intricate designs with fine details and smooth edges. Compared to vinyl cutting, laser cutting offers more flexibility in terms of materials that can be used, including wood, acrylic, leather, and even metal. Additionally, laser cutting allows for faster production times and higher accuracy, resulting in a more efficient and cost-effective process. With all these advantages, it’s no wonder that laser cutting has become the go-to method for many designers and manufacturers. Moving on to understanding the basics of vinyl cutting…

Understanding the Basics of Vinyl Cutting

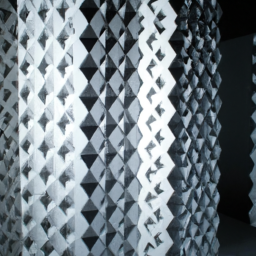

If you’re interested in vinyl cutting, it’s important to understand the basics. Vinyl cutting works by using a sharp blade to cut through a sheet of vinyl material, creating intricate designs or shapes.

When choosing materials for vinyl cutting, it’s best to opt for materials that are thin and flexible, such as adhesive vinyl or heat transfer vinyl.

Additionally, when designing for vinyl cutting, you should consider factors like the size and complexity of your design, as well as any limitations or restrictions of the cutting machine you’ll be using.

How Vinyl Cutting Works

To create intricate designs with a vinyl cutter, you simply feed a sheet of vinyl into the machine and watch as the sharp blade glides across the surface, effortlessly slicing through the material like a precision knife through butter. It’s truly fascinating how vinyl cutting techniques allow for such precision and accuracy in creating intricate designs.

Here are four key aspects of vinyl cutting that make it a versatile method for design creation:

-

Scalability: Vinyl cutting machines can handle various sizes of vinyl sheets, allowing you to create designs of different scales.

-

Intricacy: The sharp blade of the vinyl cutter can navigate intricate details with ease, capturing even the smallest design elements.

-

Speed: Vinyl cutting is a relatively quick process, enabling you to produce designs efficiently.

-

Ease of Use: With its user-friendly interface, vinyl cutting machines make it easy for beginners to get started and experiment with different designs.

With these advantages in mind, let’s explore the materials suitable for vinyl cutting.

Materials Suitable for Vinyl Cutting

Vinyl cutting offers a wide range of materials to work with, including adhesive vinyl, heat transfer vinyl, and specialty vinyl. Each material offers unique possibilities for design and personalization. Did you know that adhesive vinyl is the most popular material for vinyl cutting, accounting for over 70% of all vinyl cutting projects? This statistic highlights the widespread appeal and versatility of vinyl cutting in creating custom designs.

When comparing vinyl cutting to laser cutting, one of the key advantages is the variety of materials available. While laser cutting can work with certain materials like wood, acrylic, or metal, vinyl cutting allows for a wider selection, especially when it comes to creating intricate designs and detailed graphics. This flexibility gives vinyl cutting an edge in terms of versatility.

Now, let’s explore the design considerations for vinyl cutting.

Design Considerations for Vinyl Cutting

Now that you have a good understanding of the materials suitable for vinyl cutting, let’s dive into the design considerations for this versatile technique.

When designing for vinyl cutting, there are a few key techniques to keep in mind. First, simplify your design by opting for clean lines and bold shapes instead of intricate details. Second, use contrasting colors to ensure that your design stands out and is easily visible.

Next, consider the size of your design. While vinyl cutting allows for precision, smaller designs may be more challenging to work with. Lastly, before committing to a final cut, it’s always a good idea to test your design on a small scale to ensure it meets your expectations.

With these vinyl cutting techniques in mind, you’ll be able to create designs that are both visually appealing and easy to work with.

Now, let’s explore the advantages of vinyl cutting.

Exploring the Advantages of Vinyl Cutting

Vinyl cutting offers a range of advantages that make it a popular choice for many businesses and individuals. Firstly, it’s a cost-effective option as it requires minimal materials and can be done quickly and efficiently.

Secondly, vinyl cutting provides a wide range of colors and finishes, allowing for endless creative possibilities.

Lastly, vinyl decals are easy to apply and remove, making them convenient for temporary signage or promotional materials.

Cost-Effectiveness

To maximize cost-effectiveness, you can consider the versatility of laser cutting in optimizing designs. Laser cutting allows for precise and intricate cuts, reducing material waste and ultimately cutting down on costs. Additionally, laser cutting can work with a wide variety of materials, including wood, acrylic, and metal, giving you more options when it comes to material selection. This versatility means you can choose the most cost-effective material for your project, further enhancing the overall cost-effectiveness of laser cutting.

Furthermore, laser cutting offers a smooth and clean cut, reducing the need for post-processing and saving you time and money. With laser cutting, you can achieve high-quality results at an affordable price.

Transitioning into the subsequent section, laser cutting also offers a wide range of colors and finishes to choose from, adding even more versatility to your designs.

Wide Range of Colors and Finishes

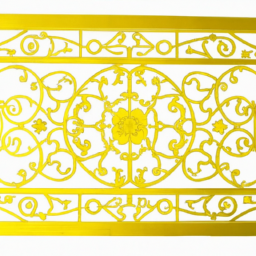

With its vast array of vibrant colors and stunning finishes, laser cutting offers a creative and eye-catching touch to your designs. When it comes to colors, laser cutting provides a wide range of options to choose from, allowing you to bring your designs to life in the most vibrant and visually appealing way possible.

Additionally, laser cutting offers a range of textures and finishes, including matte, glossy, metallic, and even textured surfaces, giving your designs a unique and professional look. Furthermore, laser cutting provides durability options, allowing you to choose materials that are resistant to wear and tear, ensuring that your designs can withstand the test of time. With such versatility, laser cutting is the perfect choice for adding a touch of style and durability to your designs.

Transitioning into the subsequent section, laser cutting also offers easy application and removal, making it a convenient choice for any project.

Easy Application and Removal

Now that we’ve discussed the wide range of colors and finishes available in both laser cutting and vinyl cutting, let’s move on to another important aspect: easy application and quick removal.

When it comes to vinyl cutting, applying the designs onto various surfaces is a breeze. With the help of transfer tape, you can easily position and adhere the vinyl to your desired object, whether it’s a wall, a window, or a vehicle. On the other hand, if you ever need to remove the vinyl, it can be done quickly and cleanly, without leaving any residue behind. This flexibility makes vinyl cutting a great choice for temporary or promotional designs.

However, when it comes to laser cutting, the application and removal process can be more complex, especially if you’re working with intricate designs or delicate materials. Transitioning into the next section, let’s explore the factors you should consider when choosing between laser cutting and vinyl cutting.

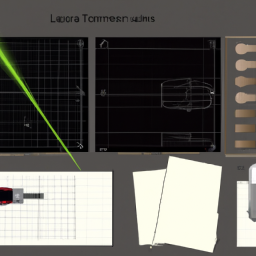

Factors to Consider when Choosing between Laser Cutting and Vinyl Cutting

When choosing between laser cutting and vinyl cutting, there are several factors to consider.

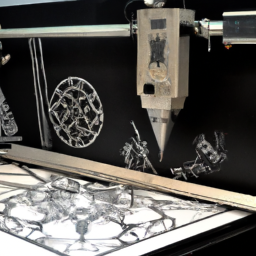

First, think about the complexity and intricacy of your design. Laser cutting is more versatile and can handle intricate designs with fine details, while vinyl cutting may be better suited for simpler designs.

Secondly, consider the quantity and production time. Laser cutting is faster and more efficient for large quantities, while vinyl cutting is better for smaller quantities.

Lastly, think about the desired end result and application. Laser cutting provides a clean and precise finish, making it ideal for high-end products, while vinyl cutting is great for applications that require flexibility and durability.

Complexity and Intricacy of Design

Creating intricate and detailed designs is a breeze when using laser cutting or vinyl cutting. Both methods offer their own advantages when it comes to complexity and intricacy of design. Laser cutting provides precision and accuracy, making it ideal for intricate patterns and delicate details. On the other hand, vinyl cutting offers flexibility, allowing for more simplified and versatile designs. To help you understand the differences, take a look at the table below:

| Complexity vs Simplicity | Precision vs Flexibility |

|---|---|

| Laser Cutting | Vinyl Cutting |

| Ideal for intricate | Offers flexibility for |

| patterns and delicate | simplified and versatile |

| details | designs |

Considering the complexity and intricacy of your design, both laser cutting and vinyl cutting can cater to your needs. However, if you require a more intricate and detailed design, laser cutting might be your best choice. Moving forward, let’s explore the next aspect: quantity and production time.

Quantity and Production Time

With the ability to effortlessly replicate designs in large quantities and in a fraction of the time, laser cutting proves to be a game-changer in the world of production. When it comes to quantity and production time, laser cutting offers several advantages over vinyl cutting. Here’s why:

-

Production Efficiency: Laser cutting machines are incredibly fast and can cut through materials with precision and speed. This allows for quicker turnaround times and increased productivity.

-

Scalability: Laser cutting is highly scalable, meaning it can easily handle large production runs without compromising on quality. Whether you need a few hundred or thousands of pieces, laser cutting can accommodate your needs.

-

Versatility: Laser cutting machines can work with a wide range of materials, including wood, metal, acrylic, and fabric. This versatility allows for more diverse and complex designs, making it an ideal choice for various industries.

With its production efficiency, scalability, and versatility, laser cutting provides a superior option for quantity and production time.

Now, let’s move on to discussing the desired end result and application of laser cutting in comparison to vinyl cutting.

Desired End Result and Application

To achieve your desired end result and effectively apply laser cutting or vinyl cutting, consider the specific requirements and characteristics of your project.

Laser cutting offers more versatility when it comes to intricate designs and detailed cuts. It’s ideal for projects that require precision and intricate details, such as intricate patterns, delicate engravings, or complex shapes.

Vinyl cutting, on the other hand, is better suited for simpler designs and larger-scale productions. It’s commonly used for creating signage, decals, and graphics for vehicles or windows.

The desired end result and practical applications of your project will determine which cutting method is more suitable. If you need precise, detailed cuts, laser cutting is the way to go. However, if you require simpler designs for larger-scale productions, vinyl cutting may be the better option.

Frequently Asked Questions

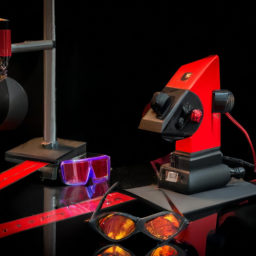

Are there any safety precautions or considerations to keep in mind when using laser cutting machines?

When using laser cutting machines, it’s important to take certain safety precautions.

Always wear appropriate protective gear, such as safety glasses, to shield your eyes from the laser beam.

Make sure the workspace is well-ventilated to prevent the buildup of harmful fumes.

Additionally, familiarize yourself with the common materials used in laser cutting, such as acrylic, wood, and metal, and understand their specific safety requirements.

By following these precautions, you can ensure a safe and efficient laser cutting process.

Can laser cutting be used on all types of materials, or are there limitations?

Laser cutting is a powerful tool that can be used on a wide range of materials, including wood, metal, plastics, and fabrics. However, it does have its limitations. Some materials, like PVC or vinyl, can release toxic fumes when cut with a laser, making them unsuitable for this method.

On the other hand, vinyl cutting offers advantages in terms of versatility and ease of use, as it can be used on a variety of materials without the same limitations as laser cutting.

What are the key differences in terms of cost between laser cutting and vinyl cutting?

When comparing the cost of laser cutting and vinyl cutting, there are a few key factors to consider.

Laser cutting tends to be more expensive due to the high cost of equipment and maintenance.

Vinyl cutting, on the other hand, is generally more affordable.

Additionally, material limitations should be taken into account.

Laser cutting can be used on a wider range of materials compared to vinyl cutting, which is limited to vinyl and similar materials.

How does the level of intricacy or detail in a design impact the choice between laser cutting and vinyl cutting?

The level of intricacy or detail in a design can greatly impact the choice between laser cutting and vinyl cutting. Laser cutting is more suitable for intricate designs as it can achieve extremely fine cuts with high precision. On the other hand, vinyl cutting has certain design limitations due to the nature of the material and the cutting process.

Therefore, if your design requires complex patterns or intricate details, laser cutting would be the better option.

Are there any specific post-processing steps required after using laser cutting or vinyl cutting?

After using laser cutting or vinyl cutting, there are specific post-processing steps that may be required. These steps can include removing any excess material or debris, smoothing out rough edges, and cleaning the cut pieces.

Additionally, depending on the material limitations of the cutting method used, there may be additional steps such as applying a protective coating or adhesive. It’s important to consider these post-processing steps when choosing between laser cutting and vinyl cutting for your design.

Conclusion

As you reach the end of this journey, you stand at a crossroads, contemplating the versatility of laser cutting versus vinyl cutting.

Symbolically, laser cutting represents precision and intricacy, while vinyl cutting embodies flexibility and affordability.

Each path offers unique advantages, but it’s up to you to decide which one aligns with your creative vision.

Consider your project’s complexity, budget, and desired outcome.

Embrace the power of choice, for it’s through these decisions that your design aspirations will truly flourish.