You might be wondering, with the plethora of engraving options available, why should you even consider raster engraving or electric engraving?

After all, wouldn’t a traditional method be more reliable? While that may be a valid concern, it’s essential to explore the conveniences that these modern techniques offer.

In this article, we will delve into the world of raster engraving and electric engraving to help you determine which is more convenient for your needs.

Raster engraving involves using a laser to burn a design onto a surface, providing intricate detail and precision. On the other hand, electric engraving utilizes a powered tool to etch patterns onto various materials swiftly.

Both techniques have their advantages and drawbacks, making it crucial to consider factors such as efficiency, speed, maintenance, and durability.

By the end of this article, you will have a comprehensive understanding of raster engraving and electric engraving, empowering you to make an informed decision.

So, let’s dive in and discover which engraving method is truly more convenient for you.

Key Takeaways

- Raster engraving is more cost-effective and user-friendly

- Electric engraving offers more versatility and may require more technical expertise

- Laser engraving excels in creating complex designs but has a higher cost of replacing the laser tube

- Regular maintenance is essential for keeping engraving equipment in top shape and avoiding costly repairs

Understanding Raster Engraving

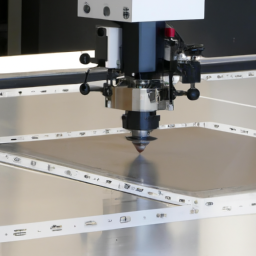

If you want to understand raster engraving, imagine a printer moving back and forth across a surface, creating a design by etching tiny dots.

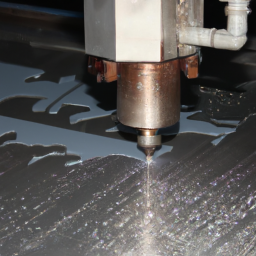

Raster engraving, also known as laser engraving, is one of the most common laser engraving techniques used today. It involves using a laser beam to etch a design onto a material by vaporizing the surface layer. The laser moves in a raster pattern, which means it scans the material line by line, creating a series of dots that make up the design.

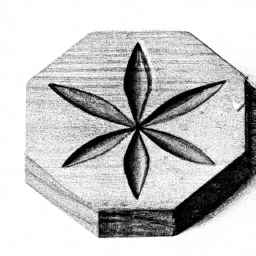

One of the main advantages of raster engraving is its ability to create highly detailed and precise designs. The laser can control the depth and intensity of the etching, allowing for intricate patterns and fine details.

Now let’s explore electric engraving and see how it compares.

Exploring Electric Engraving

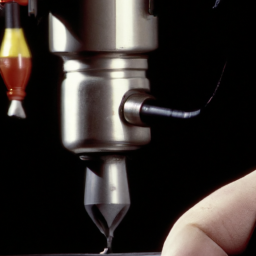

Exploring the world of electric engraving reveals a versatile and efficient method of creating intricate designs on various materials. Electric engraving offers several benefits over other methods, making it a popular choice among professionals and hobbyists alike.

Here are some advantages of electric engraving:

-

Precision: Electric engraving tools provide precise control, allowing you to create intricate and detailed designs with ease.

-

Speed: Electric engraving is faster compared to other methods, allowing you to complete projects in less time.

-

Versatility: Electric engraving tools can be used on a wide range of materials, including metal, wood, glass, and plastic.

-

Ease of use: Electric engraving tools are user-friendly and require minimal setup, making them accessible even for beginners.

Considering these benefits, it becomes evident that electric engraving is a convenient choice for creating high-quality designs.

Moving forward, let’s explore the factors to consider in choosing the right electric engraving tool for your needs.

Factors to Consider in Choosing

When you’re in the market for an electric engraving tool, it’s important to consider several factors to ensure you make the right choice.

First and foremost, you need to think about your budget. Electric engraving tools can vary significantly in price, so finding one that fits within your budget is essential.

Additionally, consider the type of materials you’ll be working with. Different tools have different capabilities and may be better suited for certain materials.

Lastly, think about the level of detail you want to achieve. Some tools offer higher engraving quality than others, so it’s important to choose one that meets your specific needs.

By carefully considering these cost considerations and engraving quality factors, you can find the perfect tool that will bring your creative vision to life.

This will be discussed further in the subsequent section about efficiency and speed.

Efficiency and Speed

When considering efficiency and speed in engraving, it’s important to compare the engraving speed between raster engraving and electric engraving.

Raster engraving is known for its high-speed capabilities, allowing for quick and efficient engraving of designs. Electric engraving, on the other hand, may offer slower engraving speeds but excels in producing complex designs and fine details with precision.

Additionally, when it comes to production output, raster engraving can typically handle higher volumes due to its faster engraving speed, making it a more suitable choice for large-scale production.

Comparison of Engraving Speed

To fully appreciate the convenience, let’s dive into how much faster electric engraving can be for you. When comparing engraving techniques, speed is a crucial factor to consider.

Electric engraving surpasses raster engraving in terms of efficiency and time-saving. With electric engraving, the process is automated and can engrave at a much faster pace. The speed of the engraver’s movement, combined with the precision of the machine, ensures quick and accurate results. This allows you to complete projects in a fraction of the time compared to raster engraving.

Moreover, electric engraving maintains a consistent engraving quality throughout the process, ensuring that every detail is perfectly replicated. Transitioning into the subsequent section about complex designs and fine details, electric engraving proves to be the ideal choice for intricate and precise engravings.

Complex Designs and Fine Details

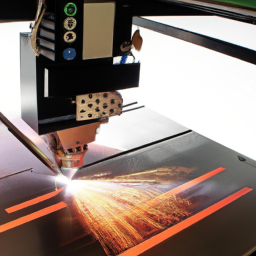

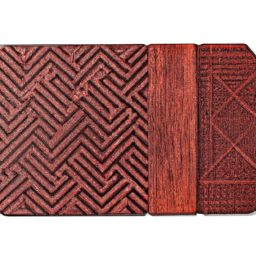

In terms of engraving complex designs and fine details, laser engraving has a clear advantage over electric engraving. With its precise and accurate laser beam, laser engraving can achieve intricate designs that would be challenging to replicate with electric engraving. The laser beam can create sharp and clean lines, allowing for the reproduction of intricate patterns and delicate details. Additionally, laser engraving can work on a variety of materials, including wood, metal, glass, and plastic, further expanding its capabilities. Techniques such as varying laser power and speed can be used to achieve different depths and effects in the engraving process. Overall, laser engraving offers more flexibility and precision when it comes to creating complex designs and fine details. Moving forward, let’s explore the impact of these techniques on production output.

Production Output

One may wonder, how does laser engraving impact the production output? Laser engraving, whether raster or electric, offers significant advantages in terms of output efficiency and production capacity. Here are three reasons why:

-

Speed: Laser engraving machines can operate at high speeds, completing intricate designs and fine details in a fraction of the time compared to electric engraving methods.

-

Precision: Laser engraving ensures consistent and accurate results, eliminating human errors that may occur with electric engraving. This precision allows for faster production and higher output.

-

Versatility: Laser engraving machines can handle a wide range of materials, including metal, wood, glass, and plastic. This versatility enables businesses to diversify their product offerings and increase production capacity.

Considering the output efficiency and production capacity benefits, laser engraving proves to be a more convenient choice. Moreover, it’s important to discuss the maintenance and durability aspects of these engraving methods.

Maintenance and Durability

When it comes to maintenance and durability of engraving equipment, there are three key points to consider.

First, the longevity of the equipment is crucial, as you want it to last for a long time without any major issues.

Second, the upkeep and repair of the equipment should be taken into account, as regular maintenance is necessary to ensure optimal performance.

Lastly, it is important to consider the potential replacement costs of the equipment, as this can have a significant impact on your budget.

Longevity of Engraving Equipment

Contrary to popular belief, the longevity of engraving equipment greatly impacts its convenience. When comparing the longevity of raster engraving and electric engraving machines, it becomes evident that one option outlasts the other. The longevity comparison directly affects production efficiency and cost-effectiveness. To better understand this, let’s examine a comparison table showcasing the average lifespan of each type of engraving equipment.

| Engraving Equipment | Average Lifespan |

|---|---|

| Raster Engraving | 5-10 years |

| Electric Engraving | 15-20 years |

As the table demonstrates, electric engraving machines have a significantly longer lifespan compared to raster engraving machines. This longevity positively impacts production as it reduces the need for frequent replacements and minimizes downtime. Moreover, the extended lifespan of electric engraving equipment contributes to higher cost savings in the long run. Now, let’s delve into the subsequent section about upkeep and repair, exploring how these factors further affect convenience and productivity.

Upkeep and Repair

To keep your engraving equipment in top shape and avoid costly repairs, regular maintenance and occasional tune-ups are essential. Here are some tips to help you with the upkeep of your equipment:

- Clean the engraving machine regularly to prevent dust and debris from affecting its performance.

- Lubricate the moving parts to ensure smooth operation and reduce wear and tear.

- Check and replace worn-out parts such as belts, bearings, and cutting tools to maintain optimal engraving quality.

- Troubleshoot common issues like misalignment, inconsistent depth, or poor engraving results by adjusting settings and calibrating the machine.

By following these maintenance practices and troubleshooting tips, you can minimize upkeep costs and extend the lifespan of your engraving equipment. However, if repairs become too frequent or costly, it may be time to consider exploring replacement options.

Replacement Costs

When considering the upkeep and repair of engraving machines, it is essential to also take into account the potential costs of replacement. In the case of raster engraving machines, the cost of replacing the laser tube can be quite significant. Laser tubes typically have a lifespan of around 1,000 to 3,000 hours, depending on the usage. Once the laser tube reaches the end of its lifespan, it needs to be replaced, which can cost several hundred to a few thousand dollars. On the other hand, electric engraving machines do not have a laser tube that needs to be replaced, which can significantly reduce long-term investment costs. While electric engraving machines may require occasional maintenance and parts replacement, these costs are generally much lower compared to raster engraving machines. With this cost comparison in mind, let’s move on to the final verdict: which engraving method is best suited for your needs?

Final Verdict: Which is Best for You?

Ultimately, determining which method is most convenient depends on your specific needs and preferences. When considering cost comparison, raster engraving tends to be more cost-effective in terms of initial investment and ongoing maintenance. Electric engraving, on the other hand, may require a higher upfront cost but can be more economical in the long run due to lower material costs.

In terms of ease of use, raster engraving is generally considered to be more user-friendly, with its straightforward software interface and minimal setup requirements. Electric engraving, while offering more versatility in terms of materials and depth control, may require more technical expertise and adjustment for optimal results.

Therefore, if you prioritize cost-effectiveness and ease of use, raster engraving may be the best choice for you. However, if you require more flexibility and are willing to invest in the learning curve, electric engraving could be a suitable option.

Frequently Asked Questions

Can raster engraving be used on all types of materials?

Raster engraving can be used on a wide range of materials, making it a versatile option. However, it’s important to consider the limitations. While it works well on materials like wood, plastic, and acrylic, it may not be suitable for engraving on harder surfaces like metal or glass. This is due to the fact that raster engraving uses a laser to remove material, and harder surfaces may require more power or a different engraving technique.

Keep these pros and cons in mind when choosing the right engraving method for your materials.

Is electric engraving more expensive than raster engraving?

Electric engraving can be more expensive than raster engraving due to the cost of the equipment and the maintenance required. However, it offers certain advantages over raster engraving.

Electric engraving provides greater precision and control, allowing for more intricate designs. It can also be used on a wider range of materials, including metal, glass, and plastic. Additionally, electric engraving produces cleaner and sharper lines, resulting in a higher quality finished product.

How long does it take to learn how to use an electric engraving machine?

Learning how to use an electric engraving machine can be a piece of cake. The pros of electric engraving include its speed, precision, and versatility. Compared to raster engraving, electric engraving offers greater control and allows for more intricate designs. However, it does have its cons, such as the need for a power source and the potential for higher costs.

Overall, with some practice and patience, you can become proficient in using an electric engraving machine in no time.

Can electric engraving machines be used for large-scale projects?

Yes, electric engraving machines can be used for large-scale projects, although they do have certain limitations. These machines are capable of engraving on a wide range of materials, including metal, wood, and plastic. However, they may struggle with highly detailed and intricate designs due to their limited resolution.

On the other hand, raster engraving offers several advantages for large-scale projects, such as higher resolution and the ability to create more intricate designs with finer details.

Are there any safety precautions to take when using raster engraving machines?

When using raster engraving machines, it’s crucial to prioritize safety precautions and maintenance. Are you aware of the potential risks involved? To ensure a safe working environment, always wear protective gear such as goggles and gloves.

Regularly inspect the machine for any signs of damage or wear, and promptly address any issues. Additionally, familiarize yourself with emergency procedures and keep a fire extinguisher nearby.

By following these precautions and maintaining your machine, you can engrave with confidence.

Conclusion

After carefully considering the factors, it’s clear that both raster engraving and electric engraving have their own conveniences.

Raster engraving offers precise and detailed results, perfect for intricate designs.

On the other hand, electric engraving provides efficiency and speed, making it ideal for larger projects.

Ultimately, your choice should depend on your specific needs and preferences.

Just like a skilled painter selecting the perfect brushstroke, choose the engraving technique that’ll bring your vision to life with precision and finesse.