Have you ever wondered which engraving technique is more efficient: raster engraving or rotary engraving? Well, let us unveil the truth behind this theory.

Engraving plays a crucial role in various industries, from signage and personalization to manufacturing and jewelry. Raster engraving involves etching an image by scanning a laser back and forth, while rotary engraving utilizes a spinning cutting tool to create designs.

Both techniques have their merits, but when it comes to efficiency, there is a clear winner. By analyzing factors such as speed, accuracy, and versatility, it becomes evident that rotary engraving takes the lead. Its ability to swiftly and precisely engrave intricate patterns on a variety of materials makes it the go-to choice for professionals seeking optimal efficiency.

However, before making a decision, it’s essential to consider specific requirements and limitations. So, let’s dive deeper into the world of engraving to help you choose the right technique for your needs.

Key Takeaways

- Rotary engraving is more efficient in terms of speed, accuracy, and versatility.

- Raster engraving is better for highly detailed designs, while rotary engraving works best for simple designs.

- Raster engraving is suitable for projects requiring intricate details and shading.

- Rotary engraving is better for deep, durable markings on harder materials like metal and glass.

Understanding Raster Engraving

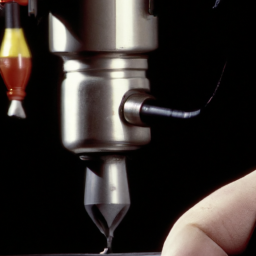

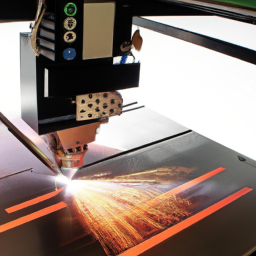

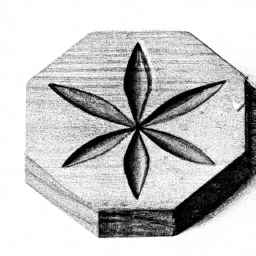

Imagine yourself watching as the laser swiftly moves back and forth, etching intricate patterns line by line, revealing the detailed beauty of raster engraving. This engraving technique uses a raster image format, which consists of a grid of pixels.

Unlike vector engraving, which uses mathematical equations to create smooth lines and curves, raster engraving focuses on filling in the pixels within the image. By adjusting the laser power and speed, raster engraving can create varying depths and shades, resulting in a more realistic and detailed engraving.

However, raster engraving can be time-consuming, as the laser has to move across the entire image.

Now, let’s delve into exploring rotary engraving, another technique that offers its own unique advantages.

Exploring Rotary Engraving

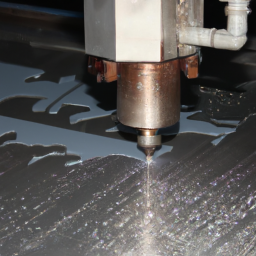

With rotary engraving, you’ll be amazed at how lightning-fast and precise the process can be! Rotary engraving involves using a spinning cutting tool to remove material from the surface of an object.

One of the biggest advantages of rotary engraving is its ability to create deep and detailed engravings on a wide range of materials, including metal, plastic, and wood. The rotary engraving process also allows for the creation of intricate designs and patterns with sharp edges and smooth curves.

However, there are some limitations to rotary engraving. It may not be suitable for very delicate or fragile materials, as the spinning cutting tool can cause damage. Additionally, rotary engraving may not be as suitable for creating grayscale or shaded designs compared to raster engraving.

Transitioning to the efficiency comparison, let’s now explore how rotary engraving measures up against raster engraving.

Efficiency Comparison

To maximize your productivity, consider the efficiency of rotary engraving compared to raster engraving. When it comes to laser engraving, speed is a crucial factor to consider.

Rotary engraving offers a significant advantage in terms of speed compared to raster engraving. This is because rotary engraving uses a spinning cutting tool to remove material, allowing for faster and more precise engraving. In contrast, raster engraving uses a laser beam to create individual pixels, resulting in a slower engraving process.

The speed difference between the two methods can be substantial, with rotary engraving being several times faster than raster engraving. This increased speed can greatly impact your productivity and turnaround time for engraving projects.

Now, let’s delve into the factors you need to consider when choosing between these two methods.

Factors to Consider

When considering the efficiency of engraving methods, there are several key factors to take into account.

First, project requirements play a crucial role in determining which method is more efficient.

Second, material compatibility is essential to ensure optimal results and prevent damage to the material being engraved.

Finally, cost and maintenance considerations are important to assess the long-term viability and practicality of each engraving method.

By carefully evaluating these factors, you can determine the most efficient engraving method for your specific needs.

Project Requirements

Although both methods have their advantages, it’s important to consider the project requirements when deciding between raster engraving and rotary engraving. When it comes to project timeline, raster engraving is typically more efficient. It uses a laser to engrave images or designs onto a material, allowing for quick and precise results.

On the other hand, rotary engraving involves using a rotating tool to physically engrave the material, which can be time-consuming for intricate designs. Additionally, equipment specifications should be considered. Rotary engraving requires a specialized machine with a rotating spindle, while raster engraving can be done with a laser engraving machine.

Considering these factors will help determine which method is more efficient for your project.

Now, let’s delve into the next section about material compatibility.

Material Compatibility

Now that you understand the project requirements, let’s delve into the current subtopic: material compatibility. When deciding between raster engraving and rotary engraving, it’s crucial to consider the limitations of different materials and their surface finish.

-

Delicate materials like glass or acrylic may be more suited for raster engraving due to their susceptibility to breakage during rotary engraving.

-

Metals with a polished surface finish may require rotary engraving to maintain their smooth appearance.

-

Wood with intricate grain patterns may benefit from raster engraving as it allows for more detailed designs.

-

Plastics with textured surfaces may be better suited for rotary engraving to ensure a consistent and even engraving depth.

Considering these material limitations and surface finish requirements, you can now make an informed decision on which engraving method to choose.

Moving forward, let’s explore the next section: cost and maintenance.

Cost and Maintenance

Let’s dive into the topic of cost and maintenance and uncover some surprising insights.

When considering the cost effectiveness of engraving techniques, it is important to take into account both initial investment and long-term maintenance expenses. Raster engraving, which involves burning pixels onto the material, typically requires less expensive equipment compared to rotary engraving. Additionally, raster engraving machines tend to have lower maintenance costs due to their simpler design and fewer moving parts.

On the other hand, rotary engraving, which involves cutting into the material with a rotating tool, may require more expensive machinery and regular maintenance to ensure optimal performance. Equipment durability is also a crucial factor to consider. Rotary engraving machines are generally more durable and can withstand continuous use for extended periods. This durability can result in lower replacement and repair costs over time.

Considering these factors, choosing the right engraving technique is essential in maximizing cost effectiveness and equipment durability. Transitioning into the subsequent section about choosing the right engraving technique, it is important to carefully evaluate other aspects such as speed and versatility.

Choosing the Right Engraving Technique

When choosing the right engraving technique, it’s crucial to match the technique to the specific project at hand. This ensures that the desired outcome is achieved efficiently and effectively.

Additionally, considering long-term goals is essential as it allows for scalability and future-proofing of the engraving process.

Lastly, seeking expert advice can provide valuable insights and recommendations based on years of experience in the industry, leading to optimal engraving results.

Matching Technique to Project

Choose the engraving technique that matches your project, and watch as intricate designs come to life before your eyes. When finding alternative methods, evaluate the complexity of your project. Consider the following factors to help you make an informed decision:

-

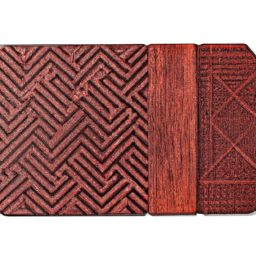

Material: Raster engraving is ideal for materials like wood, acrylic, and leather, while rotary engraving is better suited for metals and harder materials.

-

Design intricacy: If your project involves highly detailed designs or fine lines, raster engraving is the way to go. Rotary engraving works best for simple, bold designs.

-

Time efficiency: Raster engraving is faster for large areas, while rotary engraving is quicker for individual items or small details.

By considering these factors, you can choose the technique that’ll yield the best results for your project.

Now, let’s explore the next step of considering long-term goals.

Considering Long-Term Goals

Consider your long-term goals and how they align with the engraving technique you choose. This decision can have a significant impact on the success and durability of your project.

Long-term planning is crucial when it comes to engraving. It involves analyzing the productivity of different techniques over extended periods. By conducting a productivity analysis, you can determine which technique is more efficient in terms of time, cost, and quality.

For instance, raster engraving may be more suitable for projects that require intricate details and shading. On the other hand, rotary engraving is better for deep, durable markings.

Understanding your long-term goals and conducting a productivity analysis will enable you to make an informed decision on the most efficient engraving technique for your project. Seeking expert advice will further enhance your understanding and assist you in making the right choice.

Seeking Expert Advice

Seeking expert advice can greatly enhance your understanding and guide you towards making the right decision for your project, ensuring its success and durability. When considering whether to use raster engraving or rotary engraving, it’s important to consult with professionals in the field who have extensive experience in both methods. These experts can provide you with valuable insights and recommendations based on their expertise.

Here are some pros and cons to consider:

-

Pros of raster engraving:

- Ideal for intricate designs and detailed artwork.

- Allows for a wide range of shading and texture effects.

- Works well on materials like wood, acrylic, and leather.

-

Pros of rotary engraving:

- Suitable for engraving on curved or irregular surfaces.

- Provides deep and long-lasting engravings.

- Works effectively on harder materials like metal and glass.

Based on expert recommendations, they can assess your specific project requirements and suggest the most efficient engraving method for achieving the desired results.

Frequently Asked Questions

Can I use both raster engraving and rotary engraving techniques on the same material?

Yes, you can use both raster engraving and rotary engraving techniques on the same material. Combining these techniques offers several advantages.

Raster engraving allows for detailed and precise designs, while rotary engraving can create deeper and more pronounced engravings. By using both techniques together, you can achieve a wider range of creative applications and possibilities.

However, it’s important to note that this approach may require more time and effort compared to using either technique individually.

Is one engraving technique more suitable for certain materials than the other?

When comparing the precision of raster engraving and rotary engraving for different materials, it’s essential to consider their distinct characteristics.

While raster engraving is ideal for intricate designs on softer materials like wood and leather, rotary engraving offers better results on harder surfaces such as metal and glass.

Additionally, when exploring the aesthetic differences, raster engraving provides a finer, more detailed finish, while rotary engraving produces a deeper, more pronounced effect on various surfaces.

Are there any limitations or restrictions when it comes to the size of the design that can be engraved using raster or rotary techniques?

When it comes to engraving techniques, both raster and rotary have their limitations. In raster engraving, common challenges include achieving fine details and intricate designs due to the pixel-based nature of the process.

On the other hand, rotary engraving faces design complexity restrictions due to the limitations of the rotary tool. However, the size of the design that can be engraved is not significantly restricted in either technique.

Now, let’s compare the design complexity limitations in raster engraving and rotary engraving.

Can the choice of engraving technique affect the longevity or durability of the engraved surface?

The choice of engraving technique can indeed have an impact on the longevity and durability of the engraved surface.

Rotary engraving, for example, tends to produce deeper and more durable engravings compared to raster engraving. However, raster engraving can offer higher surface quality due to its ability to create fine details.

In terms of production speed, raster engraving is generally faster than rotary engraving. Therefore, the choice of technique must consider the desired surface quality and production speed.

Are there any additional costs or investments required when using raster engraving or rotary engraving techniques?

When comparing the costs of raster engraving and rotary engraving techniques, it’s important to consider the equipment requirements.

The initial investment for rotary engraving machines can be significant, with prices ranging from $5,000 to $20,000. On the other hand, raster engraving machines are generally cheaper, starting at around $1,000.

Additionally, rotary engraving requires the use of specialized tools and bits, which can result in higher ongoing costs compared to raster engraving.

Conclusion

Based on the efficiency comparison between raster engraving and rotary engraving, it’s clear that rotary engraving takes the lead. Its ability to swiftly etch intricate designs with precision sets it apart.

Like a well-oiled machine, rotary engraving smoothly carves through materials, leaving behind a flawless masterpiece.

However, before making a decision, it’s crucial to consider factors such as material type and desired outcome. By choosing the right engraving technique, you can unlock a world of endless possibilities, where your imagination is etched into reality with utmost efficiency.