Are you searching for the perfect technique to etch your design onto a surface? Look no further, as we delve into the intriguing world of raster engraving and sandblasting to uncover which method reigns supreme in terms of cost-effectiveness. Like a master sculptor shaping clay, you must carefully consider the intricacies of each process before making your decision.

In this article, we will explore the technicalities of raster engraving and sandblasting, analyzing their cost-effectiveness based on data-driven evidence. From the speed and precision of raster engraving to the versatility and texture of sandblasting, we will compare these techniques with a keen eye for detail. To provide a comprehensive understanding, we will also examine various factors that play a crucial role in determining cost-effectiveness.

Embark on this journey with us as we navigate case studies and examples, equipping you with the knowledge to make the right choice for your engraving needs.

Key Takeaways

- Raster engraving and sandblasting are techniques used for etching designs onto surfaces.

- Raster engraving offers precise control over depth and intensity, while sandblasting can create intricate designs and works on various materials.

- Raster engraving is slower and limited by dot size and spacing, while sandblasting can be time-consuming and may damage delicate materials.

- Factors like design size, surface material, and production volume impact the cost-effectiveness of raster engraving and sandblasting.

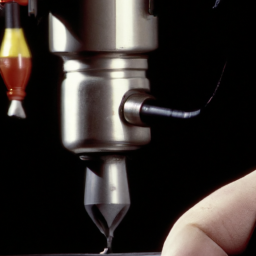

Understanding Raster Engraving

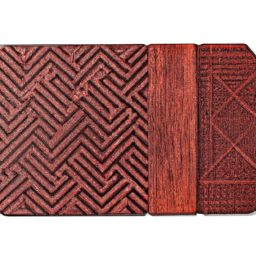

If you’re looking to understand raster engraving, you’ll need to grasp the concept of using a laser beam to create a pattern of dots that form an image, resulting in a more detailed and intricate design.

Raster engraving offers several advantages over other methods of engraving. Firstly, it allows for precise control over the depth and intensity of the engraving, resulting in highly accurate and consistent results. Additionally, raster engraving can achieve a wide range of textures and shading, giving the final product a realistic and three-dimensional appearance. However, raster engraving does have its limitations. It’s generally slower than other engraving methods, as each dot is individually engraved. Furthermore, the resolution of the engraving is limited by the size and spacing of the dots.

Transitioning into exploring sandblasting, this alternative technique offers its own unique benefits and considerations.

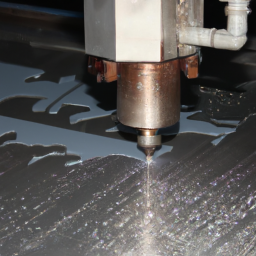

Exploring Sandblasting

When you’re considering options for etching designs onto a surface, sandblasting offers a unique and efficient method. With sandblasting, high-pressure air or water is used to propel fine particles of abrasive material onto a surface, creating a desired design or texture.

This process offers several benefits, including the ability to etch intricate designs with precision and consistency. Sandblasting is also versatile, as it can be used on a variety of materials such as glass, metal, and stone. However, it does have its limitations.

Sandblasting can be time-consuming, especially for larger or more complex designs. Additionally, it may not be suitable for delicate materials that can be easily damaged by the abrasive particles.

Transitioning into the subsequent section on comparing cost-effectiveness, it is important to consider both the benefits and limitations of sandblasting when evaluating its overall efficiency.

Comparing Cost-Effectiveness

To determine the most efficient option for your project, consider the financial implications of different methods of etching designs onto surfaces. When it comes to comparing the cost-effectiveness of raster engraving and sandblasting, a cost-effectiveness analysis is crucial.

In this analysis, you need to consider not just the initial investment but also the ongoing costs and potential cost-saving strategies. Raster engraving typically requires expensive equipment and consumables, such as laser machines and specialized inks.

On the other hand, sandblasting involves one-time equipment purchases, like sandblasting cabinets and nozzles, but the ongoing costs are relatively low.

To maximize cost-effectiveness, it is important to explore factors such as the size and complexity of your designs, surface materials, and volume of production. By considering these factors, you can make an informed decision on the most cost-effective method for your project.

Factors to Consider

Consider different factors when deciding between raster engraving and sandblasting for your project. These factors play a crucial role in determining the cost-effectiveness of each method.

When it comes to size and complexity, raster engraving is more suitable for intricate designs and small-scale projects, while sandblasting is better suited for larger designs and surfaces.

Additionally, the material being engraved or blasted also affects the cost, as certain materials may require specialized equipment or techniques.

Finally, the volume of production is a key consideration, as sandblasting is generally more time-consuming and may not be efficient for high-volume projects.

Taking all these factors into account will help you make an informed decision about which method is more cost-effective for your specific project.

Moving on to case studies and examples…

Case Studies and Examples

When considering the real-life applications of raster engraving, you’ll find that it is widely used in industries such as signage, awards and trophies, and personalized gifts. Many success stories can be found with sandblasting, particularly in the field of glass etching and monument engraving.

In comparing costs between these two methods, it’s important to analyze different industries and their specific requirements, as the cost-effectiveness may vary.

Real-Life Applications of Raster Engraving

Imagine yourself walking into a jewelry store and being enchanted by the intricately detailed designs on a pendant, all thanks to the magic of raster engraving. This versatile engraving technique finds its applications in various industries, including jewelry, signage, and personalization.

The benefits of raster engraving are evident in its ability to create highly detailed designs with fine lines and smooth curves. It allows for precise control over engraving depth, resulting in a visually appealing finished product.

Raster engraving is commonly used to engrave logos, images, and text on a wide range of materials, such as wood, acrylic, glass, and metal. Its versatility and precision make it an ideal choice for creating personalized gifts, promotional items, and customized products.

Transitioning into the subsequent section about success stories with sandblasting, let’s explore another engraving technique that has its own unique advantages.

Success Stories with Sandblasting

Step into the world of sandblasting and discover the remarkable success stories that have been achieved using this powerful engraving technique. Through various case studies, it becomes clear that sandblasting offers numerous benefits across different industries. One such case study involves a glass manufacturer that used sandblasting to create intricate designs on their glass products. This allowed them to attract more customers and increase sales by 30% within a year. Another success story comes from the automotive industry, where sandblasting was utilized to engrave logos and designs on car parts. This not only enhanced the aesthetic appeal of the products but also improved brand recognition, resulting in a 20% increase in customer loyalty. The versatility and precision of sandblasting make it a highly effective engraving method in a wide range of applications.

Transitioning to the subsequent section about ‘cost comparisons in different industries,’ it is important to consider the financial implications of these success stories and how they relate to the overall cost-effectiveness of sandblasting.

Cost Comparisons in Different Industries

The financial landscape of various industries is dramatically transformed when sandblasting is introduced, as costs are reshaped and industries are able to achieve more bang for their buck. Cost comparisons across different industries reveal that sandblasting offers a cost-effective solution for a wide range of applications.

In the manufacturing industry, for example, sandblasting is a highly efficient and cost-effective method for cleaning and preparing surfaces for painting or coating. It eliminates the need for manual labor and reduces the overall time and cost involved in the process.

Similarly, in the automotive industry, sandblasting is used to remove rust and paint from car parts, saving both time and money compared to traditional methods.

By analyzing the cost savings and efficiencies brought about by sandblasting, industries can make informed decisions about the best approach for their specific needs, ultimately ensuring optimal outcomes and cost-effectiveness.

Transitioning into the subsequent section about ‘making the right choice’, it is crucial to consider the specific requirements and goals of each industry.

Making the Right Choice

To make the right choice, you need to consider the cost-effectiveness of raster engraving versus sandblasting, and how it can impact your budget and overall satisfaction. Weighing your options and conducting a thorough cost analysis is essential. Let’s look at the cost comparison between raster engraving and sandblasting in different industries:

| Industry | Raster Engraving Cost | Sandblasting Cost |

|---|---|---|

| Jewelry | $2 per item | $5 per item |

| Signage | $10 per square foot | $8 per square foot |

| Automotive | $50 per part | $40 per part |

| Awards | $1 per item | $3 per item |

As you can see from the table, the cost of raster engraving varies across industries. It is important to analyze the cost implications for your specific business needs. By conducting a thorough cost analysis, you can make an informed decision that aligns with your budget and ensures your overall satisfaction.

Frequently Asked Questions

Can raster engraving and sandblasting be used on all types of materials?

Both raster engraving and sandblasting have limitations when it comes to the types of materials they can be used on. Raster engraving is typically limited to softer materials like wood, acrylic, and certain types of metal.

Sandblasting, on the other hand, can be used on a wider range of materials including glass, stone, and metal.

Additionally, the technique used in raster engraving involves a laser etching a pattern onto the material, while sandblasting uses abrasive materials to physically remove layers of the material’s surface.

Is there any difference in the durability of raster engraving and sandblasting?

When comparing the durability of raster engraving and sandblasting, it’s important to consider maintenance requirements. Both methods can provide durable results, but sandblasting generally requires less maintenance.

Sandblasted surfaces are more resistant to wear and tear, making them suitable for high-traffic areas. On the other hand, raster engraving may require occasional touch-ups to maintain its appearance.

Overall, sandblasting offers a slightly higher level of durability with lower maintenance requirements compared to raster engraving.

How long does it typically take to complete a raster engraving or sandblasting project?

On average, a raster engraving or sandblasting project can take anywhere from a few hours to several days to complete. The specific duration depends on factors such as the complexity of the design, the size of the surface being worked on, and the level of detail required.

Despite the time investment, both methods offer numerous benefits, including precise etching and customizable designs. With their technical prowess, these techniques ensure a high-quality and professional finish to your project.

Are there any limitations or restrictions on the size of designs that can be created with raster engraving or sandblasting?

When it comes to the limitations of raster engraving, the size of the design is a crucial factor. Raster engraving is suitable for smaller designs due to its precision and detailed nature.

On the other hand, sandblasting has restrictions on size due to the physical limitations of the sandblasting equipment. Large designs may require multiple passes or sections, which can increase the overall project time and complexity.

Therefore, both techniques have their size limitations and restrictions that need to be considered.

Can raster engraving and sandblasting be used for both indoor and outdoor applications?

Raster engraving and sandblasting can be used for both indoor and outdoor applications, offering unique benefits for different materials. Raster engraving is ideal for intricate designs and detailed text on a variety of surfaces. It is better suited for larger designs and creating texture on materials like glass or stone. Factors to consider when choosing between the two methods include the material’s durability, desired aesthetic, and the level of detail needed for the project.

Conclusion

In conclusion, when it comes to choosing between raster engraving and sandblasting, the decision ultimately boils down to your specific needs and budget.

Both techniques offer unique advantages and considerations. Raster engraving provides precise and detailed results, while sandblasting offers a more textured and rustic finish.

By carefully evaluating factors such as material, design complexity, and production volume, you can make an informed decision.

Remember, just as a skilled painter chooses the right brush for their masterpiece, selecting the appropriate engraving method will ensure a cost-effective and visually stunning outcome.