Are you tired of the same old engraving techniques? Looking for something more versatile and cutting-edge? Well, look no further! In this article, we will explore the fascinating world of raster engraving and ultrasonic engraving, two innovative techniques that are revolutionizing the engraving industry.

But wait, there’s more! We’re not just going to compare these two techniques; we’re going to dive into the deeper meaning behind them. Through the technique of satire, we’ll uncover the hidden truths and shed light on the true essence of versatility.

So buckle up, dear reader, as we embark on this journey to discover which technique reigns supreme in the battle of raster engraving vs. ultrasonic engraving: Which is More Versatile? Get ready to have your mind blown and your engraving horizons expanded like never before!

Key Takeaways

- Raster engraving uses laser or mechanical tools for detailed designs and can engrave wood, acrylic, and metal.

- Ultrasonic engraving uses high-frequency vibrations and is commonly used in jewelry making, electronics manufacturing, and medical device production.

- Ultrasonic engraving offers precise control over depth and width of engravings and allows for faster engraving speeds.

- Choosing between raster engraving and ultrasonic engraving depends on the material, design complexity, and desired outcome of the project.

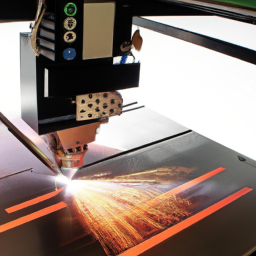

Overview of Raster Engraving Technique

When it comes to exploring the world of engraving techniques, raster engraving is the one you want to dive into. It offers a versatile and captivating way to bring your designs to life.

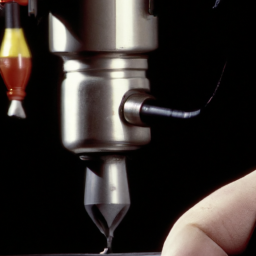

Raster engraving techniques involve using a laser or a mechanical tool to create engraved patterns by removing material from the surface of an object. The main advantage of raster engraving is its ability to create intricate and detailed designs with high precision.

However, it is important to consider the pros and cons of raster engraving. On the positive side, it allows for a wide range of materials to be engraved, including wood, acrylic, and metal. Additionally, raster engraving offers great flexibility in terms of design options.

However, it can be time-consuming and may not be suitable for engraving large areas.

Moving on to the next section about the overview of ultrasonic engraving technique…

Overview of Ultrasonic Engraving Technique

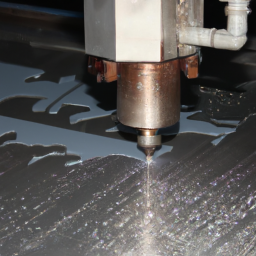

Ultrasonic engraving is a technique that utilizes high-frequency vibrations to create precise markings on various materials. It works by applying these vibrations to a cutting tool, which then etches the design onto the surface.

This technique is commonly used in industries such as jewelry making, electronics manufacturing, and medical device production, where intricate and detailed engraving is required. The applications of ultrasonic engraving include marking serial numbers, logos, and decorative patterns on metal, plastic, glass, and even delicate materials like ceramics.

Explanation of how ultrasonic engraving works

Imagine being able to create intricate designs with precision and finesse, all thanks to the revolutionary technology of ultrasonic engraving. This cutting-edge technique utilizes high-frequency vibrations to remove material from a workpiece, resulting in highly detailed and accurate engravings. Ultrasonic engraving offers several advantages, such as the ability to engrave on a wide range of materials, including metals, plastics, ceramics, and glass. Additionally, it allows for precise control over the depth and width of the engravings, ensuring consistent and uniform results. However, ultrasonic engraving also has its limitations, including the inability to engrave complex 3D shapes and the potential for heat generation during the process. Nonetheless, despite these limitations, ultrasonic engraving finds numerous applications in industries such as jewelry making, electronics manufacturing, and automotive part production. With its versatility and precision, ultrasonic engraving has become an indispensable tool in various industries, pushing the boundaries of design and creativity.

Applications and uses of ultrasonic engraving

You’ll be amazed at the wide range of applications and uses for ultrasonic engraving, like a paintbrush in the hands of a skilled artist, bringing intricate designs to life with precision and finesse.

Ultrasonic engraving offers several advantages over traditional engraving methods, making it a preferred choice in various industries. Some of the benefits include faster engraving speeds, which significantly reduces production time, and the ability to engrave on a wide range of materials, including metals, plastics, and even fragile materials like glass.

Innovative applications of ultrasonic engraving technology have emerged in industries such as jewelry, electronics, and medical devices. For example, in the jewelry industry, ultrasonic engraving allows for intricate patterns and textures on precious metals, enhancing the overall design. In electronics, ultrasonic engraving is used to create precise and durable markings on circuit boards. Additionally, in the medical field, ultrasonic engraving is utilized for engraving surgical instruments, ensuring clear identification and traceability.

With its versatility and numerous advantages, ultrasonic engraving surpasses traditional engraving methods in many applications. Now, let’s explore how it compares to raster engraving in terms of versatility.

Comparison of Versatility

When it comes to versatility, raster engraving is a more flexible option. Raster engraving offers several advantages over ultrasonic engraving.

Firstly, raster engraving can create more intricate and detailed designs with ease. It can engrave images, text, and complex patterns on various materials, including metals, plastics, and wood. In contrast, ultrasonic engraving has limitations in terms of the complexity and detail it can achieve.

Secondly, raster engraving allows for greater control over the depth and intensity of the engraving. This is particularly useful when working with different materials that require varying levels of engraving. Ultrasonic engraving, on the other hand, has limited control over these factors.

Overall, raster engraving’s versatility in creating detailed designs and controlling depth makes it a superior option.

In the subsequent section, we will explore the strengths of raster engraving further.

Strengths of Raster Engraving

Raster engraving has several strengths that make it an ideal choice for certain projects. Firstly, it’s particularly well-suited for intricate designs and fine details, allowing for precise and accurate engraving.

Additionally, raster engraving is suitable for engraving on a variety of materials, such as wood, acrylic, glass, and metal, making it a versatile option.

Lastly, it’s a cost-effective choice for certain projects, offering a more affordable solution compared to other engraving methods.

Ideal for intricate designs and fine details

Ultrasonic engraving is like a skilled surgeon’s scalpel, perfect for creating intricate designs and capturing fine details. Its advantages lie in its ability to produce highly precise and clean lines, making it ideal for engraving intricate patterns and small text.

Additionally, ultrasonic engraving can achieve a greater level of depth and intricacy compared to raster engraving. It also allows for the engraving of delicate materials without causing damage or distortion. However, it does have limitations.

The process is slower compared to raster engraving, which can be a drawback when time is a factor. Additionally, ultrasonic engraving is more suitable for engraving on softer materials such as wood, plastic, and certain metals. It may not be as effective on harder materials like glass or stone.

Transitioning into the subsequent section, ultrasonic engraving’s versatility extends beyond its ability to engrave intricate designs. It is also suitable for engraving on a variety of materials, making it a valuable tool for a wide range of applications.

Suitable for engraving on a variety of materials

One of the advantages of ultrasonic engraving is its ability to work on a wide range of materials, making it a valuable tool for various applications. This versatility allows for engraving on materials such as metals, glass, ceramics, plastics, and even some organic materials. By contrast, raster engraving is limited to certain materials, such as wood, acrylic, and some metals. The ability of ultrasonic engraving to work on a variety of materials expands its applications, making it suitable for industries such as jewelry making, signage, electrical components, and even medical devices. The benefits of this versatile engraving technique include the ability to create intricate designs and fine details on diverse surfaces. This makes ultrasonic engraving a cost-effective option for certain projects, as it eliminates the need for multiple engraving machines.

Cost-effective option for certain projects

A significant cost-saving advantage of ultrasonic engraving is its ability to eliminate the need for multiple engraving machines, making it a practical choice for various projects. Did you know that using ultrasonic engraving can save businesses up to 50% in equipment costs?

This cost-saving benefit stems from the fact that ultrasonic engraving can be used on a wide variety of materials, including metals, plastics, ceramics, and even glass. In contrast, raster engraving is limited in its capabilities, often requiring specialized machinery for different materials.

By utilizing ultrasonic engraving, businesses can streamline their engraving processes, reduce the need for multiple machines, and ultimately save money.

Now, let’s delve into the strengths of ultrasonic engraving and explore its full potential.

Strengths of Ultrasonic Engraving

Imagine the possibilities when you harness the power of ultrasonic engraving, unlocking a whole new level of versatility in your projects. With ultrasonic engraving, you can enjoy numerous advantages and benefits that will elevate your engraving experience.

Here are the key strengths of ultrasonic engraving:

-

Enhanced precision: Ultrasonic vibrations allow for more precise engraving, ensuring intricate details and fine lines are accurately reproduced.

-

Versatile material compatibility: Ultrasonic engraving can be used on a wide range of materials, including metals, plastics, glass, and ceramics.

-

Reduced risk of damage: The non-contact nature of ultrasonic engraving minimizes the risk of material damage, ensuring the integrity of your work.

By understanding the strengths of ultrasonic engraving, you can determine the best technique for your needs, ensuring your projects are executed with precision and efficiency.

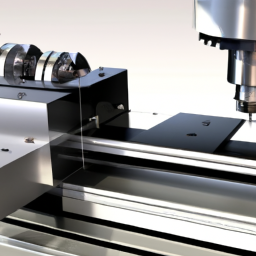

Determining the Best Technique for Your Needs

To determine the best technique for your needs, picture yourself exploring various engraving methods that’ll bring your projects to life. When comparing the pros and cons of raster engraving and ultrasonic engraving, there are several factors to consider.

Raster engraving, also known as laser engraving, offers precise and detailed results with the ability to engrave on a wide range of materials. It’s a versatile technique that can create intricate designs and patterns.

On the other hand, ultrasonic engraving provides a different set of advantages. It’s ideal for engraving on hard materials such as glass or metal, and it offers deeper and more pronounced engravings. However, it may not be as suitable for intricate designs.

Ultimately, the best technique for your needs depends on the material, design complexity, and desired outcome of your project.

Frequently Asked Questions

What are the main differences between raster engraving and ultrasonic engraving techniques?

When comparing raster engraving and ultrasonic engraving techniques, it’s important to understand their main differences.

Raster engraving involves using a laser to etch patterns onto a surface, offering precise and detailed results.

On the other hand, ultrasonic engraving utilizes high-frequency vibrations to create marks, ideal for harder materials.

Advantages of raster engraving include versatility in design and compatibility with various materials.

However, ultrasonic engraving is advantageous for its ability to engrave harder materials efficiently.

Choosing between the two depends on the specific application and desired outcome.

Can both raster engraving and ultrasonic engraving be used on all types of materials?

Both raster engraving and ultrasonic engraving have their pros and cons when it comes to different materials. Raster engraving is generally more versatile, as it can be used on a wide range of materials such as wood, plastic, and metal. However, it may not be as precise as ultrasonic engraving, which is better suited for delicate materials like glass or ceramics. Additionally, ultrasonic engraving tends to offer faster engraving speeds compared to raster engraving.

How do raster engraving and ultrasonic engraving techniques affect the durability of the engraved designs?

The durability of engraved designs is influenced by both raster engraving and ultrasonic engraving techniques. Raster engraving creates a shallower depth, which may result in less durability compared to ultrasonic engraving.

Ultrasonic engraving, on the other hand, creates a deeper and more durable engraving. Additionally, the impact on design quality varies between the two techniques, with raster engraving offering finer details and ultrasonic engraving providing better contrast.

In terms of engraving speeds, raster engraving generally has a faster speed compared to ultrasonic engraving.

Are there any limitations or restrictions when it comes to the size of the designs that can be engraved using either technique?

When it comes to engraving techniques, both raster engraving and ultrasonic engraving have limitations on design size. Raster engraving is limited by the resolution of the engraving machine, which determines the smallest details that can be engraved.

Ultrasonic engraving, on the other hand, is limited by the size of the ultrasonic tool used. However, neither technique has a significant impact on design durability as the engraved designs are typically durable regardless of size.

What are some common industries or applications where raster engraving is preferred over ultrasonic engraving, and vice versa?

To investigate the truth of a theory, let’s delve into the common industries for raster engraving and applications for ultrasonic engraving.

Raster engraving is commonly preferred in industries such as signage, trophy manufacturing, and jewelry making due to its ability to create intricate designs.

On the other hand, ultrasonic engraving finds its applications in industries like medical device manufacturing, electronics, and automotive, where precision and non-contact engraving are crucial.

Conclusion

Based on the comparison of raster engraving and ultrasonic engraving, it’s clear that both techniques have their own strengths and versatility.

Raster engraving offers precise and detailed results, making it ideal for intricate designs and fine materials.

On the other hand, ultrasonic engraving boasts its ability to work on a wide range of materials, making it versatile for various applications.

Ultimately, the choice between the two techniques will depend on your specific needs and preferences. Consider the level of detail required and the materials you’ll be working with to determine the best technique for your engraving needs.