Are you in the market for a cutting-edge technology to tackle thick materials? Look no further than raster engraving and waterjet cutting. Both methods offer unique advantages, but which one is better suited for your specific needs? Let’s dive into the technical details and analyze the pros and cons of each.

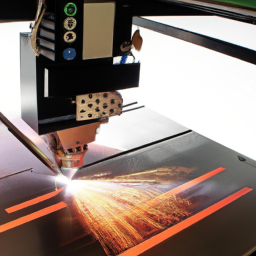

Imagine you have a project that requires precise and intricate designs on a thick material. In this case, raster engraving might be your best bet. With its ability to etch detailed patterns by manipulating the intensity and direction of laser beams, raster engraving ensures unparalleled precision and detail.

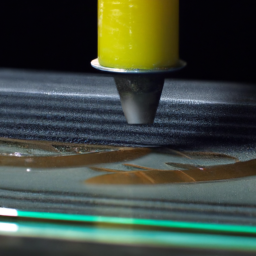

On the other hand, waterjet cutting utilizes a high-pressure stream of water combined with abrasive materials to effortlessly slice through thick substances. This method offers exceptional speed and efficiency, making it ideal for large-scale projects with tight deadlines.

As we delve deeper into these techniques, we will compare their precision, speed, and compatibility with different materials. By the end, you’ll have the knowledge needed to make an informed decision and choose the superior option for your thick material cutting needs.

Key Takeaways

- Raster engraving is ideal for jewelry making, signage, and decorative pieces, but not suitable for cutting thick materials.

- Waterjet cutting is efficient for cutting thick substances and can handle a wide range of materials, including thick metals and glass.

- Laser cutting is efficient and precise for cutting thick materials but may cause thermal damage to the material.

- Plasma cutting offers faster cutting speeds and can handle thicker materials but may produce rougher edges and require additional post-processing.

Understanding Raster Engraving

Raster engraving is a super cool and precise laser engraving technique that uses a grid pattern to create intricate designs on various materials. It offers numerous benefits, such as high precision, fine detail, and the ability to engrave complex designs.

However, raster engraving also has its limitations. One major limitation is that it is not suitable for cutting thick materials. Since raster engraving works by burning away the top layer of the material, it is more effective on thin materials where the laser can easily penetrate.

Additionally, raster engraving may produce a rough surface finish, especially on certain materials like metal. Therefore, when working with thick materials or requiring a smooth finish, exploring waterjet cutting is a logical next step.

Exploring Waterjet Cutting

In the realm of material manipulation, waterjet cutting emerges as a formidable contender, harnessing its fluidic prowess to carve through substantial substrates with precision and finesse. The advantages of waterjet cutting are numerous.

Firstly, it offers a high degree of accuracy, with tolerances as low as 0.003 inches, making it ideal for intricate designs and complex geometries.

Additionally, waterjet cutting is a cold cutting process, minimizing heat-affected zones and reducing the risk of material distortion or warping.

Moreover, it is a versatile technique that can be used on a wide range of materials, including metal, stone, glass, and composites.

However, waterjet cutting is not without its drawbacks. It tends to be a slower process compared to other cutting methods, and the initial investment and maintenance costs can be quite high.

Nonetheless, when comparing precision and detail, waterjet cutting offers unparalleled capabilities.

Comparing Precision and Detail

When comparing the precision and detail between raster engraving and waterjet cutting, it’s important to consider the specific requirements of thick materials. Raster engraving offers a high level of precision due to its ability to create intricate patterns and fine details.

On the other hand, waterjet cutting provides a different level of precision, as it’s capable of cutting through thick materials with extreme accuracy. Ultimately, the choice between the two techniques depends on the specific needs and desired outcomes for thick material projects.

Raster Engraving’s Precision

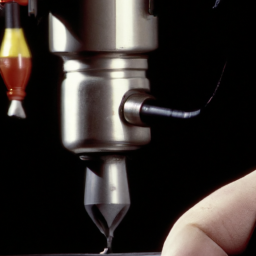

Imagine being able to achieve the utmost precision in engraving, allowing you to create intricate designs with ease. Raster engraving is the perfect solution for this, offering unparalleled precision that is essential for various applications.

With raster engraving, you can accurately etch detailed patterns onto thick materials, ensuring that every line and curve is precisely replicated. This technique utilizes a laser beam that moves back and forth over the material, engraving each pixel individually. The result is a highly detailed and precise engraving that is ideal for applications such as jewelry making, signage, and decorative pieces.

While waterjet cutting also offers precision, raster engraving excels in intricate designs and delicate details. Transitioning to the discussion on waterjet cutting’s precision, it is important to consider its advantages and limitations in comparison to raster engraving.

Waterjet Cutting’s Precision

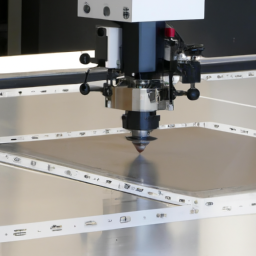

Unleash the power of precision with waterjet cutting, creating flawless designs that will leave you in awe. Waterjet cutting’s versatility and accuracy make it an ideal choice for a wide range of applications. Whether you need to cut through thick metals, stone, or even glass, waterjet cutting can handle the task with ease. The process involves using a high-pressure stream of water mixed with abrasive materials to erode the material and create intricate designs with utmost precision.

To fully understand the capabilities of waterjet cutting, let’s take a look at a comparison between raster engraving and waterjet cutting:

| Raster Engraving | Waterjet Cutting | |

|---|---|---|

| Precision | Limited | Exceptional |

| Versatility | Limited | Extensive |

| Applications | Limited | Wide range |

| Speed | Fast | Moderate |

| Material Thickness | Thin | Thick |

Now that we’ve explored waterjet cutting’s precision and versatility, let’s delve into the subsequent section to determine which method is better for thick materials.

Which is Better for Thick Materials?

Now that you understand the precision offered by waterjet cutting, let’s explore which method – raster engraving or waterjet cutting – is better for thick materials.

When it comes to thick materials, waterjet cutting has a clear advantage. It can effortlessly cut through thick materials, such as metals and stones, with ease. Additionally, waterjet cutting provides a smooth finish and doesn’t cause any heat-affected zones or material distortion.

To give you a better perspective, let’s compare the two methods in terms of cost and maintenance requirements:

-

Cost Comparison:

-

Waterjet cutting machines generally have a higher upfront cost compared to raster engraving machines. However, waterjet cutting can be more cost-effective in the long run due to its ability to cut through thick materials efficiently.

-

Maintenance Requirements:

-

Waterjet cutting machines require regular maintenance to ensure optimal performance. Raster engraving machines generally have lower maintenance requirements.

By evaluating the speed and efficiency of both methods, we can determine which is the most suitable for your needs.

Evaluating Speed and Efficiency

When evaluating the speed and efficiency of raster engraving, you’ll find that it’s a rapid and efficient process. The laser beam moves quickly across the material, resulting in precise and detailed engravings.

On the other hand, waterjet cutting is also known for its speed and efficiency, especially when it comes to thick materials. The high-pressure water jet swiftly cuts through the material, ensuring clean and accurate cuts.

In comparing the two techniques for thick materials, waterjet cutting may have the edge due to its ability to handle thicker materials with ease.

Raster Engraving’s Speed and Efficiency

Although raster engraving is known for its speed and efficiency, it’s important to consider the thickness of the material being engraved. When it comes to raster engraving techniques, optimizing engraving speed is crucial. Here are four key factors to consider:

-

Material Density: Thick materials with high densities may require slower engraving speeds to achieve precise and clean results. Higher engraving speeds on dense materials can lead to uneven and shallow engravings.

-

Laser Power: Adjusting the laser power is essential for optimizing engraving speed. Higher laser power can increase the engraving speed, but it may also cause excessive heat, resulting in material damage or poor engraving quality.

-

Engraving Depth: The desired depth of the engraving also plays a role in speed optimization. Deeper engravings require slower speeds to ensure accuracy and prevent overburning.

-

Engraving Pattern: The complexity of the engraving pattern can affect the speed. Intricate designs may require slower speeds to maintain precision.

Considering these factors, it’s important to evaluate whether raster engraving can meet the speed and efficiency requirements for engraving thick materials.

Transitioning to the subsequent section about waterjet cutting’s speed and efficiency, let’s explore another alternative for thick materials.

Waterjet Cutting’s Speed and Efficiency

With waterjet cutting, you can slice through thick materials like a knife through butter, allowing for swift and efficient production. Waterjet cutting’s versatility is a key factor in its speed and efficiency. This cutting method can be used on a wide range of materials such as metal, stone, glass, and composites, making it suitable for various applications.

The high-pressure water stream creates a narrow kerf, resulting in minimal material waste. Additionally, waterjet cutting doesn’t generate heat, minimizing the risk of warping or melting the material. The ability to precisely control the cutting path and depth further enhances its efficiency.

Waterjet cutting’s versatility and precision make it a powerful tool for thick material processing.

Moving forward to the subsequent section about ‘which is better for thick materials?’, let’s examine raster engraving’s capabilities.

Which is Better for Thick Materials?

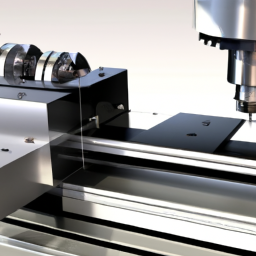

For thick materials, you’ll find that one method stands out in terms of efficiency and precision. Laser cutting is a popular choice due to its ability to produce clean and precise cuts in thick materials. The laser beam can easily penetrate through the material, resulting in smooth edges and minimal material wastage. However, there are some limitations to consider.

Laser cutting can be slower compared to other methods, especially when cutting through thick materials. Additionally, laser cutting may cause thermal damage to the material due to the high temperatures involved. On the other hand, plasma cutting offers faster cutting speeds and the ability to handle thicker materials. However, it may produce rougher edges and require additional post-processing.

Considering material compatibility, let’s now explore the next section.

Considering Material Compatibility

When it comes to material compatibility, you’ll find that thick materials are like sturdy mountains that can be conquered by either raster engraving or waterjet cutting.

Both methods have their advantages and limitations when it comes to thick materials. Raster engraving is suitable for materials like wood, acrylic, and leather, but may struggle with metals and glass due to their hardness.

On the other hand, waterjet cutting can handle a wide range of materials, including thick metals and glass, thanks to its high-pressure water stream and abrasive particles. However, waterjet cutting can be more expensive compared to raster engraving, especially for large projects.

Therefore, when making an informed decision, consider the material suitability and cost comparison between raster engraving and waterjet cutting. By weighing these factors, you can choose the method that best suits your needs.

Making an Informed Decision

To make the best choice, imagine yourself standing at the crossroads of material compatibility and cost, carefully considering the options before you. When it comes to raster engraving and waterjet cutting for thick materials, it’s crucial to evaluate the cost comparison and the environmental impact of each method.

Here is a breakdown of the two options:

-

Raster Engraving:

- Utilizes a high-powered laser to remove material and create intricate designs.

- Generally more cost-effective due to lower equipment and maintenance costs.

- May have a higher environmental impact due to the use of energy-intensive lasers.

-

Waterjet Cutting:

- Utilizes a high-pressure stream of water mixed with abrasive particles to cut through thick materials.

- Can be more expensive due to the need for specialized equipment and frequent maintenance.

- Generally has a lower environmental impact as it doesn’t rely on energy-intensive lasers.

Considering the cost comparison and environmental impact, it’s important to weigh these factors against your specific requirements to make an informed decision.

Frequently Asked Questions

What are some common industries or applications that frequently use raster engraving?

Common industries that frequently use raster engraving include the manufacturing, jewelry, and signage industries.

Raster engraving offers several advantages in artistic applications. It allows for precise and detailed designs, making it ideal for creating intricate patterns and textures on various materials. Additionally, raster engraving provides excellent control over the depth and density of the engraving, enabling artists to achieve desired effects and create visually stunning pieces.

Can waterjet cutting be used on materials other than metal?

Waterjet cutting isn’t limited to metal materials. In fact, it can be used on a wide range of non-metal materials such as ceramics, composites, plastics, and even stone.

The advantages of waterjet cutting for thick materials are numerous. Its high-pressure stream of water mixed with abrasives can easily cut through thick materials without causing heat damage or warping. This makes waterjet cutting a highly versatile and efficient option for various industries.

Are there any limitations to the level of precision and detail that can be achieved with raster engraving?

When considering the limitations of raster engraving, it’s important to note that the level of precision and detail that can be achieved is contingent upon several factors. These include the resolution of the engraving machine, the type of material being engraved, and the complexity of the design.

Higher resolution machines tend to produce more intricate and precise engravings. However, it’s essential to understand that even with advanced technology, there are inherent limitations to the precision and detail achievable in raster engraving.

How does the cost of waterjet cutting compare to other cutting methods?

When it comes to cost comparison, waterjet cutting offers both advantages and disadvantages.

For instance, the initial investment for a waterjet cutting machine can be quite high, but the operating costs are generally lower compared to other cutting methods.

The advantages include reduced material waste and the ability to cut a wide range of materials.

However, the disadvantages include the need for regular maintenance and the potential for higher energy consumption.

What factors should be considered when determining the best cutting method for a specific project?

When determining the best cutting method for a specific project, several factors should be considered.

Firstly, the material properties play a crucial role in selecting the appropriate method. Factors such as hardness, density, and thickness can impact the effectiveness of the cutting process.

Secondly, the desired precision of the project must be taken into account. Different cutting methods offer varying levels of accuracy, so the required level of detail should be evaluated.

Overall, considering material properties and desired precision is essential when choosing a cutting method for a specific project.

Conclusion

In conclusion, when it comes to choosing between raster engraving and waterjet cutting for thick materials, it ultimately depends on your specific needs and preferences. Both methods offer unique advantages and disadvantages.

If precision and intricate detail are your priorities, raster engraving may be the way to go. On the other hand, if speed and efficiency are paramount, waterjet cutting has the upper hand.

Additionally, considering the compatibility of your materials is crucial. So, carefully weigh these factors and make an informed decision. Remember, the world of engraving and cutting is as vast as the universe itself!