Are you caught in the crossroads of creativity, unsure of which path to take? Like a sculptor chiseling away at a block of marble, or an artist delicately adding brushstrokes to a canvas, you too can shape your project with precision.

In the world of manufacturing, two powerful techniques stand before you, each offering its own unique advantages. Subtractive laser cutting, the art of removing material with a laser beam, and additive manufacturing, the process of building objects layer by layer. Both hold incredible potential, but which technique is best suited for your project?

In this article, we will delve into the depths of these two methods, exploring their intricacies and considering the factors that will guide your decision. So, as you embark on your journey of creation, let us be your guide, helping you choose the technique that will bring your vision to life.

Key Takeaways

- Subtractive laser cutting offers high precision and repeatability, and can cut through various materials.

- Additive manufacturing allows for complex designs and customization, and provides increased design freedom, reduced material waste, and faster production times.

- Additive manufacturing has seen a 42% increase in global market share over the past five years, and offers advantages such as design freedom, material efficiency, customization, and rapid prototyping.

- The choice between subtractive laser cutting and additive manufacturing depends on project requirements, precision, and materials, and weighing these factors will help in making the decision.

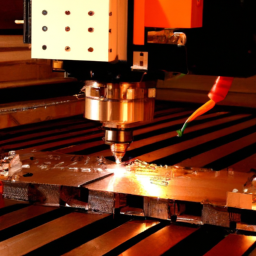

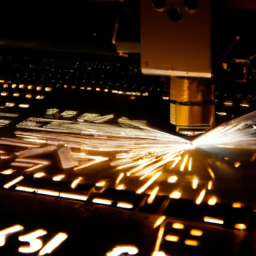

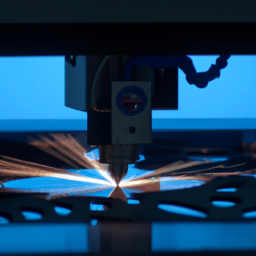

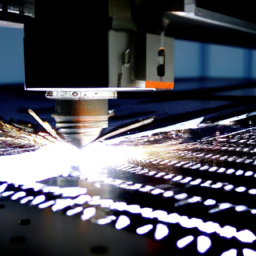

Understanding Subtractive Laser Cutting

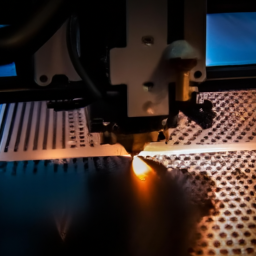

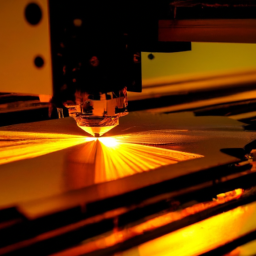

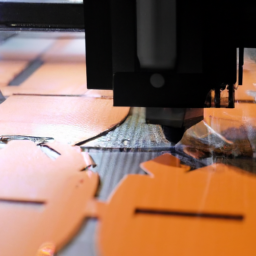

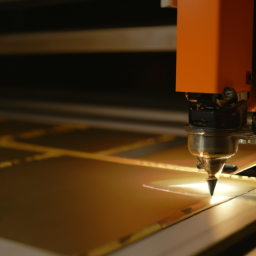

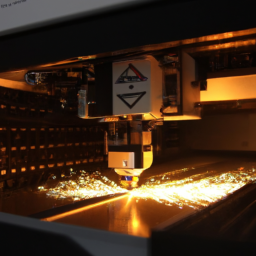

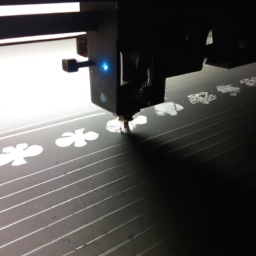

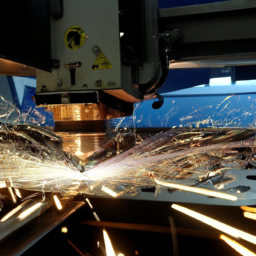

If you’re looking for a precise and efficient way to cut through materials, subtractive laser cutting is the technique for you. Subtractive laser cutting applications are diverse and include industries such as automotive, aerospace, and signage.

With this method, a laser beam is used to remove material, creating intricate and accurate cuts. The benefits of subtractive laser cutting are numerous. It allows for high precision and repeatability, ensuring consistent results every time. It can cut through a wide range of materials, including metals, plastics, and wood.

Additionally, subtractive laser cutting is a fast process, reducing production time and costs.

Now, let’s transition into exploring additive manufacturing, another innovative technique for creating three-dimensional objects.

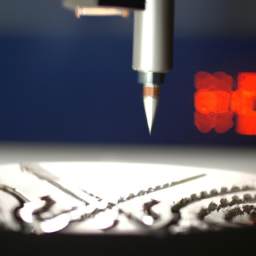

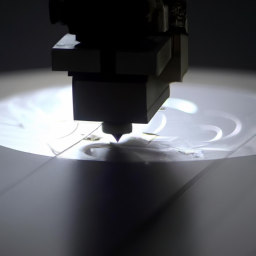

Exploring Additive Manufacturing

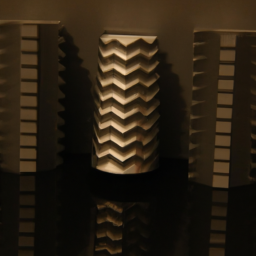

Additive manufacturing, also known as 3D printing, is a process of creating three-dimensional objects by adding layers of material on top of each other. There are various types of additive manufacturing techniques, such as fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

These techniques allow for the production of complex geometries and customized designs. However, additive manufacturing also has its advantages and disadvantages. It has the ability to create prototypes quickly, but it also has limitations in terms of material choices and production speed.

What is additive manufacturing

When it comes to bringing your project to life, you’ll be amazed at the possibilities of additive manufacturing. This revolutionary technique offers numerous advantages over traditional manufacturing methods. With additive manufacturing, you can create complex designs and intricate details that would be impossible with subtractive techniques. Additionally, additive manufacturing allows for customization and rapid prototyping, reducing time and costs. The applications of additive manufacturing are vast and diverse, ranging from aerospace and automotive industries to healthcare and consumer goods. It can be used to create prototypes, functional parts, and even entire products. In fact, additive manufacturing is transforming the way we design and manufacture products, opening up new possibilities and pushing the boundaries of innovation. In the next section, we will explore the different types of additive manufacturing techniques.

Types of additive manufacturing techniques

Ready to dive into the exciting world of additive manufacturing techniques? Let’s explore the different types and discover the endless possibilities they offer for bringing your projects to life.

Additive manufacturing, also known as 3D printing, has revolutionized the manufacturing industry by allowing the creation of complex and customized objects. There are several types of additive manufacturing techniques, such as fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

Each technique has its own unique benefits and applications. FDM is great for rapid prototyping and functional parts, while SLA is perfect for creating high-resolution and detailed models. SLS is ideal for producing durable and robust parts.

These techniques provide increased design freedom, reduced material waste, and faster production times. Now, let’s move on to explore the advantages and disadvantages of additive manufacturing.

Advantages and disadvantages

To fully understand the advantages and disadvantages of additive manufacturing, you’ll need to consider factors such as cost, material selection, and production speed.

-

Pros and cons: Additive manufacturing offers numerous benefits, including cost effectiveness, as it eliminates the need for complex tooling and can reduce material waste. However, it also has limitations, such as high initial equipment costs and slower production rates compared to subtractive laser cutting.

-

Cost effectiveness: Additive manufacturing can be cost effective for small production runs or customized products, as it allows for quick and easy design changes without incurring additional expenses. However, for large-scale production, subtractive laser cutting may be more economical.

-

Precision and accuracy: Additive manufacturing enables the creation of highly intricate and complex designs with precise dimensions. However, it may not achieve the same level of accuracy as subtractive laser cutting for certain applications.

-

Material limitations, speed, and efficiency: Additive manufacturing allows for the use of a wide range of materials, including plastics, metals, and ceramics. However, some materials may have limitations in terms of strength, durability, or heat resistance. Additionally, additive manufacturing can be time-consuming and less efficient for producing large quantities.

Considering these factors, you can now move on to the subsequent section about ‘considerations for your project’ to make an informed decision.

Considerations for Your Project

First, think about the specific requirements and intricacies of your project before deciding which technique, subtractive laser cutting or additive manufacturing, best fits your needs. Design considerations and material compatibility are crucial factors to consider.

| Design Considerations | Material Compatibility |

|---|---|

| Precision and detail | Compatible with a wide range of materials |

| Versatility and complexity | Limited compatibility with certain materials |

| Speed and efficiency | May require specific materials for optimal results |

| Cost-effectiveness | Can work with both rigid and flexible materials |

| Size and scale | Can accommodate various sizes and scales |

By evaluating these factors, you can determine which technique aligns with your project requirements. Once you have considered these aspects, you can move on to comparing the techniques in order to make an informed decision.

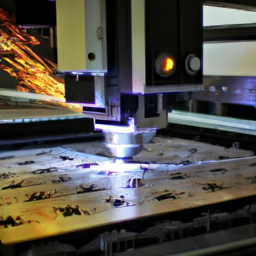

Comparing the Techniques

When comparing the two techniques, it’s fascinating to note that additive manufacturing has seen a 42% increase in global market share over the past five years. This growth can be attributed to the numerous benefits of additive manufacturing, including:

-

Design freedom: With additive manufacturing, you have the ability to create complex geometries and intricate designs that would be difficult to achieve with subtractive laser cutting.

-

Material efficiency: Additive manufacturing only uses the necessary amount of material, reducing waste and making it a more sustainable option.

-

Customization: Additive manufacturing allows for easy customization, making it ideal for creating personalized products.

-

Rapid prototyping: With additive manufacturing, you can quickly iterate and test designs, speeding up the development process.

On the other hand, subtractive laser cutting offers benefits such as precision and versatility for certain applications. When choosing the best technique for your project, it’s important to consider the specific requirements and constraints of your design.

Choosing the Best Technique for Your Project

Now that you have a clear understanding of the differences between subtractive laser cutting and additive manufacturing, it’s time to consider which technique is best suited for your project.

When making this decision, there are several key considerations to keep in mind. First and foremost, you need to evaluate your project requirements. Think about the desired outcome, the level of precision required, and the materials you plan to use.

Are you looking to create complex, intricate designs? Additive manufacturing might be the better choice. On the other hand, if you need to cut through thick materials or want to achieve a smooth finish, subtractive laser cutting could be the way to go.

By carefully weighing these factors, you can ensure that you choose the best technique to bring your project to life.

Frequently Asked Questions

What are the advantages of using subtractive laser cutting over additive manufacturing?

When considering subtractive laser cutting, you’ll find several advantages over additive manufacturing. Firstly, it offers precise and accurate results due to its ability to remove material with high precision.

Additionally, subtractive laser cutting is often more cost-effective compared to additive manufacturing, especially when working with high volumes or large-scale projects.

With subtractive laser cutting, you can achieve intricate designs and complex shapes while maintaining cost efficiency.

Are there any limitations or drawbacks to using additive manufacturing?

When it comes to additive manufacturing, there are a few limitations that you should be aware of. One of the main drawbacks is the limited range of materials that can be used. While there are many options available, they may not be suitable for all projects.

Additionally, the process can be time-consuming and expensive, especially for larger-scale projects. However, it’s important to remember that additive manufacturing does offer unique advantages, such as the ability to create complex and intricate designs.

Can subtractive laser cutting and additive manufacturing be used together in a single project?

Using subtractive laser cutting and additive manufacturing in combination for complex projects allows you to take advantage of the unique strengths of each technique. By exploring the potential synergies between subtractive laser cutting and additive manufacturing, you can achieve greater precision and efficiency in your project.

This combination allows for the creation of intricate designs with additive manufacturing and the refinement of those designs with subtractive laser cutting.

How do the costs compare between subtractive laser cutting and additive manufacturing?

When comparing the costs of subtractive laser cutting and additive manufacturing, it’s important to consider factors such as material compatibility. Additive manufacturing may require specialized materials that can be costly.

On the other hand, subtractive laser cutting can work with a wide range of materials, potentially reducing costs. Additionally, additive manufacturing often involves a longer production time, which can increase expenses.

Overall, the cost comparison between the two techniques depends on the specific project requirements and materials involved.

Are there any specific industries or applications where one technique is more suitable than the other?

In certain industries, subtractive laser cutting is the go-to technique for precision and accuracy. It excels in sectors like automotive, aerospace, and engineering, where intricate designs and tight tolerances are essential.

On the other hand, additive manufacturing finds its applications in industries such as medical, jewelry, and prototyping. With its ability to create complex geometries and customize designs, additive manufacturing is a valuable tool for these specific sectors.

Conclusion

So, when it comes to deciding between subtractive laser cutting and additive manufacturing for your project, it’s important to consider various factors. Both techniques have their benefits and limitations, and it ultimately depends on your specific needs.

However, it’s worth noting that additive manufacturing is gaining popularity rapidly, with a growth rate of 21.2% in the global market between 2020 and 2027. This statistic highlights the increasing demand and potential of additive manufacturing in various industries, making it an intriguing option to explore for your next project.