Imagine you’re a sculptor, standing in front of a gigantic block of marble. With chisel in hand, you begin the arduous task of chipping away at the stone, piece by piece, until your masterpiece emerges. It’s a laborious process, requiring immense patience and precision.

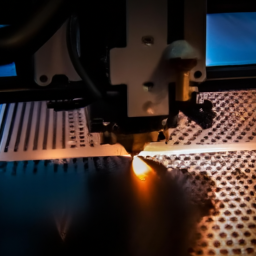

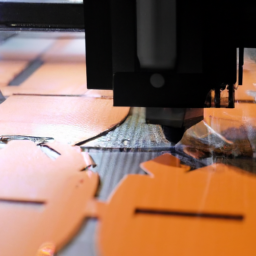

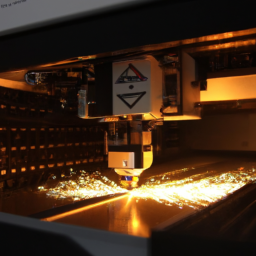

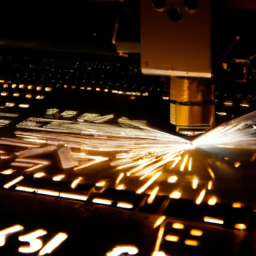

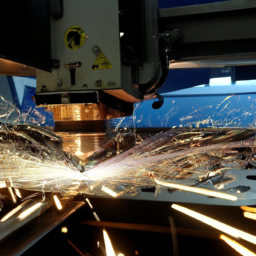

Now, let’s take a leap forward in time. Instead of a chisel, you have a powerful laser beam at your disposal. With a few swift movements, the laser effortlessly slices through the material, shaping it into your desired form. This is the power of subtractive laser cutting.

But, there’s also electric cutting, a method that offers its own conveniences. In this article, we will explore the differences between subtractive laser cutting and electric cutting, and determine which one is more convenient for your needs.

So, whether you’re a sculptor, a manufacturer, or simply someone interested in the world of cutting technology, read on to discover the best cutting method for you.

Key Takeaways

- Subtractive laser cutting offers high precision and the ability to create intricate designs with exceptional accuracy.

- Electric cutting is more affordable with lower operating costs and is cleaner and more eco-friendly.

- Subtractive laser cutting is preferred for delicate materials and industries that require high precision cuts.

- Electric cutting is preferred in industries that require faster cutting speeds and can tolerate lower precision.

Understanding Subtractive Laser Cutting

To fully grasp the intricacies of subtractive laser cutting, you should familiarize yourself with the process and its various applications.

Subtractive laser cutting is a highly precise and versatile method that uses laser technology to cut materials by vaporizing or melting them away. One of the main advantages of this technique is its ability to create intricate designs and patterns with exceptional accuracy. Additionally, subtractive laser cutting can be used on a wide range of materials, including wood, acrylic, and metal. However, it does have its limitations.

For instance, it may not be suitable for cutting thick or reflective materials.

Now, let’s transition into exploring electric cutting, another popular method that offers its own set of advantages and limitations.

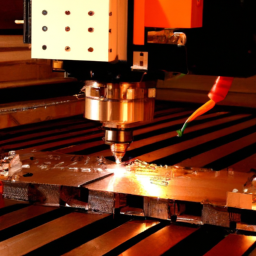

Exploring Electric Cutting

In this discussion, we’ll explore electric cutting and its key points: how it works, its benefits and drawbacks, and its applications and suitability.

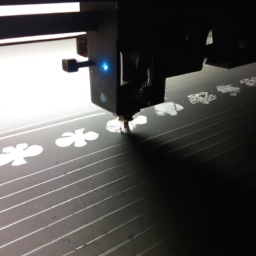

Electric cutting works by using an electrically-powered cutting tool to slice through various materials. It offers benefits such as precision and versatility. However, it also has drawbacks like limitations in cutting thickness and potential safety hazards.

Understanding its applications and suitability will help you determine if electric cutting is the right choice for your projects.

How it Works

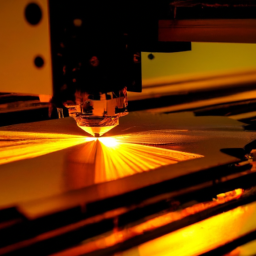

Imagine yourself standing in front of a laser cutting machine, watching as the intense laser beam slices through the material with precision and ease. It’s a fascinating process that involves several steps:

-

Material Preparation: Before cutting, the material is carefully prepared, ensuring it’s clean and properly positioned for accurate results.

-

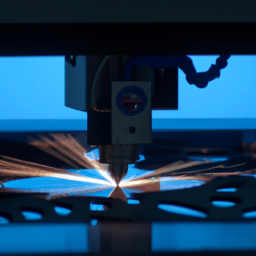

Laser Alignment: The laser beam is precisely aligned to the desired cutting path, ensuring a clean and accurate cut.

-

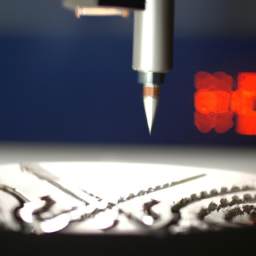

Material Cutting: The laser beam vaporizes or melts the material along the cutting path, creating a clean and smooth edge.

-

Precision Control: Laser cutting machines offer high precision control, allowing for intricate designs and complex shapes to be cut with minimal errors.

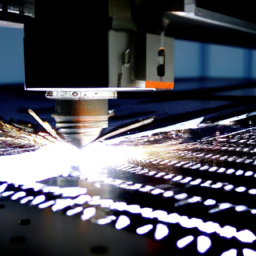

Advantages of laser cutting include its ability to cut a wide range of materials, high precision, and minimal material wastage. However, there are also disadvantages such as high initial cost and the need for regular maintenance.

Now, let’s explore the benefits and drawbacks of laser cutting in the next section about ‘benefits and drawbacks’ without writing ‘step’.

Benefits and Drawbacks

You’ll appreciate the benefits and drawbacks of laser cutting as it offers high precision control and the ability to cut a wide range of materials. Laser cutting provides the benefits of precision, allowing for intricate and detailed cuts, which is particularly useful in industries such as jewelry making and electronics. However, one drawback of laser cutting is its speed. While it offers precise cuts, the process can be slower compared to electric cutting methods. To help you better understand the differences, here is a quick comparison table:

| Benefits of Laser Cutting | Drawbacks of Laser Cutting |

|---|---|

| High precision control | Slower cutting speed |

| Ability to cut various materials |

This table highlights the key advantages and disadvantages of laser cutting. Now, let’s move on to discussing the applications and suitability of these cutting methods.

Applications and Suitability

Take a moment to consider the various industries and tasks that can benefit from these cutting methods and determine which one suits your needs best.

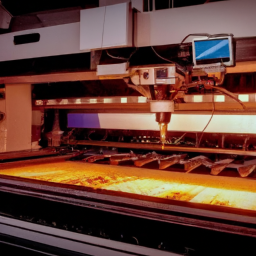

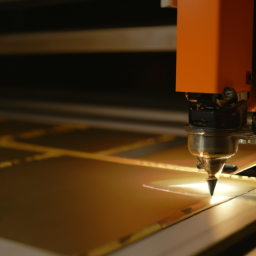

Subtractive laser cutting has wide applications in manufacturing, making it a popular choice for industries such as automotive, aerospace, and electronics. It is particularly suitable for intricate designs, as it offers high precision and the ability to cut through a wide range of materials.

On the other hand, electric cutting is often preferred in industries that require faster cutting speeds and can tolerate a slightly lower level of precision. It is commonly used in industries like construction, metal fabrication, and shipbuilding.

When comparing the convenience of subtractive laser cutting and electric cutting, it is important to consider factors such as your specific industry, the complexity of your designs, and the desired cutting speed.

Comparing the Convenience of Subtractive Laser Cutting and Electric Cutting

When it comes to convenience, subtractive laser cutting and electric cutting offer distinct advantages. Here’s a quick comparison to help you decide which method is more convenient for your needs:

-

Cost comparison: Subtractive laser cutting requires expensive equipment and maintenance, which can be a significant investment. On the other hand, electric cutting machines are generally more affordable and have lower operating costs. This makes electric cutting a more convenient option for those on a tight budget.

-

Environmental impact: Subtractive laser cutting produces harmful fumes and waste materials that need proper disposal. Electric cutting, on the other hand, is a cleaner and more eco-friendly option, as it doesn’t generate harmful emissions or waste. This makes electric cutting a more convenient choice for those concerned about the environment.

Considering these factors, it’s important to choose the right cutting method for your needs. Now, let’s explore the next section to help you make an informed decision.

Choosing the Right Cutting Method for Your Needs

When choosing the right cutting method for your needs, there are several key points to consider.

First, think about the specific requirements of your application and whether subtractive laser cutting or electric cutting would be more suitable.

Next, take into account your budget and available resources to determine which method is more cost-effective for your business.

Lastly, consider the potential for future expansion and flexibility, as this can influence your decision on the cutting method that best aligns with your long-term goals.

Considerations for Different Applications

One important aspect to consider when choosing between subtractive laser cutting and electric cutting is the specific application at hand. To help you make an informed decision, here are some industry-specific considerations and factors to keep in mind when choosing equipment:

-

Material: Different materials require different cutting techniques. For example, subtractive laser cutting is often preferred for delicate materials like paper or fabric, while electric cutting may be more suitable for tough materials like metal.

-

Precision: If your application requires high precision cuts, subtractive laser cutting may be the better choice. Laser cutting offers precise and intricate designs, making it ideal for industries such as jewelry making or electronics manufacturing.

-

Speed: Electric cutting is generally faster than subtractive laser cutting, making it a preferred option for applications that require quick turnaround times.

Considering these factors will help you choose the right cutting method for your specific needs.

Now, let’s move on to the next section and discuss budget and resources.

Budget and Resources

Now that you’ve considered the various applications for subtractive laser cutting and electric cutting, let’s delve into the next important factor: budget and resources.

When it comes to choosing the most convenient option, cost-effectiveness and efficiency play a crucial role. Subtractive laser cutting can be more expensive initially due to the high cost of laser equipment and maintenance. However, it offers greater efficiency in terms of speed, accuracy, and material utilization, which can lead to long-term cost savings.

On the other hand, electric cutting may have a lower upfront cost, but it might not be as efficient in terms of speed and precision. Considering your budget and available resources, you can make an informed decision that aligns with your needs and goals.

With that in mind, let’s explore the aspect of future expansion and flexibility in the next section.

Future Expansion and Flexibility

Looking ahead, you can consider the potential for expanding your capabilities and adapting to future needs with both subtractive laser cutting and electric cutting. Both options offer the possibility for future innovation and technological advancements.

As new technologies emerge and improve, you can easily upgrade your equipment to stay up-to-date and take advantage of the latest features. With subtractive laser cutting, for example, you can explore the potential for higher cutting speeds and more precise cuts as laser technology continues to advance. Similarly, electric cutting machines can benefit from advancements in automation and control systems, allowing for increased efficiency and accuracy.

By investing in either option, you are positioning yourself to take advantage of future advancements in the industry.

Transitioning to the next section, let’s explore some case studies and examples to further illustrate the benefits of these technologies.

Case Studies and Examples

To truly appreciate the convenience of subtractive laser cutting vs. electric cutting, imagine yourself in the shoes of a designer who effortlessly creates intricate patterns with the precision of a surgeon.

Case studies and real-life examples showcase the superiority of subtractive laser cutting in terms of convenience. For instance, a furniture designer utilized subtractive laser cutting to create complex and precise joinery, resulting in reduced production time and improved overall quality.

In another case, a fashion designer used subtractive laser cutting to intricately cut fabric patterns, allowing for intricate designs that were previously impossible to achieve with traditional electric cutting methods.

These examples demonstrate the convenience and versatility of subtractive laser cutting, making it the preferred choice for designers seeking precision and efficiency in their craft.

Frequently Asked Questions

Are there any safety concerns associated with subtractive laser cutting?

Yes, subtractive laser cutting can be quite dangerous if proper laser safety precautions aren’t followed. The intense laser beam can cause severe burns and eye injuries if not properly shielded. There’s also the potential hazard of fire if the material being cut is flammable. So, it’s crucial to ensure that laser safety protocols are strictly adhered to while using subtractive laser cutting technology.

Can electric cutting be used on all types of materials?

Electric cutting can be used on a wide range of materials, including delicate ones. It offers versatility and precision, making it a viable option for various applications.

However, subtractive laser cutting has certain advantages over electric cutting. With laser cutting, you can achieve intricate designs with high accuracy and minimal material wastage. Additionally, laser cutting allows for non-contact processing, reducing the risk of damage to delicate materials.

How does the cost of subtractive laser cutting compare to electric cutting?

When comparing the cost of subtractive laser cutting and electric cutting, an efficiency analysis is crucial.

Subtractive laser cutting tends to be more expensive due to the high cost of laser equipment and maintenance.

On the other hand, electric cutting is generally more cost-effective as it requires less specialized equipment and maintenance.

Therefore, in terms of cost comparison, electric cutting is a more affordable option compared to subtractive laser cutting.

Are there any limitations to the size or thickness of materials that can be cut using subtractive laser cutting?

Cutting through thick materials with subtractive laser cutting has its limits, but don’t let that rain on your parade. There are size and thickness limitations when it comes to this technique.

The size of the material being cut can be restricted by the size of the laser bed, while the thickness is limited by the laser’s power and the material’s ability to withstand the heat. However, with careful planning and consideration, you can still achieve remarkable results.

Can electric cutting achieve the same level of precision as subtractive laser cutting?

Electric cutting can achieve a similar level of precision as subtractive laser cutting. Both methods offer high accuracy in cutting materials. However, the precision comparison also depends on the specific equipment used and the expertise of the operator.

Additionally, when it comes to material compatibility, electric cutting may have limitations compared to laser cutting. Laser cutting is known for its versatility in cutting a wide range of materials, while electric cutting may be more suitable for certain types of materials.

Conclusion

So, as you can see, when it comes to convenience, subtractive laser cutting takes the cake! With its precision and speed, it’s like having a superhero in your workshop.

Electric cutting may have its uses, but it just can’t compete with the efficiency and versatility of laser cutting.

So, if you want to save time, money, and headaches, go with subtractive laser cutting. Trust me, it’s a game-changer!