Imagine you are an artist, with a blank canvas before you. You have a vision in your mind, a masterpiece waiting to come to life. But how do you bring that vision into reality with precision and accuracy? This is where the battle between subtractive laser cutting and milling begins.

Subtractive laser cutting and milling are two techniques that offer unique advantages and challenges when it comes to precision. Like a skilled sculptor, each method works to shape and carve your material, transforming it into a work of art.

In this article, we will delve into the world of subtractive laser cutting and milling, comparing their precision levels, exploring their techniques, and examining their applications. We will also discuss the limitations and considerations of each method, helping you choose the right one for your specific needs.

So, whether you’re a creative artist, an engineer, or a DIY enthusiast, join us on this journey as we unravel the mysteries of subtractive laser cutting and milling, and discover which technique reigns supreme in the realm of precision.

Key Takeaways

- Laser cutting offers high precision, minimal material wastage, and the ability to cut a wide range of materials.

- Milling offers high precision and versatility compared to other cutting methods.

- Precision in laser cutting is determined by the spot size of the laser beam and the speed at which it moves.

- Precision in milling is determined by factors such as machine rigidity, cutting tool quality, and workpiece stability.

Understanding Subtractive Laser Cutting

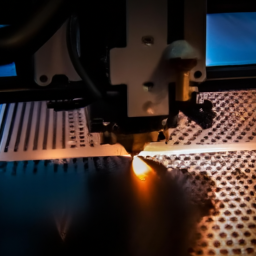

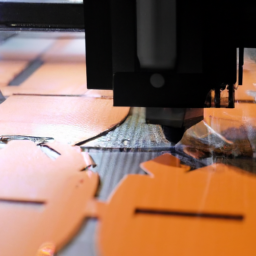

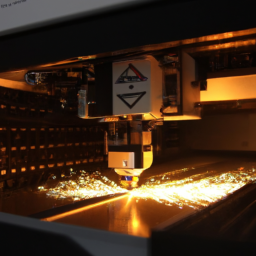

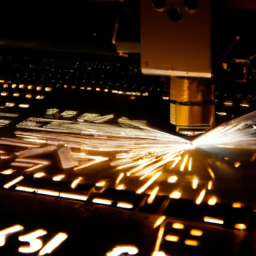

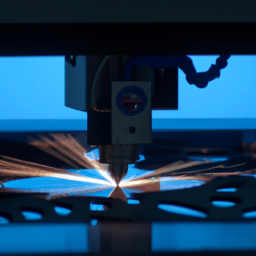

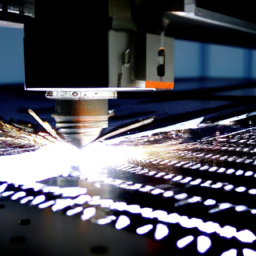

Imagine yourself standing in front of a state-of-the-art laser cutter as it precisely slices through materials, leaving behind clean and precise cuts. Understanding the laser beam is key to comprehending the process of subtractive laser cutting.

The laser beam, emitted from the machine, is focused on the material, melting or vaporizing it. This results in accurate and intricate cuts, making it a popular choice for industries such as manufacturing and engineering.

Laser cutting offers numerous advantages, including high precision, minimal material wastage, and the ability to cut a wide range of materials. However, it also comes with some disadvantages, such as the high cost of the equipment and the potential for thermal damage to certain materials.

Now, let’s delve into exploring milling techniques.

Exploring Milling Techniques

In this discussion, we’ll explore milling techniques and their key points. You’ll learn about the overview of the milling process, the precision levels it offers, and the various applications it can be used for.

Understanding these aspects will give you a comprehensive understanding of milling and its potential uses in different industries.

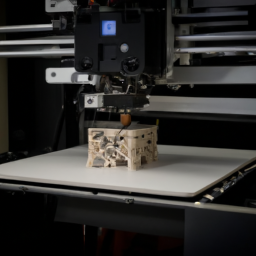

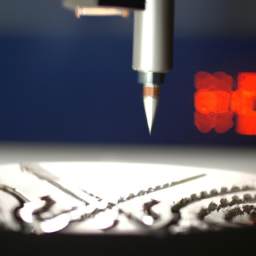

Overview of Milling Process

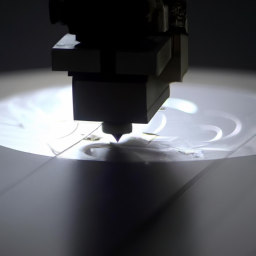

To get a precise cut, you need to understand the milling process. Milling equipment plays a crucial role in achieving accuracy and consistency in the final product. The milling process involves several steps, including selecting the appropriate tooling, setting the cutting parameters, and securing the material to be milled. These steps ensure that the milling machine can remove material precisely and efficiently.

To emphasize the importance of the milling process, let’s take a look at a table that compares the milling process with other cutting methods:

| Milling Process | Laser Cutting | Waterjet Cutting |

|---|---|---|

| Requires tooling and setup | No tooling required | No tooling required |

| Can achieve high precision | High precision | High precision |

| Suitable for a wide range of materials | Limited materials | Limited materials |

As you can see, the milling process offers high precision and versatility compared to other cutting methods. This precision is essential when aiming for intricate and accurate cuts. Moving on to the next section about precision levels, we will explore how milling compares to subtractive laser cutting in terms of accuracy.

Precision Levels

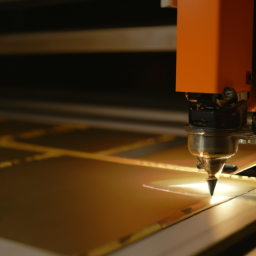

Surprisingly, achieving precise cuts is not as straightforward as you might think. When it comes to precision levels in subtractive laser cutting and milling, there are several factors influencing the outcome.

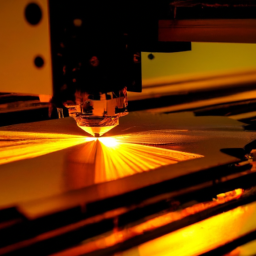

In laser cutting, the precision is mainly determined by the spot size of the laser beam and the speed at which it moves. Smaller spot sizes and slower speeds generally result in higher precision. On the other hand, milling precision is determined by factors such as the rigidity of the machine, the quality of the cutting tool, and the stability of the workpiece.

While both methods have their benefits and drawbacks, laser cutting tends to offer higher precision due to the smaller spot size and the ability to cut intricate details. However, milling can provide better precision in certain applications that require high accuracy and tight tolerances, such as aerospace or medical industries.

Moving on to applications…

Applications

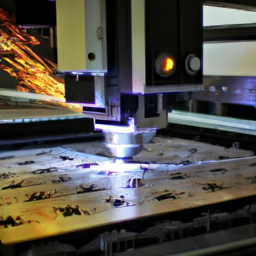

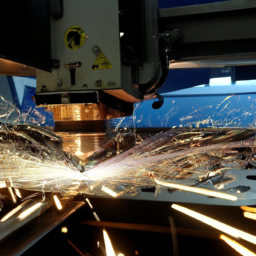

Let’s explore the wide range of applications where precision cutting and milling techniques truly shine! When it comes to industrial advantages, subtractive laser cutting is often favored for its ability to cut through a variety of materials with high accuracy. It is commonly used in industries such as automotive, aerospace, and electronics, where precise and intricate cuts are required.

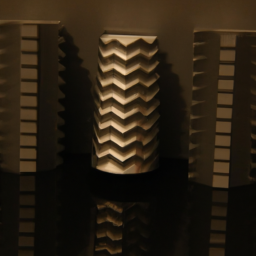

On the other hand, milling offers its own set of advantages, particularly in applications that require more complex shapes or the removal of large amounts of material. Its versatility and material compatibility make it ideal for industries like woodworking and metal fabrication.

Now, let’s transition into the subsequent section about comparing precision levels, where we’ll delve deeper into the specific differences between these two techniques.

Comparing Precision Levels

When comparing precision levels in milling techniques, it’s important to consider several factors that can affect the overall precision of the process.

These factors include:

- The type of material being used

- The quality of the machine and its components

- The skill and experience of the operator

Tolerances and accuracy are also crucial aspects to consider. They determine how closely the final result matches the intended design specifications.

Factors Affecting Precision

To achieve the highest precision in your work, it’s essential to consider the various factors that can affect the outcome. These factors include material properties, machine calibration, tool selection, and operator skill.

Material properties: The type and characteristics of the material being worked on can significantly impact the precision of the process.

Machine calibration: The accuracy of the machine’s positioning system and its alignment with the workpiece play a crucial role in achieving precise cuts or milling.

Tool selection: Choosing the right cutting or milling tool for the specific application is vital in ensuring accurate results.

Operator skill: The expertise and proficiency of the person operating the machine can greatly affect the precision of the outcome.

Considering these factors is essential for achieving the desired level of precision in subtractive laser cutting or milling. This attention to detail will be further discussed in the subsequent section about ‘tolerances and accuracy’.

Tolerances and Accuracy

Achieving high precision in your work requires considering the tolerances and accuracy of the process. In subtractive laser cutting, tolerance analysis plays a crucial role in determining the achievable precision. By carefully analyzing the material properties and laser parameters, you can determine the optimal settings to achieve the desired accuracy.

Precision measurement is also essential in subtractive laser cutting, as it allows you to verify the actual dimensions of the cut parts and make necessary adjustments if needed. By using advanced measurement tools such as laser scanners or vision systems, you can ensure that the tolerances are within the required limits.

Understanding the importance of tolerance analysis and precision measurement is crucial in achieving precise results in subtractive laser cutting. Transitioning into the subsequent section about examining applications, it is important to consider the specific requirements of different industries and how they impact precision.

Examining Applications

In this discussion, we’ll explore the applications of subtractive laser cutting and milling techniques in different industries. You’ll learn about the industries that heavily rely on subtractive laser cutting, such as automotive, aerospace, and electronics.

Additionally, we’ll delve into the industries that extensively utilize milling techniques, including manufacturing, prototyping, and woodworking.

Industries Using Subtractive Laser Cutting

When it comes to industries utilizing subtractive laser cutting, you’ll find that it’s as common as a bee buzzing around a hive. This versatile technology has found its way into a wide range of industries, offering numerous benefits.

In the automotive industry, subtractive laser cutting is used for precision cutting of various components, such as chassis parts and door panels.

The aerospace industry relies on this technique for intricate cutting of aircraft parts, ensuring accuracy and reducing material waste.

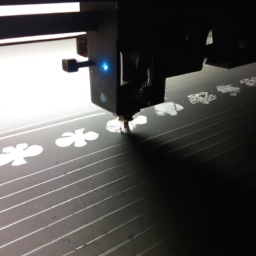

The electronics industry benefits from subtractive laser cutting by precisely shaping delicate circuit boards and creating intricate patterns.

With its ability to cut through a variety of materials with extreme precision, subtractive laser cutting has become a go-to solution for many industries. However, it’s also important to explore the industries using milling techniques, as they offer a different set of advantages.

Industries Using Milling Techniques

Industries across various sectors have embraced the use of milling techniques, leveraging its versatility and efficiency in shaping and fabricating a wide range of components and parts. From aerospace and automotive to medical and electronics, there is a broad range of industries utilizing milling to achieve their manufacturing goals. With advancements in milling techniques, such as computer numerical control (CNC) systems and high-speed machining, the precision and accuracy of milling have significantly improved. This has allowed industries to produce intricate and complex designs with minimal errors. In fact, milling has become the go-to method for creating prototypes, molds, and custom parts. However, like any manufacturing process, there are limitations and considerations to keep in mind when using milling techniques.

Limitations and Considerations

To ensure the highest precision for your project, it’s important to consider the limitations and factors to take into account when choosing between subtractive laser cutting and milling. Here are three key limitations and accuracy considerations to keep in mind:

-

Material Compatibility: Both laser cutting and milling have specific material limitations. Laser cutting works best with materials like wood, acrylic, and certain metals, while milling is more versatile but may struggle with materials that are too hard or brittle.

-

Complexity of Design: Laser cutting is more suitable for intricate and detailed designs due to its precise laser beam. On the other hand, milling can handle more complex geometries and three-dimensional shapes with greater ease.

-

Surface Finish: Milling can leave behind visible tool marks or require additional finishing processes, while laser cutting generally produces smoother and cleaner edges.

Considering these limitations and accuracy considerations, you can now make an informed decision on choosing the right method for your needs.

Choosing the Right Method for Your Needs

Make sure you choose the method that best suits your needs and achieves the level of precision you desire. When it comes to choosing between subtractive laser cutting and milling, precision is a crucial factor to consider. Both methods have their strengths and limitations, so it’s important to understand which one will give you the accuracy you require.

Subtractive laser cutting is known for its high precision and smooth finish, making it ideal for intricate designs and delicate materials. On the other hand, milling offers excellent precision as well, especially for larger and more robust materials.

The choice ultimately depends on the specific requirements of your project. Consider the intricacy of your design, the type of material you’re working with, and the level of precision you need. By carefully evaluating these factors, you can make an informed decision and ensure that you achieve the desired level of precision.

Frequently Asked Questions

What is the cost difference between laser cutting and milling?

When it comes to the cost difference between laser cutting and milling, there are a few factors to consider.

Laser cutting generally has a higher upfront cost due to the expensive equipment required. However, it can be more cost-effective in the long run because it’s faster and requires less manual labor.

On the other hand, milling may have lower upfront costs but can be more expensive in terms of materials and labor.

Ultimately, the cost difference depends on your specific project and requirements.

Can both laser cutting and milling be used on the same material?

Yes, both laser cutting and milling can be used on the same material, offering interchangeability. Combining these techniques has advantages and disadvantages. Laser cutting provides precise and clean cuts, while milling allows for more complex shapes and intricate detailing.

By using both methods together, you can achieve superior precision and versatility in your projects. However, the cost and time involved in using both techniques may be higher compared to using just one of them.

Are there any safety considerations when using laser cutting or milling?

When using laser cutting or milling, there are safety precautions you need to take into consideration. It’s important to wear protective equipment such as goggles and gloves to prevent any injuries.

Additionally, make sure you have the necessary equipment, such as fire extinguishers and ventilation systems, in case of emergencies.

Following these safety measures will help ensure a safe working environment when using laser cutting or milling techniques.

What are the environmental impacts of laser cutting and milling?

When considering the environmental impacts of laser cutting and milling, it’s important to focus on environmental sustainability. Both processes have their own set of considerations.

Laser cutting produces minimal waste and uses less energy, making it more environmentally friendly. However, it requires proper ventilation and filtration to ensure the safety of workers and prevent harmful emissions.

Milling can generate more waste and consume more energy, but it also has its own health and safety precautions to consider.

How long does it typically take to complete a project using laser cutting or milling?

When it comes to project completion time, efficiency is key. Laser cutting and milling are both efficient methods, but their speeds can vary.

Laser cutting is like a lightning bolt, swiftly slicing through materials with precision. On the other hand, milling is like a meticulous sculptor, carefully shaping and carving the desired outcome.

While it ultimately depends on the project complexity and material, laser cutting tends to be faster, making it a popular choice for those seeking timely results.

Conclusion

So, when it comes to subtractive laser cutting versus milling, you’ve seen that both methods have their strengths and limitations.

While subtractive laser cutting offers precise and intricate cuts, milling techniques provide versatility and the ability to work with a wide range of materials.

Ultimately, the right method for your needs depends on the specific application and requirements. Remember, precision is key in any manufacturing process, so choose wisely and let your creativity cut through the noise like a laser beam through steel.