Did you know that the global metal cutting market is projected to reach a value of $8.3 billion by 2025? With such a significant market, it’s important to choose the right cutting method for your specific needs.

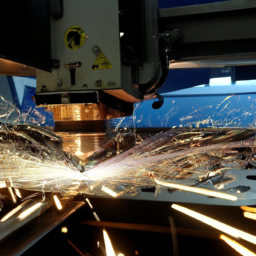

When it comes to subtractive laser cutting and plasma cutting, both methods offer unique advantages. Subtractive laser cutting utilizes a high-powered laser beam to precisely cut through materials, while plasma cutting uses a jet of hot plasma to achieve similar results.

But which method should you choose? In this article, we will explore the differences between subtractive laser cutting and plasma cutting, and discuss the factors you should consider when making a decision. Whether you prioritize precision and accuracy, efficiency and productivity, or cost-effectiveness, understanding the pros and cons of each cutting method will help you make an informed choice.

So, let’s dive in and discover which method is right for you.

Key Takeaways

- Laser cutting is faster and more efficient compared to plasma cutting.

- Plasma cutting is suitable for cutting thick materials and is more affordable, especially for thicker materials.

- Both laser cutting and plasma cutting improve efficiency and productivity in cutting projects.

- Consulting with experts is important to receive tailored insights and recommendations for the most suitable cutting method and to avoid costly mistakes.

Understanding Subtractive Laser Cutting

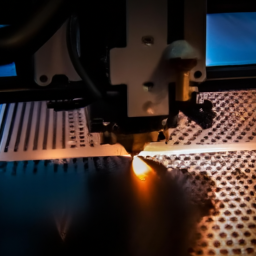

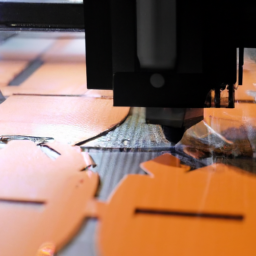

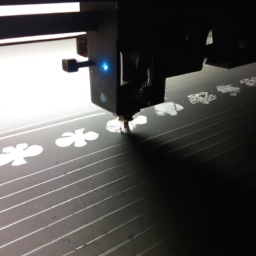

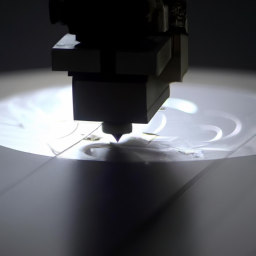

If you’re looking to understand subtractive laser cutting, you’ll be amazed at the precise and intricate cuts that can be achieved with this method.

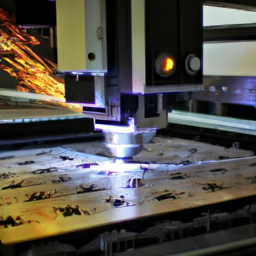

Laser cutting uses a high-powered laser to cut through materials with extreme accuracy. The precision in laser cutting is unmatched, allowing for intricate designs and fine details that other cutting methods can’t achieve. This method is ideal for projects that require delicate cuts or complex shapes.

One of the major benefits of laser cutting is its ability to cut a wide range of materials, including metal, wood, and plastic. It’s also a faster and more efficient process compared to other cutting methods.

Laser cutting is a versatile and precise method that can bring your designs to life.

Now, let’s explore plasma cutting and see how it compares.

Exploring Plasma Cutting

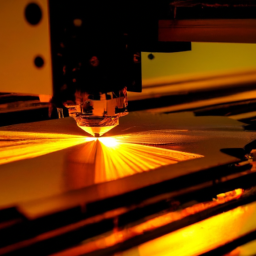

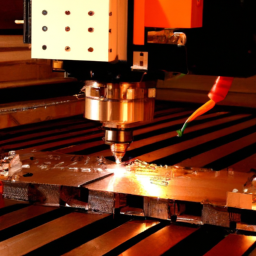

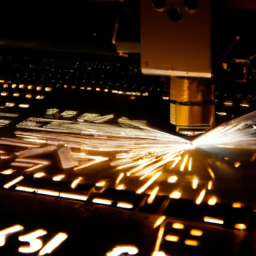

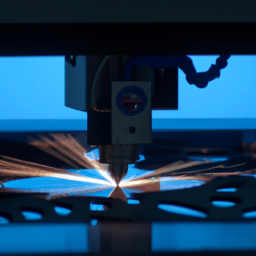

If you’re considering plasma cutting, it’s important to understand the basics of this method. Plasma cutting involves using a high-velocity jet of ionized gas to melt and cut through materials.

This process offers several advantages, such as its ability to cut through thick materials and its high cutting speed. However, it also has some drawbacks, such as the production of smoke and noise during the cutting process.

The Basics of Plasma Cutting

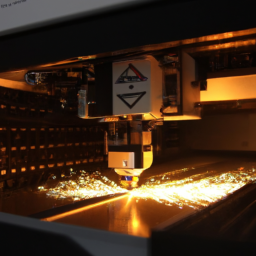

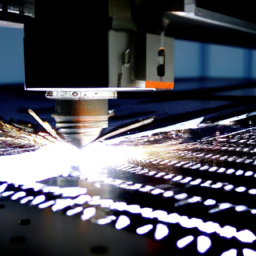

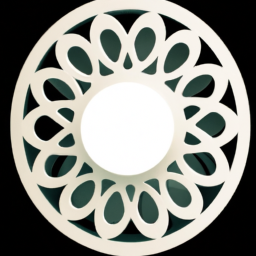

Plasma cutting, a method commonly used in metal fabrication, utilizes an ionized gas to create a high-temperature plasma that swiftly cuts through materials. This technique offers a range of applications, including cutting thick metal sheets, creating intricate shapes, and even piercing through reflective surfaces.

When it comes to plasma cutting techniques, there are two main approaches: manual and CNC (Computer Numerical Control) cutting. Manual cutting allows for more flexibility and is ideal for small-scale projects, while CNC cutting offers precision and efficiency for larger-scale productions.

In terms of plasma cutting applications, it’s widely used in industries such as automotive, aerospace, and construction. It’s suitable for cutting materials like stainless steel, aluminum, and copper.

As we move into the next section about the pros and cons of plasma cutting, it’s important to understand the basics of this method and its versatility in various industries.

Pros and Cons

One advantage of plasma cutting is its ability to swiftly cut through materials, making it a popular choice for industrial applications. The intense heat generated by the plasma arc allows for quick and efficient cutting, reducing production time.

However, a disadvantage of plasma cutting is the potential for warping or distorting the metal being cut. The high heat can cause the metal to expand and contract, leading to inaccuracies in the final product. Additionally, plasma cutting produces a larger heat-affected zone compared to other cutting methods, which may affect the material’s structural integrity.

When considering the pros and cons of plasma cutting, factors such as material type, thickness, and desired precision should be taken into account. These factors will help determine the most suitable cutting method for your specific needs.

Now, let’s move on to the factors to consider when choosing a cutting method.

Factors to Consider When Choosing a Cutting Method

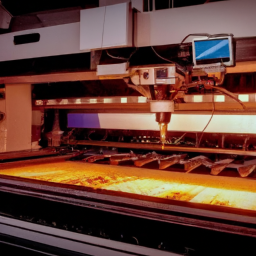

When considering a cutting method, it’s important to take into account various factors in order to make an informed decision. Here are four factors to consider:

-

Material: Different cutting methods are better suited for certain materials. For example, laser cutting is ideal for intricate designs on thin materials like acrylic or wood, while plasma cutting is better for thicker metals.

-

Precision: Laser cutting offers higher precision, with the ability to create intricate details and sharp edges. Plasma cutting, on the other hand, may result in a slightly rougher edge.

-

Speed: Plasma cutting is generally faster than laser cutting, making it a better choice for large-scale projects that require quick turnaround times.

-

Cost: Laser cutting tends to be more expensive due to the high cost of laser machines and maintenance. Plasma cutting, on the other hand, is more affordable, especially for thicker materials.

Considering these factors will help you make an informed decision. Now let’s move on to comparing precision and accuracy in the next section.

Comparing Precision and Accuracy

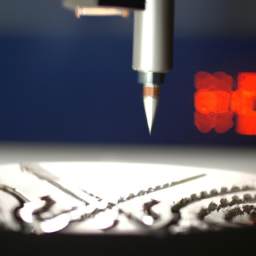

To make an informed decision on which cutting method is best suited for your needs, it’s important to understand the differences between precision and accuracy.

Precision refers to the consistency and repeatability of the cuts, while accuracy relates to how closely the cuts match the intended design.

When it comes to precision and speed, subtractive laser cutting has the advantage. Laser cutting offers high precision, allowing for intricate and detailed cuts. On the other hand, plasma cutting may not be as precise, but it is faster, making it suitable for projects that prioritize efficiency over intricate designs.

Additionally, when considering the cost comparison, plasma cutting tends to be more affordable than laser cutting. However, it’s important to note that precision and accuracy should not be compromised solely for cost savings.

With a clear understanding of precision and accuracy, let’s explore the next section on efficiency and productivity.

Efficiency and Productivity

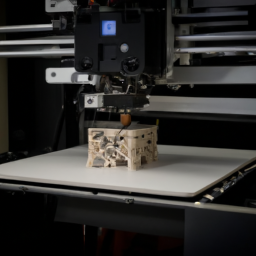

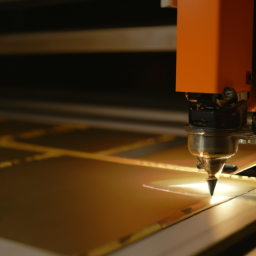

Maximizing efficiency and productivity is crucial when selecting the most suitable method for your cutting needs. When it comes to subtractive laser cutting and plasma cutting, both methods have their advantages in terms of improving speed and maximizing output.

Subtractive laser cutting uses a laser beam to melt and vaporize the material, resulting in precise and clean cuts. This method is known for its high cutting speed, allowing for faster completion of projects.

On the other hand, plasma cutting uses a jet of hot plasma to cut through metal, which can be faster for thicker materials.

Considering the efficiency and productivity of each method is essential in making an informed decision about which method to choose for your specific requirements.

Transitioning into the subsequent section, let’s explore other factors to consider when making this decision.

Making an Informed Decision

When it comes to making an informed decision about whether to choose subtractive laser cutting or plasma cutting, there are two key points to consider.

First, it’s important to assess your cutting needs and determine which method aligns best with your specific requirements.

Second, consulting with experts in the field can provide valuable insights and guidance to help you make the right choice.

So, take the time to evaluate your needs and seek expert advice before deciding on the cutting method that will best suit your needs.

Assessing Your Cutting Needs

Consider evaluating your cutting needs by visualizing the materials you plan to cut and the precision required, which will help you determine the most suitable method for your project. When evaluating cost, keep in mind that subtractive laser cutting may be more expensive upfront due to the cost of the laser machine, but it can provide higher precision and cleaner cuts. On the other hand, plasma cutting is often more affordable and better suited for thicker materials like metals. Determining material compatibility is crucial as well. Subtractive laser cutting works well with a wide range of materials, including wood, acrylic, and plastic, while plasma cutting is primarily used for metals. By assessing your cutting needs, you can make an informed decision about the best cutting method for your project. In the next section, we will discuss the importance of consulting with experts in the field.

Consulting with Experts

When it comes to choosing between subtractive laser cutting and plasma cutting, it’s crucial to assess your cutting needs.

Once you have a clear understanding of the materials, thicknesses, and intricacies involved in your cutting project, the next step is to consult with experts.

Seeking professional advice can provide invaluable insights and recommendations tailored to your specific requirements.

Experts in the field have a deep understanding of the pros and cons of each cutting method and can guide you towards the most suitable option for your project.

Their expertise can help you avoid costly mistakes and ensure optimal results.

So, before making a decision, take the time to consult with experts and benefit from their valuable recommendations.

Frequently Asked Questions

What materials can be cut using subtractive laser cutting?

When it comes to subtractive laser cutting, the possibilities are endless. With a beam of intense light, it can effortlessly slice through materials like wood, plastic, fabric, and even metals. The precision and speed of a laser cutter make it the go-to choice for intricate designs and delicate materials. However, if you’re dealing with thick materials like steel or aluminum, plasma cutting might be a better option. Its high-temperature plasma jet can easily handle the job, providing an advantage in terms of efficiency and cost-effectiveness.

What are the safety considerations when using plasma cutting?

When using plasma cutting, there are important safety precautions to keep in mind. Always wear appropriate protective gear, such as gloves, goggles, and a welding helmet, to protect yourself from sparks, heat, and harmful fumes.

Make sure the work area is well-ventilated to prevent the buildup of toxic gases. Additionally, it’s crucial to have a fire extinguisher nearby and to be aware of the potential for electrical hazards.

Taking these safety measures will help ensure a safe plasma cutting experience.

Can plasma cutting be used for intricate designs and fine details?

Yes, plasma cutting can be used for intricate designs and fine details. Its precision cutting techniques allow for accurate and detailed cuts. With plasma cutting, you can achieve intricate shapes and designs with ease.

The advantages of plasma cutting include its ability to cut a wide range of materials, its fast cutting speed, and its cost-effectiveness. So, if you need precision cutting for intricate designs, plasma cutting is a great choice.

How does the cost of maintenance compare between subtractive laser cutting and plasma cutting?

Maintenance requirements and cost comparison are important factors to consider when choosing between subtractive laser cutting and plasma cutting. Both methods have their own maintenance needs and associated costs.

Subtractive laser cutting typically requires regular cleaning, alignment checks, and replacement of consumable parts, which can be more expensive. On the other hand, plasma cutting may have lower maintenance costs but may require more frequent replacement of consumables.

Considering these factors will help you make an informed decision based on your specific needs and budget.

Are there any environmental concerns associated with either subtractive laser cutting or plasma cutting?

When considering the environmental impact, both subtractive laser cutting and plasma cutting have their concerns.

Subtractive laser cutting produces toxic fumes and emits harmful gases, requiring proper ventilation and filtration systems.

On the other hand, plasma cutting consumes a significant amount of energy, contributing to higher carbon emissions.

Therefore, when comparing energy consumption, plasma cutting is less energy-efficient than subtractive laser cutting.

Overall, both methods have environmental considerations that need to be addressed.

Conclusion

So, in conclusion, when it comes to choosing between subtractive laser cutting and plasma cutting, it all comes down to your specific needs and requirements.

Both methods have their advantages and disadvantages, and it’s essential to consider factors such as precision, accuracy, efficiency, and productivity.

However, one theory that holds true is that with the right understanding and informed decision-making, you can achieve the desired results with either method.

So, take your time, evaluate your needs, and make a choice that aligns with your goals.