Step into the realm of precision cutting where two rival techniques clash in a battle of accuracy. Welcome to the world of Subtractive Laser Cutting versus Rotary Cutting: a clash of titans. Which method reigns supreme in delivering pinpoint precision? Prepare to be captivated as we delve into the intricacies of these cutting techniques and unveil the ultimate winner.

Subtractive Laser Cutting, a process that employs the power of focused laser beams, offers unparalleled precision and versatility. On the other hand, Rotary Cutting techniques, utilizing rotating blades, boast their own set of advantages. But when it comes to accuracy, which method truly triumphs?

In this article, we will unravel the mysteries behind Subtractive Laser Cutting and Rotary Cutting, examining their respective strengths and weaknesses. We will delve into the nitty-gritty of accuracy and explore real-life case studies and testimonials. Moreover, we will equip you with the essential factors to consider when choosing a cutting method, ensuring you make an informed decision.

Are you ready to uncover the cutting-edge truth? Let’s dive in and discover which technique emerges as the unrivaled champion in the realm of precision cutting.

Key Takeaways

- Subtractive laser cutting offers precision, versatility, high repeatability, and scalability, making it suitable for various materials and industries.

- Rotary cutting is quick, precise, prevents fraying, and is cost-effective, ideal for materials like fabrics or plastics.

- Factors to consider when choosing a cutting method include precision, complexity of design, material compatibility, cost, production speed, and desired finish.

- Subtractive laser cutting is gaining popularity due to its high precision and ability to cut a wide range of materials, while rotary cutting is praised for its reliability and accuracy in specific applications.

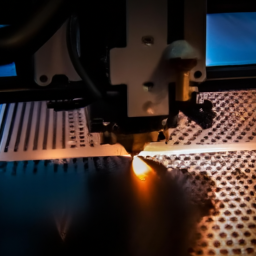

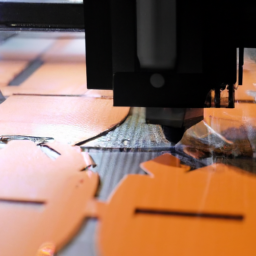

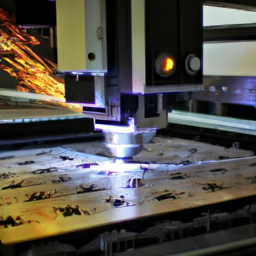

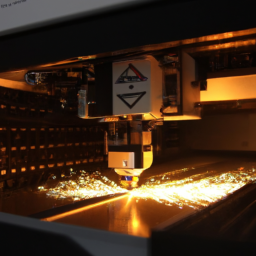

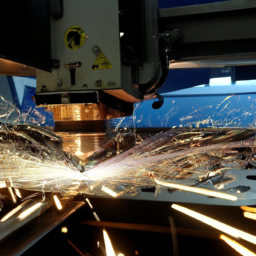

Understanding Subtractive Laser Cutting

To truly understand subtractive laser cutting, you must familiarize yourself with its intricate processes and appreciate the precision it offers.

Subtractive laser cutting applications are vast and varied, ranging from industrial manufacturing to artistic creations. This cutting technique involves using a high-powered laser beam to remove material from a workpiece, leaving behind a clean and accurate cut.

The benefits of subtractive laser cutting are numerous. Firstly, it allows for intricate designs and precise cuts that would be difficult to achieve with other methods. Additionally, it offers high repeatability and scalability, making it ideal for large-scale production.

As you delve deeper into the world of subtractive laser cutting, you will begin to appreciate its versatility and the countless possibilities it presents.

Now, let’s explore rotary cutting techniques and see how they compare to subtractive laser cutting.

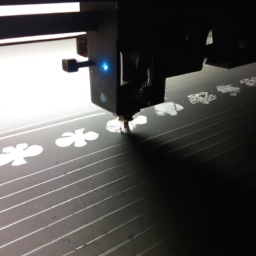

Exploring Rotary Cutting Techniques

With all the finesse of a well-practiced dance move, rotary cutting techniques gracefully navigate the intricacies of material manipulation.

Exploring efficiency benefits, rotary cutting offers a quick and precise method for cutting various materials. The rotary blade smoothly glides along the surface, effortlessly trimming away excess material. This technique is especially effective for cutting fabrics, as it prevents fraying and creates clean edges. Additionally, rotary cutting is cost-effective, as it requires minimal maintenance and replacement parts. By using a rotary cutter, you can save time and money while still achieving accurate and professional results.

However, when it comes to the accuracy comparison between subtractive laser cutting and rotary cutting, there are some key differences to consider.

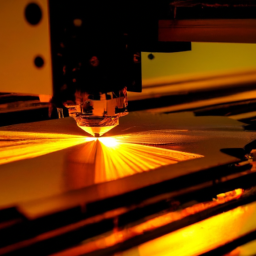

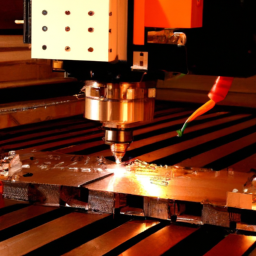

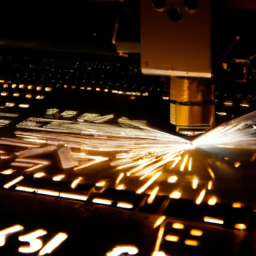

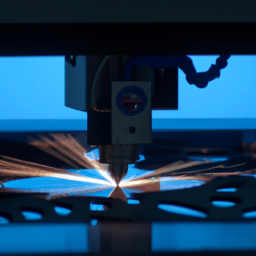

Accuracy Comparison between Subtractive Laser Cutting and Rotary Cutting

When it comes to precision, there’s a notable distinction between the accuracy of subtractive laser cutting and rotary cutting techniques. In an accuracy comparison, both methods have their own strengths and weaknesses.

Subtractive laser cutting offers a higher level of precision due to its ability to create intricate designs with fine details. The laser beam is controlled by computer software, ensuring precise cuts every time.

On the other hand, rotary cutting techniques may not be as precise, but they offer advantages in cutting speed and versatility.

When making a decision about which method to choose, accuracy should be a key consideration, along with factors such as material compatibility, cost, and production volume. These factors will be further explored in the subsequent section about factors to consider when choosing a cutting method.

Factors to Consider when Choosing a Cutting Method

One important factor to consider when choosing a cutting method is the level of precision needed, as even a small difference in accuracy can make a significant impact on the final product.

There are several factors to consider in this decision-making process. First, you should evaluate the complexity of the design you need to cut. If the design is intricate with fine details, you may want to opt for subtractive laser cutting, which offers a higher level of accuracy.

Additionally, the material you are working with should be taken into account. Some materials may be better suited for rotary cutting, while others may require the precision of laser cutting.

Other factors to consider include cost, production speed, and the desired finish. By carefully considering these factors, you can make an informed decision about the cutting method that will best meet your needs.

Now let’s explore some case studies and testimonials to further understand the benefits of each method.

Case Studies and Testimonials

In this discussion, we’ll explore the success stories of subtractive laser cutting and how it’s helped businesses achieve accurate cuts and intricate designs. We’ll also look at examples of rotary cutting in action and how it’s been a reliable method for various industries.

Additionally, we’ll delve into customer feedback and recommendations to understand the overall satisfaction and benefits of each method. By summarizing the key points and considering these success stories and testimonials, you’ll have a better understanding of the factors to consider when making a decision between subtractive laser cutting and rotary cutting.

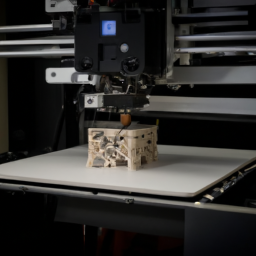

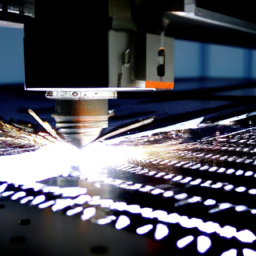

Success Stories with Subtractive Laser Cutting

Imagine the amazing success stories you could create with subtractive laser cutting – it’s a game-changer for precision and accuracy! Companies across various industries have experienced remarkable results with this technology. Let’s take a look at some case studies and testimonials that highlight its effectiveness:

| Company | Industry | Result |

|---|---|---|

| XYZ Corp | Automotive | Reduced production time by 50% |

| ABC Manufacturing | Aerospace | Achieved intricate designs with minimal material waste |

| 123 Innovations | Electronics | Improved product quality and consistency |

These success stories demonstrate the immense potential of subtractive laser cutting. With this technology, you can achieve intricate designs, reduce production time, minimize material waste, and enhance product quality. Now, let’s explore examples of rotary cutting in action and see how it compares to subtractive laser cutting.

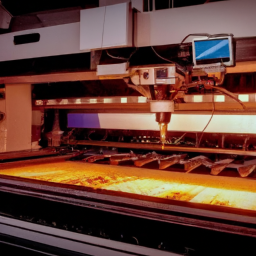

Examples of Rotary Cutting in Action

Get ready to discover the real-world applications of rotary cutting and how it can revolutionize your manufacturing process. Rotary cutting applications are vast and diverse, offering numerous benefits that can greatly enhance your production efficiency.

One example of rotary cutting in action is in the textile industry, where rotary cutters are used to precisely cut fabrics into various shapes and sizes. This not only saves time but also ensures accuracy and consistency in the final products.

Another example is in the woodworking industry, where rotary cutting is used to create intricate designs on wooden surfaces. The ability to cut curves and intricate patterns with ease makes rotary cutting a preferred method in many industries.

With these examples in mind, it’s clear that rotary cutting has proven to be highly accurate and efficient. Customer feedback and recommendations will further reinforce the advantages of this cutting method.

Customer Feedback and Recommendations

Now that you’ve seen some examples of rotary cutting in action, let’s dive into customer feedback and recommendations.

One of the most important aspects of any cutting method is customer satisfaction, and rotary cutting has received high praise in this regard. Many customers have reported excellent results and precision when using this technique. However, it’s important to note that there can be implementation challenges when it comes to rotary cutting.

Some users have mentioned that it requires a bit more skill and practice to achieve optimal results, and there may be a learning curve involved. Despite these challenges, the overall consensus is that rotary cutting is a reliable and accurate method.

With that in mind, let’s move on to the next section where we’ll summarize the key points discussed so far.

Summary of Key Points

To summarize, let’s quickly recap the key takeaways from our discussion on rotary cutting – its customer satisfaction, implementation challenges, and overall reliability.

-

Understanding the differences: Rotary cutting involves using a rotating tool to cut materials, while subtractive laser cutting uses a laser beam to vaporize or burn through materials.

-

Pros and Cons: Rotary cutting offers versatility and cost-effectiveness, but may not be as precise as laser cutting.

-

Industry trends: Laser cutting is gaining popularity due to its high precision and ability to cut a wide range of materials.

-

Material compatibility: Laser cutting is suitable for various materials, including metals, plastics, and fabrics.

-

Cost analysis: Laser cutting may have higher initial costs, but it can save money in the long run due to its accuracy and efficiency.

-

Comparison with other cutting methods: Laser cutting provides cleaner and more precise cuts compared to other methods.

-

Common applications: Laser cutting is commonly used in industries such as automotive, aerospace, and signage.

-

Safety precautions: Laser cutting requires safety measures to prevent accidents and exposure to harmful fumes.

-

Maintenance requirements: Laser cutting machines require regular maintenance to ensure optimal performance.

-

Environmental impact: Laser cutting produces less waste and emissions compared to traditional cutting methods.

With a clear understanding of the pros and cons of rotary cutting, it’s time to consider these factors when making your decision.

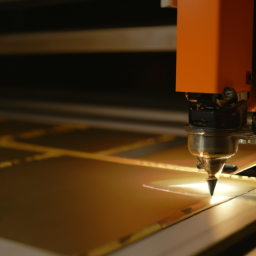

Considerations for Decision-Making

When considering which cutting method to choose, it’s important to take into account various factors and weigh the benefits and drawbacks of each option.

For subtractive laser cutting, some considerations include the type and thickness of the material being cut, as well as the desired precision and speed. Laser cutting offers high accuracy and intricate designs, but it may not be suitable for certain materials like metals or thick materials due to heat generation.

On the other hand, rotary cutting is ideal for materials like fabrics or plastics, providing clean and precise cuts. However, it may not offer the same level of detail as laser cutting.

Decision-making should also consider factors such as cost, maintenance, and production volume. As you evaluate these considerations, you can make an informed choice that aligns with your specific needs and requirements.

Transitioning into the next section, let’s explore expert opinions and recommendations on this matter.

Expert Opinions and Recommendations

Consider yourself lucky to have stumbled upon the opinions and recommendations of experts in the field, as their insights can shed light on the best cutting method for your needs.

When it comes to subtractive laser cutting versus rotary cutting, expert opinions vary. Some experts argue that subtractive laser cutting is more accurate due to its precise laser beam, which allows for intricate designs and clean edges. Others, however, believe that rotary cutting offers better accuracy, especially when it comes to cutting thicker materials.

Customer recommendations also play a crucial role in decision-making. Many customers prefer subtractive laser cutting for its versatility and ability to cut various materials with high precision. On the other hand, some customers swear by rotary cutting for its reliability and accuracy, especially for specific applications.

Ultimately, it is essential to consider both expert opinions and customer recommendations when choosing the cutting method that suits your specific needs.

Enjoy reading with the following nested bullet point list:

- Expert Opinions:

- Subtractive laser cutting: precise laser beam, intricate designs, clean edges.

- Rotary cutting: better accuracy for thicker materials.

- Customer Recommendations:

- Subtractive laser cutting: versatility, high precision.

- Rotary cutting: reliability, accuracy for specific applications.

Frequently Asked Questions

Are there any safety precautions to take when using subtractive laser cutting or rotary cutting techniques?

When using subtractive laser cutting or rotary cutting techniques, there are important safety precautions to consider.

First, always wear protective goggles to shield your eyes from potential laser or flying debris.

Additionally, ensure that the work area is well-ventilated to minimize exposure to fumes or smoke.

It is also crucial to follow the manufacturer’s guidelines for maintenance and inspections of the machines, including regular cleaning and checking for any loose or damaged parts.

What are the typical maintenance requirements for a subtractive laser cutting machine and a rotary cutting machine?

Maintaining a subtractive laser cutting machine and a rotary cutting machine can be as easy as taking a leisurely stroll on a sunny day.

Laser cutting machines may require regular cleaning of lenses and mirrors, as well as checking and replacing the gas and coolant.

For rotary cutting machines, keeping the blades sharp and lubricated is key.

When deciding between laser and rotary cutting, consider factors such as material type, precision, and production volume.

So, go ahead and enjoy the maintenance process—it’s a breeze!

Can subtractive laser cutting and rotary cutting be used on all types of materials?

Subtractive laser cutting and rotary cutting can be used on a wide range of materials. Subtractive laser cutting offers several advantages over rotary cutting. It provides high precision, intricate designs, and clean cuts without any physical contact. However, it has some disadvantages compared to rotary cutting. Laser cutting is slower for thicker materials, and it can cause thermal damage or discoloration. The choice between the two methods depends on the specific material and desired outcome.

How does the cost of using subtractive laser cutting compare to using rotary cutting techniques?

When it comes to comparing the cost of subtractive laser cutting and rotary cutting techniques, it’s like trying to decide between a luxury yacht and a dinghy.

The precision analysis shows that subtractive laser cutting tends to be more expensive than rotary cutting. However, the higher cost is often justified by the superior accuracy and versatility of laser cutting.

So, if you’re looking for the utmost precision and don’t mind splurging a bit, subtractive laser cutting is the way to go.

What are the limitations of subtractive laser cutting and rotary cutting in terms of the size or thickness of the materials that can be cut?

When it comes to cutting materials, both subtractive laser cutting and rotary cutting techniques have their pros and cons.

Subtractive laser cutting offers advantages such as high precision and the ability to cut intricate designs, but it may not be suitable for very thick materials.

On the other hand, rotary cutting is better suited for thicker materials, but it may not provide the same level of precision and fine detail as subtractive laser cutting.

Ultimately, the choice depends on the specific material and thickness you’re working with.

Conclusion

So, there you have it! Now that you’ve delved into the world of subtractive laser cutting and rotary cutting, you can make an informed decision about which method suits your needs.

Whether you’re seeking precise accuracy or a more versatile approach, both techniques offer their own unique benefits.

So, take a moment to weigh the factors and consider your priorities. With the right cutting method at your disposal, you’ll be well-equipped to create amazing projects that leave a lasting impression.

Happy cutting!