In the world of manufacturing, the battle between subtractive laser cutting and router cutting rages on. Like two warriors vying for supremacy, these techniques go head-to-head, each armed with its own unique set of advantages.

Subtractive laser cutting, a symbol of precision and speed, wields its powerful beam to effortlessly slice through a variety of materials with unparalleled accuracy. On the other hand, router cutting, a symbol of versatility and reliability, relies on its trusty rotating bit to carve intricate designs with absolute finesse.

But amidst this epic clash, one question looms large: which technique is truly more cost-effective? In this article, we delve into the world of subtractive laser cutting and router cutting, comparing their costs and exploring the factors that must be considered.

Through enlightening case studies, we aim to uncover the ultimate winner in this cost-effective battle, guiding you towards the most economical choice for your manufacturing needs.

Key Takeaways

- Subtractive laser cutting is more expensive initially but may be more cost-effective in the long run.

- Subtractive laser cutting produces cleaner and more precise cuts.

- Router cutting may be more efficient for larger projects with faster production speed.

- Router cutting is ideal for handling thicker materials and projects that require durability and strength.

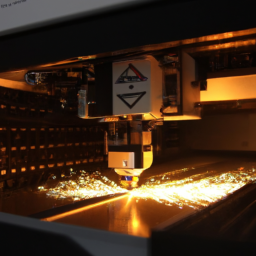

Understanding Subtractive Laser Cutting

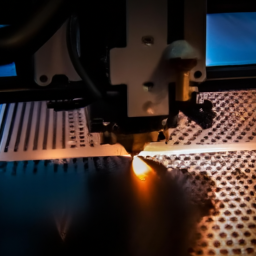

If you’re looking to understand subtractive laser cutting, you’re in for a fascinating journey into the world of precision cutting with a beam of powerful laser light.

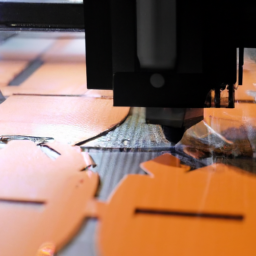

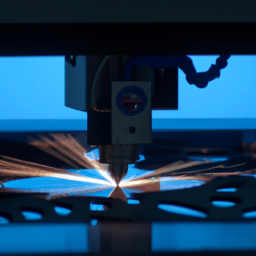

Subtractive laser cutting applications are vast and varied, ranging from industrial manufacturing to small-scale hobby projects. The process involves directing a laser beam onto a material, which melts or vaporizes it, resulting in intricate and precise cuts.

One of the major benefits of subtractive laser cutting is its ability to cut through a wide range of materials, including wood, metal, plastic, and fabric. However, it’s important to note that while subtractive laser cutting offers high precision and versatility, it may not be the most cost-effective option for every project.

That’s where exploring router cutting comes in, offering a different approach to cutting materials.

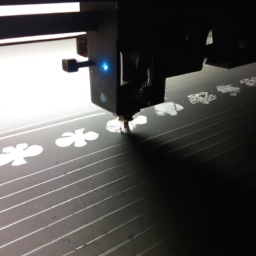

Exploring Router Cutting

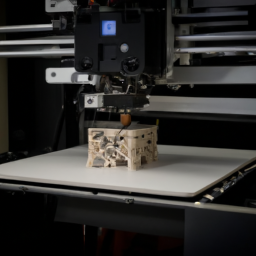

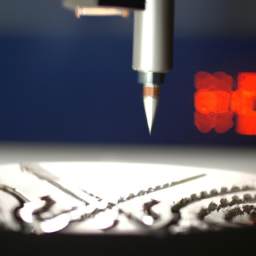

If you’re curious about router cutting, let’s dive into how it works and what materials are suitable for this method. Router cutting involves using a rotating cutting tool to carve out or shape materials like wood, plastic, or metal. It offers a versatile and precise cutting technique, but it may not be as efficient for thick or hard materials compared to other methods.

How it Works

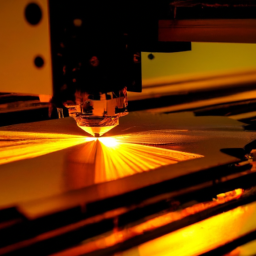

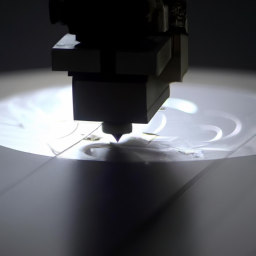

By harnessing the power of laser beams or router blades, these cutting methods skillfully sculpt materials into intricate designs. Whether you choose subtractive laser cutting or router cutting, each technique offers its own advantages and applications. Here are five key points to consider:

- Laser cutting provides high precision and accuracy, making it ideal for intricate and delicate designs.

- Router cutting offers versatility, allowing for the creation of three-dimensional shapes and patterns.

- Both methods can be used on a wide range of materials, including wood, acrylic, metal, and foam.

- Laser cutting is commonly used in industries such as signage, jewelry making, and electronics manufacturing.

- Router cutting is often utilized in woodworking, cabinetry, and architectural applications.

Understanding the capabilities and strengths of each technique can help you determine the most suitable method for your project.

Now, let’s explore the materials suitable for router cutting.

Materials Suitable for Router Cutting

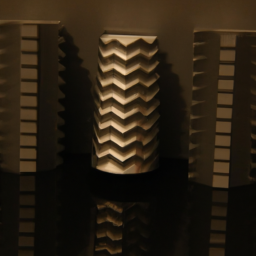

Utilizing router cutting techniques allows for the creation of intricate three-dimensional shapes and patterns on a diverse range of materials.

Woodworking materials such as plywood, MDF, and solid wood can be easily cut using a router, making it an ideal choice for creating intricate designs in furniture, cabinetry, and decorative items.

The router can also handle plastic materials like acrylic and PVC, enabling the production of custom signage, display cases, and prototypes.

It offers precise control and the ability to cut through thick materials, making it a versatile option for various projects.

However, before deciding on router cutting, it’s important to consider the pros and cons of this method compared to subtractive laser cutting.

Pros and Cons

One advantage of router cutting is its ability to create intricate designs on a wide range of materials, but there are also drawbacks to consider. Pros of router cutting include its versatility, as it can work with materials like wood, plastic, and metal. It also allows for the creation of complex shapes and details, making it ideal for customized projects. Additionally, router cutting offers a high level of precision and accuracy, ensuring clean and smooth cuts.

However, there are cons to consider as well. Factors such as the time it takes to set up and calibrate the router, as well as the noise and dust generated during the cutting process, may impact efficiency and overall cost-effectiveness. Transitioning to the subsequent section about ‘cost comparison’, it’s important to evaluate these factors when comparing router cutting to subtractive laser cutting.

Cost Comparison

Save money by comparing the cost-effectiveness of subtractive laser cutting and router cutting. When it comes to cost effectiveness, a comparison analysis is crucial.

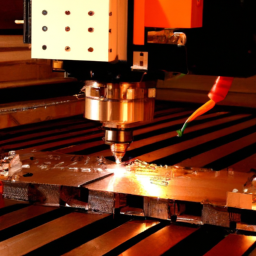

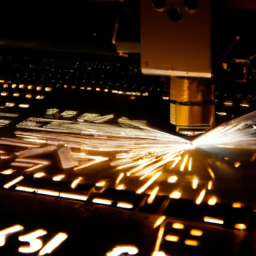

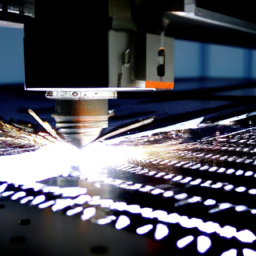

Subtractive laser cutting involves using a laser to remove material and create precise cuts, while router cutting uses a rotating bit to remove material.

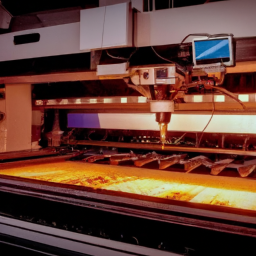

In terms of initial cost, subtractive laser cutting machines tend to be more expensive than routers. However, laser cutting can be more cost-effective in the long run due to lower operating costs and higher cutting speeds.

Additionally, laser cutting produces cleaner and more precise cuts, reducing the need for post-processing and saving on labor costs.

Consider these factors when deciding which method is more cost-effective for your specific needs.

Factors to Consider

Now that you have a clear cost comparison between subtractive laser cutting and router cutting, let’s delve into the factors you should consider when deciding which method is more cost-effective for your specific needs.

When it comes to cost effectiveness, it’s crucial to evaluate the efficiency comparison between these two technologies. Consider factors such as material waste, production time, and maintenance costs.

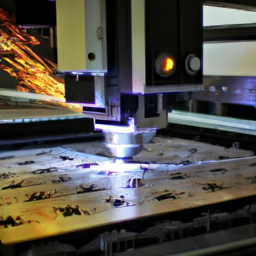

Subtractive laser cutting offers high precision and minimal material waste, making it a cost-effective choice for intricate designs. On the other hand, router cutting may be more efficient for larger projects that require faster production speed.

By carefully analyzing these factors, you can make an informed decision that aligns with your budget and production requirements.

Now, let’s move on to the next section and explore some case studies to further illustrate the benefits of each method.

Case Studies

In this discussion, you’ll explore success stories with subtractive laser cutting and router cutting. You’ll learn about real-life examples where these cutting methods have been used effectively. Discover how businesses have utilized subtractive laser cutting and router cutting to achieve their goals and overcome challenges.

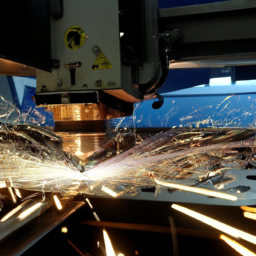

Success Stories with Subtractive Laser Cutting

Imagine how your business could thrive with subtractive laser cutting as you see precise and intricate designs effortlessly come to life before your eyes. With success stories like these, it’s clear why subtractive laser cutting is the preferred choice for many businesses:

-

Customized signage: Witness your logo and brand message beautifully etched onto various materials, capturing attention and leaving a lasting impression on potential customers.

-

Intricate jewelry: Watch as delicate patterns and intricate details are flawlessly carved into precious metals, creating stunning pieces that customers will cherish forever.

-

Architectural models: Experience the transformation of your architectural designs into breathtaking physical models, showcasing every intricate detail with impeccable precision.

-

Prototyping: See your product ideas materialize into tangible prototypes, allowing you to test and refine your designs quickly and cost-effectively.

As you explore the success stories with subtractive laser cutting, get ready to be inspired by the possibilities. But now, let’s move on to success stories with router cutting.

Success Stories with Router Cutting

Get ready to be amazed by the incredible success stories that businesses like yours have achieved with router cutting. Witness intricate designs effortlessly come to life and open up a world of possibilities for your products.

Router cutting applications have proven to be highly versatile. They allow businesses to create intricate shapes, patterns, and engravings on a wide range of materials such as wood, plastic, and metal.

With router cutting, you can achieve precise cuts and intricate details that would be difficult or time-consuming to achieve with other methods. One of the key advantages of router cutting is its ability to handle thicker materials, making it ideal for projects that require durability and strength.

Whether you need to create custom signs, decorative panels, or prototypes, router cutting provides the precision and versatility to bring your ideas to life and propel your business forward.

Frequently Asked Questions

What is the maximum thickness of material that can be cut using subtractive laser cutting?

The maximum thickness of material that can be cut using subtractive laser cutting depends on the specific laser cutting machine being used. However, in general, subtractive laser cutting has the advantage of being able to cut through thicker materials compared to router cutting.

When choosing between the two methods, factors to consider include the desired level of precision, the complexity of the design, and the material being cut.

Are there any limitations to the shapes that can be achieved through router cutting?

There are some limitations to the shapes that can be achieved through router cutting. Router cutting is generally better suited for simpler, geometric shapes, as it relies on a spinning bit to remove material.

Intricate or complex shapes may be more difficult to achieve with this method. On the other hand, subtractive laser cutting offers more flexibility in terms of shapes, as it uses a laser beam to precisely cut through materials. This advantage makes subtractive laser cutting a preferred choice for intricate and complex shapes.

Can both subtractive laser cutting and router cutting be used on the same material?

Although using both subtractive laser cutting and router cutting on the same material may seem like mixing oil and water, it can actually offer a range of advantages. By combining the precision of subtractive laser cutting with the versatility of router cutting, you can achieve intricate designs with high accuracy.

This hybrid approach allows for greater flexibility in creating complex shapes and patterns, giving you the best of both worlds when it comes to precision and accuracy.

Are there any safety precautions that need to be taken when using subtractive laser cutting?

When using subtractive laser cutting, there are important safety precautions you need to take.

First, always wear protective goggles to shield your eyes from the intense laser beam.

Additionally, make sure to keep flammable materials away from the laser cutter to prevent any accidents.

Moreover, it’s crucial to have proper ventilation in the workspace to minimize the risk of inhaling harmful fumes.

Lastly, it’s important to note that the maximum thickness for subtractive laser cutting is typically around 0.5 inches.

How do the maintenance requirements for laser cutting machines compare to those of router cutting machines?

Maintenance requirements for laser cutting machines and router cutting machines differ significantly. Laser cutting machines require regular inspections and cleaning of the laser source, optics, and cooling system. Additionally, the mirrors and lenses need frequent alignment.

On the other hand, router cutting machines need routine maintenance such as lubrication of bearings and screws, and occasional replacement of cutting tools.

When comparing costs, laser cutting machines generally have higher initial costs but lower maintenance costs compared to router cutting machines.

Conclusion

So there you have it, my friend. After diving deep into the world of subtractive laser cutting and router cutting, we’ve come to the thrilling conclusion: it all comes down to cost-effectiveness.

While both methods have their merits, the laser cutting steals the show with its precise and efficient performance. But hey, don’t count out the router cutting just yet. It may not be as flashy, but it can still get the job done.

So weigh your options, my savvy reader, and choose wisely. Your budget will thank you.