Are you tired of cutting materials with outdated, slow methods? Well, get ready to blast into the future with a cutting-edge battle of efficiency!

In one corner, we have the sleek and precise subtractive laser cutting, while in the other corner, the powerful and versatile ultrasonic cutting stands tall. These two titans of technology are about to go head-to-head to determine which method reigns supreme.

Picture this: lasers slicing through materials like a hot knife through butter, or ultrasonic vibrations delicately separating layers with surgical precision. But which method will come out on top?

In this article, we will delve into the world of subtractive laser cutting versus ultrasonic cutting, comparing their speed, accuracy, and versatility. Buckle up, because this showdown is about to revolutionize the way you think about cutting materials.

Key Takeaways

- Subtractive laser cutting uses a high-powered laser beam to vaporize or melt materials, while ultrasonic cutting employs high-frequency vibrations to slice through materials.

- Subtractive laser cutting is mainly used for wood, metal, acrylic, and paper, while ultrasonic cutting is more versatile and can work with textiles, rubber, plastics, and food products.

- Subtractive laser cutting produces heat-affected zones that may affect material properties, while ultrasonic cutting leaves a smooth edge without burrs or fraying, reducing the risk of material damage.

- Ultrasonic cutting is faster than subtractive laser cutting and offers remarkable accuracy with clean edges, but it may not be as efficient for thicker materials and is not suitable for heat-sensitive or brittle materials.

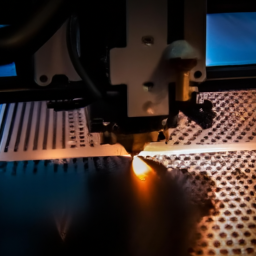

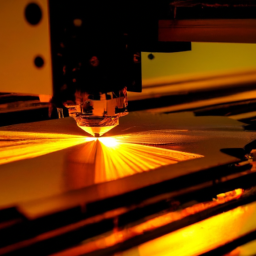

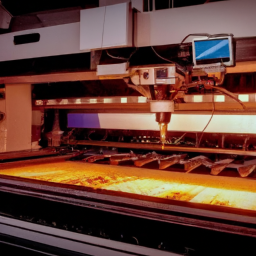

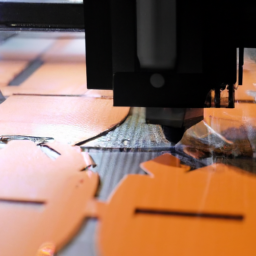

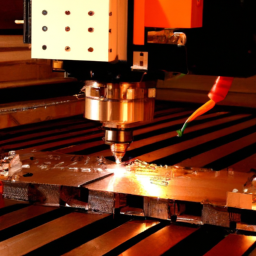

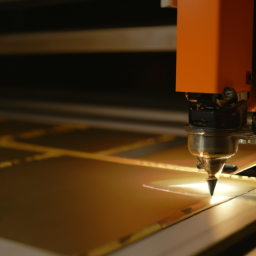

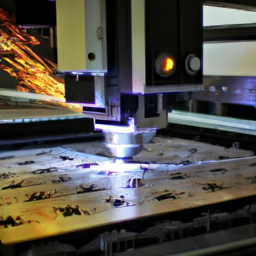

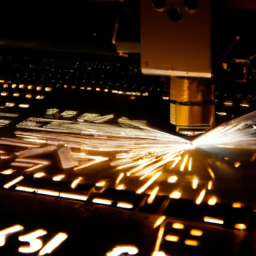

Overview of Subtractive Laser Cutting

You’ll be amazed at how quickly and precisely subtractive laser cutting can effortlessly slice through materials, leaving you in awe of its incredible efficiency. This cutting method utilizes a high-powered laser beam to vaporize or melt the material, resulting in clean and precise cuts.

One of the main advantages of subtractive laser cutting is its ability to work with a wide range of materials, including metals, plastics, and wood. Additionally, it allows for intricate designs and precise cuts, making it a popular choice in industries such as manufacturing, automotive, and aerospace. However, there are also limitations to consider.

Subtractive laser cutting can produce heat-affected zones, which may affect the material’s properties. Moreover, the initial investment and maintenance costs can be high.

In contrast, let’s now delve into the overview of ultrasonic cutting.

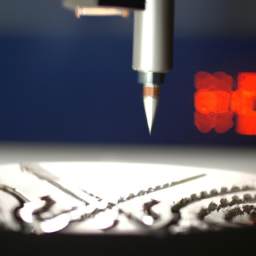

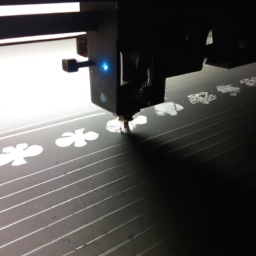

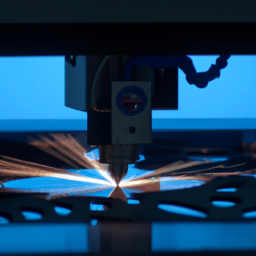

Overview of Ultrasonic Cutting

Ironically, ultrasonic cutting employs high-frequency vibrations to effortlessly slice through materials. This innovative cutting method offers several advantages over traditional methods.

Firstly, ultrasonic cutting produces clean and precise cuts, resulting in minimal material wastage. Additionally, it is highly versatile and can be used on a wide range of materials, including plastics, rubber, and fabrics. This makes it ideal for various applications such as automotive, aerospace, and textile industries.

Ultrasonic cutting also eliminates the need for additional finishing processes, as it leaves a smooth edge without any burrs or fraying. Moreover, it is a non-contact cutting method, which means that it does not exert any pressure on the material, reducing the risk of damage.

As we move on to the speed comparison, you’ll see how ultrasonic cutting stacks up against subtractive laser cutting.

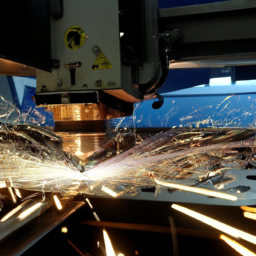

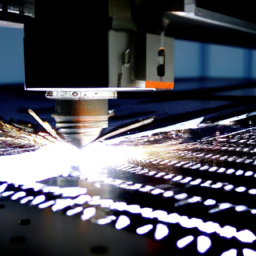

Speed Comparison

Surprisingly, when it comes to speed, the difference between subtractive laser cutting and ultrasonic cutting is truly remarkable.

Ultrasonic cutting is known for its incredibly fast cutting speed, making it a preferred choice for many applications. Its high-frequency vibrations allow for precise and rapid cutting, resulting in increased efficiency and productivity.

On the other hand, subtractive laser cutting also offers high speed, but it may not match the speed of ultrasonic cutting. However, it’s important to note that the speed of both methods can vary depending on the specific application and material being cut.

Moving forward to the accuracy comparison, it’s worth exploring how these two methods differ in terms of precision and cutting quality.

Accuracy Comparison

For the utmost precision and flawless cutting quality, nothing compares to the remarkable accuracy of ultrasonic cutting. This cutting method utilizes high-frequency vibrations to create incredibly precise cuts with clean edges. On the other hand, subtractive laser cutting also offers some advantages in terms of accuracy. It uses a laser beam to cut through materials with great precision, allowing for intricate and detailed designs. However, there are some drawbacks to consider when it comes to ultrasonic cutting. The main disadvantage is that it is not suitable for all materials, particularly those that are heat-sensitive or brittle. Additionally, ultrasonic cutting may not be as efficient when cutting through thicker materials. Nevertheless, when it comes to accuracy, ultrasonic cutting reigns supreme. Moving on to the next section about versatility comparison…

Versatility Comparison

In terms of versatility, ultrasonic cutting outshines its laser counterpart, offering a wider range of applications and materials it can work with.

Ultrasonic cutting has several advantages over subtractive laser cutting when it comes to versatility. One of the main advantages is that ultrasonic cutting can work with a variety of materials, including textiles, rubber, plastics, and even food products. This makes it a preferred choice in industries such as textile manufacturing, packaging, and food processing.

On the other hand, subtractive laser cutting is more limited in its range of applications and materials. It’s mainly used for cutting and engraving materials such as wood, metal, acrylic, and paper. While laser cutting is highly precise and efficient in these specific applications, it lacks the versatility of ultrasonic cutting.

Frequently Asked Questions

Are there any specific safety precautions that need to be taken when using subtractive laser cutting or ultrasonic cutting?

When using subtractive laser cutting or ultrasonic cutting, there are important safety precautions to consider. For subtractive laser cutting, wear protective eyewear to shield your eyes from the intense laser beam. It’s also crucial to ensure proper ventilation to minimize the inhalation of fumes and particles.

When using ultrasonic cutting, be cautious of the sharp blade and avoid placing your fingers near the cutting area. Additionally, always follow the manufacturer’s guidelines for safe usage.

Comparing the precision of subtractive laser cutting and ultrasonic cutting, both methods offer high precision. Subtractive laser cutting uses a focused laser beam to accurately cut through materials, while ultrasonic cutting utilizes high-frequency vibrations for precise cutting.

The choice between the two methods depends on the specific requirements of the project and the materials being cut.

Can subtractive laser cutting or ultrasonic cutting be used on all types of materials?

Subtractive laser cutting and ultrasonic cutting are like chefs with different knives. They each have their advantages and disadvantages when it comes to working with different materials.

Subtractive laser cutting is great for precise and accurate cuts on materials like wood, acrylic, and metal.

On the other hand, ultrasonic cutting is more suitable for delicate materials like fabrics and foams.

So, depending on the type of material you’re working with, one method may be more efficient than the other.

What are the main factors that can affect the speed and efficiency of subtractive laser cutting or ultrasonic cutting?

Factors affecting cutting efficiency include the type of material being cut, the power and speed settings of the cutting device, and the design of the cutting tool. The comparison of cutting capabilities between subtractive laser cutting and ultrasonic cutting depends on these factors.

The efficiency of each method is influenced by how well they can adapt to different materials, their precision in cutting, and the speed at which they can complete the cutting process.

Are there any limitations in terms of the size or thickness of materials that can be cut using subtractive laser cutting or ultrasonic cutting?

When it comes to size limitations, subtractive laser cutting and ultrasonic cutting have different capabilities.

Subtractive laser cutting is highly versatile and can handle a wide range of materials, including metals, plastics, and woods. However, it may struggle with extremely thick materials.

On the other hand, ultrasonic cutting excels with thicker materials but may have difficulty with very large pieces.

Both techniques have their strengths, so it’s important to consider the specific requirements of your project.

How do the costs of equipment and maintenance compare between subtractive laser cutting and ultrasonic cutting?

When comparing the initial investment and long-term maintenance between subtractive laser cutting and ultrasonic cutting, it’s important to consider the costs.

Subtractive laser cutting equipment tends to have a higher initial investment compared to ultrasonic cutting equipment. Additionally, laser cutting machines require regular maintenance and replacement of components, which can increase long-term costs.

On the other hand, ultrasonic cutting equipment requires less maintenance and has lower long-term costs.

Moreover, it’s worth analyzing the environmental impacts of both methods to make an informed decision.

Conclusion

So, when it comes to efficiency, both subtractive laser cutting and ultrasonic cutting have their advantages. Subtractive laser cutting is incredibly fast, making it ideal for high-volume production. On the other hand, ultrasonic cutting offers unparalleled accuracy, making it perfect for intricate designs. However, in terms of versatility, subtractive laser cutting takes the lead, as it can cut through a wide range of materials.

Overall, the choice between the two techniques depends on the specific needs of your project. For example, a company specializing in jewelry might opt for ultrasonic cutting to create delicate and precise pieces.