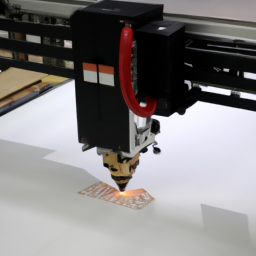

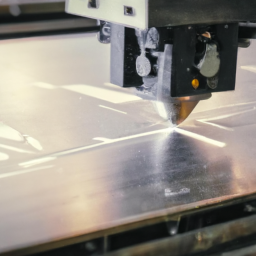

Are you tired of struggling with traditional cutting methods that limit your ability to create complex shapes and designs? Look no further than 3D laser cutting, the revolutionary technique that is transforming industrial applications.

By harnessing the power of lasers, this cutting-edge technology offers a multitude of benefits that will enhance your efficiency, productivity, and overall operations.

Picture this: while conventional cutting methods may leave you frustrated with their limitations, 3D laser cutting opens up a world of possibilities. With its precision and accuracy, you can effortlessly cut through even the most intricate designs, giving you the freedom to explore new dimensions in your work.

But it doesn’t stop there. 3D laser cutting also brings increased efficiency to the table. With its rapid cutting speed and minimal downtime, you can complete projects in record time, boosting your productivity and staying ahead of the competition.

Moreover, this technology is incredibly versatile. It can effortlessly cut through a wide range of materials and thicknesses, giving you the flexibility to work with various substrates without compromising on quality.

And let’s not forget about the cost-effectiveness and reduced waste. With 3D laser cutting, you can say goodbye to expensive tooling and the need for multiple setups. This translates to significant savings and a more sustainable approach to manufacturing.

Safety is paramount in any industrial setting, and 3D laser cutting does not disappoint. With its state-of-the-art safety features, you can have peace of mind knowing that your operators and equipment are protected at all times.

Last but not least, the potential for customization and personalization is unparalleled with 3D laser cutting. Whether you need to create unique prototypes or mass-produce customized products, this technology has got you covered.

In conclusion, 3D laser cutting is the game-changer you’ve been waiting for. With its precision, efficiency, versatility, cost-effectiveness, safety features, and customization potential, it is revolutionizing industrial applications. So why settle for less when you can elevate your work to new heights with 3D laser cutting? The possibilities are endless, and the benefits are undeniable.

Key Takeaways

- Increased efficiency and productivity with rapid cutting speed and minimal downtime.

- Versatility to cut through a wide range of materials and thicknesses.

- Cost-effective solution that reduces waste and eliminates the need for expensive tooling and multiple setups.

- Enhanced safety features that prioritize workplace safety and reduce the risk of injuries.

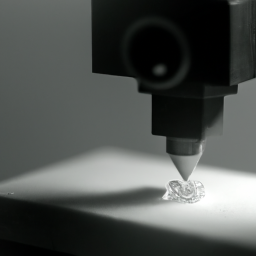

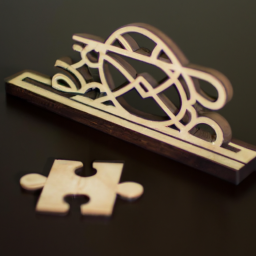

Precision Cutting for Complex Shapes and Designs

You’ll be amazed at how 3D laser cutting can precisely cut even the most intricate shapes and designs for your industrial needs. With its high precision capabilities, this cutting-edge technology allows for intricate detailing that was once impossible.

Whether it’s complex geometries or delicate patterns, 3D laser cutting can handle it all with exceptional accuracy. By using a focused laser beam, it can precisely melt or vaporize the material, resulting in clean and precise cuts. This level of precision ensures that your industrial components are manufactured to the highest standards, reducing the need for additional finishing processes.

As a result, you can expect increased efficiency and productivity in your operations. With the ability to create intricate shapes effortlessly, 3D laser cutting sets the stage for the subsequent section on increased efficiency and productivity.

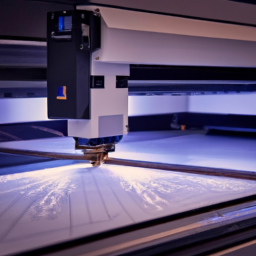

Increased Efficiency and Productivity

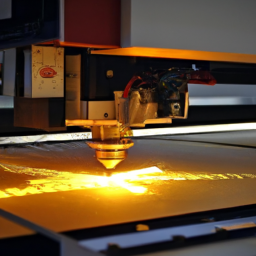

By harnessing the power of 3D laser cutting, businesses can experience a significant boost in their operational efficiency, allowing them to complete tasks quicker and more effectively. This cutting-edge technology enables improved production output by providing precise and accurate cuts, reducing the need for manual adjustments and minimizing material waste.

The streamlined manufacturing processes achieved through 3D laser cutting eliminate the need for multiple tools and equipment, simplifying the workflow and reducing production time. With the ability to cut through a variety of materials with varying thicknesses, businesses can optimize their manufacturing operations and meet the demands of diverse projects.

The versatility of 3D laser cutting technology not only improves efficiency but also opens up new possibilities for innovation and design.

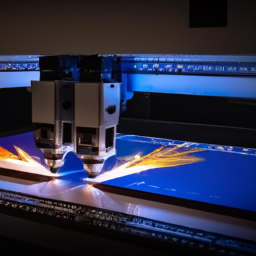

Versatility in Materials and Thicknesses

With its ability to effortlessly handle a wide range of materials and thicknesses, 3D laser cutting technology revolutionizes manufacturing processes and allows for endless possibilities in design and innovation. This versatility translates into reduced downtime and improved product quality, making it an invaluable tool for industrial applications.

Here are four key benefits of 3D laser cutting in terms of materials and thicknesses:

-

Adaptability: 3D laser cutting can easily handle materials such as steel, aluminum, plastic, wood, and even composites, providing flexibility in manufacturing various products.

-

Precision: The technology ensures precise cutting, even with complex designs and intricate patterns, resulting in high-quality end products.

-

Thickness range: Whether it’s thin sheets or thick plates, 3D laser cutting can seamlessly cut through different thicknesses, eliminating the need for multiple tools or processes.

-

Minimal distortion: The precise laser beam minimizes heat-affected zones, reducing distortion and ensuring dimensional accuracy.

This versatility in materials and thicknesses makes 3D laser cutting a cost-effective solution that significantly reduces waste.

Cost-Effectiveness and Reduced Waste

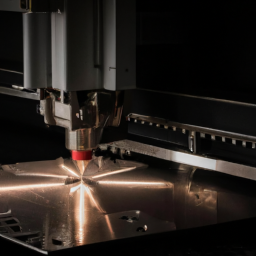

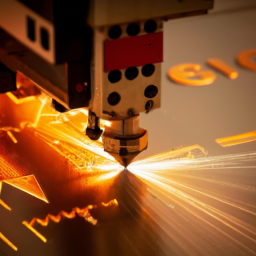

The cost-effectiveness and waste reduction of 3D laser cutting make it a highly advantageous solution in manufacturing processes. By using laser cutting technology, companies can significantly reduce their production costs and minimize material waste.

Traditional cutting methods often result in excess material being discarded, leading to higher costs and environmental impact. However, with 3D laser cutting, the precision and accuracy of the laser allow for optimal material utilization, minimizing waste and maximizing efficiency. This not only benefits the company’s bottom line but also contributes to sustainability efforts by reducing the consumption of resources.

Additionally, the improved product quality achieved through 3D laser cutting ensures that the end products meet the highest standards. The sustainability benefits and improved product quality make 3D laser cutting an attractive choice for industrial applications. Furthermore, the incorporation of enhanced safety features in this technology further enhances its appeal.

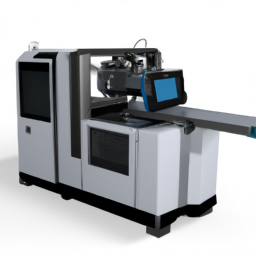

Enhanced Safety Features

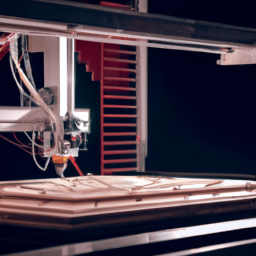

One intriguing theory suggests that incorporating enhanced safety features in 3D laser cutting technology could revolutionize manufacturing processes. By implementing improved work environment protocols and reducing risk factors, this advancement has the potential to significantly enhance workplace safety.

With the integration of sensors and advanced software, 3D laser cutting machines can detect potential hazards and automatically adjust their operations to prevent accidents. Additionally, these machines can be equipped with safety shields and emergency stop buttons, providing workers with added protection. This not only reduces the risk of injuries but also increases overall productivity by minimizing downtime caused by accidents.

Furthermore, by creating a safer work environment, companies can attract and retain skilled workers who value their wellbeing. Consequently, the incorporation of enhanced safety features in 3D laser cutting technology paves the way for the subsequent section on the potential for customization and personalization.

Potential for Customization and Personalization

Now that we have explored the enhanced safety features of 3D laser cutting, let’s dive into the potential for customization and personalization that this technology offers. With 3D laser cutting, manufacturers can create customized products that meet the specific needs and preferences of their customers. This level of customization allows for a more personalized manufacturing process, resulting in products that are tailored to individual requirements. To illustrate the significance of this capability, consider the following table:

| Customization Options | Benefits |

|---|---|

| Unique designs | Increased customer satisfaction |

| Personalized sizes | Improved product functionality |

| Customized materials | Enhanced product aesthetics |

| Tailored features | Better product performance |

As you can see, the possibilities for customization and personalization with 3D laser cutting are vast, providing unparalleled opportunities for manufacturers to meet the diverse demands of their customers.

Frequently Asked Questions

How does 3D laser cutting compare to traditional cutting methods in terms of precision and accuracy?

When comparing 3D laser cutting to traditional cutting methods in terms of precision and accuracy, it offers significant advantages.

The cost effectiveness of 3D laser cutting is evident as it eliminates the need for expensive tooling and reduces material waste.

Additionally, the time-saving benefits of using this technology are remarkable, as it allows for faster and more efficient cutting processes.

With its precise and accurate results, 3D laser cutting proves to be a superior choice for industrial applications.

Can 3D laser cutting be used on materials other than metals?

Advantages of 3D laser cutting on non-metal materials are numerous.nnDid you know that 3D laser cutting can achieve an accuracy of up to 0.1 mm?nnThis precision is crucial when working with delicate materials.nnAdditionally, 3D laser cutting allows for intricate designs and complex shapes to be cut with ease.nnApplications of 3D laser cutting on non-metal materials range from fabric cutting in the textile industry to precise cutting of acrylic for artistic purposes.

Are there any limitations to the thickness of materials that can be cut using 3D laser cutting?

Thickness limitations for 3D laser cutting are an important consideration in industrial applications. While 3D laser cutting offers many advantages, such as high precision and efficiency, it does have limitations when it comes to cutting thick materials. The maximum thickness that can be effectively cut using this method varies depending on the specific laser system and material being cut.

It is crucial to carefully assess the thickness requirements of your project to ensure successful results with 3D laser cutting.

What safety precautions should be taken when operating a 3D laser cutting machine?

When operating a 3D laser cutting machine, it’s crucial to follow strict safety measures to ensure the well-being of operators and prevent accidents. Proper training and understanding of the machine’s operation are essential. Safety glasses should be worn to protect the eyes from laser radiation, and operators should avoid direct exposure to the laser beam.

Clear and marked work areas, emergency stop buttons, and regular maintenance checks are also necessary to maintain a safe working environment during machine operation.

Is it possible to integrate 3D laser cutting technology into existing manufacturing processes?

Integrating 3D laser cutting technology in existing manufacturing processes is indeed possible. By incorporating this advanced technology, you can enhance efficiency and precision in your operations.

With its ability to cut complex shapes and materials, 3D laser cutting offers a versatile solution for various industries. By seamlessly integrating this technology into your manufacturing processes, you can streamline production, reduce material waste, and achieve higher levels of accuracy.

Embracing this cutting-edge technology will pave the way for a more efficient and productive future.

Conclusion

In conclusion, the benefits of 3D laser cutting for industrial applications are truly remarkable. You’ve witnessed how this technology offers precision cutting for complex shapes and designs, resulting in increased efficiency and productivity.

The versatility it offers in terms of materials and thicknesses is akin to a chameleon adapting to different environments effortlessly. Moreover, the cost-effectiveness and reduced waste it brings to the table are like a well-oiled machine, optimizing resources.

With enhanced safety features, this technology ensures a secure working environment. Lastly, the potential for customization and personalization is like a painter’s palette, allowing for endless possibilities.

Embrace the power of 3D laser cutting and revolutionize your industrial processes.