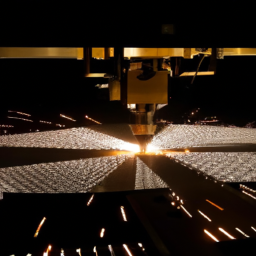

Are you tired of wasting time, money, and effort on outdated metal fabrication techniques that just don’t cut it? Well, it’s time to illuminate your manufacturing process with the revolutionary power of laser cutting.

Picture this: a world where precision and accuracy are no longer distant dreams, but everyday realities. Laser cutting for metal fabrication structural components offers a level of precision that will leave you in awe. With its versatility in design, you can let your creativity soar as you craft intricate and complex shapes with ease.

And the best part? Say goodbye to the excessive heat that traditional methods generate. Laser cutting minimizes heat transfer, ensuring that your materials stay cool and unaffected.

But that’s not all – laser cutting also boosts efficiency and productivity, allowing you to meet deadlines and exceed expectations. And with its cost-effectiveness and ability to deliver high-quality finished products, laser cutting is truly a game-changer in the world of metal fabrication.

So, why settle for less when you can embrace the brilliance of laser cutting?

Key Takeaways

- Laser cutting revolutionizes metal fabrication with precision and accuracy.

- Laser cutting boosts efficiency and productivity in metal fabrication.

- Laser cutting reduces material waste and improves turnaround time.

- Laser cutting provides a superior level of precision.

Precision and Accuracy

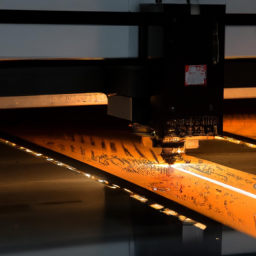

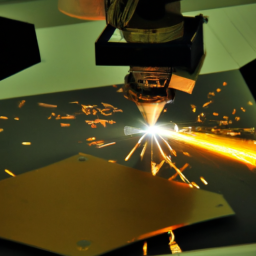

When it comes to precision and accuracy, laser cutting is the ultimate game-changer for metal fabrication structural components. The improved cutting speed achieved through laser technology allows for precise and intricate cuts, ensuring that every piece is shaped to perfection. With laser cutting, there is minimal room for error, resulting in precise measurements and clean edges.

This level of precision not only enhances the overall quality of the structural components but also reduces the need for additional finishing work. Additionally, laser cutting reduces material waste by maximizing the utilization of the metal sheet, as the laser beam can be programmed to cut with minimal gaps between parts. This efficient use of material not only saves costs but also promotes sustainability in the fabrication process.

Moreover, laser cutting’s precision and accuracy provide a seamless transition into the subsequent section about the versatility in design.

Versatility in Design

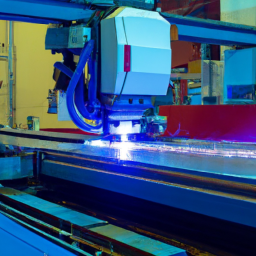

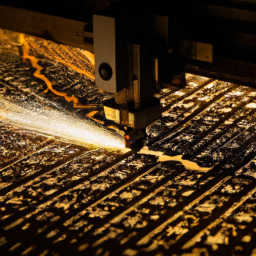

Incorporating laser technology allows for greater freedom in creating intricate and customized designs for various applications. Laser cutting provides a wide range of customization options, enabling the fabrication of complex shapes that would be difficult or impossible to achieve with traditional cutting methods.

With laser cutting, you can easily create intricate patterns, detailed lettering, and complex geometries, giving your metal components a unique and personalized touch. This versatility in design opens up endless possibilities for architects, artists, and engineers to explore and push the boundaries of what is possible in metal fabrication.

Furthermore, laser cutting ensures precision and accuracy, guaranteeing that every cut is consistent and flawless. This seamless transition into the next section about ‘minimal heat generation’ highlights another significant advantage of laser cutting technology.

Minimal Heat Generation

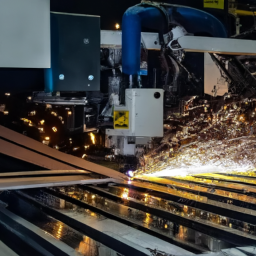

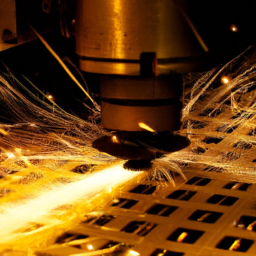

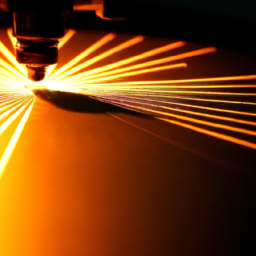

Maximizing efficiency in your designs, laser technology allows for precise and flawless cuts that maintain the integrity of your materials. Laser cutting for metal fabrication structural components offers the advantage of low environmental impact by significantly reducing heat-related emissions.

The process involves the use of a highly focused laser beam that melts the material, leaving a narrow kerf and minimal heat-affected zone. This results in reduced material waste as there’s no need for additional trimming or finishing. The minimal heat generated during laser cutting prevents distortion, warping, and discoloration of the metal, ensuring high-quality, dimensionally accurate components.

Moreover, the absence of heat-related issues allows for faster cutting speeds and increased efficiency in the production process.

Transitioning into the next section, the increased efficiency and productivity of laser cutting make it the ideal choice for metal fabrication applications.

Increased Efficiency and Productivity

Looking to increase your productivity and efficiency? How can laser technology revolutionize your metal fabrication process?

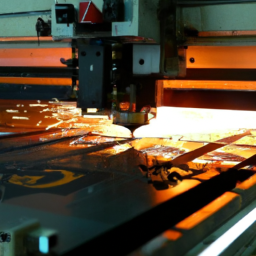

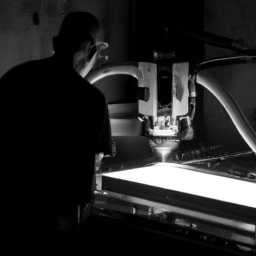

Laser cutting offers numerous benefits, including reduced material waste and improved turnaround time. With laser cutting, the precision and accuracy of the cuts result in minimal material waste, allowing you to optimize the use of your raw materials. This not only reduces costs but also contributes to a more sustainable approach to metal fabrication.

Additionally, laser cutting enables increased efficiency by significantly reducing the time required for cutting and shaping metal components. The laser beam is capable of cutting through various thicknesses and types of metals with ease, resulting in a faster turnaround time for your projects.

By incorporating laser cutting into your metal fabrication process, you can enhance productivity and streamline your operations. Transitioning to the next section, laser cutting also offers significant cost-effectiveness.

Cost-effectiveness

Save money and increase profitability by utilizing laser technology in your metal fabrication process, as it offers a cost-effective solution that maximizes efficiency and minimizes waste.

Laser cutting for metal fabrication provides significant cost savings and an economic advantage for manufacturers. The precision and accuracy of laser cutting reduce material waste, as it allows for intricate and complex designs to be cut with minimal kerf width.

Additionally, laser cutting eliminates the need for secondary operations such as drilling or punching, further reducing costs. The speed of laser cutting also contributes to its cost-effectiveness, as it allows for faster production times and higher throughput.

By implementing laser cutting technology, you can achieve cost savings while maintaining high-quality finished products.

High-Quality Finished Products

Producing metal parts with laser technology ensures a superior level of precision, resulting in a remarkably low defect rate of less than 1%. This guarantees customers receive exceptionally high-quality finished products.

Laser cutting allows for customizable designs, enabling manufacturers to create intricate and complex shapes with ease. This level of precision ensures that each component fits perfectly, reducing the need for additional modifications or adjustments.

Additionally, laser cutting minimizes material waste by optimizing the use of raw materials. The laser beam melts or vaporizes the metal, allowing for precise cuts and reducing the amount of material that is wasted during the fabrication process. As a result, manufacturers can maximize their efficiency and reduce costs associated with material waste.

Overall, laser cutting offers a cost-effective solution that delivers high-quality finished products while minimizing material waste.

Frequently Asked Questions

Can laser cutting be used for materials other than metal in structural component fabrication?

Yes, laser cutting can be used for materials other than metal in structural component fabrication. Non-metal materials such as wood, acrylic, plastic, and even textiles can be cut precisely and accurately using laser cutting technology. The advantages of laser cutting in structural component fabrication include high precision, clean cuts, minimal material wastage, and the ability to create intricate designs. Laser cutting also offers faster production times and is highly efficient, making it an ideal choice for various materials.

How does laser cutting compare to other cutting methods in terms of precision and accuracy?

Precision and accuracy are critical in structural component fabrication, and laser cutting excels in these areas when compared to traditional cutting methods. Laser cutting offers unparalleled precision, thanks to its focused beam of light that can accurately cut intricate shapes with minimal material waste. This method ensures consistent results, even with complex designs.

Laser cutting also eliminates the need for secondary processes like deburring, further enhancing accuracy. As the adage goes, "Measure twice, cut once," laser cutting delivers precise and accurate cuts every time.

Are there any limitations to the complexity of designs that can be achieved through laser cutting?

When it comes to laser cutting, there are certain limitations to the complexity of designs that can be achieved. While laser cutting is highly precise and accurate, intricate and complex designs may pose challenges.

However, laser cutting still offers numerous benefits for complex designs. Its ability to create intricate shapes and patterns with high precision allows for the production of intricate and detailed metal fabrication components. This makes laser cutting an ideal choice for projects that require complex designs.

What are some potential drawbacks or challenges associated with laser cutting in metal fabrication?

When it comes to laser cutting in metal fabrication, there are potential drawbacks and challenges to consider. One limitation is the complexity of designs that can be achieved. Precision comparison is also important, as laser cutting may not always provide the same level of accuracy as other methods.

Material compatibility is another factor, as certain metals may not be suitable for laser cutting. Additionally, scalability can be a challenge, as laser cutting may not be efficient for large-scale production.

Can laser cutting be used for both small-scale and large-scale metal fabrication projects?

Yes, laser cutting can be used for both small-scale and large-scale metal fabrication projects. Laser cutting applications have proven to be highly versatile and effective in various industries, including metal fabrication. The cost effectiveness of laser cutting makes it a preferred choice for both small and large projects. With its precise and detailed cutting capabilities, laser cutting offers efficient and accurate results, regardless of the project size.

Conclusion

In conclusion, laser cutting for metal fabrication structural components offers a multitude of benefits. Its precision and accuracy ensure that every cut is exact, resulting in high-quality finished products.

The versatility in design allows for intricate and complex shapes to be easily achieved. Additionally, the minimal heat generation during the cutting process prevents distortion and warping of the metal.

This, coupled with increased efficiency and productivity, makes laser cutting a cost-effective solution for metal fabrication. So, why settle for anything less when laser cutting can deliver precise results every time?