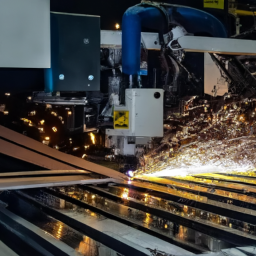

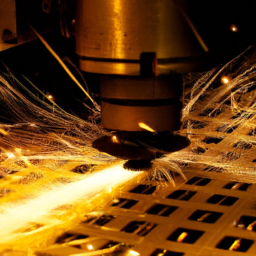

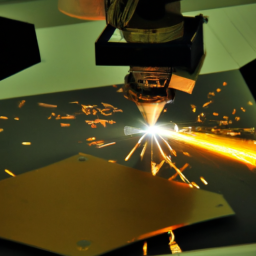

Imagine a precision instrument, capable of slicing through metal with a beam of light, leaving behind a clean, perfect cut. This is the power of laser cutting in metal fabrication. With its high level of precision and accuracy, laser cutting has revolutionized the industry, offering a range of benefits that traditional methods simply cannot match.

When it comes to design, laser cutting provides unparalleled versatility. Its ability to cut intricate shapes and patterns allows for limitless possibilities, giving designers the freedom to create without limitations. And with faster production times, laser cutting allows for increased efficiency and productivity, ensuring projects are completed in a timely manner.

But the benefits don’t stop there. Laser cutting also reduces material waste, making it an environmentally-friendly option. Additionally, it opens up new design possibilities, allowing for customizations and personalizations that were once unimaginable.

When it comes to consistency and quality, laser cutting delivers. With its precise and controlled cutting process, every piece is produced to the highest standards, ensuring a flawless end result.

In this article, we will delve deeper into the benefits of laser cutting in metal fabrication, exploring how it has transformed the industry and why it is a technique worth embracing.

Key Takeaways

- Laser cutting offers unparalleled precision and accuracy, allowing for the cutting of intricate shapes and patterns.

- It reduces material waste by maximizing material usage through nesting and minimizing scrap and offcuts.

- Laser cutting enables faster production times and increased efficiency, eliminating the need for additional finishing processes.

- It enhances design possibilities and expands creative horizons in metal fabrication, allowing for the creation of complex and personalized metal pieces.

Precision and Accuracy

Laser cutting offers unparalleled precision and accuracy, making it the ideal choice for metal fabrication projects. With laser technology, improved efficiency is achieved as the laser beam follows a predetermined path, resulting in precise and clean cuts. The laser’s high energy density allows for the cutting of intricate designs and complex shapes with minimal distortion. This level of precision ensures that each component is manufactured to exact specifications, resulting in high-quality results.

The accuracy of laser cutting eliminates the need for additional finishing processes, saving both time and resources. Furthermore, the laser’s ability to cut through a wide range of materials, including stainless steel, aluminum, and titanium, showcases its versatility in design. This adaptability allows for the creation of intricate and innovative metal fabrications.

Versatility in Design

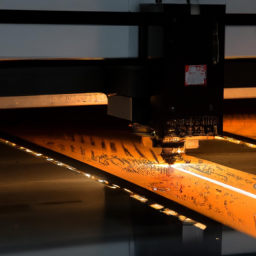

With its ability to bring intricate designs to life, the versatility of laser cutting in metal fabrication is truly remarkable. Laser cutting provides a wide range of customization options, allowing for the creation of complex and intricate patterns that would be difficult to achieve using traditional methods. The precision and accuracy of laser cutting technology ensure that even the most intricate designs can be replicated with ease.

This versatility in design allows for the creation of unique and personalized metal pieces that meet the specific requirements of each project. Laser cutting also offers the flexibility to work with various materials, including stainless steel, aluminum, and brass, further expanding the possibilities for design.

Moreover, the speed and efficiency of laser cutting technology contribute to faster production times, making it an ideal choice for projects that require both precision and efficiency. Transitioning into the subsequent section about ‘faster production times’, laser cutting’s versatility in design sets the foundation for increased productivity and reduced lead times.

Faster Production Times

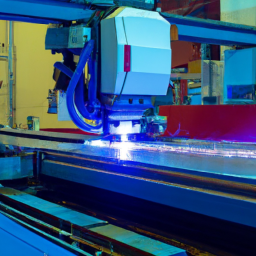

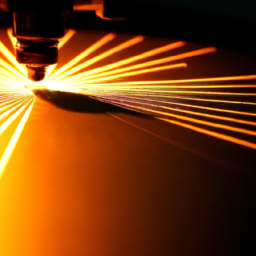

Get ready to experience faster production times and increased efficiency in your metal fabrication projects. Laser cutting technology offers numerous benefits that can significantly improve productivity in the manufacturing process. By utilizing laser cutting machines, you can achieve precise and accurate cuts at a much faster rate compared to traditional cutting methods. This allows you to complete projects in a shorter time frame, ultimately increasing your overall production output.

One of the key advantages of laser cutting is its ability to cut through various types of materials, including metals of different thicknesses. This versatility eliminates the need for multiple tools or processes, saving you time and resources. Additionally, laser cutting is a non-contact process, meaning there is no physical force applied to the material, resulting in reduced material waste. By minimizing the amount of wasted material, you can further enhance your efficiency and optimize your production process.

Reduced Material Waste

When it comes to reducing material waste in metal fabrication, laser cutting is the way to go.

With laser cutting, you can achieve minimal scrap and offcuts, ensuring that you make the most out of every sheet of metal.

This not only helps to save costs but also promotes cost-effective material usage, as laser cutting allows for precise and accurate cuts, minimizing any unnecessary wastage.

Minimal Scrap and Offcuts

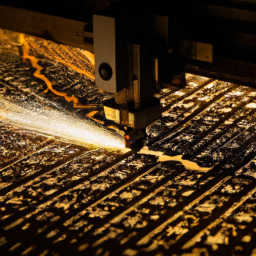

By utilizing laser cutting in metal fabrication, the reduction of scrap and offcuts becomes a seamless process, leaving behind only the purest and most precise end products. The laser cutting process ensures efficient material usage by minimizing the amount of scrap and offcuts generated during the fabrication process.

This is achieved through the precise and controlled nature of laser cutting, which allows for minimal material wastage. Laser cutting technology enables precise and accurate cutting, resulting in minimal scrap and offcuts. The ability of lasers to cut complex shapes and intricate designs reduces the need for additional processing, minimizing material wastage.

Additionally, laser cutting allows for nesting, where multiple parts can be cut from a single sheet of metal, maximizing material usage.

By minimizing scrap and offcuts, laser cutting not only improves the efficiency of material usage but also contributes to cost-effective material usage in metal fabrication.

Cost-Effective Material Usage

Maximizing your material usage is crucial in order to maintain cost-effectiveness in your metal fabrication process. Laser cutting offers efficient production by utilizing optimized resources. The precision of the laser beam allows for minimal wastage, ensuring that you can make the most out of every sheet of metal.

By accurately cutting the desired shapes, laser cutting minimizes scrap and offcuts, reducing the overall material waste. This not only saves you money but also promotes sustainability by reducing the environmental impact of your fabrication process.

In addition, laser cutting allows for nesting, which means the software can optimize the placement of parts on a sheet, further maximizing material usage.

With cost-effective material usage achieved through laser cutting, you can now explore enhanced design possibilities, expanding your creative horizons in metal fabrication.

Enhanced Design Possibilities

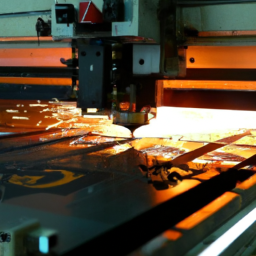

With laser cutting, the realm of design possibilities expands, allowing metal fabrication to dance with creativity, like a ballerina gracefully leaping across the stage. Laser cutting technology enables improved efficiency in metal fabrication by offering precise and accurate cuts, resulting in less material waste.

Complex and intricate detailing can be achieved effortlessly, with intricate patterns, fine engravings, and delicate contours becoming a reality. The high precision and speed of laser cutting also allow for the creation of intricate and complex designs that would be challenging or impossible to achieve with traditional cutting methods.

Laser cutting technology opens up new avenues for designers to explore and push the boundaries of metal fabrication. This enhanced design capability seamlessly transitions into the subsequent section about consistency and quality, as laser cutting ensures unmatched precision and accuracy, resulting in superior and consistent quality in metal fabrication.

Consistency and Quality

Achieving a high level of consistency and quality becomes effortless with the use of laser cutting technology. Laser cutting offers increased productivity and improved efficiency in metal fabrication processes. The precision and accuracy of laser cutting machines ensure that each piece is cut to the exact specifications, eliminating the need for manual adjustments. This level of consistency allows for faster production times and reduces the risk of errors or defects. Laser cutting also enables the fabrication of intricate designs with sharp edges and complex shapes, further enhancing the overall quality of the finished product. Additionally, the automated nature of laser cutting reduces human error and ensures consistent results across multiple production runs. Overall, laser cutting technology revolutionizes metal fabrication by providing a reliable and efficient method for achieving consistent and high-quality results.

| Advantages of Laser Cutting in Metal Fabrication | ||

|---|---|---|

| Increased Productivity | Improved Efficiency | Enhanced Design Possibilities |

| Consistent and precise cutting | Reduction in material waste | Ability to cut complex shapes |

| Faster production times | Reduction in manual labor | Greater design flexibility |

| Higher quality finished products | Reduction in human error | Improved repeatability |

| Enhanced cost-effectiveness | Reduction in production time | Increased customer satisfaction |

Frequently Asked Questions

Are there any restrictions on the types of metal that can be cut using laser cutting?

Yes, there are certain limitations on the types of metal suitable for laser cutting. Laser cutting is generally effective on metals such as stainless steel, aluminum, and carbon steel. However, some metals like copper and brass aren’t ideal for laser cutting due to their high reflectivity. Additionally, laser cutting may not be suitable for extremely thick metals or certain alloys. These limitations should be considered when choosing the appropriate method for metal fabrication.

Can laser cutting be used for both thick and thin metal materials?

Yes, laser cutting can be used for both thick and thin metal materials. The process of laser cutting for thick metals involves using high-power lasers to melt and vaporize the material. A high-pressure gas stream then removes the molten metal.

For thin metals, laser cutting involves using lower-power lasers to create precise, clean cuts without the need for additional finishing processes.

Laser cutting is a versatile and efficient method for metal fabrication across a range of thicknesses.

Are there any specific safety precautions that need to be taken when using laser cutting in metal fabrication?

When using laser cutting in metal fabrication, it’s crucial to take specific safety precautions to ensure the well-being of workers and prevent accidents. Proper training is essential to understand the potential hazards and operate the equipment correctly.

Safety precautions include wearing appropriate personal protective equipment, such as goggles and gloves, ensuring proper ventilation in the workspace, and following strict guidelines for laser operation.

Adhering to these safety measures is imperative for a safe and efficient laser cutting process.

How does laser cutting compare to traditional metal cutting methods in terms of cost?

Laser cutting offers a cost-effective alternative to traditional metal cutting methods. While initial setup costs may be higher, laser cutting provides greater efficiency and precision, resulting in reduced material waste and labor costs.

Additionally, laser cutting allows for complex designs and intricate details that would be difficult or time-consuming with traditional methods. An efficiency analysis shows that laser cutting can save significant time and money in the long run, making it a worthwhile investment for metal fabrication projects.

Can laser cutting be used to create intricate and detailed designs on metal surfaces?

Yes, laser cutting can be used to create intricate and detailed designs on metal surfaces. Laser cutting techniques utilize a focused beam of intense light to precisely cut and shape metal. This allows for the creation of complex patterns, fine details, and intricate designs that would be difficult to achieve with traditional metal cutting methods.

Laser cutting applications in metal fabrication include jewelry making, automotive parts manufacturing, and architectural metalwork, among others.

Conclusion

In conclusion, laser cutting in metal fabrication offers a multitude of benefits. It ensures flawlessly cut parts with its precision and accuracy, resulting in improved product quality. Its versatility in design allows for intricate and complex shapes, expanding the possibilities in metal fabrication. Laser cutting enables faster production times, reducing manufacturing lead times. Notably, it significantly reduces material waste by up to 88%, contributing to a more sustainable and eco-friendly manufacturing process. Embrace this cutting-edge technology to achieve consistent, high-quality results in your metal fabrication projects.